Abstract

ω-Hydroxy fatty acids (ω-HFAs) are of great interest because they provide the long carbon chain monomers in the synthesis of polymer materials due to the location of the hydroxyl group close to the end of the first methyl carbon. ω-HFAs are widely used as building blocks and intermediates in the chemical, pharmaceutical, and food industries. Recent achievements in metabolic engineering and synthetic biology enabled Escherichia coli to produce these fatty acids with high yield and productivity. These include (i) design and engineering of the ω-HFA biosynthetic pathways, (ii) enzyme engineering to enhance stability and activity, and (iii) increase of tolerance of E. coli to toxic effects of fatty acids. Strategies for improving product yield and productivity of ω-HFAs and their related chemicals (e.g., α,ω-dicarboxylic acids and ω-amino carboxylic acids) are systematically demonstrated in this review.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Lipids and fatty acids are one of the most abundant renewable resources in nature. In Asia, for instance, 84.8 million metric tons of vegetable oils were produced in 2014–2015 (Mittaine 2016). Large amounts of fatty acids are used in the chemical industry to manufacture biodiesel and building blocks for plastics such as polyamides, polyesters, and polyurethanes. However, hydroxy fatty acids (HFAs) are usually difficult to be produced from renewable biomass by chemical process because of harsh reaction conditions (e.g., ozonolysis or caustic pyrolysis), tedious steps, and poor selectivity (Kockritz and Martin 2011; Liu et al. 2011). HFAs, which contain hydroxyl group(s) in the carbon skeleton of fatty acids, occur as components of triacylglycerols, waxes, cerebrosides, and other essential lipids in living organisms (Chance et al. 1998). HFAs have gained great interest because of their special properties such as much higher viscosity and reactivity compared with nonhydroxylated fatty acids (Hou et al. 1999). They are widely used as starting materials for the synthesis of nylons, resins, waxes, plastics, biopolymers, and lubricants, and as additives in coatings and paintings (Biermann et al. 2011; Metzger and Bornscheuer 2006).

The composition of fatty acids in vegetable oils provides an opportunity to produce value-added materials. Most plant oils consist of a mole of glycerol and three moles of fatty acids, in which oleic acid and linoleic acid are mainly present (Karmakar and Ghosh 2015). Among several kinds of HFAs, ω-hydroxy fatty acids (Fig. 1a) are of great interest because they provide the longest carbon chain as the monomer in the synthesis of polymer materials due to the location of the hydroxyl group close to the end of the first methyl carbon (Cao and Zhang 2013). In view of industrial applications, ω-HFAs can be used for the production of α,ω-dicarboxylic acids and ω-amino carboxylic acids (Fig. 1), which are the starting materials of polyamides, polyesters, and other chemical products (Griehl and Ruestem 1970; Liu et al. 2008). ω-HFA can be biosynthesized from fatty acids via oxygenation of the terminal C–H bond or internal oxidative cleavage of fatty acids. While the C–H bond is oxidized by P450 monooxygenase or alkane hydroxylase, the oxidative cleavage of fatty acids is catalyzed by Baeyer–Villiger monooxygenase (BVMO) or a combination of lipoxygenase and hydrogen peroxide lyase. This review particularly focused on recent achievements in biosynthesis of ω-HFA via the oxidative cleavage of fatty acid mediated by BVMO. Detailed information of the C–H bond oxygenation can be found in a review (Seo et al. 2015).

Despite of numerous advantages of Escherichia coli as a workhorse in all areas of bioprocess, potential roadblocks in ω-HFA production by recombinant E. coli still exist. First, instability of cascade enzymes for ω-HFA bioconversion and low rate of fatty acid transport into E. coli cells across their cell membrane led to low yield and productivity of ω-HFAs. Second, the productivities are often low due to product toxicity that hampers the performance of whole-cell biocatalysts. Recently, attempts to overcome these limitations in ω-HFA production have been reported.

In this review, we summarized metabolic and/or protein engineering strategies to improve ω-HFA production by engineered E. coli. Especially, we focused on recent progress in (1) construction of the efficient ω-HFA conversion pathway by searching for novel enzymes with high specificity and activity, (2) enhancing stability of a rate-limiting enzyme and accessibility to its substrate, (3) conversion of ω-HFAs into α,ω-dicarboxylic acids and ω-amino carboxylic acids, and (4) alleviation of product toxicity by chemoenzymatic synthesis or introduction of genes related to acid tolerance.

