Abstract

Agar is a major polysaccharide of red algal cells and is mainly decomposed into neoagarobiose by the co-operative effort of β-agarases. Neoagarobiose is hydrolyzed into monomers, d-galactose and 3,6-anhydro-l-galactose, via a microbial oxidative process. Therefore, the enzyme, 1,3-α-3,6-anhydro-l-galactosidase (α-neoagarobiose/neoagarooligosaccharide hydrolase) involved in the final step of the agarolytic pathway is crucial for bioindustrial application of agar. A novel cold-adapted α-neoagarooligosaccharide hydrolase, Ahg786, was identified and characterized from an agarolytic marine bacterium Gayadomonas joobiniege G7. Ahg786 comprises 400 amino acid residues (45.3 kDa), including a 25 amino acid signal peptide. Although it was annotated as a hypothetical protein from the genomic sequencing analysis, NCBI BLAST search showed 57, 58, and 59% identities with the characterized α-neoagarooligosaccharide hydrolases from Saccharophagus degradans 2–40, Zobellia galactanivorans, and Bacteroides plebeius, respectively. The signal peptide-deleted recombinant Ahg786 expressed and purified from Escherichia coli showed dimeric forms and hydrolyzed neoagarobiose, neoagarotetraose, and neoagarohexaose into 3,6-anhydro-l-galactose and other compounds by cleaving α-1,3-glycosidic bonds from the non-reducing ends of neoagarooligosaccharides, as confirmed by thin-layer chromatography and mass spectrometry. The optimum pH and temperature for Ahg786 activity were 7.0 and 15 °C, respectively, indicative of its unique cold-adapted features. The enzymatic activity severely inhibited with 0.5 mM ethylenediaminetetraacetic acid was completely restored or remarkably enhanced by Mn2+ in a concentration-dependent manner, suggestive of the dependence of the enzyme on Mn2+ ions. Km and Vmax values for neoagarobiose were 4.5 mM and 1.33 U/mg, respectively.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Agarose and porphyran are the key polysaccharides that make agar (galactan), an extract from the red algae. Agarose comprises alternating 3-O-linked β-d-galactopyranose (G) and 4-O-linked α-3,6-anhydro-l-galactopyranose (AHG). Porphyran is a more complex galactan with repeating units of G and 4-O-linked α-l-galactopyranose-6-sulfate (G6S) and is often masked by ester sulfate, methyl, or pyruvic acid acetal groups (Usov 1998; Hehemann et al. 2010). Galactan backbones are hybrids derived from the structures of agarobiose (G-AHG) and porphyrobiose (G-G6S), and the proportions of the two moieties are variable among agar (Hehemann et al. 2010).

Agarose consists of mainly agarobiose and accounts for 60% of the dry cell weight of red algae such as Gracilariales. Agarose may be degraded by two routes, namely, α- and β-agarolytic pathways, by several kinds of agar hydrolytic enzymes (agarases) found in some microorganisms (Chi et al. 2012; Leon et al. 1992). The β-agarolytic pathway of agar is catalyzed by β-agarase (EC 3.2.1.81) that hydrolyzes agarose at β-1,4-glycosidic linkages of G and AHG residues and produces neoagarooligosaccharides (NAOSs) with G residues at their reducing ends (Chi et al. 2012; Araki 1959). Several types of β-agarases have been identified in various bacteria; these belong to four distinct glycosyl hydrolase (GH) families (GH16, GH50, GH86, and GH118) in the carbohydrate-active enZYmes (CAZY) database (http://www.cazy.org/). However, very little is reported on α-agarases (EC 3.2.1.158) that are involved in α-agarolytic pathways (Potin et al. 1993; Ohta et al. 2005; Zhang et al. 2018); hence, the β-agarolytic pathway is more common for agar degradation in nature. The final product of β-agarolytic pathway, neoagarobiose (NA2), should be further hydrolyzed into monomeric sugars, G and AHG, for their microbial oxidation or bioconversion into valuable products for industrial application (Fig. 1).

Schematic representation of β-agarose hydrolytic pathway. Polymeric agarose is initially cleaved at the β-1,4 linkage by the exported enzyme, β-agarase I. The resulting neoagarooligosaccharide is then broken down to neoagarobiose through the action of β-agarase II. Finally, neoagarobiose is cleaved at the α-1,3 linkage by 1,3-α-3,6-anhydro-l-galactosidase (α-neoagarobiose/neoagarooligosaccharide hydrolase) to produce d-galactose (G) and 3,6-anhydro-l-galactose (AHG)

The enzymes crucial for the production of these monomeric sugars are α-neoagarobiose hydrolase (α-NABH) and α-NAOS hydrolase (α-NAOSH), wherein α-NABH refers to an enzyme that is specific for the substrate NA2. These enzymes act exogenously on α-1,3 linkages from the non-reducing ends of NAOS to release AHG and other molecules. CAZy database has grouped them in the GH117 family. Till date, only 11 α-NABH/NAOSHs have been biochemically identified (Table 1).

Marine biomass is a rich source of agar and serves as a promising sustainable resource for chemical feed stocks and bioenergy. For instance, G may be converted into biofuel as well as other chemicals such as the sweetener d-tagatose (Patel et al. 2016). Moreover, G exerts anti-inflammatory and antioxidant activities (Liu et al. 2008) and helps the immune and digestive systems (Mohammad et al. 2011). Recent studies have reported the skin whitening, moisturizing, anti-inflammatory, and anticariogenic effects of AHG (Yun et al. 2017). Therefore, it is anticipated that agar biomass may create a big market for new industrial applications in the future. Although multiple enzyme treatment such as β-agarase I (exo-type), β-agarase II (endo/exo-type), and α-NABH/NAOSH (exo-type) is needed for the efficient production and industrial application of G and AHG from agar, the biochemical knowledge about α-NABH/NAOSHs is inadequate as compared with that about β-agarases.

