Abstract

We have isolated a novel exopolysaccharide (EPS) produced by the extreme halophilic archaeon Haloterrigena turkmenica. Some features, remarkable from an industrial point of view, such as emulsifying and antioxidant properties, were investigated. H. turkmenica excreted 20.68 mg of EPS per 100 ml of culture medium when grown in usual medium supplemented with glucose. The microorganism excreted the biopolymer mainly in the middle exponential growth phase and reached the maximal production in the stationary phase. Analyses by anion exchange chromatography and SEC-TDA Viscotek indicated that the EPS was composed of two main fractions of 801.7 and 206.0 kDa. It was a sulfated heteropolysaccharide containing glucose, galactose, glucosamine, galactosamine, and glucuronic acid. Studies performed utilizing the mixture of EPS anionic fractions showed that the biopolymer had emulsifying activity towards vegetable oils comparable or superior to that exhibited by the controls, moderate antioxidant power when tested with 2,2′-diphenyl-1-picrylhydrazyl (DPPH·), and moisture-retention ability higher than hyaluronic acid (HA). The EPS from H. turkmenica is the first exopolysaccharide produced by an archaea to be characterized in terms of properties that can have potential biotechnological applications.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Exopolysaccharides (EPSs) are high molecular weight polymers secreted by microorganisms into the surrounding environment. These macromolecules can be found as in capsular material or as dispersed slime with no association to any particular cell (Sutherland 1982), and they act like an adhesin favoring interactions and cellular associations among microorganisms. In this manner, EPSs create micro-environments within which the transfer of genes and metabolites is very common, so providing a way for microorganisms to ensure their survival in nutrient-starved environments (Sutherland 2001). Another important role concerns the protective function they provide against high or low temperature and salinity or against possible predators (Krüger et al. 2008; Nichols et al. 2005). Their composition greatly varies: they can be either homo- or heteropolysaccharides and may also contain a number of different organic and inorganic substituents such as acetic acid, pyruvic acid, sulfate, and phosphate. EPSs have stimulated great interest among biotechnologists because they can have a wide range of potential applications in many industrial fields in which emulsifying, viscosifying, antioxidant, and chelating agents are required (Freitas et al. 2011). For example, xanthan gum, one of the most well-known microbial EPSs, is commonly used as a thickener in both food and non-food industries due to its physical properties (Becker et al. 1998). Moreover, large attention has been devoted to these molecules because of their bioactive role; in fact, bacterial EPSs have also received an increasing pharmaceutical interest as antitumor, antiviral, immune-stimulatory, and anti-inflammatory agents (Arena et al. 2006; Arena et al. 2009). The antioxidant power of the EPSs has also been pointed out by several authors (Priyanka et al. 2014; Sun et al. 2014), and EPSs having antioxidant activity could be used as food supplements or as protective agents in pharmaceutics (Guo et al. 2010).

Extracellular polysaccharide-producing microorganisms are found in different classes of two domains, Bacteria and Archaea, living in a variety of environments, even extreme. A thermophilic aerobic Bacillus isolated from a shallow hydrothermal vent at Vulcano island, Italy, was found to excrete two different exopolysaccharides, and the extremely thermophilic anaerobic bacterium Thermotoga maritima was able to produce a significant amount of biofilms (Nicolaus et al. 2000; Van Fossen et al. 2008). Among halophilic bacteria, the commonest EPS-producing microorganisms belong to the genus Halomonas and the most important are represented by H. maura, H. eurihalina, H ventosae, H. anticariensis, and Halomonas sp. (Arias et al. 2003; Béjar et al. 1998; Mata et al. 2006; Poli et al. 2009).