Expression of cascade enzymes in E. coli for ω-HFA production

Microbial synthesis of various ω-HFAs from renewable fatty acids such as oleic acid, linoleic acid, and ricinoleic acid has been intensively investigated. Multistep enzymatic reactions involve the hydration of internal carbon atoms in fatty acids by a hydratase, oxidation of the hydroxy group to the ketone by an alcohol dehydrogenase (ADH), oxidation to an ester by BVMO, and hydrolysis of this ester to yield ω-HFAs (Fig. 2). The first example is the cleavage of ricinoleic acid into n-heptanoic acid and ω-hydroxyundec-9-enoic acid (ω-HUA) (Fig. 2a). For bioconversion of ricinoleic acid to ω-HUA, an ADH from Micrococcus luteus, a BVMO from Pseudomonas putida KT2440, and an esterase (PFE1) from Pseudomonas fluorescens SIK WI were overexpressed in E. coli BL21(DE3) (Jang et al. 2014). Biotransformation during stationary growth phase of recombinant E. coli in a bioreactor allowed to produce ω-HUA and n-heptanoic acid at a productivity of 3.2 mM/h and > 80% yield (Table 1).

Designed biotransformation pathways for production of ω-HFAs from ricinoleic acid (a), oleic acid (b), and linoleic acid (c). a Ricinoleic acid is converted into ω-hydroxyundec-9-enoic acid (ω-HUA) and n-heptanoic acid. b Oleic acid is converted into ω-hydroxy nonanoic acid and n-nonanoic acid. c Linoleic acid is converted into ω-hydroxy-cis-9-dodecenoic acid and n-hexanoic acid by multistep enzyme-catalyzed reactions

Unlike ricinoleic acid, most fatty acids from plant oils are nonhydroxylated (Biermann et al. 2011). Therefore, an enzyme to catalyze the formation of hydroxylated fatty acids was introduced into the cleavage pathway (Fig. 2b). Most of the HFAs produced by microbes are considered to be synthesized by fatty acid double-bond hydratases (e.g., oleate hydratase and linoleate hydratase), which catalyze the region-specific, irreversible addition of a hydrogen atom and a hydroxy group from water to the carbon–carbon cis-double bond in unsaturated fatty acids (Kim and Oh 2013). The gene encoding oleate hydratase (OhyA) from Stenotrophomonas maltophilia was selected based on a previous study showing that the OhyA has a high enzyme activity of 3600 U/mg protein toward hydroxylation of oleic acid into 10-hydroxystearic acid (Joo et al. 2012). To evaluate the performance of the extended pathway, recombinant E. coli cells expressing the S. maltophilia ohyA gene as well as the ADH from M. luteus and the BVMO from P. putida KT2440 were constructed and used for the biotransformation of oleic acid (Song et al. 2013). In this case, addition of the cell extract of E. coli BL21(DE3) expressing the esterase (PFE1) gene from P. fluorescens SIK WI led to the production of 0.67 mM ω-hydroxynonanoic acid at > 60% yield.

While a number of C-9 double-bond hydratases was identified and characterized in detail, C-12 double-bond hydratase had remained unidentified. Recently, a linoleate 13-hydratase from Lactobacillus acidophilus was characterized to be specific to hydration of the C-12 double bond in linoleic acid, and thereby its expression allowed the selective production of 13-hydroxy-cis-9-octadecenoic acid from linoleic acid (Oh et al. 2015). 13-Hydroxy-cis-9-octadecenoic acid can be converted to ω-hydroxy-cis-9-dodecenoic acid and n-hexanoic acid by the cascade enzymes (Fig. 2c). ω-Hydroxy-cis-9-dodecenoic acid was produced from linoleic acid by serial reactions of recombinant E. coli expressing the linoleate 13-hydratase and recombinant E. coli BL21(DE3) expressing the ADH from M. luteus, the BVMO from P. putida KT2440, and PFE1 from P. fluorescens SIK WI (Oh et al. 2015). The maximal specific reaction rate of the recombinant cells reached 1.4 U/g dry cells in 2 h of biotransformation, resulting in the production of 1.8 mM ω-hydroxy-cis-9-dodecenoic acid from 2.0 mM 13-hydroxy-cis-9-octadecenoic acid.

