Abstract

Cellulose is a highly available and renewable carbon source in nature. However, it cannot be directly metabolized by most microbes including Komagataella phaffii (formerly Pichia pastoris), which is a frequently employed host for heterologous protein expression and production of high-value compounds. A K. phaffii strain was engineered that constitutively co-expresses an endoglucanase and a β-glucosidase both from Aspergillus niger and an exoglucanase from Trichoderma reesei under the control of bidirectional promoters. This engineered strain was able to grow on cellobiose and carboxymethyl cellulose (CMC) but not on Avicel. However, the detected release of cellobiose from Avicel by using the produced mixture of endoglucanase and exoglucanase as well as the released glucose from Avicel by using the produced mixture of all three cellulases at 50 °C indicated the production of exoglucanase under the liquid culture conditions. The successful expression of three cellulases in K. phaffii demonstrated the feasibility to enable K. phaffii to directly use cellulose as a carbon source for producing recombinant proteins or other high-value compounds.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Cellulose is the most abundant organic molecule in the biosphere and the major fraction of lignocellulose (Dashtban et al. 2009). It is a linear polymer of glucose residues which are interlinked with β 1 ➔ 4 glycosidic bonds. Huge amounts of lignocellulosic biomass accumulate as waste from different industries (e.g., food, paper) and agriculture (Bayer et al. 2007; Dashtban et al. 2009; Juturu and Wu 2014). This waste is mostly burned directly or biologically degraded to greenhouse gases but is also increasingly used for biofuel production by conversion of lignocellulose to fermentable sugars and further conversion to final products. Since food, feed, energy, and chemical demands are increasing worldwide while fossil fuel sources are limited, improving the efficiency of making use of renewables has high priority (Papanikolaou and Aggelis 2011; Yamada et al. 2013). Therefore, research on lignocellulosic waste especially degradation of cellulose has become increasingly important during the last decades. The current focus on improvement of bioethanol production can be summarized in three categories: (i) availability of lignocellulosic biomass and optimization of its pre-treatment, (ii) cost reduction of cellulases, and (iii) improvement of the enzymatic saccharification efficiency of cellulose to glucose (Dashtban et al. 2009; Klein-Marcuschamer and Blanch 2015).

Cellulases play a key role in the enzymatic degradation of cellulose to glucose by cleaving β 1 ➔ 4 glycosidic bonds. β-glucosidases and endo- and exoglucanases are three key enzymes involved in this process (Kostylev and Wilson 2012; Teeri 1997). Exoglucanases cleave cellobiose from the ends in the crystalline region of cellulose molecules. The endoglucanases cleave cellulose randomly in the amorphous regions and β-glucosidases cleave cellobiose further into two glucose molecules. The interaction of endo- and exoglucanases has a synergistic effect on cellulose degradation (Kostylev and Wilson 2012; Teeri 1997). Recent discoveries like the cellulolytic activity of GH61 enzymes showed that further enzymes are needed for the complete degradation of crystalline cellulose to glucose (Morgenstern et al. 2014). Efficient cellulose-degrading fungi secrete endo- and exoglucanases, β-glucosidases, and GH61 enzymes (Mathew et al. 2008; Morgenstern et al. 2014). Most prominent fungi which are used in biotechnology as model organisms for cellulose degradation and for production of cellulases are filamentous fungi like Trichoderma sp., Aspergillus sp., and Neurospora sp. (Mathew et al. 2008; Tian et al. 2009). There are also some oleaginous yeasts with cellulolytic activities belonging mainly to the genera Trichosporon and Cryptococcus. These yeasts are used for production of single cell oil from pre-treated lignocellulosic biomass which can be converted into biofuels (Dennis 1972; Liu et al. 2012.; Papanikolaou and Aggelis 2011; Stursova et al. 2012).

Beside natural cellulolytic yeasts, non-cellulolytic yeasts were engineered enabling a one-step conversion of cellulose to ethanol by heterologous protein expression of cellulases. Saccharomyces cerevisiae and Kluyveromyces marxianus were successfully engineered in which endo- and exoglucanases and β-glucosidase were co-expressed in both strains (Chang et al. 2012; Den Haan et al. 2007; Yamada et al. 2013). The co-expression of all three cellulases enabled K. marxianus to grow on carboxymethyl cellulose (CMC) but not on phosphoric-acid swollen cellulose (PASC) or Avicel (Chang et al. 2012). It was reported that a S. cerevisiae strain was engineered to grow on PASC by co-expression of an endoglucanase and a β-glucosidase (Den Haan et al. 2007). Very recently, an engineered S. cerevisiae strain was shown to give increased ethanol production by displaying an optimized mixture of cellulolytic enzymes (Liu et al. 2017). Moreover, Guo and co-workers demonstrated the growth of an engineered Yarrowia lipolytica strain on pre-treated lignocellulose (Guo et al. 2017).

The yeast Komagataella phaffii (formerly Pichia pastoris) is widely used for heterologous gene expression. One important advantage of K. phaffii as expression host is that only a very low amount of endogenous proteins is naturally secreted. The heterologous expressed proteins which are secreted are the vast majority of total protein in the supernatant of a K. phaffii culture (Cereghino and Cregg 2000; Vogl et al. 2013). It has tremendous applications in protein characterization, industrial production of proteins (e.g., pharmaceuticals), and other high-value products (Cereghino and Cregg 2000; Geier et al. 2012, 2013; Vogl et al. 2013; Wriessnegger et al. 2014).

