Abstract

The genetic improvement of winemaking yeasts is a virtually infinite process, as the design of new strains must always cope with varied and ever-evolving production contexts. Good wine yeasts must feature both good primary traits, which are related to the overall fermentative fitness of the strain, and secondary traits, which provide accessory features augmenting its technological value. In this context, the superiority of “blind,” genetic improvement techniques, as those based on the direct selection of the desired phenotype without prior knowledge of the genotype, was widely proven. Blind techniques such as adaptive evolution strategies were implemented for the enhancement of many traits of interest in the winemaking field. However, these strategies usually focus on single traits: this possibly leads to genetic tradeoff phenomena, where the selection of enhanced secondary traits might lead to sub-optimal primary fermentation traits. To circumvent this phenomenon, we applied a multi-step and strongly directed genetic improvement strategy aimed at combining a strong fermentative aptitude (primary trait) with an enhanced production of glutathione (secondary trait). We exploited the random genetic recombination associated to a library of 69 monosporic clones of strain UMCC 855 (Saccharomyces cerevisiae) to search for new candidates possessing both traits. This was achieved by consecutively applying three directional selective criteria: molybdate resistance (1), fermentative aptitude (2), and glutathione production (3). The strategy brought to the selection of strain 21T2-D58, which produces a high concentration of glutathione, comparable to that of other glutathione high-producers, still with a much greater fermentative aptitude.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Winemaking is a complex process in which many factors, including grape variety and must quality, technological procedures, and involved microorganisms contribute to obtain the final product (Fleet 2003; Sipiczki 2011). Selected yeast starter cultures are widely used in winemaking, as they contribute to the establishment of predictable and reliable processes. The applied cultures have to cope with many different environmental conditions such as the competition provided by the resident microbial flora (Fleet 2003; Schütz and Gafner 1994), the presence of antifungine agents such as pesticides and metals in must (Cacho et al. 1995; García-Esparza et al. 2006; Sala et al. 1996) and the occurrence of low-nitrogen juices during warmer and drier vintages (Van Leeuwen and Darriet 2016). Because of this wide range of oenological stress factors, it is no longer sufficient to simply improve yeasts for a single trait of interest but it is necessary to apply an integrated approach for the rapid constitution of yeasts expressing several complex phenotypes (Winkler and Kao 2014; De Vero et al. 2017). Therefore, the design of new wine yeasts is aimed at the fulfilling of both primary and secondary traits of interest. Primarily, yeasts for the wine industry should be endowed with high fermentative fitness, able to begin the fermentation with vigor, and bring it to completion without being affected by varying and possibly adverse environmental conditions (Bisson 1999; Bonciani et al. 2016). Other primary traits are the tolerance to the high concentrations of ethanol (10–13%), the resistance to SO2 (up to 200 ppm), and a low-to-null production of off-flavors (Regodón et al. 1997; Pretorius 2000). Most primary traits are quantitative and rely on the effect of multiple genetic elements spread across the genome (Giudici et al. 2005; Ambroset et al. 2011; Swinnen et al. 2012); these traits are essential for the competition against other must-borne microorganisms, thus playing a key role in the prevalence of the selected strain at the end of the fermentation. In addition, yeasts can also benefit from secondary traits such as the production or release of specific compounds like flavor-active esters, thiols, and terpenes (Swiegers et al. 2005). These traits are accessory and not essential for a good outcome of the fermentation; however, they can positively contribute to the application of wine starters to specific working contexts, enhancing their market value. The design of new starters should always care that the requirements for the primary traits are satisfied before focusing on the secondary ones. The secondary traits have gotten renewed interest over the last 20 years, leading to the development of several specialized wine yeasts (Hara et al. 1980; Quatrini et al. 2008; Giudici and Zambonelli 1992; Rainieri et al. 1998). Among the secondary traits, the production of glutathione (GSH) by yeasts has recently received much attention by both the scientific and industrial communities (Kritzinger et al. 2013; De Vero et al. 2017). The application of GSH in winemaking is deeply connected to the long-term preservation of wine, with positive effects on both color and flavor stability, especially in the case of white wines (Dubourdieu and Lavigne 2004; Simpson 1982; Sonni et al. 2011a, b). Nearly all the positive attributes of GSH are related to its redox properties (E′0 = −240 mV), which make it prone to be easily oxidized. Thus, GSH exerts a protective action towards the aromatic molecules such as the afore-mentioned thiols and terpenes (Roussis et al. 2009; Tirelli et al. 2010). Although the direct addition of GSH was addressed in a recent International Organisation of Vine and Wine (OIV) regulation (OENO 445–2015), the use of yeast strains able to produce GSH during the fermentation is still worthwhile. These strains directly produce GSH in loco, which avoids the addition of either pure GSH or further GSH-based nutrients, resulting in an overall cheaper process.

In a previous work (Mezzetti et al. 2014), we applied an adaptive evolution strategy based on sporulation and selection under a specific selective pressure, which was a high concentration of ammonium molybdate Mo(VI). We obtained multiple molybdate-resistant strains starting from the parental strain 21T2 (= UMCC 855), belonging to the species S. cerevisiae. Among the obtained evolved strains, Mo21T2-5 (= UMCC 2851) stood out due to its ability to produce enhanced amounts of GSH in wine.