Modulation of enzymes in the ω-HFA biosynthetic pathways

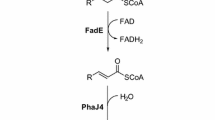

BVMO catalyzes the Bayer–Villiger oxidation and sulfoxidation with high regioselectivity and enantioselectivity (Balke et al. 2012; Orru et al. 2011). BVMO contains two-domain architecture with FAD-binding and NADPH-binding domains, in which the active site is located in a cleft at the domain interface. The crystal structure of BVMO from Rhodococcus sp. HI-31 in a complex with its substrate and NADP+ and FAD suggested that the enzyme undergoes a series of conformational changes during catalysis, resulting in the formation of an unstable structure (Yachnin et al. 2012). Also, the ester formation rate was abruptly reduced to zero within 2 h after initiation of the biotransformation, and the intermediate of keto-fatty acid was accumulated gradually in the reaction medium (Baek et al. 2015). Considering these unstable enzymatic properties and reaction profiles, the ester-forming reaction catalyzed by BVMO has been recognized as a limiting step in the conversion of fatty acids to ω-HFAs (Fig. 2) (Baek et al. 2015; Jeon et al. 2015). To increase functional expression and activity of BVMO under reaction conditions, fusion proteins of ADH-Gly-BVMO consisting of the ADH of M. luteus and the BVMO from either P. putida KT2440 or R. jostii RHA1 were designed (Jeon et al. 2015), in which a glycine-rich peptide (Pazmino et al. 2008) was used as the linker. Activity of recombinant E. coli expressing the ADH-Gly-BVMO with ricinoleic acid substrate was about 40% greater than that of recombinant E. coli expressing ADH and BVMO independently. The BVMO activity of the ADH-Gly-BVMO fusion enzyme was further improved by co-expression of a single subunit recombinant thermosome (r-THS) from Methanocaldococcus jannaschii, which is known to stabilize unstable proteins (Bergeron et al. 2009). The recombinant E. coli expressing both ADH-Gly-BVMO and r-THS showed approximately 2-fold higher final product concentration than the recombinant E. coli expressing ADH-Gly-BVMO only (Baek et al. 2015). Moreover, 3′-untranslated region (3′UTR) engineering was adopted to improve solubility of BVMOs in E. coli. Insertion of gene fragments containing putative endonucleolytic cleavage sites of RNase E into the 3′UTR in the BVMO genes led to the reduction of mRNA levels (Song et al. 2016). While the total expression level of BVMOs with the putative RNase E sites was lower than that of BVMOs without the RNase E sites, the soluble expression level and catalytic activity were significantly improved by the insertion of the putative RNase E sites. Also, stability and expression of the BVMO from P. putida KT2440 at 30 °C were substantially enhanced via fusion with hexa-glutamate (E6) tag (Seo et al. 2016). This result was consistent with a previous study reporting that negatively charged residues at the N- or C-terminus played an important role in thermal stability of chaperonines from Pyrococcus furiosus and Methanococcoides burtonii (Luo and Robb 2011). Furthermore, a synthetic promoter was used for inducer-free constitutive expression of the engineered BVMO (E6-BVMO) in large-scale biotransformation. In a 70-L-scale biotransformation, (E)-11-(heptanoyloxy)undec-9-enoic acid (11-HOUA), the ester intermediate converted from ricinoleic acid by ADH and BVMO (Fig. 2a), was produced at over 70 mM in the broth within 6 h after biotransformation (Seo et al. 2016). Stability of the E6-BVMO was further improved by substituting cysteine to leucine at the 302th amino acid (Woo et al. 2018), which is consistent with a previous study reporting that amino acids with sulfur group were sensitive to reactive oxygen species (Schoneich 2008).

The extremely low solubility of fatty acids in aqueous reaction mixture impedes the journey of substrate to enzyme active sites. Therefore, it is necessary to increase the efficiency of fatty acid transport to catalytic enzymes in order to improve biotransformation rates. Fatty acids are transported into E. coli cells across cell membranes via a transport/acyl-activation mechanism involving an outer membrane protein (FadL) and an inner membrane-associated acyl-CoA synthase (FadD) (DiRusso and Black 1999; Maloy et al. 1981). The gene coding for FadL was introduced into recombinant E. coli BL21(DE3) containing plasmids of pACYC-ADH-OhyA and pJOE-E6BVMO with the strong inducible T7 promoter. The resulting recombinant E. coli strain exhibited 6-fold higher oleic acid biotransformation rate and 9-(nonanoyloxy)-nonanoic acid (Fig. 2b) production rate than those for the control strain without the FadL overexpression (Jeon et al. 2016). In addition, the FadL overexpression increased biotransformation rate of ricinoleic acid to 11-HOUA by a 2-fold (Jeon et al. 2018). These results indicated that the delivery of oleic acid and ricinoleic acid into the cascade enzymes inside cells plays an important role in determination of the biotransformation rate. Furthermore, activity of fatty acid hydration in recombinant E. coli expressing S. maltophilia OhyA was improved by targeting the catalytic enzyme into the periplasm instead of the cytoplasm. The hydration rate of oleic acid by recombinant E. coli expressing the OhyA fused with the PelB signal sequence was > 10-fold higher than that of E. coli expressing the OhyA in the cytoplasm (Jung et al. 2015). The PelB signal sequence is a popular leader sequence able to deliver target protein to the periplasmic space (Kim et al. 2015). Meanwhile, the physiochemical property of 11-HOUA remained a problem for efficient biotransformation of ricinoleic acid to ω-HUA. Since a long-chain free fatty acid of 11-HOUA is highly hydrophobic, it can be imbedded into the cytoplasmic membrane of E. coli, which may hamper the reaction of esterase expressed in the E. coli cytoplasm (Cho et al. 2018). To increase the frequency of substrate binding, a substrate/membrane-binding domain from an esterase in P. fluorescens DSM50106 was fused to the N-terminal end of PFE1 from P. fluorescens SIK WI. This method led to a substantial increase in its hydrolytic activity of 11-HOUA to ω-HUA and n-heptanoic acid (Lee et al. 2014). Moreover, to improve accessibility of PFE1 to the 11-HOUA substrate, a truncated version of the PelB signal sequence without the recognition site of signal peptidase was attached to the N-terminus of PFE1 (tPelB-PFE1). A fed-batch type biotransformation of ricinoleic acid by E. coli expressing tPelB-PFE1 in addition to ADH and BVMO resulted in 13.2-, 2.9-, and 2.6-fold increases in ω-HUA concentration, yield, and productivity, relative to those for the control strain without the PelB signal sequence in a batch-type biotransformation (Cho et al. 2018). For a fed-batch type biotransformation, glycerol was continuously or intermittently added in the stage of ricinoleic acid biotransformation to facilitate the regeneration of co-factors required in the ADH and BVMO reactions, and maintain cell viability (Cho et al. 2017).