Gayadomonas joobiniege G7, an agarolytic bacterium belonging to the family Alteromonadaceae, was isolated from coastal sea water (Chi et al. 2013). Its genome study predicted many genes encoding hydrolytic enzymes, which may play important roles in the complete breakdown of sulfated algal polysaccharides such as agar (Kwak et al. 2012). In previous studies, we identified several types of β-agarases in G. joobiniege G7 (Jung et al. 2017a, b; Lee et al. 2018), but the lack of knowledge on α-NABH/NAOSHs encouraged us to conduct studies for the characterization of the candidate genes. As a result, we report a unique cold-adapted exo-acting α-NAOSH from G. joobiniege, hereafter named as Ahg786.

Materials and methods

Bacterial strains and culture conditions

G. joobiniege G7T (ATCC BAA-2321 = DSM25250T = KCTC23721T) was used as the genomic source for ahg786 gene (NCBI accession No. WP_017446786) and grown on artificial sea water (ASW) agar plate (Kim and Hong 2012). Plasmid pET-28a(+) was used for cloning. Escherichia coli Rosetta-gami was used for the transformation and expression of the recombinant plasmid. E. coli was routinely grown in Luria-Bertani (LB) medium (Green and Sambrook 2012) at 37 °C. Kanamycin (50 μg/mL) was added when required.

Enzymes and chemicals

Restriction enzymes, T4 DNA ligase, and Taq DNA polymerase were purchased from New England Bio Labs (Ipswich, MA, USA). Primers for polymerase chain reaction (PCR) were obtained from Genotech, South Korea. All other chemicals were procured from Sigma-Aldrich Corporation (St. Louis, MI, USA). Thin-layer chromatography (TLC) silica gel plate (60G F254) was obtained from Merck KGaA (Darmstadt, Germany). NA2, neoagarotetraose (NA4), and neoagarohexaose (NA6) were supplied by DyneBio Inc. (Seongnam, Korea).

Cloning of ahg786 from G. joobiniege G7

Bacterial cells from glycerol stock were grown on ASW agar plate at 28 °C for 24 h. Genomic DNA was isolated using Hi Yield Genomic DNA Mini Kit (RBC Company, Taiwan). The DNA fragment (1203 bp) carrying the coding region of the mature form without the predicted N-terminal signal peptide (1–25 amino acids) of the open reading frame (ORF), Ahg786, was amplified by PCR using the following primers: forward primer having BamHI site (underlined) 5′-GTCTTGGATCCGTTAGATTCGTTTTTTCTG-3′ and reverse primer having NheI site (underlined) 5′-ACAGATAGCTAGCATGAAATCACTCAAACA-3′. Amplification reactions were performed in TaKaRa PCR Thermal Cycler Dice ®Gradient (Takara Bio, Japan) at an initial temperature of 95 °C for 5 min, followed by 30 cycles of 96 °C for 1 min, 55 °C for 30 s, and 72 °C for 90 s. The final step at 72 °C for 10 min was performed using Ex-Taq polymerase. The PCR product was digested by restriction enzymes (NheI and BamHI) and inserted into corresponding sites of pET-28a(+) to obtain pET-28a-Ahg786. The construct was designed to express the recombinant Ahg786 (rAhg786) protein with 20 additional amino acids including a 6×His tag at the N-terminus. After confirmation of the desired sequence, the recombinant plasmid was transformed into E. coli Rosetta-gami.

Expression and purification of the recombinant Ahg786

E. coli Rosetta-gami/pET-28a-Ahg786 was cultivated in LB (100 mL) medium at 37 °C to OD600 of 0.6. The cells were induced with 0.5 mM (final concentration) isopropyl-β-d-thiogalactopyranoside (IPTG) and incubated at 16 °C for 12 h. Cells were harvested by centrifugation for 10 min at 10,000×g, and the cell pellet was resuspended in 5 mL of phosphate-buffered saline (PBS, 137 mM NaCl, 2.7 mM KCl, 10 mM Na2HPO4, and 1.8 mM KH2PO4, pH 7.4). After disruption of the cells by sonication (output control 5 and duty cycle 50%) using Branson Sonifier 450 (Branson Ultrasonics Corp., Danbury, CT, USA), the cell-free extract was obtained by centrifugation of the sample at 15,000×g for 30 min at 4 °C. The extract was applied onto TALON metal affinity resin (Clontech Laboratories Inc., CA, USA) and PBS buffer containing 200 mM imidazole was used as the elution buffer to retrieve the His-tagged protein. The eluent was dialyzed overnight at 4 °C to remove imidazole. Molecular weight and purity of the protein were confirmed by 0.1% sodium dodecyl sulfate and 12% polyacrylamide gel electrophoresis (SDS-PAGE) according to method of Laemmli (1970). The protein concentrations were determined according to method of Bradford (1976).

Determination of molecular mass of Ahg786 by gel-filtration chromatography

Molecular mass of the purified rAhg786 was determined by gel-filtration chromatography performed on a Superose 12 10/300 GL column equilibrated with 50 mM Tris-HCl (pH 8.0) containing 100 mM NaCl in an ÄKTA-FPLC system (GE Healthcare Life Sciences, Chicago, IL, USA). Gel filtration was performed at room temperature at a flow rate of 0.5 mL/min and the protein elution was monitored at 280 nm wavelength. The column was calibrated using size markers as follows: β-amylase (200 kDa), yeast alcohol dehydrogenase (150 kDa), bovine serum albumin (66 kDa), and bovine carbonic anhydrase (29 kDa).

