Abstract

Rhodobacter sphaeroides is a bacterium that can produce hydrogen by interaction with hydrogenase and nitrogenase. We report a hydrogen production system using co-cultivation of hydrogenase in liquid medium and immobilized nitrogenase in Escherichia coli. The recombinant plasmid has been constructed to analyze the effect of hydrogen production on the expression of hupSL hydrogenase and nifHDK nitrogenase isolated from R. sphaeroides. All recombinant E. coli strains were cultured anaerobically, and cells for nitrogenase were immobilized in agar gel, whereas cells for hydrogenase were supplemented on the nitrogenase agar gel. The hupSL hydrogenase has been observed to enhance hydrogen production and hydrogenase activity under co-culture with nifHDK nitrogenase. The maximum hydrogen production has been obtained at an agar gel concentration and a cell concentration for co-culture of 2 % and 6.4 × 108 CFU. Thus, co-culture of hupSL hydrogenase and nifHDK nitrogenase provides a promising route for enhancing the hydrogen production and hydrogenase activity.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Hydrogen is receiving much attention currently due to its being a clean, efficient, and renewable fuel and is being used in fuel cells. As the global energy system is expected to change from fossil fuels to hydrogen and methane, there is an urgent need for the development of simple methods for hydrogen production. Most of the current chemical or electrochemical methods used for hydrogen production are not cost effective as they operate at high temperatures. The use of biological methods for hydrogen production can reduce energy costs significantly as these processes operate at ambient temperature and pressure. Biological methods generally depend upon hydrogenases, which catalyze the reaction: 2H+ + 2e− ← > H2 (g) [4]. Microorganisms have two main pathways for hydrogen production through either photosynthetic or fermentative process, and in general fermentative hydrogen production per cell is more efficient than photosynthetic [5, 15]. Recently, efforts have been made to improve the yield and rate of hydrogen production using metabolic engineering approaches. Most of these efforts deal with modification of hydrogen (uptake hydrogenase) and central carbon (lactate dehydrogenases) metabolism pathway [2]. E. coli is generally used for hydrogen production, as it is the most extensively characterized bacterium and is also easy to manipulate genetically [4]. Escherichia coli cells have four hydrogenases, but only hydrogenase 3 has hydrogen production activity and it produces hydrogen from formate by the formate hydrogen lyase (FHL) system. It consists of hydrogenase 3 and formate dehydrogenase-H, and FHL system is probably used for the regulation of internal pH in cells [5]. Various recombinant E. coli strains have been also developed for biological hydrogen production systems [10].

Hydrogenase and nitrogenase play key roles in the hydrogen metabolism of purple non-sulfur photosynthetic bacteria. Nitrogenase is an enzymatic complex consisting of two proteins, MoFe protein (dinitrogenase), which contains the active site for nitrogen reduction, and Fe protein (dinitrogenase reductase), which transfers electrons to MoFe protein [13, 14]. The expression of nifHDK, structural genes coding for nitrogenase, is also repressed in response to ammonium ion. The molecular hydrogen production by purple non-sulfur photosynthetic bacteria during photosynthetic growth is directly mediated by nitrogenase [1]. In the co-culture fermentation system of dark and photo-fermentation bacteria, organic acid produced by dark fermentation was in situ converted into hydrogen by photo-fermentation [12]. For the development of co-culture fermentative hydrogen production process into practice, the control strategies of co-culture fermentation need to be investigated in detail.

In the present study, we report the development and optimization of hydrogen production system using recombinant E. coli which exhibits high hydrogen productivity. We constructed two recombinant plasmids to express hydrogenase and nitrogenase encoded by hupSL and nifHDK that were isolated from R. sphaeroides in E. coli. Furthermore, hydrogen production and hydrogenase activity have been studied for optimization of co-culture conditions. Optimum conditions for hydrogen production, such as cell loading and agar concentration, have been also investigated.

