Abstract

While Saccharomyces cerevisiae is a popular organism to produce ethanol, its fermentation performance is affected at high sugar concentrations due to osmotic stress. We hypothesized that adaptation under ionic stress conditions will improve the fermentation performance at high sugar concentrations due to cross-stress adaptation. We, therefore, adapted a high-performance yeast strain, S. cerevisiae CEN.PK 122, to increasing salt concentrations in an industrial medium. Control cells were adapted in the medium without added salt. The cells adapted to 3.5% (w/v) salt concentration demonstrated a superior performance when fermenting 10–30% (w/v) glucose. When fermenting 30% (w/v) glucose, the ethanol yields of the adapted cells (0.49 ± 0.01 g g−1) were about 30% higher than the control cells (0.37 ± 0.01 g g−1) and are comparable with the best reported to date for any medium employed. Similar improvements were also observed when fermenting 10% (w/v) sucrose. However, little improvement in fermentation was observed at the higher temperature tested (40 °C), even though the growth of the adapted cells was greater when tested in YPD medium. The improvements in fermentation at 30 °C were primarily related to the faster growth of the adapted cells and not to an increase in specific intake rates. Additionally, a significantly reduced lag phase was also observed when fermenting 30% (w/v) glucose. Thus, our work shows the application of a simple strategy to significantly improve high-gravity fermentation (HGF) performance through adaptation.

Key points

• Cell adapted on 3.5% NaCl made 28% more ethanol when fermenting 30% glucose.

• The adapted cells had reduced lag phase, grew faster, and produced less glycerol.

• The improvements were not related to increased specific rates of production.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Industrial bioethanol production typically employs Saccharomyces cerevisiae because it can produce high ethanol titers and provide high rates of fermentation (Dhar et al. 2011). Another advantage of S. cerevisiae over other fermentative organisms such as Escherichia coli and Zymomonas mobilis is that the biomass can be used as a feed which adds value to the whole process. However, this also means that the yeast used should not be a genetically modified organism (GMO). The economics of industrial fermentations can be improved by fermenting a high concentration of sugar (Pereira et al. 2010). Most yeast strains show reduced fermentation efficiency when fermenting high-gravity sugar solutions and at elevated temperatures (Kitichantaropas et al. 2016).

Exposure to high-gravity sugar solution causes osmotic stress to yeast cells. Previous studies suggest that there is a significant overlap in the osmotic and ionic stress responses and in ionic stress and heat stress responses (Melamed et al. 2008; Dhar et al. 2011; Szopinska et al. 2011; Pandey et al. 2019). Exposure to salt stress leads to systemic changes in yeast cells at multiple levels (Mulet et al. 1999; Melamed et al. 2008). Short-term exposure to NaCl stress and high glucose has been shown to negatively impact the formation of beta-glucan during alcoholic fermentation (Varelas et al. 2017). However, most previous studies have looked into the short-term responses of the cells to the stresses (Aguilera et al. 2010; Dragosits and Mattanovich 2013).

S. cerevisiae has many advantages for adaptive evolution studies due to its ease of culture and well-established methods for its analysis and molecular manipulation. Given the overlap in cellular responses to osmotic and ionic stresses and the ease of adaptation of S. cerevisiae, we hypothesized that long-term adaptation in ionic stress conditions should improve the fermentation performance of S. cerevisiae in high-gravity fermentation. We have chosen ionic stress over heat stress based on two reasons: (a) while some correlation between heat and osmotic stress has been suggested in the literature, we believe that osmotic and salt stresses have greater similarity than heat and osmotic stress. (b) In a typical lab, adaptation at higher temperature would require purchasing a separate shaking incubator—a significant additional expenditure and space requirement, which may not be feasible. Ionic stress adaptation is, therefore, easier to implement and is likely to be more effective than heat-stress adaptation for high-gravity fermentations. We have used CEN.PK 122 cells for testing the effect of adaptation because previous studies have indicated that these cells have comparative fermentation performance to CEN.PK 113-7D cells when fermenting a high-gravity sugar solution (Pereira et al. 2010b). Our results show that adaptation to salt stress in 10% (w/v) glucose improves fermentation performance in both normal-gravity (10% w/v sugar) and high-gravity (30% w/v glucose) fermentation. Thus, our work suggests salt-stress adaptation as a simple, non-GMO method, to significantly improve ethanol titers and fermentation rates in an industrial medium and should, in principle, be applicable to other industrial strains.