Determination of the enzyme activity by 3,5-dinitrosalicylic acid assay

The amount of released reducing sugar after reaction between Ahg786 and the substrate was measured by 3,5-dinitrosalicylic acid (DNS) method, as previously described (Miller, 1959). The reaction mixture containing 10 μL of NA2 (0.1 mg) in 440 μL of assay buffer (50 mM sodium phosphate, pH 7.0) was incubated for 5 min at 15 °C, followed by the addition of 50 μL of enzyme and subsequent incubation for 30 min at indicated temperatures. A total of 500 μL of DNS reagent (6.5 g of DNS, 325 mL of 2 N NaOH, and 45 mL of glycerol in 1 L of distilled water) was added to the reaction mixture, and tubes were boiled for 10 min at 100 °C. The samples were cooled in ice-cold water for 2 min, and the absorbance at 540 nm (A540) was recorded using Spectronic Unicam Genesys 8 Spectrophotometer (Thermo Scientific™, MA, USA). The amount of reducing sugars produced was calculated by subtracting the value of blank (without enzyme) from that of enzyme reaction.

Biochemical characterization of rAhg786

Optimum pH conditions were determined at 15 °C in different buffers from pH 4.0–6.0 (50 mM sodium citrate buffer), pH 6.0–9.0 (50 mM sodium phosphate buffer), and pH 9.0–11.0 (50 mM glycine-NaOH buffer). The optimum temperature was determined from 0 to 80 °C. Thermal stability was determined under standard assay conditions (30 min at 15 °C in 50 mM sodium phosphate buffer, pH 7.0) after pre-incubating the enzyme from 0 to 80 °C for 60 min. To check the effect of different metal ions on enzyme activity, various metal ions (CaCl2, CoCl2, CuCl2, MgCl2, MnCl2, NiCl2, NaCl, ZnCl2, and FeCl2) or ethylenediaminetetraacetic acid (EDTA) at a final concentration of 0.5, 1, or 5 mM were used under standard assay conditions.

Assessment of kinetic parameters

Kinetic parameters Km and Vmax of the enzyme were determined using NA2 as the substrate under defined optimum conditions (15 °C and pH 7.0) for 20 min. Km and Vmax were calculated from Lineweaver-Burk plot (Lineweaver and Burk 1934).

Thin-layer chromatography and mass analysis of the hydrolyzed products

The recombinant protein Ahg786 (15 μg) was incubated with 50 μg of NA2, NA4, or NA6 (total reaction volume 15 μL) for 16 h at 20 °C. Hydrolyzed products were spotted on TLC silica gel plates (60G F254) and developed with a solvent (n-butanol:ethanol:water = 3:1:1, v/v). Hydrolyzed products were visualized by spraying 20% (v/v) methanol prepared in concentrated sulfuric acid (Sugano et al. 1994).

For mass spectrometry analysis of the hydrolyzed products, the reaction mixtures were dried and resolved in methanol and centrifuged at 15,000×g for 10 min. Insoluble particles were removed and the supernatant was dried in Eyela centrifugal evaporator CVE-2000 (EYELA, Japan). Samples were analyzed using an Agilent 1200 series high-performance liquid chromatography system coupled to a 4000 QTRAP MS/MS detector (AB SCIEX, Foster City, CA, USA) with an electrospray ionization Turbo V ion source. A resolution of 80,000 (200 m/z) was used to acquire the MS spectra at a mass range of 150–1000 m/z.

Multiple sequence alignment, construction of phylogenetic tree, and structural modeling

Clustal program (https://www.ebi.ac.uk/Tools/msa/clustalo/) was used for multiple sequence alignment of Ahg786 amino acid sequence. The neighbor-joining (NJ) method (Saitou and Nei 1987) from the Mega 6 program (Tamura et al. 2013) was used for constructing the phylogenetic tree. Bootstrap analysis was used to evaluate the tree topology of NJ data by performing 1000 re-samplings and marking the branching points. The evolutionary distances were computed using the Poisson correction method (Zuckerkandl and Pauling 1965). The three-dimensional (3-D) structure of Ahg786 was modeled using AhgA (SMTL ID 3p2n.1, Rebuffet et al. 2011) as the template in Swiss Model (http://swissmodel.expasy.org/).

Results

In silico analysis of Ahg786 from G. joobiniege G7

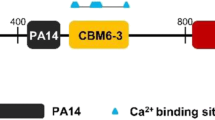

Based on the genomic sequencing data of G. joobiniege G7, many genes were annotated for encoding hydrolytic enzymes probably involved in the hydrolysis of sulfated algal polysaccharides such as 50 sulfatases, 17 glycoside hydrolases, and 13 agarases (Kwak et al. 2012). The ORF of Ahg786 (WP_017446786.1) annotated as a hypothetical protein showed 57, 58, and 59% identities with already characterized α-NAOSHs such as SdNABH from Saccharophagus degradans 2–40 (Ha et al. 2011), AhgA from Zobellia galactanivorans (Rebuffet et al. 2011), and BpGH117 from Bacteroides plebeius (Hehemann et al. 2012a), respectively. It carries a conserved domain (cd08992) belonging to the GH43 family in a broad region spanning between Ser-48 and Lys-398 with an e value of 0 that is also found in most of the reported α-NABH/NAOSHs. Despite the presence of the GH43 family domain, α-NABH/NAOSHs were proposed to be assigned to the GH117 family (Rebuffet et al. 2011).