Microbial synthesis of α,ω-dicarboxylic acids and ω-amino carboxylic acids from renewable fatty acids and oils

Although α,ω-dicarboxylic acids and ω-amino carboxylic acids can be produced from hydrocarbons by a yeast of C. tropicalis (Eschenfeldt et al. 2003), and chemical catalysts (Zhang et al. 2009), these processes are limited by the availability of substrates used and low product yields. Therefore, biotransformation of fatty acids into α,ω-dicarboxylic acids and/or ω-amino carboxylic acids directly from fatty acids (e.g., oleic acid, ricinoleic acid, lesquerolic acid) using recombinant E coli-based biocatalysts has been investigated. ω-HFAs produced from oxidative cleavage of fatty acid were oxidized to α,ω-dicarboxylic acids by alcohol dehydrogenase (ADH and AlkJ) from P. putida GPo1 or converted into ω-amino carboxylic acids by the combination of ADH from P. putida GPo1 and an ω-transaminase from Silicibacter pomeroyi (Fig. 3). A representative example is the production of α,ω-undecanedioic acid from 12-hydroxystearic acid. 12-Hydroxystearic acid was first cleaved into ω-hydroxyundecanoic acid and n-heptanoic acid by recombinant E. coli expressing ADH from M. luteus, a BVMO from P. putida KT2440, and the esterase from P. fluorescens SIK WI. ω-Hydroxyundecanoic acid was then oxidized by the recombinant E. coli expressing AlkJ from P. putida GPo1, resulting in production of 3.6 mM α,ω-undecanedioic acid with a yield of 72% (Song et al. 2014). On the other hand, recombinant E. coli BL21 (DE3) expressing AlkJ from P. putida GPo1 and a ω-transaminase from S. pomeroyi converted 4 mM ω-hydroxydodecanoic acid into 2.6 mM ω-aminododecanoic acid and 0.8 mM α,ω-dodecanedioic acid in the presence of 10 mM l-alanine (Song et al. 2014). Also, a recent study showed that α,ω-nonanedioic acid could be produced from renewable oils (e.g., olive oil and yeast-derived oil) by lipase from Thermomyces lanuginosus and recombinant E. coli expressing alcohol/aldehyde dehydrogenases (ChnDE) from Acinetobacter sp. NCIMB9871 in addition to OhyA from S. maltophilia, ADH from M. luteus, and an engineered BVMO (E6-BVMO) from P. putida KT2440. This strategy resulted in the production of 4.3 mM α,ω-nonanedioic acid from 3 g/L olive oil at an average rate of 3.1 U/g dry cells (Seo et al. 2018). A more engineered E. coli strain overexpressing FadL produced α,ω-nonanedioic acid from ricinoleic acid at a productivity of 20 U/g cells with an aid of P. fluorescens SIK WI esterase added exogenously (Cha et al. 2018).

Biotransformation of ω-hydroxyundecanoic acid into α,ω-undecanedioic acid and ω-amino dodecanoic acid. ω-Hydroxyundecanoic acid is oxidized into α,ω-undecanedioic acid by alcohol dehydrogenase (AlkJ) from P. putida GPo1. Otherwise, it is converted into ω-amino dodecanoic acid via tandem reactions catalyzed by the AlkJ from P. putida GPo1 and ω-transaminase from S. pomeroyi. Q ubiquinone, QH2 ubiquinol