Material and methods

Medium components

We have used a cost-effective medium, originally developed by Pereira et al. (2010a) for high-gravity fermentations, for both adaptation and fermentation. The medium components including glucose, yeast extract, peptone, and agar were obtained from Hi-Media Laboratories (Mumbai, India). Corn steep liquor (CSL) was obtained from Sigma (India). All chemicals used were of analytical grade unless mentioned otherwise. The medium contained 10% (w/v) glucose as the carbon source, 3% (v/v) CSL, 2.3 g L−1 urea, 3.8 g L−1 MgSO4·7H2O, and 0.03 g L−1 CuSO4·5H2O (Pereira et al. 2010). The initial pH of the medium was set to 5 (Ganigué et al. 2016). For very high-gravity (VHG) fermentation, the medium contained 30% (w/v) glucose and 5% (v/v) CSL. The medium was sterilized by filtering through a 0.22-µm polystyrene membrane. For fermentations in YPD medium, yeast extract (10 g L−1) and peptone (20 g L−1) were dissolved in water and autoclaved at 121 °C for 20 min. Upon cooling, a filter-sterilized 50% (w/v) glucose solution was aseptically added to the medium to a final concentration of 2% (w/v).

Yeast strain and basic culture conditions

S. cerevisiae CEN.PK 122 cells were maintained at 30 °C in 250-mL Erlenmeyer flasks containing 50 mL culture. The flasks were shaken at 180 rpm in a shaking incubator (New Brunswick Innova 44R, Eppendorf AG, Hamburg, Germany). For long-term preservation, the cells were resuspended in a medium containing 25% (v/v) glycerol and stored at − 80 °C.

Adaptation of S. cerevisiae to increasing concentration of salt (NaCl)

The adaptation was performed by serial passaging every 24 h in 250-mL shake flasks. Cells were seeded at an optical density (OD600) of 1.0 in the shake flasks. For adaptation to increasing concentrations of NaCl, the cells were grown in 10% (w/v) glucose and the NaCl concentration in the medium was increased gradually from 0.5 to 3.5% (w/v), as detailed below. Control cells were passaged in parallel, but in the control medium without any added salt.

For the adaptation, every step change in NaCl concentration was made on agar plates and the colony obtained was then transferred to a liquid medium containing the same concentration of NaCl. Initially, the control (unadapted) cells were streaked onto a plate containing 0.5% (w/v) NaCl. Once the colonies appeared, the largest colony was transferred to the liquid medium containing 0.5% (w/v) salt and passaged every 24 h. Once the culture started to grow well, the culture was spread on plates containing 1.5% (w/v) NaCl and the largest colony obtained was then transferred to a liquid medium containing 1.5% (w/v) NaCl and serially passaged every 24 h. Again, when a luxurious growth appeared, i.e., there were 1.5 × 108 colony-forming units per mL of culture, the culture was plated on agar plates containing 2.0% (w/v) NaCl and the process was repeated. Finally, the NaCl concentration was increased to 3.5% (w/v), first in agar plates and then in liquid medium. To account for the possibility of improved fermentation due to continuous passaging in a medium containing 10% (w/v) glucose, the control cells were also passaged in parallel in the industrial medium without any added NaCl. When the control cells were plated on plates containing NaCl, no colonies appeared. This indicated that the adapted cells, but not the control cells, have become salt-tolerant.

Fermentation experiments

All the fermentation experiments were conducted in 500-mL Multivessel fermenters (Multifors 2, Infors HT, Switzerland) containing 300 mL medium with 300-rpm stirring and no aeration. Also, the pH of the media was not adjusted during the course of the fermentations.