Analysis of gene arrangement around the ahg786 gene shows a very different environment from other α-NAOSH genes (Fig. 2). Several genes probably related to agar degradation and G/AHG metabolism are present near the NAOSH gene in other bacteria, but the gene coding for galactose oxidase is the only one predicted to be associated with agar metabolism around the ahg786 gene in G. joobiniege G7.

Comparison of the gene clusters comprising the 1,3-α-3,6-anhydro-l-galactosidase gene (ahg786) and its orthologous genes. The three gene clusters from Zobellia galactanivorans (Rebuffet et al. 2011), Bacteroides plebeius (Hehemann et al. 2012b), and Streptomyces coelicolor A3(2) (Bentley et al. 2002) were used for comparison. Arrows indicate individual ORFs, with stop codons marked with arrowheads. The ORF number is depicted in each arrow. The predicted function for each ORF is shown in the lower row. The 1,3-α-3,6-anhydro-l-galactosidase gene is indicated by an arrow filled in black, and genes related to agar metabolism are indicated by shaded arrows. DH, dehydrogenase; TR, transcriptional regulator

Expression and purification of Ahg786

SIGNALP 4.1 program (http://www.cbs.dtu.dk/services/SignalP/) predicted that Ahg786 had a signal peptide with a cleavage site between Ala-25 and Thr-26. Indeed, NAOSH activity was confirmed in the extracellular protein prepared from the cell culture of G. joobiniege G7, and the presence of the protein (probably Ahg786) with the expected molecular weight (45.3 kDa) was also validated by SDS-PAGE analysis (Fig. S1). Therefore, a signal peptide-deleted recombinant protein (rAhg786) with an N-terminal His tag was expressed in E. coli and purified using TALON metal-affinity chromatography. The molecular weight of the purified rAhg786 was estimated to be approximately 47 kDa as per the SDS-PAGE analysis, consistent with the calculated molecular weight (47.5 kDa) with N-terminal accessory (Fig. 3a). The purity of the rAhg786 was confirmed to be 93% by Bio-Rad GS670 imaging densitometer (USA). Gel-permeation chromatography on a Superose 12 10/300 GL column revealed that the protein had an apparent molecular weight of 99.4 kDa, suggesting that the protein exists as a dimer (Fig. 3b).

Sodium dodecyl sulfate polyacrylamide gel electrophoresis (SDS-PAGE) and gel-filtration chromatography analysis of the purified rAhg786. a SDS-PAGE analysis. rAhg786 with an N-terminus His tag was purified by TALON metal-affinity chromatography from E. coli Rosetta-gami/pET-28a-Ahg786. Lanes: M, molecular mass marker; 1, cell-free extract before IPTG induction; 2, cell-free extract after IPTG induction; 3, purified rAhg786. The migration of Ahg786 protein is indicated by the arrow. b Determination of the molecular mass of rAhg786 by gel-filtration chromatography. a Gel-filtration chromatography. Sample containing 600 μg of NABH protein was injected onto a Superose 12 10/300 GL column. Gel filtration was performed at a flow rate of 0.5 mL/min, and the elution profiles were monitored by measuring the absorbance at 280 nm. b Determination of the molecular mass. Gel-filtration chromatography of rAhg786 and size marker proteins was performed on a Superose 12 10/300 GL column: position a, β-amylase (200 kDa); position b, yeast alcohol dehydrogenase (150 kDa); position c, bovine serum albumin (66 kDa); and position d, bovine carbonic anhydrase (29 kDa). For comparison, the position of the elution peak for NABH is indicated with an arrow

Enzymatic property of rAhg786

From the amino acid sequence, Ahg786 protein was assumed to be involved in agar degradation. Therefore, the enzymatic property of the purified rAhg786 was tested using NA2, NA4, NA6, and agarose. TLC analysis of the reacted samples revealed that the protein was unable to hydrolyze agarose but could act on NA2, NA4, and NA6 to release common products equivalent to AHG and other molecules from all substrates (Fig. 4a). Therefore, the hydrolysates from rAhg786 catalysis reaction were analyzed by mass spectrometry. The hydrolysate of NA2 showed two spots equivalent to AHG and G on TLC; these were confirmed to have molecular masses of AHG (m/z 185 [M + Na]+) and G (m/z 203 [M + Na]+; Fig. 4b). Furthermore, the enzyme completely hydrolyzed NA4 into AHG (m/z 185.3 [M + Na]+) and neoagarotriose (m/z 509 [M + Na]+) and NA6 into AHG (m/z 185 [M + Na]+) and neoagaropentaose (m/z 815 [M + Na]+) (Figs. S2 and S3). All these results indicate that rAhg786 is an exo-type α-NAOSH (1,3-α-3,6-anhydro-l-galactosidase) that cleaves α-1,3-glycosidic linkages to release AHG from the non-reducing ends of NAOS.

Instrumental analysis of neoagarooligosaccharides hydrolysates generated by rAhg786. a Thin-layer chromatography (TLC). Neoagarooligosaccharides and agarose hydrolysates generated by rAhg786 were analyzed on a silica gel (60G F254) TLC plate. The enzyme reaction was performed for 16 h at 20 °C with the indicated substrates in PBS buffer. b Ion-trap mass spectrometry. The hydrolysate of neoagarobiose (NA2) in (a) was dried in vacuo and extracted with methanol. The molecular mass distribution was determined using a high-performance liquid chromatography system coupled to a 4000 QTRAP MS/MS detector with an electrospray ionization Turbo V ion source. a Mass spectrometry for substrate, NA2. The peak for the molecular ion at m/z 347 (M + Na)+ corresponding to NA2 is indicated by an arrow. b Mass spectrometry of NA2 hydrolysate by rAhg786. The peaks for molecular ions at m/z 203 (M + Na)+ and m/z 185 (M + Na)+ corresponding to d-galactose and 3,6-anhydro-l-galactose, respectively, are indicated by arrows

Biochemical characterization of rAhg786

The biochemical properties of rAhg786 as an α-NAOSH were studied using NA2 substrate in various conditions. Maximum activity was observed in 50 mM sodium phosphate buffer (pH 7.0), whereas the enzyme activity dropped to 31 and 42 % of the maximum activity at pH 4.0 and 8.0, respectively (Fig. 5a).