Materials and Methods

DNA Isolation, Manipulation, and Transformation

The chromosomal DNA was prepared from R. sphaeroides using a Wizard SV genomic DNA kit (Promega, Madison, USA). The plasmid DNA was prepared from the E. coli cells with an alkaline lysis technique using a QIA spin miniprep kit (QIAGEN, Germany). DNA modification, analysis by agarose gel electrophoresis, and ligation were carried out. E. coli cells were transformed by electroporation with an electro cell manipulator (BTX Technologies Inc., USA).

Construction of Plasmids for nifHDK Nitrogenase Expression in E. coli

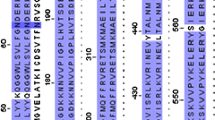

The nifH, nifD and nifK coding regions were amplified from the chromosomal DNA of R. sphaeroides by PCR using the primer pairs nifH-f (5′-TTC TCT AGA ATG GGA AAA CTC CGG CAG ATC-3′, XbaI) and nifH-r (5′-ATA CAT ATG TCA GGC CTC GGC GGC GGC GAT-3′, NheI) for amplification of the nifH gene, nifD-f (5′-CCG CAT ATG ATG GCG AAA GAT ATC GCT-3′, NdeI) and nifD-r (5′-AAG GCT AGC TCA GGC CGT CTT CTT CCA-3′, NheI) for amplification of the nifD gene, and nifK-f (5′-ATT GCT AGC ATG CCG CAG TCG GCC GAA-3′, NheI) and nifK-r (5′-ATT AAG CTT TCA GCG GGT CAG GTC GAA-3′, HindIII) for amplification of the nifK gene. The PCR experiments were carried out using a T gradient thermocycler (Biometra, Germany), Ex Taq™ DNA polymerase (TAKARA Bio Inc., Japan), and chromosomal DNA as the template. The PCR products were purified using a QIAquick PCR purification kit (QIAGEN, Germany). The oligonucleotides used for PCR amplification were purchased from AccuOligo (Bioneer Co., Korea). The PCR product for nifH gene was digested with XbaI/NdeI and ligated with plasmid pET-28b restricted with the same enzymes (Fig. 1). Subsequently, the PCR product for nifD gene was digested with NdeI/NheI, ligated with plasmid-inserted nifH, and restricted with the same enzyme. The PCR product for nifK gene was digested with NheI/HindIII, ligated with plasmid-inserted nifH and nifD, and restricted with the same enzymes. The final plasmid was transformed to E. coli BL21 (DE3) by electroporation.

Growth Conditions and Co-culture

The strains and plasmids used in the present study are shown in Table 1. E. coli BL21 (DE3) (Novagen Chemicals Inc., Germany) was grown at 37 °C in Luria–Bertani medium. Complex medium was used in all experiments to optimize hydrogen production [7]. The complex medium contained (per liter): 20 g glucose, 5.0 g yeast extract, 5.0 g tryptone, 7.0 g K2HPO4, 5.5 g KH2PO4, 0.5 g l-cystein–HCl·H20, 1.0 g (NH4)2SO4, 0.25 g MgSO4·7H2O, 0.021 g CaCl2·2H2O, 0.029 g Co(NO3)2·6H2O, 0.039 g Fe(NH4)2SO4·6H2O, 2.0 mg nicotinic acid, 0.172 mg Na2SeO3, 0.02 mg NiCl2, and 10 ml of trace element solution containing 0.5 g MnCl2·4H2O, 0.1 g H3BO3, 0.01 g AlK(SO4)2·H2O, 0.001 g CuCl2·2H2O, and 0.5 g Na2EDTA. Selection for the presence of plasmids was carried out using 50 µg/ml ampicillin and 25 µg/ml kanamycin. Growth of the shake-flask cultures was monitored by measuring the optical density at 600 nm using an UV/VIS spectrophotometer (Mecasys Co., LTD., Korea).

The grown culture of recombinant E. coli was collected by centrifugation at 3000 rpm. Agar was dissolved in 10 ml water and sterilized. This solution was cooled to 40–50 °C and mixed with 1 ml of prepared E. coli suspension. The agar culture solution was immediately mixed into 50-ml sealed crimp-top vials. Other cells suspended in a complex medium were injected onto immobilized cells. The bottles were shaken at 150 rpm and a constant temperature of 30 °C under dark conditions.