As a Crabtree negative yeast, K. phaffii does not produce high amounts of ethanol like Crabtree positive yeasts during cultivation conditions. Therefore, energy and carbon sources can be more efficiently used for products of interests as high-value compounds (Hagman et al. 2014, Osawa et al. 2009; Vogl et al. 2013). Geier and co-workers demonstrated that expression and engineering of human cytochrome P450 in K. phaffii can be used for biocatalytic applications (Geier et al. 2013). In addition, comparison of expression levels of human cytochrome P450 in four different expression hosts (Escherichia coli, S. cerevisiae, Y. lipolytica, and K. phaffii) showed that P450 was most efficiently expressed in K. phaffii (Geier et al. 2012). Recently, K. phaffii was used as a whole-cell biocatalyst to produce high-value aroma compound (+)-nootkatone (Wriessnegger et al. 2014). Moreover, it has also been shown to produce high-value compounds β-carotene and violacein in the same K. phaffii strain by co-expression of the carotenoid and violacein biosynthesis pathways (Geier et al. 2015), demonstrating new opportunities for efficient pathway design and expression in this yeast.

Therefore, a K. phaffii strain which is able to use natural cellulose or lignocellulosic hydrolysate as carbon source for production of high-value compounds would be a very attractive platform strain for industrial applications. Here we present the work of K. phaffii strains that express cellulases from filamentous fungi Aspergillus niger and Trichoderma reesei using bidirectional promoters. To the best of our knowledge, this is the first report that endo- and exoglucanases and β-glucosidase were co-expressed in a single K. phaffii strain.

Material and methods

Strains and culture conditions

K. phaffii strains BG10 (BioGrammatics, Carlsbad, CA, USA) and BSY11G1 (a Δgut1, Δaox1 derivative of BG10) (Bisy, Hofstaetten/Raab, Austria) which is glycerol auxotrophic were used. K. phaffii was cultivated in YPD medium containing 2% (w/v) glucose, 2% (w/v) peptone, and 1% (w/v) yeast extract (1.5% (w/v) agar YPD for agar plates). When selective markers were used, the antibiotic concentrations were 50 mg/L zeocin and 300 mg/L geneticin, respectively. The yeast cultures were incubated at 30 °C, and liquid cultures were shaken at 130 rpm. Buffered minimal medium (BM_medium) was used for cultivation of K. phaffii in growth experiments and cellulase activity assay. BM_medium was made as previously described (Weis et al. 2004) but with no biotin added to the medium.

E. coli Top10 and E. coli Top10F’ (both from Thermo Fischer Scientific, Waltham, MA, USA) strains were transformed for vector amplification and cloning experiments. E. coli strains were incubated in LB medium. When selective markers were used, the antibiotic concentrations were 100 mg/L ampicillin, 50 mg/L kanamycin, and 25 mg/L zeocin, respectively. The E. coli cultures were incubated at 37 °C, and liquid cultures were shaken at 100 rpm.

T. reesei QM9414 (ATCC 26921, CBS 392.92) and A. niger DSM 26641 (Ottenheim et al. 2015) were used for isolation of the genes coding for cellulases. For isolation of genomic DNA, T. reesei QM9414 was incubated in potato dextrose medium containing 4 g/L potato extract and 20 g/L glucose. The culture was incubated in baffled flasks at 28 °C and 100 rpm for 3 days. Genomic DNA of T. reesei and K. phaffii was isolated following the method of Namjin Chung (Balakrishnan et al. 2013). The cultivation of A. niger DSM 26641 was performed as previously described (Ottenheim et al. 2014).

Isolation of genes

The used genes are summarized in Table 1. All components for PCR were from Thermo Fischer Scientific (Waltham, MA, USA) if not stated otherwise. Phusion polymerase was used for PCR amplification. PCR was performed following the manufacturer’s protocol. Standard overlap-extension PCR was performed as previously described (Näätsaari et al. 2012). The DNA primers were made by Integrated DNA Technologies (IDT, Coralville, IA, USA). A list of the DNA primers used is shown in Supplemental Table S1.

AnBGL1 (MF981921)

The gene sequence coding for β-glucosidase from A. niger (AM270402.1, gene < 78,981..> 81,928) was codon-optimized and synthesized by GenScript (Piscataway, NJ, USA). Its natural signal sequence was replaced with a codon-optimized version of S. cerevisiae alpha mating factor pre-pro signal sequence for protein secretion. A SpeI restriction site was added at the 3′ end of the AnBGL1 sequence. The ordered DNA sequence of the codon-optimized AnBGL1 gene is shown in Supplemental Fig. S1. The synthesized AnBGL1 gene was cloned by Genscript (Piscataway, NJ, USA) into pUC57-Mini plasmid.

TrBGL1 (U09580.1)

The gene coding for the β-glucosidase from T. reesei was isolated from genomic DNA of T. reesei QM9414. The exons in the open-reading frame of TrBGL1 were amplified by PCR and fused in order by overlap PCR. The gene was isolated without its native signal sequence for secretion because the gene was fused with S. cerevisiae alpha-mating factor pre-pro signal sequence instead. In addition, BmrI restriction sites were removed by changing one codon of the recognition site without changing the amino acid sequence. To amplify only the exons and to remove the BmrI restriction sites, TrBGL1 was divided into four parts. These four parts were amplified by PCR with the primer pairs P1 + P2, P4 + P5, P6 + P7, and P9 + P10. Part 3 of TrBGL1 had to be amplified in a subsequent PCR step with the primer pair P7 + P8 for adding nucleotides which overlap with the sequence of part 2 for overlap extension PCR. All four DNA fragments were attached to each other by several overlap-extension PCR steps.

TrCBH2 HM

TrCBH2-HM is a codon-optimized gene variant coding for exoglucanase CBH2 from T. reesei which had been used in a previous work (Mellitzer et al. 2014). A plasmid from this previous study was used as the template to get the sequence of TrCBH2-HM. TrCBH2-HM was amplified with the primers P11 + P12 for further work.