Enzymatic properties of rAhg786 toward neoagarobiose. a Effect of pH. Enzyme activity was determined at 15 °C in various pH conditions: pH 4.0–6.0 (50 mM sodium citrate buffer), pH 6.0–9.0 (50 mM sodium phosphate buffer), and pH 9.0–11.0 (50 mM glycine-NaOH buffer). b Effect of temperature. Temperature profile of rAhg786 activity was evaluated from 0 to 80 °C in 50 mM sodium phosphate buffer (pH 7.0). The temperature stability of the enzyme was determined after pre-incubation at temperatures ranging from 0 to 80 °C for 60 min. Filled circles, optimum temperature; filled squares, thermostability. In (a) and (b), the highest enzyme activity was set to 100%, and for all others, the relative activity was calculated. c Effect of metal ions and chelating agent. Effect of metal ions and EDTA on enzyme activity was determined at a final concentration of 0.5 or 1 mM. The enzyme activity without chemicals was considered as 100% while calculating the relative activities. d Determination of kinetic parameters. Lineweaver-Burk plots were used to determine the kinetic parameters of rAhg786 acting on neoagarobiose. In (a) and (d), all data shown are mean values from at least three replicates

Temperature profile results showed that the enzyme exhibited maximum activity at 15 °C and the enzyme activity was maintained between 0 and 25 °C in 50 mM sodium phosphate buffer (pH 7.0). In particular, 77 and 61% of the maximum activity (15 °C) was maintained at 4 and 0 °C, respectively (Fig. 5b). The enzyme activity was 88% of the maximum activity at 20 °C but decreased below 50% of the maximum activity above 30 °C. Thermal stability tests revealed that the enzyme is stable at a range of 0 to 20 °C but severely loses its activity over 25 °C. These results indicate that rAhg786 is a cold-adaptive and heat-sensitive enzyme, which is unique as compared with other α-NABH/NAOSHs that are reported to exhibit optimum activities at temperatures between 20 and 42 °C (Table 1).

The chelator, EDTA, inhibited the enzyme activity by 50 and 16% at 0.5 and 5 mM concentrations, respectively, suggesting that rAhg786 may require metal ions as cofactors. Addition of various metal ions (0.5 mM) resulted in the strong inhibition of the enzyme activity by Cu2+ (9% activity retention) and Ni2+ (14% retention); however, the activity was remarkably enhanced in the presence of 1 mM Mn2+ (160%). The inhibitory effect of EDTA was completely circumvented in the presence of Mn2+ ions in a concentration-dependent manner (Fig. 5c), indicating that rAhg786 is dependent on Mn2+ ion for enzyme activity.

Enzyme kinetics

Enzyme kinetics were performed using NA2 (0.2–2 mg/mL) as the substrate under standard assay conditions for 20 min. Km and Vmax were 4.5 mM and 1.33 U/mg, respectively (Fig. 5d).

Construction of phylogenetic tree and structural modeling of Ahg786

Results of protein BLAST (http://blast.ncbi.nlm.nih.gov) revealed numerous sequences that were homologous to Ahg786 from microorganisms. Till date, 11 proteins have been characterized as α-NABH/NAOSHs, and only seven of these have their amino acid sequences identified (Table 1). In the phylogenetic tree analysis with the known α-NAOSHs (Fig. 6a), Ahg786 formed a distinct clade and showed closer evolutionary distance to the metal-binding proteins, AhgA from Z. galactanivorans (Rebuffet et al. 2011) and BpGH117 from B. plebeius (Hehemann et al. 2012a), than the non-metal-binding SdNABH from S. degradans 2–40 (Ha et al. 2011).

Phylogenetic tree analysis and structural modeling of Ahg786. a Phylogenetic tree of α-NAOS hydrolases including Ahg786. The evolutionary history was inferred using the neighbor-joining method in MEGA 6. All the characterized neoagarooligosaccharide hydrolases listed in Table 1 were included. Two GH96 family α-agarases from Thalassotalea agarivorans and Alteromonas agarilytica were also presented in the tree with their GenBank accession numbers. Two β-agarases, GH16 family AgaJ11 (WP_040459371.1) and GH86 family AgaJ5 (WP_017446675.1) from G. joobiniege G7 were also included in the tree for comparison. The tree is drawn to scale, with branch lengths in the same units as those of the evolutionary distances used to infer the phylogenetic tree. The evolutionary distances were computed using the Poisson correction method by eliminating gaps and missing data. b Comparison of the three-dimensional structures of Ahg786 and AhgA. AhgA (SMTL ID 3p2n.1) was used to model the three-dimensional structure of Ahg786 in Swiss Model (http://swissmodel.expasy.org/)

The 3-D structure of Ahg786 was modeled using AhgA as the template in Swiss Model, recommended as the first priority by the program (Biasini et al. 2014). The 3-D structures of the two proteins were very similar and had a narrow substrate-binding cleft and metal-binding pocket formed by a five-bladed β-propeller catalytic domain (Fig. 6b). The three catalytic amino acids in the active site were well conserved and included Asp-88, Asp-244, and Glu-302 in Ahg786 (Fig. S4). However, amino acid residues proposed for domain interaction for dimerization in AhgA were poorly conserved and warrant further studies (Rebuffet et al. 2011).