Hydrogenase and Hydrogen Assay

Hydrogenase activity in whole cells was assayed by following the reduction of methylene blue linked to H2 oxidation. The reactions were carried out in capped vials containing cell suspension in 1 ml of 20 mM Tris–HCl pH 8, and 30 µl of 10 mM methylene blue (final 0.15 mM) and made anaerobic by gassing with argon than H2 gas. The samples were incubated at 25 °C for 20 min and their absorbance was measured at 565 nm [6].

E. coli strains (pET-21a, pEMBTL-HJ2 with 1.0 mM IPTG and 50 µg/ml ampicillin and pET-28b, pEMBTL-HJ5 with 1.0 mM IPTG and 25 µg/ml kanamycin) were inoculated into 40 ml of complex medium in 50-ml sealed crimp-top vials. After capping the vial with a gas-tight rubber stopper, it was grown anaerobically at 30 °C. The gas phase (500 µl) was withdrawn and analyzed for H2 by gas chromatography (GC) using a 6890 N gas chromatograph (Agilent Technologies, Glastonbury, CT) equipped with a thermal conductivity detector and a column containing 60/80 mesh molecular sieve 5A (Supelco, Bellefonte, Pa.). All results represent data from at least three independent experiments.

Results and Discussion

Hydrogen Production and Hydrogenase Activity

The plasmid for nifHDK nitrogenase is shown schematically in Fig. 1. The nifH, nifD, and nifK gene regions from R. sphaeroides were isolated by a PCR-based strategy discussed in detail in “Construction of plasmids for nifHDK nitrogenase expression in E. coli ” section. The resulting plasmids carrying the nifHDK region and results of the sequence of 3876 bp are confirmed. The nifHDK genes of R. sphaeroides have been cloned within pET-28b vector [14], whereas in our earlier study the hupSL genes of R. sphaeroides were cloned within pET-21a vector [3].

No significant hydrogenase activity was observed in the presence of oxygen (data not shown). E. coli carrying hupSL hydrogenase and nifHDK nitrogenase were grown anaerobically at 30 °C. Hydrogen production of these four strains of recombinant E. coli plasmid (pET-21a, pET-28b, pEMBTL-HJ2, and pEMBTL-HJ5) is shown in Fig. 2. Hydrogen production by expression of hupSL hydrogenase or nifHDK nitrogenase from recombinant E. coli increased as compared to the control E. coli (pET-21a or pET-28b, respectively). In addition, hupSL hydrogenase-expressing cells showed large enhancement in the hydrogen production compared with nifHDK nitrogenase-expressing cells. Hydrogen production by E. coli is mediated by formate hydrogenase system which consisted of hydrogenase 3 encoded by hycABCDEFGHI and formate dehydrogenase-H encoded by fdhF [4]. However, nitrogenase does not exist in E. coli. The overexpression of hupSL protein in the previous study [3] may have resulted in promoting native hydrogenase 3 in E. coli, and as a result hydrogen production was improved by recombinant E. coli harboring active hydrogenase from R. sphaeroides

Co-culture System of hupSL Hydrogenase and nifHDK Nitrogenase

An earlier work on hydrogen production by immobilized photosynthetic microorganisms was concerned exclusively for hydrogen production [9]. However, in the present study we have used two types of co-cultures (type 1 and type 2) based on hupSL hydrogenase and nifHDK nitrogenase. Type 1 is hupSL hydrogenase in liquid media and immobilized nifHDK nitrogenase. Also, type 2 is nifHDK nitrogenase in liquid media and immobilized hupSL hydrogenase. Both the co-cultures are shown schematically in Fig. 3a. In the co-culture test of hupSL hydrogenase and nifHDK nitrogenase, the hydrogen production and hydrogenase activity were measured as a function of time, and the results are shown in Fig. 3b. The hydrogen production increases with time and reaches a saturation value after 8 h for both types (type 1 and type 2) of co-cultures. However, the type 1 co-culture containing immobilized nifHDK nitrogenase and liquid-cultured hupSL hydrogenase shows higher hydrogen production. Based on the study of Kern et al. H2 accumulation depends on cellular activities of nitrogenase and hydrogenase in purple non-sulfur photosynthetic bacteria. Nitrogenase promotes hydrogenase production and hydrogenase consumes hydrogen.