However, the application of evolutionary engineering, which usually focuses on a single trait of interest, might also lead to tradeoff phenomena, consisting in the acquisition of the desired trait at the expenses of another (Çakar et al. 2012; Dragosits and Mattanovich 2013). Strongly directional selective agents, such as the case for Mo(VI), can easily lead to the loss of overall fitness (Çakar et al. 2005). This is why researchers should always ascertain that both primary and secondary traits are properly incorporated in the newly obtained strains: this is also why we decided to re-design the selection strategy for our second generation of GSH high-producer strains of S. cerevisiae.

Recently, Mezzetti et al. (2017) obtained a recombinant progeny consisting of 69 monosporic clones (MCs) starting from the same parental strain UMCC 855 as reported in Mezzetti et al. (2014). Their purpose was to characterize genomic and gene expression changes associated with the molybdate-resistant phenotype of the GSH-producing strain UMCC 2581.

The aim of the present work is the further screening of the obtained 69 MCs in order to retrieve a novel strain of S. cerevisiae with both high production of GSH and competitive fermentative behavior. This approach was expressly designed to circumvent UMCC 2581’s inability to sporulate and, as a consequence, to transmit the high GSH production trait via regular breeding. The result was achieved by performing a multi-phase selection approach: the MCs were recursively submitted to three different selective criteria, respectively, related to their ability to resist to high Mo(VI) concentrations (1), their fermentative aptitude (2), and their ability to produce GSH (3).

Materials and methods

Yeast strains and growth conditions

The strains used in this study are deposited in the University of Modena and Reggio Emilia (Unimore) Microbial Culture Collection (UMCC—www.umcc.unimore.it). There are 69 monosporic clones (Supplemental Table S1) obtained by sporulation of the parental strain UMCC 855 as described in Mezzetti et al. (2017). The strains UMCC 855 and UMCC 2581 were also included in the study. All yeast strains were stored at − 80 °C in cryovials supplemented with 25% (v/v) of glycerol as cryopreservative. A working copy of the strains were kept on YPDA medium (1% yeast extract, 1% peptone, 2% glucose, 2% agar) and stored at + 4 °C.

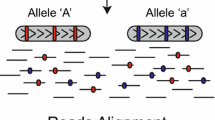

Selection and molecular typing of the molybdate-resistant strains

The 69 MCs were screened on YNB (Sigma-Aldrich, St. Louis, MO, USA) minimal medium plates (0.17% yeast nitrogen base without amino acids and ammonium sulfate—without aa and as) supplemented with 2% agar, 2% glucose, 100 μM ammonium sulfate (Sigma-Aldrich, St. Louis, MO, USA) and 2.5 mM ammonium molybdate (Carlo Erba, Rodano, Italy) as performed in the previous works (Mezzetti et al. 2014, 2017). The subset of segregants which showed a phenotype comparable to that of the strain UMCC 2581, i.e., featuring visible growth of the colonies and production of dark blue color, were characterized under the molecular point of view.

The extraction of the genomic DNA (gDNA) from the selected MCs, as well as the parental strain UMCC 855 and the evolved strain UMCC 2581, was performed on fresh cultures grown in YPD tubes at 27 °C for 24 h. The extraction protocol was performed according to Hoffman and Winston (1987). DNA quantification was achieved using Nanodrop ND-1000 (ThermoFisher Scientific, Waltham, MA, USA). After DNA quantification, all the DNA samples were properly diluted according to the applied PCR amplification protocol. The molecular fingerprint of the strains was obtained by amplifying the Interdelta (Legras and Karst 2003) and the (GTG)5 microsatellite regions (Baleiras Couto et al. 1996). The molecular fingerprints were then compared using the gel Gelcompare software (Applied Maths, Sint-Martens-Latem, Belgium), which provided a dendrogram based on mean similarity (Dice method).

Phenotypic growth tests

The preliminary screening of the MCs was the evaluation of their ability to grow in a complex medium supplemented with a higher concentration of Mo(VI). In particular, the previously selected strains were inoculated in flasks containing 50 mL of YPD medium supplemented with 15 mM Mo(VI) and kept at 27 °C in a shaker (Zhwy-200B, Zhicheng, Shanghai, China) with orbital agitation at 100 rpm for 2 days. The ability of the strains to grow was monitored by measuring the optical density (OD600) with a spectrophotometer (Jasko V-550, Tokyo, Japan).

Only the new subset of the MCs, resistant to 15 mM Mo(VI) were included in the following phenotypic screening. These MCs were grown in YNB (without aa and as) tubes with 20 g/L glucose at 27 °C. After 48 h, the cells were washed, suspended in sterile physiological solution (9 g/L NaCl) and counted using a Burker chamber (Brand, Wertheim, Germany) to standardize the inoculum on the plates. Starting from 1 × 106 cells/mL, three fivefold dilutions (5 × 105, 1 × 105, and 5 × 104 cells/mL) of the strains were obtained and 5 μL of these suspensions were spotted in triplicates on different agar media, as detailed in Table 1.