Discussion

We successfully identified Ahg786 as a unique cold-adapted exo-acting α-NAOSH classified into the GH117 family from a marine agarolytic bacterium G. joobiniege G7 (Chi et al. 2013). Among the 11 α-NABH/NAOSHs from the GH117 family listed in Table 1, crystallographic studies have been performed on three proteins, namely, AhgA from Z. galactanivorans (Rebuffet et al. 2011), SdNABH from S. degradans 2–40 (Ha et al. 2011), and BpGH117 from B. plebeius (Hehemann et al. 2012a). AhgA is an extracellular dimeric protein and each of its monomer displays a putative active site with a funnel-like topology formed by the five-bladed β-propeller folds. Three catalytic acidic residues, Asp-97, Asp-252, and Glu-310, are positioned at the bottom of this pocket (Rebuffet et al. 2011), thereby acting as a base (nucleophile) and acid (proton donor) (Pons et al. 2004). These features are also commonly found in GH32, GH43, and GH68 families, necessitating the exo-mode of action of hydrolases. The Zn2+ ion is located at the bottom of the active site pocket of AhgA, and Asp-97 or Asp-252 carboxyl group of the catalytic residues is involved in hydrogen bonding with Zn2+ in the presence of water molecules. The dimeric SdNABH and BpGH117 also have structures similar to those of AhgA. Although the binding between SdNABH and metal ions is uncertain (Rebuffet et al. 2011), BpGH117 has a metal-binding pocket for Mg2+ (Hehemann et al. 2012a).

The modeling of the 3-D structure of Ahg786 using AhgA as the template in the Swiss-Model (Biasini et al. 2014) revealed the similarities between the structures of these two proteins, including those in the narrow substrate-binding cleft for exo-glucanase and metal-binding pocket (Fig. 6b). These structures are common in AhgA and BpGH117 but not in SdNABH. The phylogenetic tree of the characterized α-NAOSHs revealed that Ahg786 formed a clade distinct from all other members, wherein AhgA and BpGH117 were closer to Ahg786 than SdNABH. This phylogenetic relationship may reflect the structural difference between metal-binding AhgA and BpGH117 and non-metal binding SdNABH. Therefore, metal binding to the pocket may be necessary for Ahg786 activity.

Ahg786 cleaved the α-1,3-glycosidic linkage from the non-reducing ends of NA2, NA4, and NA6 but not agarose. This result indicates that Ahg786 is an α-NAOSH rather than α-NABH or agarase. Among the characterized α-NABH/NAOSHs, only two α-NABHs were reported from Pseudomonas atlantica (Day and Yaphe 1975) and Cytophaga flevensis (Van Der Meulen and Harder 1976), as shown in Table 1. Therefore, α-NAOSHs rather than α-NABH seem to be the main enzymes involved in the complete hydrolysis of agar in nature. Most of α-NAOSHs reported form dimeric or multimeric complexes, but the dimeric form is common as observed for Ahg786. The location of proteins in the extracellular or intracellular environment is similar. If intracellular α-NAOSHs hydrolyze NA2 in the cell, validation studies evaluating the new system for NA2 transport into the cell are desirable.

Ahg786 α-NAOSH showed maximum activity at 15 °C and maintained 77% of its activity at 4 °C, distinct from other hydrolases that exhibit optimum activities at temperatures between 20 and 42 °C (Table 1). However, the optimum pH for Ahg786 was comparable with that of other hydrolases. As a cofactor, Mn2+ was essential for Ahg786 activity. Although α-NABH/NAOSH activities are to be enhanced by metal ions such as Mg2+ ions (Bacillus sp. MK03), Mg2+/Mn2+ ions (Cellvibrio sp. WU-0601), and Ca2+ ions (Cellulophaga sp. W5C), their dependence on metal ions is not verified (Table 1). Crystallographic analysis has shown that AhgA binds to Zn2+ (Rebuffet et al. 2011) and BpGH117 binds to Mg2+ ions (Hehemann et al. 2012a), but the dependence of enzyme activities on metal ions is unclear. In this study, the severe inhibition of Ahg786 activity by EDTA was completely restored and even remarkably enhanced in the presence of Mn2+, indicating that Ahg786 is Mn2+-dependent hydrolase (probably through the binding of Mn2+ to the metal-binding pocket). Therefore, the cofactor requirements by α-NABH/NAOSHs seem very diverse among the microorganisms. According to the 3-D structure modeling, Mn2+ ion may bind to the metal-binding pocket through hydrogen bonds mediated by Asp-88 and Asp-244 residues in the active site of Ahg786.

We have recently reported a novel cold-adapted GH39 β-agarase AgaJ9 (Jung et al. 2017b) that retains more than 80% of its activity even at a temperature of 5 °C as well as an acidic GH16 β-agarase AgaJ11 (Jung et al. 2017a) and GH86 β-agarase (Lee et al. 2018) in G. joobiniege G7. These imply that G. joobiniege G7 has a unique enzymatic system that can completely degrade agar even at low temperatures. The ability of microorganisms to degrade agar at low temperatures can offer many advantages in survival. In general, agar is a solid form in low-temperature seas, and cold-adapted enzymes can effectively degrade agar to make microbes use it as carbon source. Especially if it is possible to produce psychrophilic enzymes capable of degrading agar in the cold season such as winter, it will greatly help microbial survival.

For biotechnological applications, cold-adapted enzymes may serve as important resources because their high catalytic activities at low temperatures deem them as excellent biocatalysts, thereby eliminating the need to heat and repress microbial contamination during industrial processes. In our recent report, we demonstrated that cold-adapted AgaJ9 β-agarase could be effectively used for DNA recovery from agarose gel, and this process may work better in the presence of co-treatment with AgaJ9 and Ahg786.