For growth studies on YPD medium, the cells previously adapted in the industrial medium were centrifuged and resuspended in the YPD medium. The culture was then inoculated in the fermenters containing 300 mL of YPD medium with an initial OD of 1.0.

The inocula for the fermentation experiments were also grown in the same fermenters at 30 °C in the medium without any added salt. The incubation periods of the inocula for the control and the adapted cells were 12 and 9 h, respectively. These time periods were chosen to ensure that (a) the two inocula were in exponential growth phase, (b) the ODs of the two inocula were similar (18.82 ± 0.96 for control cells and 17.41 ± 0.81), and (c) at least half of the glucose initially added in the inocula remained unutilized (remaining glucose was 59.3 ± 2.11 g L−1 for the control cells and 51.61 ± 1.9 g L−1 for the adapted cells). Culture samples at the desired time points after inoculation were taken using a sampler attached to the fermenters (Supersafe, Infors HT, Switzerland).

Analysis of substrate consumption and product formation

Glucose, sucrose, and ethanol in the culture medium were analyzed using HPLC (1260 Infinity, Agilent Technologies, Santa Clara, CA, USA) as follows: 1 mL culture was sampled at the desired time points and centrifuged at 9300 × g for 10 min. The supernatant was filtered using a 0.22-μm nitrocellulose syringe filter (Millipore). For the HPLC analyses, 10 μL of the appropriately diluted and filtered supernatant was injected into an Aminex HPX 87H (300 × 7.8 mm) column (Bio-Rad, India) maintained at 40 °C. Four millimolars of H2SO4 was used as the mobile phase at a flow rate of 0.3 mL/min. A refractive index (RI) detector was used to detect the molecules. The molecules were quantified by dividing the sample peak area with the peak area of standards at their specific retention times.

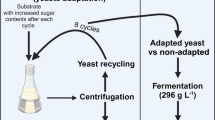

Strain reusability experiment

We seeded the medium containing 30% (w/v) glucose with 1.0 OD of the cells, and the fermentation was continued up to 120 h. We call this the fermenter 1 (F1). Three subsequent fermenters (F2–F4) were inoculated at OD600 of 1.0 with the inoculum coming from the preceding fermenter.

Calculation of lag time or (tlag)

The lag time for the cells growing in the 30% (w/v) glucose was calculated for the period where exponential growth was observed using the formula given below:

where x(t) is the OD at time t, x0 is the initial OD, μ is the specific growth rate of the culture, and tlag is the lag time.

Taking natural log (ln) and solving for tlag we get:

Statistical analysis

All the experiments were performed in biological duplicates and the data are expressed as mean ± S.D. of two independent fermenter runs. All data were statically analyzed and plotted using Sigma Plot version 12.5, SYSTAT Software Inc. Statistical significance was calculated using the paired Student t-test.

Results

Adaptation of cells in the control medium and the medium containing 3.5% (w/v) NaCl

Figure 1 shows that with continuous passaging in the liquid medium containing 3.5% NaCl, the OD of the cultures after 24 h of inoculation increased with increasing number of passages. There was an increase in the 24-h growth until about 64 passages, and thereafter, no further increases were observed. Note that the cells for adapting at 3.5% NaCl concentration (the passage number 0 here) came from a culture that was previously adapted to grow on 2.0% (w/v) NaCl. The control cells did not grow in the medium containing 3.5% salt (not shown).

Improvement in the growth of cells with passaging in a medium containing 3.5% (w/v) NaCl. The cells previously grown in a medium containing 2% (w/v) NaCl (passage 0) were passaged several times in the medium containing 3.5% NaCl and the change in the OD in 24-h period was recorded for each passage. Data presented as mean ± S.D. of n = 3 independent replicates

Growth in YPD medium containing different concentrations of salt at 30 °C and 40 °C

The adapted cells grew to a higher OD in all the conditions tested (Fig. 2). The difference in the OD between the salt-adapted and the control cells was significantly greater (p < 0.05 using t-test, Supplementary File) when the cells were grown in the medium containing 3.5% salt as compared to the lower salt concentrations tested at 40 °C (Fig. 2F). However, the difference was not significantly greater at 30 °C (p = 0.06, Fig. 2C).