Alleviation of toxicity of reaction intermediates and final products

Whole-cell biotransformation of ricinoleic acid into ω-HUA and n-heptanoic acid (Fig. 2a) was limited by high toxicity of the final products to the microbial host cells. Even though the toxicity depends on the length of chain and the contents of double bond and branches, most carboxylic acids damage cell membrane and decrease intracellular pH, and hence reduce the cell viability (Jarboe et al. 2013; Royce et al. 2015). Therefore, ricinoleic acid was converted to an ester of 11-HOUA, which is much less toxic to the cells, by recombinant E. coli expressing the ADH from M. luteus and the BVMO from P. putida KT2440. 11-HOUA was then chemically converted into ω-hydroxyundecanoic acid, which was in turn transformed into α,ω-undecanedioic acid under fairly mild reaction conditions. The biotransformation rate from ricinoleic acid to 11-HOUA was approximately 50% higher compared to the direct biotransformation of ricinoleic acid to ω-HUA and n-heptanoic acid (Jang et al. 2016). The overall molar yield of α,ω-undecanedioic acid from ricinoleic acid was 55% based on the biotransformation and chemical transformation yields of 84% and 65%, respectively (Jang et al. 2016). The specific growth rate of E. coli was also reduced by 50% in the presence of 5 mM n-nonanoic acid, the final product converted from oleic acid by the cascade enzymes (Fig. 2b) (Koppireddi et al. 2016). Therefore, biotransformation of oleic acid into a less toxic ester of 9-(nonanoyloxy)-nonanoic acid via 10-ketostearic acid was driven by recombinant E. coli cells expressing the OhyA from S. maltophilia, the ADH from M. luteus, and the BVMO from P. putida KT2440. After production of the ester, the compound was chemically hydrolyzed to n-nonanoic acid and ω-hydroxynonanoic acid, which was chemically oxidized to α,ω-nonanedioic acid with a high yield under fairly mild reaction conditions (Koppireddi et al. 2016).

Although E. coli BL21 is one of the most utilized bacteria, it is more susceptible to various stresses including acid-induced stress when compared to E. coli K-12 strains (Lease et al. 2004). Activation of the GadA/B-based glutamic acid-dependent acid resistance (GDAR) system by introducing the rcsB and dsrA genes from E. coli MG1655 into E. coli BL21(DE3) led to an increase in acid tolerance not only to HCl but also to n-heptanoic acid (Woo et al. 2016). In addition, activation of the GDAR system allowed recombinant E. coli BL21(DE3) expressing the ADH from M. luteus and the BVMO from P. putida KT2440 to produce 10 mM ω-HUA with the aid of exogenously added esterase from P. fluorescens SIK WI. The titer of ω-HUA was 1.6-fold higher as compared to the control strain without activation of the GDAR system. A recent study reported the integration of the native transcription unit (TU) of dsrA and the synthetic TU of rcsB into the E. coli BL21 genome without scar by using CRISPR-Cas9 system (Seo et al. 2017). The engineered strains expressing dsrA and/or rcsB exhibited the higher viabilities and specific growth rates under n-heptanoic acid stress than wild-type E. coli BL21.

Conclusions and future perspectives

The location of the hydroxyl group and specific properties of ω-HFAs make them useful for various applications in cosmetics, foods, and plastics. It has been demonstrated that various value-added ω-HFAs can be produced from vegetable oils or fatty acids. However, most of the ω-HFAs are currently produced at a low yield or conversion rate. In the past few years, production of ω-HFAs by engineered E. coli has been significantly improved by adapting a cutting-edge technology of metabolic engineering. Amplification and engineering of the heterologous pathways for biosynthesis of ω-HFAs and additional sugar-feeding strategy in biotransformation process enabled engineered E. coli to produce over 20 mM of ω-HUA.

Considering the low tolerance of the E. coli BL21 to ω-HFAs, the microbial strains should be engineered to achieve a much higher resistance to ω-HFAs. As most of the engineered E. coli strains for production of ω-HFAs are only tested in the laboratory scale, fermentation strategies should be employed to expand the processes to an industrial level. To improve the potential of ω-HFAs as industrial products, future approaches are suggested to not only focus on developing better microbial strains but also aim at more efficient downstream process for preparation of oils. For example, some impurities in the yeast-derived oil and microalgal oil inhibit the activities of the cascade enzymes involved in whole-cell biotransformation. Improving downstream process for the preparation of the oils will lead to greater productivities. We believe that more advances in metabolic engineering and downstream process would overcome the current problems and ultimately lead to an alternative way for the commercial supply of ω-HFAs and their related products.

References

Baek AH, Jeon EY, Lee SM, Park JB (2015) Expression levels of chaperones influence biotransformation activity of recombinant Escherichia coli expressing Micrococcus luteus alcohol dehydrogenase and Pseudomonas putida Baeyer-Villiger monooxygenase. Biotechnol Bioeng 112:889–895. https://doi.org/10.1002/bit.25521

Balke K, Kadow M, Mallin H, Sass S, Bornscheuer UT (2012) Discovery, application and protein engineering of Baeyer-Villiger monooxygenases for organic synthesis. Org Biomol Chem 10:6249–6265. https://doi.org/10.1039/c2ob25704a

Bergeron LM, Tokatlian T, Gomez L, Clark DS (2009) Redirecting the inactivation pathway of penicillin amidase and increasing amoxicillin production via a thermophilic molecular chaperone. Biotechnol Bioeng 102:417–424. https://doi.org/10.1002/bit.22142