Microvinification assay in synthetic grape juice

The microvinification assay was carried out under static conditions at 25 °C in 200-mL sterile glass bottles filled with 95 mL of sterile synthetic grape juice, prepared according to Giudici and Kunkee (1994), modified by using complete YNB (containing aa and as). The strains were pre-cultured in YPD for 24 h and cells eventually counted by using a Burker chamber. The appropriate number of cells, approximately 106, was centrifuged, washed, and suspended in 5-mL synthetic must, which were then added to the remaining 95 mL. Each strain was tested in three fermentation replicas. Each bottle was stoppered with 5-mL paraffin oil. Lead acetate strips (Sigma-Aldrich, St. Louis, MO, USA) were placed on top of the bottles to detect H2S production. Bottles were sealed with cotton plugs and incubated at 25 °C. The fermentation process was checked daily by weight loss over a period of 20 days. At the end of the fermentation, samples of each fermentation were frozen at − 20 °C until required for the subsequent chemical analyses.

The fermentative fitness of the tested strains was evaluated modifying the method by Verspohl et al. (2017). We achieved the goal through the interpolation of the fermentation curves, operated with a fifth degree polynomial function with the software GraphPad Prism (GraphPad Software Inc., San Diego, CA, USA). Two kinetic parameters were then defined, tR½ and tF½. tR½ was defined as the time (days) required to release half of the total CO2 produced by the best fermenter. tF½ was the time, expressed in days, required to release half of the total released CO2 at the end of fermentation for each single strain. Both these terms were calculated, for each strain, considering the average values of the three replicas. The ratio (fermentative ratio (FR)) between these variables, was termed as FR = tR½/tF½. An arbitrary cutoff on this value, FR ≥ 0.90, was used to designate high-performance strains.

In addition, another value was obtained for each fermentation replica by measuring the amount of developed CO2 (g) after 2 days of fermentation, which was termed fermentative vigor (FV). The obtained values were submitted to the statistical analysis by applying the analysis of variance with the Duncan post hoc test (p < 0.05).

Analytical determinations

After filtration through 0.45-μm nitrocellulose membranes, amounts of glucose, fructose, glycerol, ethanol, tartaric acid, succinic acid, and malic acid were measured by means of an HPLC apparatus (Jasco Pump PU-2080 PLUS, RI Detector RI-2031 PLUS, UV Detector MD-2070 PLUS, Tokyo, Japan). The isocratic separation was performed at 65 °C on two BioradAminex HPX87H columns (Bio-Rad, Hercules, CA, USA) set in series, with a flow rate of 0.6 mL/min. All the standards were purchased from Sigma Aldrich (St. Louis, MO, USA). The calibration curves for the standards were built with the Jasco ChromNav software (Tokyo, Japan), which also served for peak integration and adjustment. Total GSH was determined with the enzymatic Glutathione Assay Kit (Sigma-Aldrich, St. Louis, MO, USA).

Statistical analyses

Residual sugars were expressed as pure concentrations of glucose and fructose (g/L). Ethanol, glycerol, citric acid, acetic acid, and succinic acid were expressed as percent yields (produced grams for 100 g of consumed sugars), while malic acid was expressed as consumed percentage, also termed demalication activity. Glutathione values were expressed in milligrams per liter. This led to the establishment of nine phenotypic variables (glucose, fructose, tartaric acid, succinic acid yield, acetic acid yield, ethanol yield, glycerol yield, demalication activity, GSH), which were submitted to the analysis of variance (ANOVA), performed via SPSS software (IBM, Chicago, IL, USA), and to the subdivision into homogeneous groups through the Duncan post hoc test with p ≤ 0.05.

Results

Genotyping of the selected monosporic clones

The screening of the 69 MCs on YNB plates supplemented with 2.5 mM Mo(VI) confirmed the phenotype already assessed in the work by Mezzetti et al. (2017). Only nine MCs (strains 21T2-D2, -D5, -D25, -D34, -D37, -D41, -D45, -D58, and -D67) were able to grow, showing a phenotypic similarity to the high-GSH-producing strain UMCC 2581 (growth + dark blue color).

These MCs were included, alongside the parental strain UMCC 855 and high-GSH strain UMCC 2581, in two PCR amplifications aimed at differentiating the set under the molecular point of view and at assessing the actual divergence of the sibling monosporic clones. The two coupled techniques provided a complete differentiation of the progeny (Fig. 1).

Similarity tree comparing both Interdelta and (GTG)5-PCR profiles associated to the nine Mo-resistant monosporic clones. The clustering was performed via Gelcompare software, applying the criterion of mean similarity with the band-based Dice method. The similarity scale is also displayed above the similarity tree. On the right part of the figure, the matching UMCC code is indicated for each strain

Growth curves at 15-mM ammonium molybdate

The assessment of growth for the nine MCs in YPD supplemented with 15 mM Mo(VI) selected the strains which were highly resistant to Mo(VI). The MCs showed a different level of growth inhibition in the 2 days of incubation.