TrCBH2 V09

TrCBH2-V09 is a codon-optimized gene variant coding for exoglucanase CBH2 from T. reesei which had been used in a previous work (Mellitzer et al. 2014). The whole gene sequence was ordered as gBlock from IDT (Coralville, IA, USA). One codon was changed to remove a BglII restriction site without changing the amino acid sequence.

AnEG-A (MF981920)

AnEG-A is coding for endoglucanase A from A. niger DSM 26641. AnEG-A was amplified by PCR with the primers P35 + P36 using cDNA as the template. mRNA isolation from A. niger DSM 26641 and its transcription to cDNA was performed as previously described (Ottenheim et al. 2014). The gene sequence of AnEG-A is shown in Supplemental Fig. S2.

TrEG1 (M15665.1)

TrEG1 is coding for endoglucanase 1 from T. reesei. Like TrBGL1, TrEG1 was isolated from genomic DNA of QM9414 without the sequence coding for the native signal sequence. The exons were amplified by PCR and fused in order by overlap PCR. To amplify only the exons, TrEG1 was divided into two parts. Exon 1 was amplified with the primers P18 + P19. Exon 3 was added during amplification of exon 2 by using reverse primers with overhangs (first PCR, P20 + P21 and second PCR, P20 + P22).

Vector construction

All components used for cloning were from Thermo Fischer Scientific (Waltham, MA, USA) unless otherwise specified. In parallel to the restriction enzymes from Thermo Fischer Scientific (Waltham, MA, USA), also enzymes from New England Biolabs (Ipswich, MA, USA) were used. PCR products were purified using Wizard SV Gel and PCR Clean-Up System from Promega (Fitchburg, WI, USA). All original plasmids for cloning work were from Pichia pool1 of Graz University of Technology (Näätsaari et al. 2012). For expression of cellulase genes, constitutive bidirectional promoters NB2 (synonyms: pHTX1 or natbidi 2) and NB3 (synonyms: pHHX2 or natbidi 3) were used. Naturally, NB2 and NB3 are regulating histone genes in K. phaffii (Vogl et al. 2015; Vogl et al. manuscript submitted). The sequence of NB2 was amplified using K. phaffii BG10 genomic DNA as a template. The sequences of NB3 and eGFP were ordered together as one gBlock from IDT (Coralville, IA, USA). The construction of the expression vectors is described in detail in supplemental data. All used vectors are listed in Supplemental Table S2.

For engineering a K. phaffii strain that expresses endo- and exoglucanases and a β-glucosidase, the two expression vectors pPpKan_int2_SwaI_AOX1tt_NotI_TrCBH2-V09_NB2_AnEG-A_NotI_AOX1tt and pPpZeo_int8_SwaI_AOX1tt_SpeI_ AnBGL1_alpha.sig.seq_NB3_eGFP_NotI_AOX1tt were constructed. The maps of these plasmids are shown in Fig. 1, which were generated by using SnapGene Viewer software (GSL Biotech, Chicago, IL, USA).

Plasmid maps of used expression vectors for engineering the strain that expresses all three cellulases. The vector for the expression of TrCBH2 V09 and AnEG-A contains a geneticin selection marker (kanMX cassette) (a). The vector for the expression of AnBGL1 and eGFP contains a zeocin selection marker (Zeo resistance cassette). The alpha mating factor pre-pro signal sequence (sig. seq.) upstream of AnBGL1 is shown in white (b). CDS of genes and selection marker cassettes are shown in black, promoters (NB2, NB3) in dark gray, terminators (AOX1 TT) in gray, origin of replication (pUC ORI) in white, and the targeting site (int2, int8) containing the BglII site for yeast transformation in bright gray. Plasmid maps generated by using SnapGene Viewer were modified by adding bigger annotations

For using the bidirectional promoter NB2 for mono-directional expression of only one cellulase gene (β-glucosidase and endo- or exoglucanase) in control experiments, a stop codon was inserted nine bases downstream of a start codon followed by a terminator sequence in its second orientation (Fig. 2).

Pichia transformation

K. phaffii transformation and making of competent cells were performed in two different ways. The condensed method protocol was performed as previously described (Lin-Cereghino et al. 2005). The second protocol described by Wu and Letchworth (2004) was performed with a few modifications. K. phaffii was inoculated in 25–50 mL of YPD to an OD600 of 0.4 and incubated until the culture reached an OD600 of 0.8–1. In the final step, the competent cells were resuspended in 1 mL of BEDS or 1 M sorbitol, respectively, and 50 to 80 μL of aliquots of the competent cell suspension was used for transformation and 500–1500 ng of linearized vectors were added to the cells. After electroporation, 1 mL of recovery medium (1:1 mixture of YPD medium with 1 M sorbitol) was added to the transformation sample. The cells were recovered at 30 °C for 1–1.5 h without shaking before plating aliquots on YPD plates containing the corresponding antibiotic selection markers.

Cellulase activity assay and HPLC analysis

For detecting cellulase activity, K. phaffii strains which expressed cellulases were incubated in buffered minimal medium. ONCs of the test strains were used to inoculate 7 mL of BM_glycerol 1% (w/v) in 50 mL tubes (Tarsons, Kolkata, India) to an OD600 of 0.1. The tubes were fixed in a tilted position, and the cap was loosened for aeration. The cultures were incubated at 30 °C and 120 rpm for 2 days to reach the stationary phase. Subsequently, the cells were harvested and centrifuged at 3220×g for 5 min. The supernatant (0.3 mL) was mixed with 0.9 mL of 50 mM citrate buffer (pH 5.5) containing 1% Avicel in a 1.5-mL tube. The 1.5-mL tubes were incubated horizontally at 50 °C and 120 rpm for 4 h. The samples were centrifuged at 20,800×g for 1 min, and the supernatants were filtered through a 0.22-μm membrane. The measurement of cellobiose and glucose formed from Avicel using HPLC was performed as previously described (Ong et al. 2016).