EPSs have also been isolated from different genera of archaea, mainly belonging to thermophilic and halophilic groups. Various thermoacidophilic archaea, including members of the genera Sulfolobus and Thermococcus, were observed to excrete sulfated heteropolysaccharides (Nicolaus et al. 1993; Rinker and Kelly 1996), whereas Archaeoglobus fulgidus accumulated quantities of EPSs as biofilm (Hartzell et al. 1999). Amounts of EPSs are excreted by members of the halophilic genera Haloarcula, Haloferax, and Halobacterium (Nicolaus et al. 1999; Paramonov et al. 1998; Severina et al. 1990). Antón et al. (1988) firstly reported on the production of EPS by a halophilic archaeon. The authors described Haloferax mediterranei (ATCC 33500) as a producer of an extracellular polymer that gave a typical mucous character to the colonies and was responsible for the appearance of a superficial layer in an unshaken liquid medium.

With the goal of finding EPSs with novel and valuable properties, the polysaccharide-producing capacity of the extreme halophilic archaeon Haloterrigena turkmenica was investigated. This microorganism, originally isolated and described as Halococcus turkmenicus, and successively transferred to the new genus Haloterrigena, belongs to the euryarchaeal family of Halobacteriaceae (Ventosa et al. 1999). H turkmenica, isolated from sulfate saline soil in Turkmenistan, is a Gram-negative microbe with shape variable from coccoid or oval to rod and relatively fast growth. It is a chemoorganotrophic, carotenoid-containing extreme halophile which requires at least 2 M NaCl for growth. In the present study, we report on the capacity of this microorganism to synthesize an EPS in culture media added with different sugars and on the polysaccharide characterization. Moreover, properties of relevant importance in determining possible future applications of the exopolysaccharide were also investigated.

Materials and methods

Chemicals

Chemicals for the preparation of liquid growth media, bovine serum albumin (BSA), Congo red, cetylpyridinium chloride, glucose, galactose, galactosamine, glucosamine, glucuronic acid, Tween 80, Tween 20, Triton X-100, sodium alginate, chitosan, hyaluronic acid (HA), 2,2′-diphenyl-1-picrylhydrazyl free radical (DPPH·), 2,4,6-tripyridyl-S-triazine (TPTZ), ascorbic acid, and other reagents for antioxidant assays were purchased from Sigma-Aldrich Co. (Milano, Italy). Reagent for protein determination was obtained from Bio-Rad Laboratories, Inc. (Hercules, CA, USA). Ethanol was from Carlo Erba Reagents (Milano, Italy).

Media and growth conditions

H. turkmenica (DSM-5511), obtained by Deutsche Sammlung von Mikroorganismen und Zellkulturen (DSMZ) (Braunschweig, Germany), was revitalized following the manufacturer’s instructions, then grown aerobically at 37 °C in halobacteria medium M372 (DSMZ catalogue), and stored in the same medium containing 15 % (v/v) glycerol at −80 °C until use. For EPS production, two different media were tested: M372 medium, indicated below as HTR, added with 1 % (w/v) of the following sugars: glucose, mannose, galactose, fructose, and sucrose, and a modified M372 medium, named HTY-, in which the yeast extract was reduced to 1 g/l and the carbon source was represented by 1 % (w/v) of the previous sugars. All starter cultures were inoculated in 100-ml Erlenmeyer flask containing 20 ml growth medium and placed in a rotary water-bath shaker (Aquatron, Infors AG, Switzerland) at 37 °C and 180 rpm. Archaeal growth was followed by optical density measurement at 600 nm on a Varian spectrophotometer (model DMS-200, Varian Analytical Instruments, Leini, Torino, Italy). At the reaching of the exponential phase, an aliquot of each starter culture was used to inoculate a 500-ml Erlenmeyer flask containing 100 ml of the tested growth media. All these cultures were stopped at the beginning of the stationary phase, then subjected to EPS extraction and purification.