The yeast set was split into two groups (Fig. 2), one which yielded a significant growth (comprising strains 21T2-D2, -D5, -D41, and -D58) and one which was inhibited by molybdate (comprising strains 21T2-D34, -D37, -D45, and -D67). The strains belonging to the first group were thus selected for the next investigation steps, as they were the most likely to feature a high production of GSH according to the findings of Mezzetti et al. (2014).

Phenotypic screening on plates

Prior to the fermentation trials, we performed the phenotypic tests on the four selected MCs as reported in the “Materials and methods” section. The tests assessed the growth ability of the strains in many different environments and stress conditions: low (wine-like) sugar concentration (200 g/L), medium sugar concentration (250 g/L), high sugar concentration (300 g/L), 12% (v/v) ethanol, 16% (v/v) ethanol, growth at temperatures of 4 and 37 °C, and lack of nitrogen sources in the medium. The same tests were also performed on the parental strain UMCC 855 to provide a suitable comparison. All MCs showed a behavior similar to that of strain UMCC 855 concerning most of the growth conditions (Table 2). All the strains applied to the phenotypic test were able to grow at the three increasingly higher sugar concentrations. No strains were able to grow at 4 °C while all of them were able to grow at 37 °C. Notably two strains, 21T2-D2 and 21T2-D58, showed higher nitrogen requirements at the lowest cellular concentration and were not able to grow on YNB without amino acids and ammonium sulfate.

Fermentative trials

The strains belonging to the resistant group, i.e., strains 21T2-D2, -D5, -D41, and -D58, were applied to fermentative trials in synthetic must alongside parental strain UMCC 855, so that their winemaking aptitude could be further tested on the lab scale. Also, strain UMCC 2581, descended from UMCC 855 through a Mo(VI)-based adaptive evolution strategy, was tested in the same fermentative trial, as its ability to produce high amount of GSH in wine fermentations was already proved (Mezzetti et al. 2014). Two strains, monosporic clones 21T2-D41 and 21T2-D58 showed a strong fermentative behavior (R > 0.90) similar to that of parental strain UMCC 855, as shown by the plot of the developed CO2 (Fig. 3). The remaining two strains were discarded as their fermentative performance did not serve the purpose of our genetic improvement strategy.

It can be noticed how strain 21T2-D58 proved to be superior to strain 21T2-D41 in terms of FV, as testified by the analysis of variance, which located the two values into two different homogeneous groups (Table 3).

HPLC analysis coupled with the analysis of variance showed a significant divergence among the strains. Yields of both ethanol and succinic acid showed no significant divergence in the set, while residual sugars confirmed the predictions related to weight loss. All the strains featured a demalication activity ranging from 40 to 56% (Table 4).

GSH production

The obtained wines were analyzed by means of the GSH detection kit, which highlighted some heavy differences within the set. More in particular, the analysis of variance was able to divide the set into four homogeneous groups based on the Duncan post hoc test (Fig. 4). Strain UMCC 2581 showed a high production of GSH (4.71 mg/L), thus confirming the phenotype documented by Mezzetti et al. (2014). Strain UMCC 2581 was the best producer in the set and was closely followed by 21T2-D58, which produced 4.22 mg/L. Both strains were attributed to the highest homogeneous group according to the analysis of variance, which was also shared with strain 21T2-D41 (3.51 mg/L). However, only strains UMCC 2581 and 21T2-D58 yielded a GSH concentration which was significantly higher than the one produced by the parental strain UMCC 855 (2.11 mg/L).

Total glutathione concentration after microfermentative trials. Graph shows means with SD (n = 3) of the synthetic must (CTRL), the UMCC 855 parental strain, the evolved strain UMCC 2581, and four monosporic clones. Means with different uppercase letters are significantly different from each other according to the Duncan post hoc test

Discussion

The first act in our multi-phase selection of high-GSH strains of S. cerevisiae started from the screening of a set of 69 monosporic clones obtained after sporulation and tetrad dissection of the parental strain UMCC 855, which was already the progenitor of high-GSH strain UMCC 2581 (Mezzetti et al. 2014, 2017). According to the previous works, we applied the monosporic progeny to a drop-out test on YNB minimal medium with 2.5-mM ammonium molybdate. The MCs were screened for their degree of resistance to Mo(VI). In addition, also the color of the grown colonies was evaluated. Only nine MCs were selected as yielding a phenotype similar to strain UMCC 2581 (growth + dark color), confirming the data reported by Mezzetti et al. (2017). The bulk genomic analysis found that this cluster featured an enhanced frequency for alleles involved in the biosynthesis of GSH, compared to the parental-like cluster. This is extremely important as starting point for our applied research, as we knew that one or more of the MCs might have featured an improved production of GSH.

The molecular fingerprinting of the MCs showed an overall divergence of the set and all the strains were successfully differentiated. The greatest similarity was found for strains 21T2-D25 and 21T2-D58, which showed an identical Interdelta profile, while differing for a single band in the (GTG)5 amplification pattern (Fig. 1). However, since we already knew that all monosporic clones had been dissected starting from the same progenitor, this analytical step only served as due confirmation of the overall segregation of genetic elements.