Growth experiments

Growth of K. phaffii on cellobiose and CMC was monitored by measuring OD600. The spectrophotometers Shimadzu UV-1800 (Shimadzu, Kyoto, Japan) and Eppendorf Bio Photometer plus (Eppendorf, Hamburg, Germany) were used for OD600 measurement. Buffered minimal liquid medium was used for the growth experiments. CMC and Avicel (crystalline cellulose) were used as model substrates for cellulose degradation to evaluate the cellulolytic activity of the engineered K. phaffii strains. CMC is water soluble chemically modified cellulose. It can be degraded well by endoglucanases into shorter molecules (Teeri 1997). The concentrations of cellobiose in BM_cellobiose were 0.25% (w/v) and 0.5% (w/v), respectively. In BM_CMC, the concentration of CMC was 0.5% (w/v) and 1% (w/v), respectively. The different concentrations of the carbon sources in the media did not interfere the outcome of the experiments since these experiments were performed to see if the engineered strains were able to grow on the testing carbon sources. The cultures were inoculated to an OD600 of 0.05 or 0.1, respectively. The volume of the cultures was 25 mL for BM_cellobiose and 50 mL for BM_CMC, because cultivation on CMC took longer and the cell densities were much lower than in cellobiose. The cultures were incubated at 30 °C and 130 rpm for a few days until stationary phase was reached.

To test for growth on Avicel, the strains were incubated in BM_Avicel 0.5% (w/v) + 0.1% (w/v) glycerol. The glycerol was used to initiate cellulase production in the starting phase. The cultures were incubated under the same conditions as stated above for BM_CMC cultures. Growth was monitored by measurement of colony forming units (cfu). For this, 1 mL of the culture was taken daily and diluted 10−3, 10−4, and 10−5. These dilutions (25 μL) were spread onto YPD plates. Another approach for detecting growth on different carbon sources was done in buffered minimal medium agar plates using the same carbon source concentration as in liquid medium described above with exception that BM_Avicel 0.5% (w/v) agar plates did not contain glycerol. The test strains were streaked onto BM_carbon source plates and incubated at 30 °C for 2–3 days (cellobiose), 4–5 days (CMC), and up to 2 weeks (Avicel), respectively.

Results

Constitutive expression of β-glucosidase in K. phaffii

A first important step in engineering a cellulose-metabolizing K. phaffii strain was to confirm that constitutive expression of β-glucosidases using bidirectional promoters enables K. phaffii to grow on cellobiose. For this, separate expression strains were constructed for β-glucosidases AnBGL1 and TrBGL1, respectively. For expression of AnBGL1, the bidirectional promoter NB3 was used which co-expressed eGFP in its second orientation for a quick indication of expression levels (Fig. 1b). The promoter strength of this bidirectional promoter is very similar on both sides (Vogl et al. 2015; Vogl et al. manuscript submitted). This vector encoding for AnBGL1 and eGFP was integrated into K. phaffii BG10 genome. Selected BG10 transformants which have integrated AnBGL1 were streaked onto BM_cellobiose agar plates to check their ability to grow on cellobiose as the sole carbon source. After 2–3 days’ incubation, clear differences were observed between the growth of positive clones (expressing β-glucosidase AnBGL1) and negative control (parental strain BG10) on agar plates, indicating that β-glucosidase was functionally expressed (data not shown).

Engineering another β-glucosidase-expressing strain was done by using vector encoding for TrBGL1 to transform K. phaffii BSY11G1. TrBGL1 was expressed under control of constitutive bidirectional promoter NB2 using the construction shown in Fig. 2. Similar to BG10 transformants, the selected BSY11G1 transformants expressing TrBGL1 were also able to grow on BM_cellobiose agar plates. This indicates that it is feasible to reproduce the observed growth on cellobiose for recombinant K. phaffii strain expressing other β-glucosidases. Cultivation of representative clones of BG10 and BSY11G1 transformants in shake flasks confirmed that constitutive expression of β-glucosidases enabled biomass production of K. phaffii by utilization of cellobiose (Fig. 3).

Growth of β-glucosidase expressing K. phaffii on cellobiose in shake flasks. Three different time measurements of AnBGL1-expressing strain culture (gray bar) in BM_cellobiose 0.25%. Parental strain BG10 was the negative control (black bar) (a). Growth curve of TrBGL1-expressing strain (circle) in BM_cellobiose 0.5%. The negative control (triangle) was parental strain BSY11G1 (b)

Independent of the genetic backgrounds of the strains and the constitutive expression of AnBGL1 or TrBGL1, respectively, enabled K. phaffii to grow in BM_cellobiose broth medium. The respective parental strains (negative controls) did not show any relevant growth when cellobiose was used as the sole carbon source in the medium. Interestingly, the growth curve in Fig. 3b shows that the TrBGL1-expressing strain needed a long-starting phase to reach the exponential growth. After 1 day’s incubation, the cell density was still very low. The exponential growth just started between 30 and 40 h of incubation, while cultures on glucose should have already reached stationary phase under such conditions. This indicates that the biomass production depends on the amount of expressed ß-glucosidase and/or its specific activity, thereby on the release rate of glucose from cellobiose. A certain amount of β-glucosidase has to be secreted into the medium to generate enough glucose for fast cell growth.