Biermann U, Bornscheuer U, Meier MAR, Metzger JO, Schafer HJ (2011) Oils and fats as renewable raw materials in chemistry. Angew Chem Int Edit 50:3854–3871. https://doi.org/10.1002/anie.201002767

Cao Y, Zhang X (2013) Production of long-chain hydroxy fatty acids by microbial conversion. Appl Microbiol Biotechnol 97:3323–3331. https://doi.org/10.1007/s00253-013-4815-z

Cha HJ, Seo EJ, Song JW, Jo HJ, Kumar AR, Park JB (2018) Simultaneous enzyme/whole-cell biotransformation of C18 ricinoleic acid into (R)-3-hydroxynonanoic acid, 9-hydroxynonanoic acid, and 1,9-nonanedioic acid. Adv Synth Catal 360:696–703. https://doi.org/10.1002/adsc.201701029

Chance DL, Gerhardt KO, Mawhinney TP (1998) Gas-liquid chromatography mass spectrometry of hydroxy fatty acids as their methyl esters tert.-butyldimethylsilyl ethers. J Chromatogr A 793:91–98. https://doi.org/10.1016/S0021-9673(97)00876-5

Cho YH, Kim SJ, Kim HW, Kim JY, Gwak JS, Chung D, Kim KH, Park K, Park YC (2017) Continuous supply of glucose and glycerol enhances biotransformation of ricinoleic acid to (E)-11-(heptanoyloxy) undec-9-enoic acid in recombinant Escherichia coli. J Biotechnol 253:34–39. https://doi.org/10.1016/j.jbiotec.2017.05.014

Cho YH, Kim SJ, Kim JY, Lee DH, Park K, Park YC (2018) Effect of PelB signal sequences on Pfe1 expression and omega-hydroxyundec-9-enoic acid biotransformation in recombinant Escherichia coli. Appl Microbiol Biotechnol 102:7407–7416. https://doi.org/10.1007/s00253-018-9139-6

DiRusso CC, Black PN (1999) Long-chain fatty acid transport in bacteria and yeast. Paradigms for defining the mechanism underlying this protein-mediated process. Mol Cell Biochem 192:41–52. https://doi.org/10.1023/A:1006823831984

Eschenfeldt WH, Zhang Y, Samaha H, Stols L, Eirich LD, Wilson CR, Donnelly MI (2003) Transformation of fatty acids catalyzed by cytochrome P450 monooxygenase enzymes of Candida tropicalis. Appl Environ Microbiol 69:5992–5999. https://doi.org/10.1128/AEM.69.10.5992-5999.2003

Griehl W, Ruestem D (1970) Nylon-12-preparation, properties, and applications. Ind Eng Chem 62:16–22. https://doi.org/10.1021/ie50723a005

Hou CT, Kuo TM, Lanser AC (1999) Production of hydroxy fatty acids by biocatalysis. In: Knothe J, Derksen JTP (eds) Recent developments in the synthesis of fatty acid derivatives, 1st edn. AOCS Press, Champaign, Illinois, pp 213–226

Jang HY, Jeon EY, Baek AH, Lee SM, Park JB (2014) Production of omega-hydroxyundec-9-enoic acid and n-heptanoic acid from ricinoleic acid by recombinant Escherichia coli-based biocatalyst. Process Biochem 49:617–622. https://doi.org/10.1016/j.procbio.2014.01.025

Jang HY, Singha K, Kim HH, Kwon YU, Park JB (2016) Chemo-enzymatic synthesis of 11-hydroxyundecanoic acid and 1,11-undecanedioic acid from ricinoleic acid. Green Chem 18:1089–1095. https://doi.org/10.1039/c5gc01017a

Jarboe LR, Royce LA, Liu P (2013) Understanding biocatalyst inhibition by carboxylic acids. Front Microbiol 4:272. https://doi.org/10.3389/fmicb.2013.00272

Jeon EY, Baek AH, Bornscheuer UT, Park JB (2015) Enzyme fusion for whole-cell biotransformation of long-chain sec-alcohols into esters. Appl Microbiol Biotechnol 99:6267–6275. https://doi.org/10.1007/s00253-015-6392-9

Jeon EY, Seo JH, Kang WR, Kim MJ, Lee JH, Oh DK, Park JB (2016) Simultaneous enzyme/whole-cell biotransformation of plant oils into C9 carboxylic acids. ACS Catal 6:7547–7553. https://doi.org/10.1021/acscatal.6b01884

Jeon EY, Song JW, Cha HJ, Lee SM, Lee J, Park JB (2018) Intracellular transformation rates of fatty acids are influenced by expression of the fatty acid transporter FadL in Escherichia coli cell membrane. J Biotechnol 281:161–167. https://doi.org/10.1016/j.jbiotec.2018.07.019