The experimental method for co-culture system of hupSL hydrogenase and nifHDK nitrogenase. Type 1 represents hydrogenase in liquid media and immobilized nitrogenase and type 2 represents nitrogenase in liquid media and immobilized hydrogenase (a). Hydrogen production by two types (circles correspond to type 1 and squares to type 2) (b)

To understand this variation, more experiments were conducted at different agar and cell concentrations so that optimum values for maximum hydrogen production could be obtained for activated hydrogenase in E. coli.

Effect of Agar and Cell Concentration

The effect of agar concentration on hydrogenase activity and hydrogen production has been studied using agar gel concentrations in the 0–3 % range, and the results are shown in Fig. 4a. When agar gel concentration was low (0.5 %), the agar gel breakage was significant and the hydrogen production and hydrogenase activity were also very low. However, the hydrogen production and hydrogenase activity by co-culture sharply increased as the agar gel concentration increased from 1 to 2 %. With further increase in agar gel concentration to 3 %, no appreciable change was observed in the amount of hydrogen produced as well as in hydrogenase activity, and both these parameters reached a saturation value. Thus, it shows that the agar gel concentration for optimum production of hydrogen and hydrogenase activity is 2 % for the co-culture process of recombinant E. coli used in this study. This indicates that, at agar gel concentration of 2 %, the substrate and products are easily transferred through the gel. These results also demonstrate that hydrogen production is significantly affected by hydrogenase activity.

In addition to the agar gel concentration, the cell density used for immobilization is another most important factor for hydrogen production with immobilized systems [11]. The effect of cell concentration on hydrogen production and hydrogenase activity has been studied, and the results are shown in Fig. 4b. As observed from the results of Fig. 4b, the cell density for fixation in agar as a support strongly affects the hydrogen production. The enriched cells of nitrogenase affected hydrogen production, and at a cell concentration of 6.4 × 108 CFU maximum hydrogen production has been observed. The results shown in Fig. 4a and b show that the hydrogen production and hydrogenase activity depend upon agar concentration and cell concentration, and optimum values for maximum hydrogen production and hydrogenase activity are 2 % agar concentration and 6.4 × 108 CFU cell concentration. The above results show that the use of co-cultures can be a very promising approach to enhance the hydrogen production and hydrogenase activity, and the concentration of agar gel and cell can be optimized for obtaining best results.

We have developed hydrogen production system using co-cultivation of hydrogenase and nitrogenase in E. coli. The co-culture containing hydrogenase in liquid medium and immobilized nitrogenase has been observed to show higher hydrogen production and hydrogenase activity. The optimum value of hydrogen production and hydrogenase activity has been obtained at an agar gel concentration for co-culture of 2 % and a cell concentration of 6.4 × 108 CFU. Thus, co-culture of hupSL hydrogenase and nifHDK nitrogenase appears to be a promising strategy for increasing the hydrogen production and hydrogenase activity. A variety of studies have been conducted to improve the hydrogen production. Ryu et al. [8] reported hydrogen production by upregulating nitrogenase expression and decoupling its expression. The hydrogen production was improved to 4 ml/ml hydrogen in 100 h. In this study, we found that the amount of hydrogen produced was 3500 µl/µl in 12 h. E. coli can grow faster and easily reach higher biomass concentration. Although the level of production of hydrogen in E. coli is still low compared with previously reported value, it can be further improved by increasing biomass concentration and optimizing the production conditions.