Co-expression of endo- and exoglucanases and β-glucosidase in a single K. phaffii strain

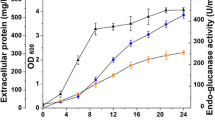

K. phaffii BG10 was co-transformed with both expression vectors (Fig. 1) in order to express all three cellulose-hydrolysing enzymes (AnBGL1 + TrCBH2 + AnEG-A). Genomic integration was evaluated by control PCR using isolated genomic DNA of transformants as a template. Selected clones were streaked onto BM_CMC agar plates to check for potential growth on CMC as the sole carbon source. A significant difference in growth between positive clones expressing all three cellulose-hydrolysing enzymes and negative control (parental strain or strains with only one integrated vector as shown in Fig. 1) was observed after 4 days’ incubation (data not shown). This ability to grow on CMC was confirmed by shake flask experiments (Fig. 4a).

Comparison of growth of different K. phaffii BG10 strains on CMC: growth curve of parental strain BG10 (filled triangle), AnBGL1-expressing strain (filled circle), and strain expressing all three cellulases (empty circle) in BM_CMC 1% (a). Growth curve of the strains expressing TrCBH2 + AnBGL1 (empty triangle), TrEG1 + AnBGL1 (filled square), and strain expressing all three cellulases (empty circle) in BM_CMC 0.5% (b)

The growth curves clearly show that the parental strain BG10 and the strain-expressing β-glucosidase AnBGL1 did not grow on CMC, whereas the BG10 strain expressing all three cellulases showed a clear growth (Fig. 4a), though slower than the ß-glucosidase-expressing strains on cellobiose. Interestingly, the strain expressing all three cellulases entered the stationary phase with an OD600 of about 1 when the CMC concentration in the medium was 1% (w/v). The experiment was stopped after 55 h’s incubation when it seemed to reach the end.

With the fact that the strain expressing all three cellulases can grow on CMC as the sole carbon source, it is still unclear if all three expressed cellulases are required for the growth or not. Therefore, two engineered strains which express TrCBH2 + AnBGL1 and TrEG1 + AnBGL1, respectively, were investigated. As mentioned above, AnBGL1 was also constitutively expressed under the NB3 promoter, and TrCBH2 and TrEG1, respectively, were constitutively expressed using only one orientation of the NB2 promoter (Fig. 2). The strain expressing all three cellulases was used as a positive control in this experiment. The growth of engineered control strains in BM_CMC 0.5% (w/v) is shown in Fig. 4b. It is seen that the strain expressing TrEG1 + AnBGL1 had a similar growth behavior with the strain expressing all three cellulases. The strain expressing TrCBH2 + AnBGL1 did not reach the OD600 of the other strains on CMC. Further experiments showed that the observed initial growth within the first 8 h after inoculation (Fig. 4b) was an experimental artifact caused mainly by glucose contamination from inoculation with the pre-culture which can be reduced but not completely avoided by washing the cells of the pre-culture with H2O before inoculation of the main cultures (data not shown). Although it remained unclear at this stage if the TrCbh2 gene was expressed at all, the result indicates that the co-expression of β-glucosidase AnBGL1 and an endoglucanase is sufficient for growth of K. phaffii in media with CMC as the sole carbon source.

Hydrolysis of Avicel by co-expressed enzymes from engineered K. phaffii strain

The BG10 strain expressing all three cellulases was evaluated for potential growth on Avicel. No significant growth was observed on BM_Avicel agar plates or in BM_Avicel liquid medium compared to the negative BG10 control strains (data not shown). In order to analyze if this is due to a failure in co-expression of all three enzymes or just due to the insufficient enzyme activity to release enough glucose from crystalline cellulose, the supernatant was harvested from different K. phaffii cultures after they reached stationary phase and mixed with Avicel. These samples were analyzed by HPLC to detect glucose and/or cellobiose after incubation at 50 °C to check cooperative action of all three enzymes (Fig. 5).

HPLC measurements of samples containing supernatants of K. phaffii strains and Avicel. Glucose measurement (black bar) and cellobiose measurement (gray bar) of the samples containing the supernatant of the strains expressing AnBGL1, TrCBH2 V04 + AnEG-A, all three cellulases, and supernatant of the non-transformed parental strain BG10 as negative control. ND means “not detectable”

It is seen that about 0.17 g/L of glucose released from Avicel was detected in the supernatant of the strain expressing all three cellulases. This is a proof that the cellulases mixture from the K. phaffii triple enzyme expression strain was able to convert Avicel into glucose. Besides, no cellobiose was detected in this sample whereas cellobiose was detected at 0.06 g/L in the supernatant of the strain expressing TrCBH2 + AnEG-A. As predicted, no glucose or cellobiose was detected in the supernatants of the BG10 strain-expressing AnBGL1 and parental strain BG10.

Discussion

So far, successful expression of different β-glucosidases by K. phaffii was mainly focused on protein yields and characterization of expressed β-glucosidases (Chen et al. 2011; Dan et al. 2000; Hong et al. 2007; Ramani et al. 2015). It has also been demonstrated that addition of cellobiose improved growth of K. phaffii MutS (methanol utilization slow) strains in methanol-containing medium when β-glucosidases were expressed under the control of inducible AOX1 promoter (Hong et al. 2007; Ramani et al. 2015). Here we described for the first time the growth of K. phaffii on cellobiose as a sole carbon source as a result of the constitutive β-glucosidase expression using histone promoters. Similar results based on constitutive expression were reported for S. cerevisiae and K. marxianus (Chang et al. 2012; Van Rensburg et al. 1998).