Kinetics of growth and EPS production

In order to identify the various phases of the EPS production, batch cultures in M372 medium supplemented with 1 % (w/v) glucose were scaled up to 1 L (500 ml in 2-l Erlenmeyer flask). At regular intervals, 100-ml samples were collected for turbidity measurements of bacterial growth and EPS estimation. Each EPS fraction was subjected to total protein content determination using the Bio-Rad protein staining assay with BSA as a standard and carbohydrate content estimation by the phenol-sulfuric acid method with glucose as a standard (Bradford 1976; Dubois et al. 1956). The nucleic acid content was evaluated spectrophotometrically by monitoring the absorbance at 260 nm.

Congo red staining

The EPS production was evidenced according to the Congo red staining method of Allison and Sutherland (1984) with minor modifications. In the assay, a coverslip was immersed in a static batch culture of H. turkmenica grown in HTR medium added with glucose until reaching the stationary phase; then, it was gently removed and treated for 30 s with 10 mM cetylpyridinium chloride, rinsed with distilled water, and air dried at room temperature for 20 to 30 min. The coverslip was then fixed in oven at 55 °C for 15 min, allowed to cool, stained, and intensified with a 2:1 (v/v) mixture of saturated aqueous Congo red solution and 10 % (v/v) Tween 80 solution for 20 min. Images were observed by a Leica DM6000 UpRight microscope in Bright Field and then collected by Leica DFC 420 RGB Camera through Leica Application Suite software.

Extraction and quantification of carotenoids

After cultivation, cells were harvested through centrifugation at 17,000 rpm for 30 min at 4 °C; then, they were suspended in methanol and stirred for 30 min to extract the pigments. Two extractions were necessary to obtain a clear color of the cells. The yellow-orange supernatants, obtained after centrifugation at 17,000 rpm for 30 min, were pooled and the absorbance at 455 nm (λ max of the extracts) was measured. The yield of pigments was calculated from total 455 nm absorbance of extract (absorbance × total volume of the extracts) divided by the volume of cell growth and expressed as A 455 nm/ml broth. The efficiency of pigment production was calculated by dividing the yield of pigments by the turbidity of culture broth at the end of growth and expressed as A 455 nm/A 600 nm (Fang et al. 2010).

EPS purification

For biopolymer purification, cells were removed from the culture broth as above described. The supernatant was boiled for 15 min to inactivate any possible depolymerase (Cerning et al. 1994) and then centrifuged at 4000 rpm for 30 min at 4 °C. The resulting liquid phase was tenfold concentrated in an Amicon ultrafiltration unit (Millipore Corporation, Bedford, USA) equipped with a 10-kDa polyethersulfone membrane (Millipore Corporation, Bedford, USA). The retentate was dialyzed in a 12–14-kDa cellulose dialysis tube for 24 h at 4 °C vs deionized water (three changes). Three volumes of cold ethanol were added drop by drop to the dialyzed sample, under vigorous stirring, to allow EPS precipitation and then the hydro-alcoholic solution was left to stand at −20 °C overnight. The crude polymer was recovered from the solution through centrifugation at 17,000 rpm for 20 min at 4 °C. The pellet was washed with absolute ethanol in order to remove any soluble low molecular weight impurity, redissolved in deionized water, and centrifuged at 13,200 rpm for 10 min at 4 °C. The liquid phase, containing the pure polymer, was lyophilized.

EPS characterization

FPLC purification (fractioning)

About 25 mg of lyophilized EPS were dissolved in 2 ml buffer A (20 mM sodium acetate, 0.5 M sodium chloride, pH 7.4) and applied to an anion exchange column (HiPrep Q sepharose 26/10 HP, GE Healthcare, Milan, Italy) attached to an ÄKTA purifier system (GE Healthcare, Milano, Italy) and previously equilibrated with buffer B (20 mM sodium acetate, 3 M sodium chloride, pH 7.4) followed by buffer A. After washing with buffer A, polysaccharides bound to the column were eluted by applying a linear salt gradient ranging from buffer A to buffer B in 4 column volumes at a flow rate of 2 ml/min and collected in 2-ml fractions. The biopolymer was monitored by UV detection at 215 nm. The main peak fractions (137–152 ml) were pooled and concentrated to a volume of approx. 1 ml by freeze drying (Christ Epsilon 2-6D, Martin Christ, Osterode am Harz, Germany) and then diafiltered and concentrated using a 100-kDa centrifugal filter device (Amicon Ultra, Millipore, Milano, Italy). The 100-kDa permeate was diafiltered and concentrated using a 10-kDa centrifugal filter device (Amicon Ultra, Millipore, Milano, Italy).