The growth trial in YPD with an increased concentration of 15 mM Mo(VI) was aimed at providing the second selection step. The application of a rich and complex medium such as YPD allowed the screening of molybdate-resistance in non-limiting nutritional conditions, thus also providing also an indirect indication concerning fitness. A further differentiation of the monosporic set was highlighted. Based on the final OD600, we identified a hyper-resistant sub-cluster consisting of monosporic cultures 21T2-D2, -D5, -D41, and -D58. Strains 21T2-D41 and 21T2-D51 were the two strains showing the highest fitness, reaching an OD600 of 1.94 and 1.76, respectively (Fig 2). According to this, we might also have postulated a better fermentative behavior for both strains compared to 21T2-D2 and 21T2-D5, as was later confirmed by the microfermentative trial.

The phenotypic tests on plates showed that all the strains retained adequate winemaking aptitude and fitness in the context of fermentation. Ethanol tolerance is especially important for its strong correlation with the fermentative fitness; therefore, we decided to keep it as our primary bottleneck to differentiate the strains. All the applied strains showed a significant growth with an ethanol concentration of 12% (v/v), while their growth was only slightly impaired at the lower cellular concentrations when the ethanol was raised to 16% (v/v). This suggests a strong ethanol-tolerant genetic background, which is a primary trait of interest in the genetic improvement of winemaking yeasts. No strains were able to grow at 4 °C while all of them were able to grow even at high temperatures such as 37 °C. This is consistent with the species-related traits associated with S. cerevisiae (Salvadó et al. 2011). Most interestingly, no strains showed any sensitivity to the increase of sugar concentration, which proved at least a mild degree of osmotolerant behavior. Only two strains, 21T2-D2 and 21T2-D58, were unable to grow in YNB without amino acid and ammonium sulfate. However, this is not to be regarded as being caused by amino acid auxotrophies, as the same strains were selected in an amino acid-free medium supplemented with Mo(VI). More likely, the impaired growth of the two strains is related to a greater requirement of nitrogen. This is easily dealt with at the winery level by the regular must nutrients, which are intended to raise yeast-available nitrogen (YAN) levels during the fermentation. Given these considerations, we decided to keep all the strains also for the next sections of the study.

In the end, we focused on our last selection step, which was intended to couple the selection of a GSH high-producer strain retaining a competitive fermentative behavior. In contrast with the strategies (Mezzetti et al. 2014; Patzschke et al. 2015) in which the application of the selective pressure was unidirectional and targeted solely to the establishment of a high production of GSH, in the present work, we have considered two different bottlenecks, fermentative performance, and GSH production. The two criteria were applied consecutively, so that the best GSH producers are detected among the best fermenters.

The first considerations were made on the basis of the fermentation curve reported in Fig. 3: two strains, 21T2-D41 (FR = 1) and 21T2-D58 (FR = 0.98), showed a fermentative performance similar to that of the parental strain UMCC 855, whose oenological suitability in different conditions was already assessed (Mezzetti et al. 2014; Gobbi et al. 2014; Verspohl et al. 2017). By examining the detected values for residual sugars, it can be seen how many yeasts are not able to completely consume sugars; also, in the case of the evolved strain UMCC 2581. This is to be attributed mainly to the overall nutritional poverty of the synthetic must. On the other hand, the minimal medium enhances the significance of the selection, as the high-fitness fermenters are thus more easily discerned from the weak ones. This led to the exclusion of strain 21T2-D2 (FR = 0.47) and of strain 21T2-D5 (FR = 0.85), both featuring an FR value lower than 0.90. The best profiles were attributed to the strains 21T2-D41 and 21T2-D58: in the latter case, the data seem to be at odds with the nutritional requirements displayed on agar plates. However, the fermentative trials have a greater practical significance compared to the screening on plates, as the actual working conditions of the microorganism are better mimicked. Most interestingly, the two best strains (21T2-D41 and 21T2-D58) were also the ones that produced the lowest amounts of acetic acid. In addition, strain 21T2-D58 also showed a good production of both glycerol and succinic acid, thus proving a moderate redirection of carbon flow towards the production of secondary metabolites associated to fermentation (Bonciani et al. 2016). Further important considerations were derived from the displayed values of the FV. This value is of primary importance in the field of winemaking yeasts, as these microorganisms must begin the fermentation with vigor, limiting the extent of the lag phase and positively contributing to the overall kinetics of the process. The vigor at the beginning of a fermentation is fundamental in terms of technological aptitude; in fact, it yields positive effects on how well the applied starter takes prevalence, more easily taking over the competing microbial populations. The best strain in the microvinification trial was the parental strain UMCC 855, closely followed by the strains 21T2-D41 and 21T2-D58. However, in this case, strain 21T2-D58 proved to be substantially superior to strain 21T2-D41, as testified by the results of the ANOVA coupled with the Duncan post hoc test.