Joo YC, Seo ES, Kim YS, Kim KR, Park JB, Oh DK (2012) Production of 10-hydroxystearic acid from oleic acid by whole cells of recombinant Escherichia coli containing oleate hydratase from Stenotrophomonas maltophilia. J Biotechnol 158:17–23. https://doi.org/10.1016/j.jbiotec.2012.01.002

Jung SM, Seo JH, Lee JH, Park JB, Seo JH (2015) Fatty acid hydration activity of a recombinant Escherichia coli-based biocatalyst is improved through targeting the oleate hydratase into the periplasm. Biotechnol J 10:1887–1893. https://doi.org/10.1002/biot.201500141

Karmakar G, Ghosh P (2015) Soybean oil as a biocompatible multifunctional additive for lubricating oil. ACS Sustain Chem Eng 3:19–25. https://doi.org/10.1021/sc500685r

Kim KR, Oh DK (2013) Production of hydroxy fatty acids by microbial fatty acid-hydroxylation enzymes. Biotechnol Adv 31:1473–1485. https://doi.org/10.1016/j.biotechadv.2013.07.004

Kim SK, Park YC, Lee HH, Jeon ST, Min WK, Seo JH (2015) Simple amino acid tags improve both expression and secretion of Candida antarctica lipase B in recombinant Escherichia coli. Biotechnol Bioeng 112:346–355. https://doi.org/10.1002/bit.25361

Kockritz A, Martin A (2011) Synthesis of azelaic acid from vegetable oil-based feedstocks. Eur J Lipid Sci Tech 113:83–91. https://doi.org/10.1002/ejlt.201000117

Koppireddi S, Seo JH, Jeon EY, Chowdhury PS, Jang HY, Park JB, Kwon YU (2016) Combined biocatalytic and chemical transformations of oleic acid to omega-hydroxynonanoic acid and alpha,omega-nonanedioic acid. Adv Synth Catal 358:3084–3092. https://doi.org/10.1002/adsc.201600216

Lease RA, Smith D, McDonough K, Belfort M (2004) The small noncoding DsrA RNA is an acid resistance regulator in Escherichia coli. J Bacteriol 186:6179–6185. https://doi.org/10.1128/Jb.186.18.6179-6185.2004

Lee YA, Jeon EY, Lee SM, Bornscheuer UT, Park JB (2014) Engineering the substrate-binding domain of an esterase enhances its hydrolytic activity toward fatty acid esters. Process Biochem 49:2101–2106. https://doi.org/10.1016/j.procbio.2014.09.019

Liu C, Liu F, Cai J, Xie W, Long TE, Turner SR, Lyons A, Gross RA (2011) Polymers from fatty acids: poly(omega-hydroxyl tetradecanoic acid) synthesis and physico-mechanical studies. Biomacromolecules 12:3291–3298. https://doi.org/10.1021/bm2007554

Liu G, Kong X, Wan H, Narine S (2008) Production of 9-hydroxynonanoic acid from methyl oleate and conversion into lactone monomers for the synthesis of biodegradable polylactones. Biomacromolecules 9:949–953. https://doi.org/10.1021/bm7012235

Luo HB, Robb FT (2011) A modulator domain controlling thermal stability in the group II chaperonins of archaea. Arch Biochem Biophys 512:111–118. https://doi.org/10.1016/j.abb.2011.04.017

Maloy SR, Ginsburgh CL, Simons RW, Nunn WD (1981) Transport of long and medium chain fatty acids by Escherichia coli K12. J Biol Chem 256:3735–3742

Metzger JO, Bornscheuer U (2006) Lipids as renewable resources: current state of chemical and biotechnological conversion and diversification. Appl Microbiol Biotechnol 71:13–22. https://doi.org/10.1007/s00253-006-0335-4

Mittaine JF (2016) Oilseeds and vegetable oils in Asia: a world of diversity. Ocl Oils Fat Crop Li 23:D602. https://doi.org/10.1051/ocl/2016040

Oh HJ, Kim SU, Song JW, Lee JH, Kang WR, Jo YS, Kim KR, Bornscheuer UT, Oh DK, Park JB (2015) Biotransformation of linoleic acid into hydroxy fatty acids and carboxylic acids using a linoleate double bond hydratase as key enzyme. Adv Synth Catal 357:408–416. https://doi.org/10.1002/adsc.201400893

Orru R, Dudek HM, Martinoli C, Torres Pazmino DE, Royant A, Weik M, Fraaije MW, Mattevi A (2011) Snapshots of enzymatic Baeyer-Villiger catalysis: oxygen activation and intermediate stabilization. J Biol Chem 286:29284–29291. https://doi.org/10.1074/jbc.M111.255075

Pazmino DET, Snajdrova R, Baas BJ, Ghobrial M, Mihovilovic MD, Fraaije MW (2008) Self-sufficient Baeyer-Villiger monooxygenases: effective coenzyme regeneration for biooxygenation by fusion engineering. Angew Chem Int Edit 47:2275–2278. https://doi.org/10.1002/anie.200704630