Hydrodynamic characterization through SEC-TDA

The analyses for molecular mass determination of the retentate 100 -kDa, the retentate 10 -kDa, and the permeate 10 -kDa were carried out using the SEC-TDA equipment by Viscotek (Malvern Instruments, Italy). EPS was analyzed at concentrations ranging from 0.3 to 4 g/l to have a column load for each analysis (injection volume × sample concentration × intrinsic viscosity) of approximately 0.2 dl, and runs were performed at 40 °C with a running time of 50 min. The fragment molecular weight distribution, molecular size distribution, polydispersity, hydrodynamic radius, and intrinsic viscosity were determined as described in La Gatta et al. (2010).

Chemical analysis

EPS was subjected to several chemical analyses: the determination of total protein, carbohydrate, and nucleic acid contents were estimated as reported above; uronic acids were estimated according to Blumenkrantz and Asboe-Hansen (1973) utilizing D-glucuronic acid as a standard, and hexosamines were determined after hydrolysis with 0.5 M trifluoroacetic acid for 2 h at 120 °C, following the Johnson’s method (1971) with D-glucosamine hydrochloride as a standard. The presence of sulfate was attested by using a high-performance liquid chromatographic system (ICS3000, Thermo Fisher Scientific, Italy) equipped with an IonPac AS4A column. A solution of 0.8 mM Na2CO3 and 6.0 mM NaHCO3 was used as eluent at a flow rate of 1 ml/min. A calibration curve prepared with Na2SO4 as a standard was used to calculate the sulfate content in the EPS.

Sugar composition was determined as follows: the purified EPS (3 mg), obtained from anion exchange chromatography, was hydrolyzed with 1 M HCl for 18 h at 100 °C in an oven. The sugar components were identified by using the above high-performance chromatographer equipped with a pulsed amperometric detector (PAD, Thermo Fisher Scientific, Italy) on an anion exchange column (Carbopac PA1, Thermo Fisher Scientific, Italy). They were eluted with a gradient of NaOH from 1 to 100 mM in a 41-min run with a flow rate of 1 ml/min. Glucose, galactose, galactosamine, glucosamine, and glucuronic acid standards were used to determine the monosaccharide composition in a concentration range from 0.05 to 0.005 mM.

Emulsifying, moisture-absorption/retention, and antioxidant activities

The assays were carried out on the anionic fraction of the EPS, obtained after FPLC purification. The emulsifying activity was assayed following the E24 method (Cooper and Goldenberg 1987) with some minor modifications. The EPS (0.5 % w/v) was dissolved in 2 ml of distilled water and placed into glass tubes, then 2 ml of hydrophobic substrates (olive oil, sunflower oil, mineral oil, n- hexane, xylene, and toluene) were added to each tube, strongly mixed to homogeneity and left to stand for 24 h at 4 °C. Emulsifying activity was expressed as the percentage of the height occupied by the emulsion layer respect to the total height after 24 h. The emulsifying properties of the EPS were compared with that of the following commercial emulsifiers: Tween 80, Tween 20, and Triton X-100.