The final evaluation was based on the production of GSH. As reported by Mezzetti et al. (2017), different mechanisms can be involved in the resistance to toxic metals, like Mo(VI), and one of them could be related to the production of GSH, which is known to have an essential role in the defense against oxidative stress and metal toxicity (Wysocki and Tamás 2010; Grant et al. 1996; Penninckx 2000). Therefore, our Mo(VI)-resistant MCs such as the four selected ones could either be GSH high producers or simply be improved for the resistance to metal- and oxide-caused stresses. This is why the evaluation of GSH production at the end of the fermentation was essential. Evolved strain UMCC 2581 confirmed the phenotype of the previous fermentative tests on the lab scale (Mezzetti et al. 2014). Its production of GSH was the best in the set. However, strain 21T2-D58 showed a comparable GSH production. The two strains were the only ones yielding a significantly higher (p < 0.95) concentration of GSH than the parental strain UMCC 855, being comprised in the same homogeneous group and, consequently, having no significant difference from one another.

Our result confirm the effectiveness of meiotic segregation/recombination in providing clones which can even be improved in certain traits compared to their parents, as stated in previous studies from several authors (Romano et al. 1985; Mortimer et al. 1994; Marullo et al. 2004; Sipiczki et al. 2004).

Generally “blind” genetic improvement techniques such as “direct mating” or “adaptive evolution” are especially apt for dealing with complex phenotypes, as they allow the free recombination of allelic variants, followed by a selective step aimed at retrieving only the individuals showing the trait of interest (Giudici et al. 2005; De Vero et al. 2011). Accordingly, the present study proved the efficiency of the application of a multi-step blind process for the selection of novel wine yeasts with several complex phenotypes together. The superiority of this strategy resides in the combination of blind genetic recombination with the search of multiple traits, rather than with just one, as in the case of common adaptive evolution. This was accomplished by subdividing the selection process in multiple steps accounting for our two targets, the fermentative fitness and the GSH production. A second generation of high-GSH strains of S. cerevisiae was established: the newly found strain, named 21T2-D58, features the same production of GSH as evolved strain UMCC 2581, previously selected through an adaptive-evolution strategy for the same trait of interest. However, strain 21T2-D58 also features a greatly improved fermentative behaviour compared to the same strain. Therefore, our three-phase strategy brought us back to the original GSH over-production trait, coupling it with a robust and reliable fermentative profile: this will allow an even more confident application of the obtained strain to the winemaking industry and to new breeding strategies aimed at transmitting the newly established traits to the next generations of wine yeasts.

The approach followed is able to satisfy the demand of winemakers interested in having novel strains with a combination of specific traits, which can confer a competitive advantage to the wine in terms of quality and consumer acceptance. In this regard, the application of wine yeasts, improved for GSH production, and provides a better stability of the product in addition to a predictable and rapid fermentation process.

References

Ambroset C, Petit M, Brion C, Sanchez I, Delobel P, Guérin C, Chiapello H, Nicolas P, Bigey F, Dequin S, Blondin B (2011) Deciphering the molecular basis of wine yeast fermentation traits using a combined genetic and genomic approach. G3 Genes Genom Gene 1:263–281. https://doi.org/10.1534/g3.111.000422

Baleiras Couto MM, Eijsma B, Hofstra H, Huis in’t Veld JH, van der Vossen JM (1996) Evaluation of molecular typing techniques to assign genetic diversity among Saccharomyces cerevisiae strains. Appl Environ Microbiol 62(1):41–46

Bisson LF (1999) Stuck and sluggish fermentations. Am J Enol Vitic 50:107–119

Bonciani T, Solieri L, De Vero L, Giudici P (2016) Improved wine yeasts by direct mating and selection under stressful fermentative conditions. Eur Food Res Technol 6(6):899–910. https://doi.org/10.1007/s00217-015-2596-6

Cacho J, Castells JE, Esteban A, Laguna B, Sagristá N (1995) Iron, copper, and manganese influence on wine oxidation. Am J Enol Vitic 46:380–384

Çakar ZP, Seker UOS, Tamerler C, Sonderegger M, Sauer U (2005) Evolutionary engineering of multiple-stress resistant Saccharomyces cerevisiae. FEMS Yeast Res 5(6-7):569–578. https://doi.org/10.1016/j.femsyr.2004.10.010

Çakar ZP, Turanli-Yildiz B, Alkim C, Yilmaz Ü (2012) Evolutionary engineering of Saccharomyces cerevisiae for improved industrially important properties. FEMS Yeast Res 12(2):171–182. https://doi.org/10.1111/j.1567-1364.2011.00775.x

De Vero L, Solieri L, Giudici P (2011) Evolution-based strategy to generate non-genetically modified organisms Saccharomyces cerevisiae strains impaired in sulfate assimilation pathway. Lett Appl Microbiol 53(5):572–575. https://doi.org/10.1111/j.1472-765X.2011.03140.x

De Vero L, Bonciani T, Verspohl A, Mezzetti F, Giudici P (2017) High-glutathione producing yeasts obtained by genetic improvement strategies: a focus on adaptive evolution approaches for novel wine strains. AIMS Microbiol 3(2):155–170. https://doi.org/10.3934/microbiol.2017.2.155

Dragosits M, Mattanovich D (2013) Adaptive laboratory evolution—principles and applications for biotechnology. Microb Cell Factories 12(1):1–17. https://doi.org/10.1186/1475-2859-12-64