Growth of the control and the salt-adapted cells when grown in YPD medium containing 2% (w/v) glucose at 30 °C (top row, a–c) or at 40 °C (bottom row, d–f) in the presence of increasing concentration of 0% (a and d), 1.5% (w/v, b and e) and 3.5% (w/v, c and f) NaCl. Asterisk represents statistically different values from the control cells, p < 0.05, n = 2 independent fermenter runs

Growth and fermentation of salt stress–adapted and control cells in normal (lacking NaCl) medium containing 10% (w/v) glucose or sucrose

The growth rates of the control and the adapted cells in the normal medium containing 10% glucose were 0.26 ± 0.01 h−1 and 0.35 ± 0.02 h−1, respectively. Similarly, the OD600 of the cells at the 12-h time point (the time point where the OD600 difference was the maximum) was 17.2 ± 2.0 and 27.9 ± 1.5, respectively, i.e., a difference of 62%. The adapted cells reached the stationary phase in just 15 h, while the control cells took 21 h to reach the same (Fig. 3a). There was no significant difference (p > 0.05) in the final OD of the adapted and control cells, which was approximately 35 ± 2.7. Both types of cells completely utilized the 10% glucose in 27 h. The final ethanol titer of the adapted cells was greater (43.0 ± 0.5 g L−1) than that of the control cells (40.4 ± 0.7 g L−1) (Fig. 3b). The ethanol productivities for the control and the adapted cells were 2.53 ± 0.01 and 3.07 ± 0.05 g (L h)−1, respectively. The other fermentation parameters are given in Table 1. The values of the fermentation parameters for the individual replicates along with the time period for which the specific values were calculated are provided in Supplementary File, Table S1. There was about 40% increase in the volumetric glucose uptake rate and a 20% increase in the ethanol production rate of the adapted cells as compared to control cells. However, the specific intake rates and production rates of the adapted cells were slightly lower than that of the control cells. All the above stated differences were statistically significant (p < 0.05).

Growth and fermentation profiles of control and salt-adapted cells when grown in a medium containing 10% (w/v) glucose without NaCl at 30 °C. a Growth profile of the cells. b Glucose consumption and ethanol production profiles. Asterisk represents statistically different values from the control cells, p < 0.05, n = 3 independent fermenter runs

When sucrose was used as the carbon source, the maximum OD of the control and the adapted cells were 33.9 ± 0.4 and 36.6 ± 0.6, respectively (Fig. 4a) after 40 h of culture (p < 0.05). The final ethanol concentrations were 46.83 ± 0.12 g L−1 and 50.0 ± 0.2 g L−1 (Fig. 4b) for the control and the adapted cells and the ethanol yields were 0.47 ± 0.01 g g−1 and 0.50 ± 0.02 g g−1, respectively (p < 0.05 for both ethanol titers and yields). Thus, the fermentation efficiency was 85% for the control cells and 92.5% for the adapted cells. The fermentation parameters are given in Table 2. The values of the fermentation parameters for the individual replicates along with the time period for which the specific values are reported are provided in Supplementary File, Table S2. The growth rate and the volumetric sucrose uptake rate of the adapted cells were significantly greater than that of the control cells (p < 0.05). The other fermentation parameters were also improved by approximately 20% in the adapted cells as compared to control cells, though the differences were not statistically significant.

Growth and fermentation profiles of control and salt-adapted cells when grown in a medium containing 10% sucrose (w/v) without NaCl at 30 °C. a Growth profile of the cells. b Sucrose consumption, and ethanol production profiles. Asterisk represents statistically different values from the control cells, p < 0.05, n = 2 independent fermenter runs

Fermentation performance of the control and the salt-adapted cells at 40 °C

There was no significant difference in the specific growth rates of the control and adapted cells when grown at 40 °C with 10% (w/v) glucose in the industrial medium (Fig. 5a). The cultures reached similar ODs of about 32.3 ± 0.7 in 50 h of fermentation. The ethanol titers of the cultures with the control and the adapted cells were 40.5 ± 0.7 g L−1 and 43.8 ± 1.2 g L−1 (p > 0.05) respectively in 50 h of fermentation (Fig. 5b). The yield of the process was 0.429 ± 0.002 g g−1 and 0.454 ± 0.008 g g−1 (p = 0.055) for the control and adapted cells, respectively. While the volumetric and specific glucose intake rates were slightly higher for the adapted cells than the control cells, the difference was not statistically significant (Table 3). Similarly, the ethanol volumetric or specific productivities were also not different. The values of the fermentation parameters for the individual replicates along with the time period for which the specific values are reported are provided in Supplementary File, Table S3.