Prior to the moisture-absorption test, EPS and the following control samples—sodium alginate, chitosan and hyaluronic acid (HA)—were pulverized to 80 mesh and dried over P2O5 in vacuo for 24 h. Then, 0.5 g of each sample was transferred into desiccators under two different relative humidity levels (RH)—81 % (using a desiccator containing saturated ammonium sulfate) and 43 % (using a desiccator containing saturated potassium carbonate)—kept there, and weighted after 3, 6, 12, 24, 48, and 72 h (Chen et al. 2003). The moisture-absorption ability was evaluated by the percentage of weight increase in the dry samples. The EPS moisture-retention ability was measured according to Sun et al. (2014) with minor modifications. Wet samples were prepared by keeping the EPS and the control samples inside a desiccator with a 81 % RH level for 72 h. After this period of time, sample and controls were weighted and then transferred in a desiccator containing allochroic silica gel, kept there, and weighted after 3, 6, 12, 24, 48, and 72 h. The moisture-retention ability was evaluated by the percentage of residual water in the wet samples.

The capacity for scavenging the DPPH · free radical was evaluated according to Blois (1958) with some modifications. Before assay, EPS and HA were solubilized in deionized water at the following concentrations: 0.1, 0.25, 0.5, 1.0, 2.0, 3.0, 5.0, 7.5, and 10.0 mg/ml. Three hundred thirty-three microliters of each dilution was added to 666 μl of 100 mM DPPH · dissolved in absolute methanol, then the mixtures were incubated in the dark for 25 min and centrifuged at 13,200 rpm for 10 min at 4 °C. A control sample, composed of 666 μl 100 mM DPPH · solution and 333 μl of deionized water, was also prepared, and samples and control were read at 517 nm against a blank consisting of 666 μl of absolute methanol and 333 μl of deionized water. DPPH · radical scavenging activity (RSA) was calculated according to the following formula:

Antioxidant activity of the EPS was also measured using the total antioxidant activity method (TAC) (Prieto et al. 1999). Prior to the assay, EPS and HA were solubilized in water (5, 10, 15, and 20 mg/ml) and a reagent solution, consisting of 0.6 M sulfuric acid, 28 mM sodium phosphate, and 4 mM ammonium molybdate, was prepared. Then, aliquots of 0.1 ml of sample solutions, mixed with 1 ml of reagent solution, were incubated at 95 °C for 90 min. After cooling, the absorbance of each sample was measured at 695 nm against a blank consisting of 1 ml of reagent solution and 0.1 ml of water incubated under the same conditions. A standard solution of ascorbic acid ranging from 2.5 to 20 μg was used to obtain a calibration curve. The total antioxidant activity of the samples was determined by comparing the absorbance values registered at the end of the assays with those of the ascorbic acid calibration curve. The results were expressed as microgram of ascorbic acid equivalents.

Ferric reducing antioxidant power (FRAP) of the EPS was measured according to Benzie and Strain (1996), with minor modifications. Briefly, the assay solution, consisting of 300 mM sodium acetate buffer, pH 3.6, 10 mM 2,4,6-tripyridyl-S-triazine (TPTZ) in 40 mM HCl, and 20 mM FeCl3·6H2O, was prepared and mixed in 10:1:1 ratio at the time of use; then, 50 μl aliquots of EPS or HA solubilized in water (5, 10, 15, and 20 mg/ml) were added to 1.5 mL of FRAP solution. After a 4-min incubation, the absorbance values were read at 593 nm against a blank consisting of only FRAP solution. Ferric reducing activity was calculated as above reported by using a calibration curve built with amounts of ascorbic acid ranging from 0.5 to 6 μg. The results were expressed as microgram of ascorbic acid equivalents.