The engineered cellobiose-utilizing K. phaffii strain expressing β-glucosidase AnBGL1 was further modified to co-express an endoglucanase (AnEG-A) and an exoglucanase (TrCBH2). This triple hydrolase expression strain as well as the strain co-expressing β-glucosidase (AnBGL1) and endoglucanase (TrEG1) were able to grow on amorphous carboxymethylated cellulose (CMC). Although it is known that many non-cellulolytic organisms are able to hydrolyse CMC with different enzymes acting on β-glucans (Lynd et al. 2002), such an effect can be excluded in the case of K. phaffii because the parental strain and the strain expressing only AnBGL1 were unable to grow on CMC. Interestingly, the culture reached an OD600 of about 1 in BM_CMC (1%, w/v), which is unexpectedly low (Fig. 4a). This might be due to CMC degradation products which were not further converted to appropriate sugars for K. phaffii to digest. Medium viscosity CMC from Sigma Aldrich was used for these growth experiments. The product information describes a substitution grade of 0.65–0.95 per glucose residue in this type of CMC, which might explain the observed growth limitation. The final OD600 values with different CMC concentrations (0.5–1%, w/v) seem to correlate directly with the amounts of added CMC, indicating that a possible inhibitory effect from CMC degradation products can be excluded.

Co-expression of both enzymes, endoglucanase and β-glucosidase, was required to enable K. phaffii to grow on CMC. The growth on CMC also indicated that the endoglucanase was functional and reasonably expressed under the control of the bidirectional histone promoter NB2. The additional co-expression of the exoglucanase TrCBH2 did not support growth on CMC at 30 °C. This was in line with previous reports. Mellitzer and co-worker described that TrCBH2 expressed in K. phaffii had a much lower activity on CMC than on Avicel (Mellitzer et al. 2012). Furthermore, it was reported that only very low or no activity of TrCBH2 on CMC was detected when it was expressed in its native host T. reesei or Schizosaccharomyces pombe (Okada et al. 1998). This might be a reasonable explanation why no relevant growth on CMC was observed when just TrCBH2 was co-expressed with AnBGL1.

Culture supernatant of the triple enzyme expression strain released significant amounts of glucose from Avicel when incubated at 50 °C. Although the observed glucose concentration of 0.17 g/L should be sufficient to enable significant growth of the engineered strain, no obvious growth of K. phaffii was observed at 30 °C, which might indicate a too low exo-glucanase (TrCBH2) activity at this temperature. The HPLC analysis showed only a little cellobiose was released from Avicel (Fig. 5) in the sample treated with the supernatant of the strain co-expressing TrCBH2 and AnEG-A.

Therefore, the next steps will be to improve expression and activity of TrCBH2 in this system. Mellitzer and co-workers achieved high-cellobiose concentrations from Avicel by multiple TrCBH2 gene expression in K. phaffii using the inducible AOX1 promoter (Mellitzer et al. 2012), indicating the feasibility of producing higher expression levels of TrCBH2 in K. phaffii. Using an alternative promoter is one possibility in addition to engineering CBH2 for higher activity at lower temperatures. The research on promoters in K. phaffii had made much progress in the past few years, which increases the chances to find a more effective promoter for expression of TrCBH2 (Vogl et al. 2016). Geier and co-workers established a technology in K. phaffii making it possible to integrate multi-gene pathways into the genome and to successfully express them even just with a single alternative strong constitutive promoter (Geier et al. 2015). This method might be used for integration of multiple TrCBH2 gene copies or for integration of different cellulase genes in the engineered K. phaffii strain to improve cellulose degradation to glucose. In conclusion, this work demonstrated that it is possible to use K. phaffii as a whole-cell biocatalyst to produce high-value compounds using cellulose or even lignocellulosic hydrolysates as cheap and renewable carbon source.

References

Balakrishnan B, Ayyavoo J, Sadayan P, Abimannan A (2013) Evaluation of antioxidant activity of Clitoria ternatea and Alternanthera sessilis plant extracts using model system for yeast cells. Afr J Basic Appl Sci 5:134–138. https://doi.org/10.5829/idosi.ajbas.2013.5.3.1135

Bayer EA, Lamed R, Himmel ME (2007) The potential of cellulases and cellulosomes for cellulosic waste management. Curr Opin Biotechnol 18:237–245. https://doi.org/10.1016/j.copbio.2007.04.004

Cereghino JL, Cregg JM (2000) Heterologous protein expression in the methylotrophic yeast Pichia pastoris. Fems Microbiol Rev 24:45–66. https://doi.org/10.1111/j.1574-6976.2000.tb00532.x

Chang J-J, Ho C-Y, Ho F-J, Tsai T-Y, Ke H-M, Wang CH-T, Chen H-L, Shih M-C, Chieh-Chen Huang C-C, Li W-H (2012) PGASO: a synthetic biology tool for engineering a cellulolytic yeast. Biotechnol Biofuels 5(1):53. https://doi.org/10.1186/1754-6834-5-53

Chen P, Fu X, Ng TB, Ye X-Y (2011) Expression of a secretory β-glucosidase from Trichoderma reesei in Pichia pastoris and its characterization. Biotechnol Lett 33(12):2475–2479. https://doi.org/10.1007/s10529-011-0724-3

Dan S, Marton I, Dekel M, Bravdo B-A, He S, Withers SG, Shoseyov O (2000) Cloning, expression, characterization, and nucleophile identification of family 3, Aspergillus niger β-glucosidase. J Biol Chem 275(7):4973–4980. https://doi.org/10.1074/jbc.275.7.4973

Dashtban M, Schraft H, Qin W (2009) Fungal bioconversion of lignocellulosic residues; opportunities & perspectives. Int J Biol Sci 5(6):578–595. https://doi.org/10.7150/ijbs.5.578