Growth and fermentation profiles of control and salt-adapted cells when grown in a medium containing 10% (w/v) glucose without NaCl at 40 °C. a Growth profile of the cells. b Glucose consumption and ethanol production profiles. Data presented as mean ± S.D. of n = 2 independent fermenter runs. Asterisk denotes p < 0.05

Very high-gravity fermentation of the control and the salt-adapted cells

There was a significantly longer lag phase of 5.1 ± 0.2 h in the control cells compared to just 0.98 ± 0.15 h for the adapted cells (p < 0.01, Supplementary File) when fermenting 30% (w/v) glucose (Fig. 6a). The adapted cells also grew at a faster rate when grown on 30% (w/v) glucose (Table 4). The adapted cells reached stationary phase after 30 h of growth while the control cells took 39 h for the same. The highest ODs, reached after 48 h of fermentation, were about 28 and 31 for the control and the adapted cells, respectively (p < 0.05). Both types of cells increased their ethanol titers until about 84 h (Fig. 6b). The ethanol titer for the adapted cells was significantly higher than that for the control cells throughout the fermentation. The highest ethanol titers reached were 137 ± 1.4 g L−1 and 106 ± 1.8 g L−1 for the adapted and the control cells, respectively (p < 0.01). This corresponds to a 28% increase in the ethanol titers. The titers correspond to ethanol yields of 0.37 ± 0.005 g g−1 and 0.487 ± 0.007 g g−1 for the control and the adapted cells, respectively (p < 0.01). Therefore, the fermentation efficiencies were 72.5% and 95.4% for the control and the adapted cells, respectively. The volumetric ethanol productivities were 1.83 ± 0.06 g (L h)−1 and 2.21 ± 0.05 g (L h)−1 (p < 0.05) for the control and adapted cells, respectively. The other fermentation parameters are shown in Table 4. The values of the fermentation parameters for the individual replicates along with the time period for which the specific values are reported are provided in Supplementary File, Table S4. The specific uptake rate was increased by 25% in the adapted cells compared to the control cells.

Growth and fermentation profiles of control and salt-adapted cells when grown in a medium containing 30% (w/v) glucose without NaCl at 30 °C. a Growth profile of the cells. b Glucose consumption and ethanol production profiles. c Glycerol production profile. Data presented as mean ± S.D. of n = 2 independent fermenter runs. Asterisk denotes p < 0.05

The control cells produced a maximum of about 65 g L−1 glycerol while the adapted cells produced only about 34 g L−1 (p < 0.05) (Fig. 6c). The glycerol levels increased until about 90 h in the control cells and until 60 h in the adapted cells. A slight consumption of the glycerol produced was seen beyond these times. Therefore, in the adapted cells, the carbon that is otherwise lost as glycerol in the VHG fermentation is significantly reduced and this could be one of the reasons for the high yield of ethanol in the adapted cells.

Reusability of the cells in 30% glucose

We seeded the 30% (w/v) VHG broth with 1.0 OD of the adapted cells, and the fermentation was continued for up to 120 h. We call this fermenter 1 (F1) and the subsequent fermenters were serially inoculated (Fig. 7). It was observed that the adapted cells maintained their performance until the F3. In F4, the titers got reduced by 20 g L−1 in comparison to F1 (p < 0.05). Therefore, the adapted cells were able to maintain their fermentation performance up to 480 h of continuous fermentation though longer culture without the salt stress reduced their performance.