References

Kim E-J, Lee M-K, Kim M-S, Lee JK (2008) Molecular hydrogen production by nitrogenase of Rhodobacter sphaeroides and by Fe-only hydrogenase of Rhodospirillum rubrum. Int J Hydrog Energy 33:1516–1521

Kim S, Seol E, Oh Y-K, Wang G, Park S (2009) Hydrogen production and metabolic flux analysis of metabolically engineered Escherichia coli strains. Int J Hydrog Energy 34:7417–7427

Lee SY, Lee HJ, Park J-M, Lee JH, Park J-S, Shin HS, Kim Y-H, Min J (2010) Bacterial hydrogen production in recombinant Escherichia coli harboring a HupSL hydrogenase isolated from Rhodobacter sphaeroides under anaerobic dark culture. Int J Hydrog Energy 35:1112–1116

Maeda T, Sanchez-Torres V, Wood TK (2007) Enhanced hydrogen production from glucose by metabolically engineered Escherichia coli. Appl Microbiol Biotechnol 77:879–890

Maeda T, Sanchez-Torres V, Wood TK (2007) Escherichia coli hydrogenase 3 is a reversible enzyme possessing hydrogen uptake and synthesis activities. Appl Microbiol Biotechnol 76:1035–1042

Oh J-I, Ko I-J, Kaplan S (2004) Reconstitution of the Rhodobacter sphaeroides cbb 3 -PrrBA signal transduction pathway in vitro. Biochemistry 43:7915–7923

Rachman MA, Furutani Y, Nakashimada Y, Kakizono T, Nishio N (1997) Enhanced hydrogen production in altered mixed acid fermentation of glucose by Enterobacter aerogenes. J Ferment Bioeng 83:358–363

Ryu M-H, Hull NC, Gomelsky M (2014) Metabolic engineering of Rhodobacter sphaeroides for improved hydrogen production. Int J Hydrog Energy 39:6384–6390

Sasikala K, Ramana CV, Raghuveer Rao P, Subrahmanyam M (1990) Photoproduction of hydrogen, nitrogenase and hydrogenase activities of free and immobilized whole cells of Rhodobacter sphaeroides OU 001. FEMS Microbiol Lett 72:23–28

Seol E, Manimaran A, Jang Y, Kim S, Oh YK, Park S (2011) Sustained hydrogen production from formate using immobilized recombinant Escherichia coli SH5. Int J Hydrog Energy 36:8681–8686

von Feiten P, Zürrer H, Bachofen R (1985) Production of molecular hydrogen with immobilized cells of Rhodospirillum rubrum. Appl Microbiol Biotechnol 23:15–20

Xie G-J, Feng L-B, Ren N-Q, Ding J, Liu C, Xing D-F, Qian G-W, Ren H-Y (2010) Control strategies for hydrogen production through co-culture of Ethanoligenens harbinense B49 and immobilized Rhodopseudomonas faecalis RLD-53. Int J Hydrog Energy 35:1929–1935

Yakunin AF, Hallenbeck PC (1998) Short-term regulation of nitrogenase activity by NH4+ in Rhodobacter capsulatus: multiple in vivo nitrogenase responses to NH4+ addition. J Bacteriol 180:6392–6395

Yakunin AF, Hallenbeck PC (2000) Regulation of nitrogenase activity in Rhodobacter capsulatus under dark microoxic conditions. Arch Microbiol 173:366–372

Yoshida A, Nishimura T, Kawaguchi H, Inui M, Yukawa H (2005) Enhanced hydrogen production from formic acid by formate hydrogen lyase-overexpressing Escherichia coli strains. Appl Environ Microbiol 71:6762–6768

Acknowledgments

This work was carried out with the support of “Cooperative Research Program for Agriculture Science & Technology Development (Project title: Development of Target-specific Antimicrobial and Neutralizing Agents for Livestock Biological Hazardous Factors, Project No: PJ01052701)” Rural Development Administration, Republic of Korea.

Author information

Authors and Affiliations

Corresponding authors

Additional information

Hyun Jeong Lee and Simranjeet Singh Sekhon have contributed equally to this work.

Rights and permissions

About this article

Cite this article

Lee, H.J., Sekhon, S.S., Kim, Y.S. et al. Enhanced Hydrogen Production by Co-cultures of Hydrogenase and Nitrogenase in Escherichia coli . Curr Microbiol 72, 242–247 (2016). https://doi.org/10.1007/s00284-015-0941-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00284-015-0941-4