Den Haan R, Rose SH, Lee R, Lynd LR, van Zyl WH (2007) Hydrolysis and fermentation of amorphous cellulose by recombinant Saccharomyces cerevisiae. Metab Eng 9:87–94. https://doi.org/10.1016/j.ymben.2006.08.005

Dennis C (1972) Breakdown of cellulose by yeast species. J Gen Microbiol 71(2):409–411. https://doi.org/10.1099/00221287-71-2-409

Geier M, Braun A, Emmerstorfer A, Pichler H, Glieder A (2012) Production of human cytochrome P450 2D6 drug metabolites with recombinant microbes – a comparative study. Biotechnol J 7(11):1346–1358. https://doi.org/10.1002/biot.201200187

Geier M, Braun A, Fladischer P, Stepniak P, Rudroff F, Hametner C, Mihovilovic MD, Glieder A (2013) Double site saturation mutagenesis of the human cytochrome P450 2D6 results in regioselective steroid hydroxylation. FEBS J 280(13):3094–3108. https://doi.org/10.1111/febs.12270

Geier M, Fauland P, Vogl T, Glieder A (2015) Compact multi-enzyme pathways in P. pastoris. Chem Commun 51:1643. https://doi.org/10.1039/C4CC08502G

Guo Z-P, Duquesne S, Bozonnet S, Cioci G, Nicaud J-M, Marty A, O’Donohue MJ (2017) Conferring cellulose-degrading ability to Yarrowia lipolytica to facilitate a consolidated bioprocessing approach. Biotechnol Biofuels 10(1):132. https://doi.org/10.1186/s13068-017-0819-8

Hagman A, Säll T, Piskur J (2014) Analysis of the yeast short-term Crabtree effect and its origin. FEBS J 281(21):4805–4814. https://doi.org/10.1111/febs.13019

Hong J, Tamaki H, Kumagai H (2007) Cloning and functional expression of thermostable β-glucosidase gene from Thermoascus aurantiacus. Appl Microbiol Biotechnol 73(6):1331–1339. https://doi.org/10.1007/s00253-006-0618-9

Juturu V, Wu JC (2014) Microbial cellulases: engineering, production and applications. Renew Sust Energ Rev 33:188–203. https://doi.org/10.1016/j.rser.2014.01.077

Klein-Marcuschamer D, Blanch HW (2015) Renewable fuels from biomass: technical hurdles and economic assessment of biological routes. AICHE J 61(9):2689–2701. https://doi.org/10.1002/aic.14755

Kostylev M, Wilson D (2012) Synergistic interactions in cellulose hydrolysis. Biofuels 3:61–70. https://doi.org/10.4155/bfs.11.150

Lin-Cereghino J, Wong WW, Xiong S, Giang W, Luong LT, Vu J, Johnson SD, Lin-Cereghino GP (2005) Condensed protocol for competent cell preparation and transformation of the methylotrophic yeast Pichia pastoris. BioTechniques 38(1):44–48. https://doi.org/10.2144/05381BM04

Liu W, Wang Y, Yu Z, Bao J (2012) Simultaneous saccharification and microbial lipid fermentation of corn stover by oleaginous yeast Trichosporon cutaneum. Bioresour Technol 118:13–18. https://doi.org/10.1016/j.biortech.2012.05.038

Liu Z, Inokuma K, Ho S-H, den Haan R, van Zyl WH, Hasunuma T, Kondo A (2017) Improvement of ethanol production from crystalline cellulose via optimizing cellulase ratios in cellulolytic Saccharomyces cerevisiae. Biotechnol Bioeng 114(6):1201–1207. https://doi.org/10.1002/bit.26252

Lynd LR, Weimer PJ, van Zyl WH, Pretorius IS (2002) Microbial cellulose utilization: fundamentals and biotechnology. Microbiol Mol Biol Rev 66(3):506–577. https://doi.org/10.1128/MMBR.66.3.506-577.2002

Mathew GM, Sukumaran RK, Singhania RR, Pandey A (2008) Progress in research on fungal cellulases for lignocellulose degradation. J Sci Ind Res 67:898–907

Mellitzer A, Weis R, Glieder A, Flicker KH (2012) Expression of lignocellulolytic enzymes in Pichia pastoris. Microb Cell Factories 11(1):61. https://doi.org/10.1186/1475-2859-11-61

Mellitzer A, Ruth C, Gustafsson C, Welch M, Birner-Grünberger R, Weis R, Purkarthofer T, Glieder A (2014) Synergistic modular promoter and gene optimization to push cellulase secretion by Pichia pastoris beyond existing benchmarks. J Biotechnol 191:187–195. https://doi.org/10.1016/j.jbiotec.2014.08.035

Morgenstern I, Powlowski J, Tsang A (2014) Fungal cellulose degradation by oxidative enzymes: from dysfunctional GH61 family to powerful lytic polysaccharide monooxygenase family. Brief Funct Genomics 13:471–481. https://doi.org/10.1093/bfgp/elu032

Näätsaari L, Mistlberger B, Ruth C, Hajek T, Hartner FS, Glieder A (2012) Deletion of the Pichia pastoris KU70 homologue facilitates platform strain generation for gene expression and synthetic biology. PLoS One 7:e39720. https://doi.org/10.1371/journal.pone.0039720

Okada H, Sekiya T, Yokoyama K, Tohda H, Kumagai H, Morikawa Y (1998) Efficient secretion of Trichoderma reesei cellobiohydrolase II in Schizosaccharomyces pombe and characterization of its products. Appl Microbiol Biotechnol 49(3):301–308. https://doi.org/10.1007/s002530051173

Ong SA, Ng ZJ, Wu JC (2016) Production of high concentration of L-lactic acid from cellobiose by thermophilic Bacillus coagulans WCP10-4. Appl Microbiol Biotechnol 100(14):6501–6508. https://doi.org/10.1007/s00253-016-7600-y