Performance of the salt stress–adapted cells for serial fermentations of 30% (w/v) glucose. The salt-adapted cells were serially tested for four fermenter runs in presence of 30% glucose and not containing any added NaCl. The cells from the previous fermenter run (e.g., F1) were used to inoculate the next fermenter run (e.g., F2). The optical density (OD 600 nm) and ethanol and glycerol titers were measured. Data presented as mean ± S.D. of n = 2 independent fermenter runs. Asterisk denotes p < 0.05

Discussion

Some previous studies have used SD medium or mild aeration while reporting similar yields with VHG fermentation (Kucharczyk and Tuszyński 2017; Pandey et al. 2019; Henriques et al. 2018). However, such medium or process modifications are costly to implement at a large scale (Humbird et al. 2017). In this paper, we have presented salt-stress adaptation as a simple-yet-effective method to improve VHG fermentation, improving the titers by about 30% and increasing the efficiency very significantly. The titers and the fermentation efficiency that we have achieved by our simple method, in a simple medium and using a simple process, are comparable to the best reported in the literature at 30% glucose in any medium. We have used serial passaging for the adaptation because it is significantly less dependent on equipment and easier to implement. An alternative to potentially speed up the process of adaptation could be to use chemostats (Li et al. 2018). Also, while we have used NaCl as the ionic stress inducer, other salts, e.g., KCl, may also produce a similar response. However, because higher intracellular concentration of NaCl is more toxic to the cells than higher KCl, it is likely that the adaptation on NaCl activates more cytoprotective pathways.

Growth in the medium with 30% (w/v) glucose impacted several cellular parameters compared to growth in the medium with 10% glucose. This included growth rate, final OD, and specific glucose intake rate. The salt stress–adapted cells, on the other hand, were less impacted by exposure to 30% glucose. The titers and the fermentation efficiency that we have achieved by our simple method, in a simple medium and using a simple process are comparable to the best reported in the literature at 30% glucose in any medium.

While the specific growth rate of the cells was reduced by half or more at 40 °C compared to 30 °C in the industrial medium, the specific consumption and production rates (increased by about 50%. These results indicate that cells require greater energy to sustain themselves at higher temperatures and the salt adaptation-induced changes do not confer a significant resistance against high-temperature stress in the industrial medium. However, the adapted cells grew faster at 40 °C compared to the control cells in YPD medium (Fig. 4d–f). Thus, the cross-stress response of salt-stress adaptation for heat stress is weak and dependent on the culture medium employed.

The salt stress–adapted cells showed faster growth and higher volumetric intake and production rates, but not higher specific intake rates when fermenting glucose or sucrose in the industrial medium at 30 °C. Identifying the molecular basis of the adaptive evolution (Gresham and Dunham 2014) will provide insights into the mechanism of improved growth and fermentation performance under VHG conditions.

Exposure to high-osmolarity solutions has been shown to activate the high-osmolarity glycerol (HOG) pathway that increases the production of the osmoprotectant glycerol by the cells (Hohmann 2002; Tekolo et al. 2010; Pastor et al. 2013; Heit et al. 2018). The reduced glycerol production in the adapted cells during the VHG fermentation indicates alternative mechanisms of osmoprotection such as increased level(s) of some other osmoprotectant(s), activation of efflux pumps, or changes in membrane composition.

Given that our strain was adapted to grow in 3.5% (w/v) NaCl concentration, it is also pertinent to compare the performance with marine strains that are exposed to similar salt concentrations. The ability of marine strains to ferment in seawater has been proposed to reduce the freshwater footprint of the bioethanol process (Zaky et al. 2018). Some salt-tolerant yeast strains were isolated from toddy (alcoholic beverage) and had shown improved fermentation at 30 °C and 40 °C in presence of 7.5% NaCl in the YPD medium (Arachchige et al. 2019), a laboratory medium. Our adapted cells also show a significantly reduced lag phase and higher ODs in YPD medium in the presence of 3.5% NaCl at 30 °C and 40 °C (Fig. 2C and F).

Thus, our work shows the utility of the salt-stress adaptation to improve the HGF of yeast cells in an industrial medium which may be applicable to other strains as well.