Royce LA, Yoon JM, Chen YX, Rickenbach E, Shanks JV, Jarboe LR (2015) Evolution for exogenous octanoic acid tolerance improves carboxylic acid production and membrane integrity. Metab Eng 29:180–188. https://doi.org/10.1016/j.ymben.2015.03.014

Schoneich C (2008) Mechanisms of protein damage induced by cysteine thiyl radical formation. Chem Res Toxicol 21:1175–1179. https://doi.org/10.1021/tx800005u

Seo EJ, Yeon YJ, Seo JH, Lee JH, Bongol JP, Oh Y, Park JM, Lim SM, Lee CG, Park JB (2018) Enzyme/whole-cell biotransformation of plant oils, yeast derived oils, and microalgae fatty acid methyl esters into n-nonanoic acid, 9-hydroxynonanoic acid, and 1,9-nonanedioic acid. Bioresour Technol 251:288–294. https://doi.org/10.1016/j.biortech.2017.12.036

Seo JH, Baek SW, Lee J, Park JB (2017) Engineering Escherichia coli BL21 genome to improve the heptanoic acid tolerance by using CRISPR-Cas9 system. Biotechnol Bioprocess Eng 22:231–238. https://doi.org/10.1007/s12257-017-0158-4

Seo JH, Kim HH, Jeon EY, Song YH, Shin CS, Park JB (2016) Engineering of Baeyer-Villiger monooxygenase-based Escherichia coli biocatalyst for large scale biotransformation of ricinoleic acid into (Z)-11-(heptanoyloxy) undec-9-enoic acid. Sci Rep 6:28223. https://doi.org/10.1038/srep28223

Seo JH, Lee SM, Lee J, Park JB (2015) Adding value to plant oils and fatty acids: biological transformation of fatty acids into omega-hydroxycarboxylic, alpha,omega-dicarboxylic, and omega-aminocarboxylic acids. J Biotechnol 216:158–166. https://doi.org/10.1016/j.jbiotec.2015.10.024

Song JW, Jeon EY, Song DH, Jang HY, Bornscheuer UT, Oh DK, Park JB (2013) Multistep enzymatic synthesis of long-chain α,ω-dicarboxylic and ω-hydroxycarboxylic acids from renewable fatty acids and plant oils. Angew Chem Int Ed Engl 52:2534–2537. https://doi.org/10.1002/anie.201209187

Song JW, Lee JH, Bornscheuer UT, Park JB (2014) Microbial synthesis of medium-chain, -dicarboxylic acids and -aminocarboxylic acids from renewable long-chain fatty acids. Adv Synth Catal 356:1782–1788. https://doi.org/10.1002/adsc.201300784

Song JW, Woo JM, Jung GY, Bornscheuer UT, Park JB (2016) 3'-UTR engineering to improve soluble expression and fine-tuning of activity of cascade enzymes in Escherichia coli. Sci Rep 6:29406. https://doi.org/10.1038/srep29406

Woo JM, Jeon EY, Seo EJ, Seo JH, Lee DY, Yeon YJ, Park JB (2018) Improving catalytic activity of the Baeyer-Villiger monooxygenase-based Escherichia coli biocatalysts for the overproduction of (Z)-11-(heptanoyloxy)undec-9-enoic acid from ricinoleic acid. Sci Rep 8:10280. https://doi.org/10.1038/s41598-018-28575-8

Woo JM, Kim JW, Song JW, Blank LM, Park JB (2016) Activation of the glutamic acid-dependent acid resistance system in Escherichia coli BL21(DE3) leads to increase of the fatty acid biotransformation activity. PLoS One 11:e0163265. https://doi.org/10.1371/journal.pone.0163265

Yachnin BJ, Sprules T, McEvoy MB, Lau PC, Berghuis AM (2012) The substrate-bound crystal structure of a Baeyer-Villiger monooxygenase exhibits a Criegee-like conformation. J Am Chem Soc 134:7788–7795. https://doi.org/10.1021/ja211876p

Zhang F, Huang CH, Xu TW (2009) Production of sebacic acid using two-phase bipolar membrane electrodialysis. Ind Eng Chem Res 48:7482–7488. https://doi.org/10.1021/ie900485k

Funding

This work was financially supported by the National Research Foundation of Korea (NRF) Grants (2016R1A2B4010842 and 2018R1C1B5044416) funded by the Korean Ministry of Science, ICT and Future Planning, and also by the R&D Program of MOTIE/KEIT (10048684).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Ethical approval

This article does not contain any studies with human participants or animals by any of the authors.

Rights and permissions

About this article

Cite this article

Kim, SK., Park, YC. Biosynthesis of ω-hydroxy fatty acids and related chemicals from natural fatty acids by recombinant Escherichia coli. Appl Microbiol Biotechnol 103, 191–199 (2019). https://doi.org/10.1007/s00253-018-9503-6

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00253-018-9503-6