Osawa F, Fujii T, Nishida T, Tada N, Ohnishi T, Kobayashi O, Toshihiro Komeda T, Yoshida S (2009) Efficient production of L-lactic acid by Crabtree-negative yeast Candida boidinii. Yeast 26(9):485–496. https://doi.org/10.1002/yea.1702

Ottenheim C, Verdejo C, Zimmermann W, Wu JC (2014) Hemicellulase production by Aspergillus niger DSM 26641 in hydrothermal palm oil empty fruit bunch hydrolysate and transcriptome analysis. J Biosci Bioeng 118:696–701. https://doi.org/10.1016/j.jbiosc.2014.05.014

Ottenheim C, Meier K, Zimmermann W, Wu JC (2015) Isolation of filamentous fungi exhibiting high endoxylanase activity in lignocellulose hydrolysate. Appl Biochem Biotechnol 175(4):2066–2074. https://doi.org/10.1007/s12010-014-1427-8

Papanikolaou S, Aggelis G (2011) Lipids of oleaginous yeasts. Part II: technology and potential applications. Eur J Lipid Sci Technol 113(8):1052–1073. https://doi.org/10.1002/ejlt.201100015

Ramani G, Meera B, Vanitha C, Rajendhran J, Gunasekaran P (2015) Molecular cloning and expression of thermostable glucose-tolerant β-glucosidase of Penicillium funiculosum NCL1 in Pichia pastoris and its characterization. J Ind Microbiol Biotechnol 42(4):553–565. https://doi.org/10.1007/s10295-014-1549-6

Stursova M, Zifcakova L, Leigh MB, Burgess R, Baldrian P (2012) Cellulose utilization in forest litter and soil: identification of bacterial and fungal decomposers. FEMS Microbiol Ecol 80:735–746. https://doi.org/10.1111/j.1574-6941.2012.01343.x

Teeri TT (1997) Crystalline cellulose degradation: new insight into the function of cellobiohydrolases. Trends Biotechnol 15:160–167. https://doi.org/10.1016/S0167-7799(97)01032-9

Tian C, Beeson WT, Iavarone AT, Sun J, Marletta MA, Cate JHD, Glass NL (2009) Systems analysis of plant cell wall degradation by the model filamentous fungus Neurospora crassa. Proc Natl Acad Sci 106(52):22157–22162. https://doi.org/10.1073/pnas.0906810106

Van Rensburg P, van Zyl WH, Pretorius IS (1998) Engineering yeast for efficient cellulose degradation. Yeast 14(1):67–76. https://doi.org/10.1002/(SICI)1097-0061(19980115)14:1<67::AID-YEA200>3.0.CO;2-T

Vogl T, Hartner FS, Glieder A (2013) New opportunities by synthetic biology for biopharmaceutical production in Pichia pastoris. Curr Opin Biotechnol 24:1094–1101. https://doi.org/10.1016/j.copbio.2013.02.024

Vogl T, Kickenweiz T, Sturmberger L, Glieder A (2015) Bidirectional promoter. US 20150011407:A1

Vogl T, Sturmberger L, Kickenweiz T, Wasmayer R, Schmid C, Hatzl A-M, Gerstmann MA, Pitzer J, Wagner M, Thallinger GG, Geier M, Glieder A (2016) A toolbox of diverse promoters related to methanol utilization: functionally verified parts for heterologous pathway expression in Pichia pastoris. ACS Synth Biol 5(2):172–186. https://doi.org/10.1021/acssynbio.5b00199

Weis R, Luiten R, Skranc W, Schwab H, Wubbolts M, Glieder A (2004) Reliable high-throughput screening with Pichia pastoris by limiting yeast cell death phenomena. Fems Yeast Res 5:179–189. https://doi.org/10.1016/j.femsyr.2004.06.016

Wriessnegger T, Augustin P, Engleder M, Leitner E, Müller M, Kaluzna I, Schürmann M, Mink D, Zellnig G, Schwab H, Pichler H (2014) Production of the sesquiterpenoid (+)-nootkatone by metabolic engineering of Pichia pastoris. Metab Eng 24:18–29. https://doi.org/10.1016/j.ymben.2014.04.001

Wu S, Letchworth GJ (2004) High efficiency transformation by electroporation of Pichia pastoris pretreated with lithium acetate and dithiothreitol. BioTechniques 36(1):152–154

Yamada R, Hasunuma T, Kondo A (2013) Endowing non-cellulolytic microorganisms with cellulolytic activity aiming for consolidated bioprocessing. Biotechnol Adv 31:754–763. https://doi.org/10.1016/j.biotechadv.2013.02.007

Acknowledgements

This work was financially supported by the Science and Engineering Research Council (SERC) of the Agency for Science, Technology and Research (A*STAR), Singapore (SERC grant no 1526004159, ICES/15-175A02) and by the A*STAR Research Attachment Programme Scholarship from the A*STAR Graduate Academy. Thanks are also given to Dr. Christoph Ottenheim for his support in the work with A. niger and critical reading of the manuscript.

Author information

Authors and Affiliations

Corresponding authors

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Ethical statement

This article does not contain any studies with human participants or animals performed by any of the authors.

Electronic supplementary material

ESM 1

(PDF 648 kb).

Rights and permissions

About this article

Cite this article

Kickenweiz, T., Glieder, A. & Wu, J.C. Construction of a cellulose-metabolizing Komagataella phaffii (Pichia pastoris) by co-expressing glucanases and β-glucosidase. Appl Microbiol Biotechnol 102, 1297–1306 (2018). https://doi.org/10.1007/s00253-017-8656-z

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00253-017-8656-z