Data availability

The datasets generated during and/or analyzed during the current study are available from the corresponding author on reasonable request.

References

Aguilera J, Andreu P, Randez-Gil F, Prieto JA (2010) Adaptive evolution of baker’s yeast in a dough-like environment enhances freeze and salinity tolerance. Microb Biotechnol 3(2):210–221. https://doi.org/10.1111/j.1751-7915.2009.00136.x

Arachchige MSA, Yoshida S, Toyama H (2019) Thermo-and salt-tolerant Saccharomyces cerevisiae strains isolated from fermenting coconut toddy from Sri Lanka. Biotechnol & Biotechnol Equip 33(1):937–944. https://doi.org/10.1080/13102818.2019.1631213

Dhar R, Sägesser R, Weikert C, Yuan J, Wagner A (2011) Adaptation of Saccharomyces cerevisiae to saline stress through laboratory evolution. J Evol Biol 24(5):1135–1153. https://doi.org/10.1111/j.1420-9101.2011.02249.x

Dragosits M, Mattanovich D (2013) Adaptive laboratory evolution–principles and applications for biotechnology. Microb Cell Factories 12(1):64. https://doi.org/10.1186/1475-2859-12-64

Ganigué R, Sánchez-Paredes P, Bañeras L, Colprim J (2016) Low fermentation pH is a trigger to alcohol production, but a killer to chain elongation. Front Microbiol 7:702. https://doi.org/10.3389/fmicb.2016.00702

Gresham D, Dunham MJ (2014) The enduring utility of continuous culturing in experimental evolution. Genomics 104(6):399–405. https://doi.org/10.1016/j.ygeno.2014.09.015

Heit C, Martin SJ, Yang F, Inglis DL (2018) Osmoadaptation of wine yeast (Saccharomyces cerevisiae) during Icewine fermentation leads to high levels of acetic acid. J Appl Microbiol 124(6):1506–1520. https://doi.org/10.1111/jam.13733

Henriques TM, Pereira SR, Serafim LS, Xavier AMRB (2018) Two-stage aeration fermentation strategy to improve bioethanol production by Scheffersomyces stipitis. Fermentation 4(4):97. https://doi.org/10.3390/fermentation4040097

Hohmann S (2002) Osmotic stress signaling and osmoadaptation in yeasts. Microbiol Mol Biol Rev 66(2):300–372. https://doi.org/10.1128/MMBR.66.2.300-372.2002

Humbird D, Davis R, McMillan JD (2017) Aeration costs in stirred-tank and bubble column bioreactors. Biochem Eng J 127:161–166. https://doi.org/10.1016/j.bej.2017.08.006

Kitichantaropas Y, Boonchird C, Sugiyama M, Kaneko Y, Harashima S, Auesukaree C (2016) Cellular mechanisms contributing to multiple stress tolerance in Saccharomyces cerevisiae strains with potential use in high-temperature ethanol fermentation. AMB Express 6(1):1–14. https://doi.org/10.1186/s13568-016-0285-x

Kucharczyk K, Tuszyński T (2017) The effect of wort aeration on fermentation, maturation and volatile components of beer produced on an industrial scale. J Inst Brew 123(1):31–38. https://doi.org/10.1002/jib.392

Li Y, Venkataram S, Agarwala A, Dunn B, Petrov DA, Sherlock G, Fisher DS (2018) Hidden Complexity of Yeast Adaptation under Simple Evolutionary Conditions. Curr Biol 28(4):515-525.e6. https://doi.org/10.1016/j.cub.2018.01.009

Melamed D, Pnueli L, Arava Y (2008) Yeast translational response to high salinity: global analysis reveals regulation at multiple levels. RNA 14(7):1337–1351. https://doi.org/10.1261/rna.864908

Mulet JM, Leube MP, Kron SJ, Rios G, Fink GR, Serrano R (1999) A novel mechanism of ion homeostasis and salt tolerance in yeast: the Hal4 and Hal5 protein kinases modulate the Trk1-Trk2 potassium transporter. Mol Cell Biol 19(5):3328–3337. https://doi.org/10.1128/MCB.19.5.3328