Dubourdieu D, Lavigne V (2004) The role of glutathione on the aromatic evolution of dry white wine. Vinidea Net - Wine Internet Tech J 2:1–9

Fleet GH (2003) Yeast interactions and wine flavour. Int J Food Microbiol 86(1-2):11–22. https://doi.org/10.1016/S0168-1605(03)00245-9

García-Esparza MA, Capri E, Pirzadeh P, Trevisan M (2006) Copper content of grape and wine from Italian farms. Food Addit Contam 23(3):274–280. https://doi.org/10.1080/02652030500429117

Giudici P, Kunkee RE (1994) The effect of nitrogen deficiency and sulfur-containing amino acids on the reduction of sulfate to hydrogen sulfide by wine yeasts. Am J Enol Vitic 45:107–112

Giudici P, Zambonelli C (1992) Criteri di selezione dei lieviti per enologia. Vignevini 9:29–34

Giudici P, Solieri L, Pulvirenti AM, Cassanelli S (2005) Strategies and perspectives for genetic improvement of wine yeasts. Appl Microbiol Biotechnol 66(6):622–628. https://doi.org/10.1007/s00253-004-1784-2

Gobbi M, De Vero L, Solieri L, Comitini F, Oro L, Giudici P, Ciani M (2014) Fermentative aptitude of non-Saccharomyces wine yeast for reduction in the ethanol content in wine. Eur Food Res Technol 239:41–48. https://doi.org/10.1007/s00217-014-2187-y

Grant CM, MacIver FH, Dawes IW (1996) Glutathione is an essential metabolite required for resistance to oxidative stress in the yeast Saccharomyces cerevisiae. Curr Genet 29(6):511–515. https://doi.org/10.1007/BF02426954

Hara S, Iimura Y, Otsuka K (1980) Breeding of useful killer wine yeasts. Am J Enol Vitic 31:28–33

Hoffman CS, Winston F (1987) A ten-minute DNA preparation from yeast efficiently releases autonomous plasmids for transformation of Escherichia coli. Gene 57(2-3):267–272. https://doi.org/10.1016/0378-1119(87)90131-4

Kritzinger EC, Bauer FF, Du Toit WJ (2013) Role of glutathione in winemaking. J Agric Food Chem 61(2):269–277. https://doi.org/10.1021/jf303665z

Legras JL, Karst F (2003) Optimisation of interdelta analysis for Saccharomyces cerevisiae strain characterisation. FEMS Microbiol Lett 221(2):249–255. https://doi.org/10.1016/S0378-1097(03)00205-2

Marullo P, Bely M, Masneuf-Pomarede I, Aigle M, Dubourdieu D (2004) Inheritable nature of enological quantitative traits is demonstrated by meiotic segregation of industrial wine yeast strains. FEMS Yeast Res 4(7):711–719. https://doi.org/10.1016/j.femsyr.2004.01.006

Mezzetti F, De Vero L, Giudici P (2014) Evolved Saccharomyces cerevisiae wine strains with enhanced glutathione production obtained by an evolution-based strategy. FEMS Yeast Res 14(6):977–987. https://doi.org/10.1111/1567-1364.12186

Mezzetti F, Fay JC, Giudici P, De Vero L (2017) Genetic variation and expression changes associated with molybdate resistance from a glutathione producing wine strain of Saccharomyces cerevisiae. PLoS One 12(7):e0180814. https://doi.org/10.1371/journal.pone.0180814

Mortimer RK, Romano P, Suzzi G, Polsinelli M (1994) Genome renewal: a new phenomenon revealed from a genetic study of 43 strains of Saccharomyces cerevisiae derived from natural fermentation of grape musts. Yeast 10(12):1543–1552. https://doi.org/10.1002/yea.320101203

Patzschke A, Steiger MG, Holz C, Lang C, Mattanovich D, Sauer M (2015) Enhanced glutathione production by evolutionary engineering of Saccharomyces cerevisiae strains. Biotechnol J 10(11):1719–1726. https://doi.org/10.1002/biot.201400809

Penninckx M (2000) A short review on the role of glutathione in the response of yeasts to nutritional, environmental, and oxidative stresses. Enzym Microbiol Technol 26(9-10):737–742. https://doi.org/10.1016/S0141-0229(00)00165-4

Pretorius IS (2000) Tailoring wine yeast for the new millennium: novel approaches to the ancient art of winemaking. Yeast 16(8):675–729. https://doi.org/10.1002/1097-0061(20000615)16:8<675::AID-YEA585>3.0.CO;2-B

Quatrini P, Marineo S, Puglia AM, Restuccia C, Randazzo CL, Spagna G, Barbagallo RN, Palmeri R, Giudici P (2008) Partial sequencing of the β-glucosidase-encoding gene of yeast strains isolated from musts and wines. Ann Microbiol 58(3):503–508. https://doi.org/10.1007/BF03175549

Rainieri S, Zambonelli C, Giudici P, Castellari L (1998) Characterisation of thermotolerant Saccharomyces cerevisiae strains. Biotechnol Lett 20(6):543–547. https://doi.org/10.1023/A:1005389309527