Results

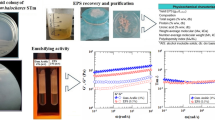

Growth studies and EPS production

The presence of the exopolysaccharide was firstly detected by observation of the H. turkmenica cells grown in unshaken cultures of HTR supplemented with glucose. Cells were embedded in an amorphous matrix which was formed on the coverslip, and the polysaccharide nature of the matrix was confirmed by retention of the Congo red dye. Two different media were used for H. turkmenica growth, namely M372 medium (HTR) and M372 containing a reduced quantity of yeast extract (HTY-). To evaluate the effect of different sugars on EPS production, the microorganism was cultivated in both media added with 1 % (w/v) glucose, mannose, galactose, sucrose, and fructose. Growth was observed in both media, with HTR medium stimulating stronger growth than HTY- medium, and also EPS production, nevertheless at different quantities in relation to the sugar used. In Table 1 are displayed the yields of the EPS obtained from the different media tested. Negligible amounts of EPS were obtained in all HTY- media, with the highest yields achieved in the presence of mannose and sucrose. The highest EPS production in HTR medium was obtained with glucose (20.68 mg/100 ml culture medium), while with the other sugars yield was from 1.8 to 4.8-fold lower. The presence of glucose led to the highest biomass yield both in HTR and HTY- media with cells being moderately orange-red colored, thus indicating production of carotenoids. The presence of the pigments was confirmed by extraction of the colored molecules and measure of the efficiency of pigment production in the extracts. A value of 0.0018 (A 455 nm/A 600 nm) was observed for the extract from cells grown in HTR supplemented with glucose in comparison with values comprised between 0.0002 and 0.0004 (A 455 nm/A 600 nm) obtained from the other growths. According to the above obtained results and because of its low cost and easy availability, glucose was chosen as the preferred sugar for further studies.

With the purpose to study the synthesis of the EPS as a function of the growth phases, H. turkmenica was grown in the 1-l HTR-glucose medium over 11 days. The cell biomass and EPS concentrations at the exponential, stationary, and decline phases of growth are summarized in Table 2. A considerable amount of EPS was produced over 48 h from the beginning of the growth, in the middle exponential phase, reaching the maximum concentration in the stationary phase (168 h). It was remarkable that the quantity of EPS in the culture remained almost constant within the following 100 h of growth, with relatively high level also when the cell density began to decrease (264 h). Maximum EPS yield on biomass was obtained at the exponential phase in correspondence with the lowest biomass yield, thus suggesting that the biopolymer production was associated with the growth phase rather than the biomass amount.

EPS purification and characterization

The EPS was obtained after centrifugation of the culture supernatant, concentration by ultrafiltration, dialysis, and ethanol precipitation. After separation by anion exchange chromatography, one main peak which accounted for 84 % of the total loaded EPS was eluted at 1.4 M NaCl, indicating that the polymer was strongly absorbed and has an anionic nature. The anionic fraction was further purified and characterized: it mainly contained carbohydrate (91 % w/w), sulfate (2.8 % w/w), and a low percentage of protein (1.4 % w/w). Nucleic acids were absent. Sugar analysis revealed that EPS is a heteropolysaccharide displaying glucose as the main sugar. The uronic acid and hexosamine contents were 12.05 and 32.54 % (w/w), respectively. The EPS was composed of the following sugars in different ratios: glucose/glucosamine/glucuronic acid/galactose/galactosamine (1:0.65:0.24:0.22:0.02). The SEC-TDA Viscotek of the main peak showed that the EPS was essentially composed of two polymers of 801.7 and 206.0 kDa recovered from the 100-kDa retentate and an additional polymer of 37.6 kDa from the 10-kDa retentate. The EPS anionic fraction was used to investigate some properties of biotechnological interest.

Emulsifying activity

The emulsifying activity of the EPS is shown in Table 3. The polymer was capable of stabilizing different emulsions formed by organic phase and water in which the hydrophobic phase was either an aliphatic hydrocarbon or a vegetable oil. In particular, the activity of the EPS was more efficient than the chemical surfactants used as controls with sunflower oil, and it showed the same emulsifying capacity of the controls when olive oil was used as organic phase. Negligible emulsifying power was exhibited towards aromatic hydrocarbons and mineral oil. EPS exhibited emulsifying capacity higher than that showed by EPSs produced by the halophilic bacteria Halomonas ventosae and Halomonas anticariensis towards sunflower and olive oils and almost comparable to the EPS from Salipiger mucosus A3T (Llamas et al. 2010; Mata et al. 2006).