Pandey AK, Kumar M, Kumari S, Kumari P, Yusuf F, Jakeer S, Naz S, Chandna P, Bhatnagar I, Gaur NA (2019) Evaluation of divergent yeast genera for fermentation-associated stresses and identification of a robust sugarcane distillery waste isolate Saccharomyces cerevisiae NGY10 for lignocellulosic ethanol production in SHF and SSF. Biotech Biofuels 12(1):40. https://doi.org/10.1186/s13068-019-1379-x

Pastor JM, Bernal V, Salvador M, Argandoña M, Vargas C, Csonka L, Sevilla Á, Iborra JL, Nieto JJ, Cánovas M (2013) Role of central metabolism in the osmoadaptation of the halophilic bacterium Chromohalobacter salexigens. J Biol Chem 288(24):17769–17781. https://doi.org/10.1074/jbc.M113.470567

Pereira FB, Guimaraes PM, Teixeira JA, Domingues L (2010) Selection of Saccharomyces cerevisiae strains for efficient very high gravity bio-ethanol fermentation processes. Biotechnol Lett 32(11):1655–1661

Pereira FB, Guimaraes PM, Teixeira JA, Domingues L (2010) Optimization of low-cost medium for very high gravity ethanol fermentations by Saccharomyces cerevisiae using statistical experimental designs. Biores Technol 101(20):7856–7863. https://doi.org/10.1016/j.biortech.2010.04.082

Szopinska A, Degand H, Hochstenbach JF, Nader J, Morsomme P (2011) Rapid response of the yeast plasma membrane proteome to salt stress. Mol Cell Proteomics 10(11):1–18. https://doi.org/10.1074/mcp.M111.009589

Tekolo OM, Mckenzie J, Botha A, Prior BA (2010) The osmotic stress tolerance of basidiomycetous yeasts. FEMS Yeast Res 10(4):482–491. https://doi.org/10.1111/j.1567-1364.2010.00612.x

Varelas V, Sotiropoulou E, Karambini X, Liouni M, Nerantzis E (2017) Impact of glucose concentration and NaCl osmotic stress on yeast cell wall β-d-glucan formation during anaerobic fermentation process. Fermentation 3(3):44. https://doi.org/10.3390/fermentation3030044

Zaky AS, Greetham D, Tucker GA, Du C (2018) The establishment of a marine focused biorefinery for bioethanol production using seawater and a novel marine yeast strain. Sci Rep 8(1):12127. https://doi.org/10.1038/s41598-018-30660-x

Acknowledgements

We would like to thank Dr. Naseem Gaur’s group at ICGEB, New Delhi, for providing the strain and for helpful discussion on the general culturing of yeasts. The strain was originally procured from EuroSCARF. We are thankful to Dr. Daniel J. Upton, University of York, for suggesting English language edits.

Funding

This research received funding from the Department of Biotechnology (DBT), Ministry of Science and Technology, India, via the DBT-ICGEB Centre for Advanced Bioenergy Research grant (No. BT/PB/Centre/03/2011-Phase 2). MA acknowledges the Department of Biotechnology (DBT), Ministry of Science and Technology, India, for the fellowship support during the period of research work.

Author information

Authors and Affiliations

Contributions

SS conceived and designed research. MA, RP, AC, and JKG conducted the adaptation work. MA conducted all the fermentation experiments and analyzed the data. CD provided essential help with fermentation and data for some growth experiments. MA and SS analyzed data. RP prepared the figures. MA and SS wrote the manuscript. All authors read and approved the manuscript.

Corresponding author

Ethics declarations

Ethics approval

This article does not contain any studies with human participants or animals performed by any of the authors.

Conflict of interest

The authors declare no competing interests.

Additional information

Publisher's note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Ahmad, M., Pathania, R., Chowdhury, A. et al. Salt-stress adaptation of yeast as a simple method to improve high-gravity fermentation in an industrial medium. Appl Microbiol Biotechnol 105, 8009–8018 (2021). https://doi.org/10.1007/s00253-021-11566-7

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00253-021-11566-7