New agarases are being discovered and characterized for their biochemical properties; a few of these display a wide range of activities at low temperatures. Therefore, further studies are warranted for the use of G. joobiniege G7 with tens of genes probably involved in the degradation of sulfated galactans to meet the current and future demands in food, cosmetic, nutraceutical, and bioenergy industries.

References

Araki C (1959) Seaweed polysaccharides. In: Wolfrom ML (ed) Carbohydrate chemistry of substances of biological interests. Pergamon Press, London, pp 15–30

Ariga O, Okamoto N, Harimoto N, Nakasaki K (2014) Purification and characterization of α-neoagarooligosaccharide hydrolase from Cellvibrio sp. OA-2007. J Microbiol Biotechnol 24(1):48–51

Bentley SD, Chater KF, Cerdeño-Tárraga AM, Challis GL, Thomson NR, James KD, Harris DE, Quail MA, Kieser H, Harper D, Bateman A, Brown S, Chandra G, Chen CW, Collins M, Cronin A, Fraser A, Goble A, Hidalgo J, Hornsby T, Howarth S, Huang CH, Kieser T, Larke L, Murphy L, Oliver K, O'Neil S, Rabbinowitsch E, Rajandream MA, Rutherford K, Rutter S, Seeger K, Saunders D, Sharp S, Squares R, Squares S, Taylor K, Warren T, Wietzorrek A, Woodward J, Barrell BG, Parkhill J, Hopwood DA (2002) Complete genome sequence of the model actinomycete Streptomyces coelicolor A3(2). Nature 417(6885):141–147

Biasini M, Bienert S, Waterhouse A, Arnold K, Studer G, Schmidt T, Kiefer F, Gallo Cassarino T, Bertoni M, Bordoli L, Schwede T (2014) SWISS-MODEL: modelling protein tertiary and quaternary structure using evolutionary information. Nucleic Acids Res 42(Web Server issue):W252–W258. https://doi.org/10.1093/nar/gku340

Bradford MM (1976) A rapid and sensitive method for the quantitation of microgram quantities of protein utilizing the principle of protein-dye binding. Anal Biochem 72:248–254

Chi WJ, Chang YK, Hong SK (2012) Agar degradation by microorganisms and agar-degrading enzymes. Appl Microbiol Biotechnol 94(4):917–930

Chi WJ, Park JS, Kwak MJ, Kim JF, Chang YK, Hong SK (2013) Isolation and characterization of a novel agar-degrading marine bacterium, Gayadomonas joobiniege gen, nov, sp. nov., from the Southern Sea, Korea. J Microbiol Biotechnol 23(11):1509–1518

Day DF, Yaphe W (1975) Enzymatic hydrolysis of agar: purification and characterization of neoagarobiose hydrolase and p-nitrophenyl alpha-galactoside hydrolase. Can J Microbiol 21(10):1512–1518

Green MR, Sambrook J (2012) Molecular cloning, a laboratory manual, 4th edn. Cold Spring Harbor Laboratory Press, Cold Spring Harbor, NY, USA

Ha SC, Lee S, Lee J, Kim HT, Ko HJ, Kim KH, Choi IG (2011) Crystal structure of a key enzyme in the agarolytic pathway, α-neoagarobiose hydrolase from Saccharophagus degradans 2–40. Biochem Biophys Res Commun 412(2):238–244

Hehemann JH, Correc G, Barbeyron T, Helbert W, Czjzek M, Michel G (2010) Transfer of carbohydrate-active enzymes from marine bacteria to Japanese gut microbiota. Nature 464(7290):908–912

Hehemann JH, Smyth L, Yadav A, Vocadlo DJ, Boraston AB (2012a) Analysis of keystone enzyme in agar hydrolysis provides insight into the degradation of a polysaccharide from red seaweeds. J Biol Chem 287(17):13985-13995

Hehemann JH, Kelly AG, Pudlo NA, Martens EC, Boraston AB (2012b) Bacteria of the human gut microbiome catabolize red seaweed glycans with carbohydrate-active enzyme updates from extrinsic microbes. Proc Natl Acad Sci U S A 109(48):19786–19791

Jung S, Jeong BC, Hong SK, Lee CR (2017a) Cloning, expression, and biochemical characterization of a novel acidic GH16 β-agarase, AgaJ11, from Gayadomonas joobiniege G7. Appl Biochem Biotechnol 181(3):961–971

Jung S, Lee CR, Chi WJ, Bae CH, Hong SK (2017b) Biochemical characterization of a novel cold-adapted GH39 β-agarase, AgaJ9, from an agar-degrading marine bacterium Gayadomonas joobiniege G7. Appl Microbiol Biotechnol 101(5):1965–1974

Kim J, Hong SK (2012) Isolation and characterization of an agarase-producing bacterial strain, Alteromonas sp. GNUM-1, from the West Sea. Korea J Microbiol Biotechnol 22(12):1621–1628

Kwak MJ, Song JY, Kim BK, Chi WJ, Kwon SK, Choi S, Chang YK, Hong SK, Kim JF (2012) Genome sequence of the agar degrading marine bacterium Alteromonadaceae sp. strain G7. J Bacteriol 194(24):6961–6962

Laemmli UK (1970) Cleavage of structural proteins during the assembly of the head of bacteriophage T4. Nature 227:680–685

Lee YR, Jung S, Chi WJ, Bae CH, Jeong BC, Hong SK, Lee CR (2018) Biochemical characterization of a novel GH86 β-agarase producing Neoagarohexaose from Gayadomonas joobiniege G7. J Microbiol Biotechnol 28(2):284–292