Regodón JA, Peréz F, Valdés ME, De Miguel C, Ramírez M (1997) A simple and effective procedure for selection of wine yeast strains. Food Microbiol 14(3):247–254. https://doi.org/10.1006/fmic.1996.0091

Romano P, Soli MG, Suzzi G, Grazia L, Zambonelli C (1985) Improvement of a wine Saccharomyces cerevisiae strain by a breeding program. Appl Environ Microbiol 50:1064–1067

Roussis IG, Papadopoulou D, Sakarellos-Daitsiotis M (2009) Protective effect of thiols on wine aroma volatiles. Open Food Sci J 3:98–102

Sala C, Fort F, Busto O, Zamora F, Arola L, Guasch J (1996) Fate of some common pesticides during vinification process. J Agric Food Chem 44(11):3668–3671. https://doi.org/10.1021/jf960218y

Salvadó Z, Arroyo-López FN, Barrio E, Querol A, Guillamón JM (2011) Quantifying the individual effects of ethanol and temperature on the fitness advantage of Saccharomyces cerevisiae. Food Microbiol 28(6):1155–1161. https://doi.org/10.1016/j.fm.2011.03.008

Schütz M, Gafner J (1994) Dynamics of the yeast strain population during spontaneous alcoholic fermentation determined by CHEF gel electrophoresis. Lett Appl Microbiol 19(4):253–257. https://doi.org/10.1111/j.1472-765X.1994.tb00957.x

Simpson RF (1982) Factors affecting oxidative browning of white wine. Vitis 21:233–239

Sipiczki M (2011) Diversity, variability and fast adaptive evolution of the wine yeast (Saccharomyces cerevisiae) genome—a review. Ann Microbiol 61(1-2):85–93. https://doi.org/10.1016/S0168-1605(03)00245-9

Sipiczki M, Romano P, Capece A, Paraggio M (2004) Genetic segregation of natural Saccharomyces cerevisiae strains derived from spontaneous fermentation of Aglianico wine. J Appl Microbiol 96(5):1169–1175. https://doi.org/10.1111/j.1365-2672.2004.02254.x

Sonni F, Clark AC, Prenzler PD, Riponi C, Scollary GR (2011a) Antioxidant action of glutathione and the ascorbic acid/glutathione pair in a model white wine. J Agric Food Chem 59(8):3940–3949. https://doi.org/10.1021/jf104575w

Sonni F, Moore EG, Clark AC, Chinnici F, Riponi C, Scollary GR (2011b) Impact of glutathione on the formation of methylmethine-and carboxymethine-bridged (+)-catechin dimers in a model wine system. J Agric Food Chem 59(13):7410–7418. https://doi.org/10.1021/jf200968x

Swiegers J, Bartowsky E, Henschke PA, Pretorius IS (2005) Yeast and bacterial modulation of wine aroma and flavour. Aust J Grape Wine Res 11(2):139–173. https://doi.org/10.1111/j.1755-0238.2005.tb00285.x

Swinnen S, Schaerlaekens K, Pais T, Claesen J, Hubmann G, Yang Y, Demeke M, Foulquié-Moreno MR, Goovaerts A, Souvereyns K, Clement L, Dumortier F, Thevelein JM (2012) Identification of novel causative genes determining the complex trait of high ethanol tolerance in yeast using pooled-segregant whole-genome sequence analysis. Genome Res 22(5):975–984. https://doi.org/10.1101/gr.131698.111

Tirelli A, Fracassetti D, De Noni I (2010) Determination of reduced cysteine in oenological cell wall fractions of Saccharomyces cerevisiae. J Agric Food Chem 58(8):4565–4570. https://doi.org/10.1021/jf904047u

Van Leeuwen C, Darriet P (2016) The impact of climate change on viticulture and wine quality. J Wine Econ 11(01):150–167. https://doi.org/10.1017/jwe.2015.21

Verspohl A, Solieri L, Giudici P (2017) Exploration of genetic and phenotypic diversity within Saccharomyces uvarum for driving strain improvement in winemaking. Appl Microbiol Biotechnol 101(6):2507–2521. https://doi.org/10.1007/s00253-016-8008-4

Winkler JD, Kao KC (2014) Recent advances in the evolutionary engineering of industrial biocatalysts. Genomics 104(6):406–411. https://doi.org/10.1016/j.ygeno.2014.09.006

Wysocki R, Tamás MJ (2010) How Saccharomyces cerevisiae copes with toxic metals and metalloids. FEMS Microbiol Rev 34(6):925–951. https://doi.org/10.1111/j.1574-6976.2010.00217.x

Funding

This research project was financially supported by the AEB Group (Brescia, Italy).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

This article does not contain any studies with human participants or animals performed by any of the authors.

Conflict of interest

The authors declare that they have no competing interests.

Electronic supplementary material

ESM 1

(PDF 79 kb)

Rights and permissions

About this article

Cite this article

Bonciani, T., De Vero, L., Mezzetti, F. et al. A multi-phase approach to select new wine yeast strains with enhanced fermentative fitness and glutathione production. Appl Microbiol Biotechnol 102, 2269–2278 (2018). https://doi.org/10.1007/s00253-018-8773-3

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00253-018-8773-3