Leon O, Quintana L, Peruzzo G, Slebe JC (1992) Purification and properties of an extracellular agarase from Alteromonas sp. strain C-1. Appl Environ Microbiol 58(12):4060–4063

Lineweaver H, Burk D (1934) The determination of enzyme dissociation constants. J Am Chem Soc 56(3):658–666

Liu N, Yang M, Mao X, Mu B, Wei D (2016) Molecular cloning and expression of a new α-neoagarobiose hydrolase from Agarivorans gilvus WH0801 and enzymatic production of 3,6-anhydro-l-galactose. Biotechnol Appl Biochem 63(2):230–237

Liu SC, Yang DJ, Jin SY, Hsu CH, Chen SL (2008) Kinetics of color development, pH decreasing, and anti-oxidative activity reduction of Maillard reaction in galactose/glycine model systems. Food Chem 108(2):533–541

Miller GL (1959) Use of dinitrosalicylic acid reagent for determination of reducing sugar. Anal Chem 31(3):426–428

Mohammad MA, Sunehag AL, Rodriguez LA, Haymond MW (2011) Galactose promotes fat mobilization in obese lactating and nonlactating women. Am J Clin Nutr 93(2):374–381

Ohta Y, Hatada Y, Miyazaki M, Nogi Y, Ito S, Horikoshi K (2005) Purification and characterization of a novel α-agarase from a Thalassomonas sp. Curr Microbiol 50(4):212–216

Patel MJ, Patel AT, Akhani R, Dedania S, Patel DH (2016) Bioproduction of D-tagatose from D-galactose using phosphoglucose isomerase from Pseudomonas aeruginosa PAO1. Appl Biochem Biotechnol 179(5):715–727

Pons T, Naumoff DG, Martínez-Fleites C, Hernández L (2004) Three acidic residues are at the active site of a beta-propeller architecture in glycoside hydrolase families 32, 43, 62, and 68. Proteins 54(3):424–432

Potin P, Richard C, Rochas C, Kloareg B (1993) Purification and characterization of the alpha-agarase from Alteromonas agarlyticus (Cataldi) comb. nov., strain GJ1B. Eur J Biochem 214(2):599–607

Ramos KRM, Valdehuesa KNG, Maza PAMM, Nisola GM, Lee WK, Chung WJ (2017) Overexpression and characterization of a novel α-neoagarobiose hydrolase and its application in the production of D-galactonate from Gelidium amansii. Process Biochem 63:105–112

Rebuffet E, Groisillier A, Thompson A, Jeudy A, Barbeyron T, Czjzek M, Michel G (2011) Discovery and structural characterization of a novel glycosidase family of marine origin. Environ Microbiol 13(5):1253–1270

Saitou N, Nei M (1987) The neighbor-joining method: a new method for reconstructing phylogenetic trees. Mol Biol Evol 4(4):406–425

Sugano Y, Kodama H, Terada I, Yamazaki Y, Noma M (1994) Purification and characterization of a novel enzyme, alpha-neoagarooligosaccharide hydrolase (alpha-NAOS hydrolase), from a marine bacterium, Vibrio sp. strain JT0107. J Bacteriol 176(22):6812–6818

Suzuki H, Sawai Y, Suzuki T, Kawai K (2002) Purification and characterization of an extracellular alpha-neoagarooligosaccharide hydrolase from Bacillus sp. MK03. J Biosci Bioeng 93(5):456–463

Tamura K, Stecher G, Peterson D, Filipski A, Kumar S (2013) MEGA6: Molecular Evolutionary Genetics Analysis version 6.0. Mol Biol Evol 30(12):2725–2729

Usov AI (1998) Structural analysis of red seaweed galactans of agar and carrageenan groups. Food Hydrocolloid 12(3):301–308

Van Der Meulen HJ, Harder W (1976) Characterization of the neoagarotetra-ase and neoagarobiase of Cytophaga flevensis. Antonie Leeuwenhoek 42:81–94

Watanabe T, Kashimura K, Kirimura K (2017) Purification, characterization and gene identification of a α-neoagarooligosaccharide hydrolase from an alkaliphilic bacterium Cellvibrio sp. WU-0601. J Mol Catal B: Enzym:S328–S336

Yun EJ, Yu S, Kim KH (2017) Current knowledge on agarolytic enzymes and the industrial potential of agar-derived sugars. Appl Microbiol Biotechnol 101(14):5581–5589

Zhang W, Xu J, Liu D, Liu H, Lu X, Yu W (2018) Characterization of an α-agarase from Thalassomonas sp. LD5 and its hydrolysate. Appl Microbiol Biotechnol 102(5):2203–2212

Zuckerkandl E, Pauling L (1965) Evolutionary divergence and convergence in proteins. In: Evolving genes and proteins by V. Bryson and H.J. Vogel, pp. 97-166 Academic Press, New York

Funding

This work was carried out with the support of “Cooperative Research Program for Agriculture Science and Technology Development (Project No. PJ01328801)” Rural Development Administration, Republic of Korea.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Ethics approval

This article does not contain any studies with human participants or animals performed by any of the authors.

Electronic supplementary material

ESM 1

(PDF 709 kb)

Rights and permissions

About this article

Cite this article

Asghar, S., Lee, CR., Park, JS. et al. Identification and biochemical characterization of a novel cold-adapted 1,3-α-3,6-anhydro-l-galactosidase, Ahg786, from Gayadomonas joobiniege G7. Appl Microbiol Biotechnol 102, 8855–8866 (2018). https://doi.org/10.1007/s00253-018-9277-x

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00253-018-9277-x