Moisture-absorption and retention abilities

The moisture-absorption and retention abilities of the EPS were studied, and the results were compared with those of sodium alginate, chitosan, and HA, usually used in several industrial sectors. The weight of all polysaccharides increased rapidly within the first 6 h, with HA exhibiting the highest absorption rate at both 43 and 81 % RH. The findings also indicated that the moisture-absorption rate increased with RH increase; in fact after 12 h, the weight increase for the EPS was 4.01 % ± 0.09 at 43 % RH and 7.32 % ± 0.11 at 81 % RH. All the compounds reached the highest weight increase after 12 h of exposure to the humidity and maintained a constant weight over the following 60 h. Comparison of moisture-absorption among the polysaccharides was the following: HA > sodium alginate > EPS > chitosan at both RH. The moisture-absorption capacity of all tested compounds at 81 % RH is shown in Fig. 1a.

For moisture-retention test, the samples were maintained in a desiccator containing silica gel and the results are depicted in Fig. 1b. The weight of the polysaccharides decreased with the time, showing the greatest weight loss within the first 3 h. Then, the water release was slower but continuous till the end of the experiment, and samples retained 8–14 % moisture after 72 h with an order opposite to that of the absorption ability test: chitosan > EPS > sodium alginate > HA.

Antioxidant activity

Antioxidant activity of the EPS was evaluated by using three different methods, namely radical scavenging activity (RSA) by DPPH assay, total antioxidant capacity (TAC assay), and ferric reducing antioxidant power (FRAP assay). Comparison with antioxidant power of HA, largely employed in the cosmetic field, was performed. As depicted in Fig. 2, the antioxidant power of the EPS increased with its concentration in all assays. At a concentration of 10 mg/ml, the RSA of the polymer was 68.2 % ± 1.1 with IC50 value (inhibitory concentration giving 50 % reduction of the free radical DPPH) of 6.03 mg/ml, whereas HA did not show scavenging capacity (Fig. 2a). The RSA was higher compared to the DPPH radical scavenging activity reported for some non-sulfated EPSs, such as EPS17 and RPS20 produced by two Bacillus licheniformis strains, as well as for the sulfated SM-A87 EPS isolated from deep-sea bacterium Zunongwangia profunda (Song et al. 2011; Sun et al. 2014). When the antioxidant power was investigated through the TAC and FRAP assays, the polymer was able to react with both Mo6+ and Fe3+ ions showing a dose-dependent linear increase of the activity. Already at a concentration of 5 mg/ml, the EPS showed a better capacity to react with molybdenum ions than ferric ions and the amount of ascorbic acid equivalents was fivefold higher (2.0 and 0.4 μg, respectively). At a concentration of 20 mg/ml, the ascorbic acid equivalents were 9.40 and 1.59 μg with TAC and FRAP assays, respectively. HA did not exhibit antioxidant capacity with both tests (Fig. 2b, c).

Discussion

Considering the widespread interest towards the use of microbial polysaccharides in several application areas, the search for novel EPSs provided with appreciable properties at an industrial level led us to investigate the capacity of the halophilic archaeon H. turkmenica in synthesizing polysaccharides. Negligible amounts of EPS were detected when H. turkmenica was grown in the presence of a reduced supply of yeast extract in comparison to those produced in the complete halobacteria medium. The type of carbon source influenced the quantity of EPS, but biomass and EPS yields were not correlated; in fact, although the biomass amount of H. turkmenica grown in the presence of fructose was 2.3-fold higher than that reached with galactose, the EPS production was lower. These results agree with those of some authors asserting that cell growth and EPS biosynthesis may have diverse nutritional requirements (Gorret et al. 2001; Poli et al. 2010). However, H. turkmenica produced the highest biomass and EPS amounts when grown in medium added with glucose, and in addition, cells appeared fairly orange-red colored. This is an interesting feature since it opens the way to the utilization of the biomass also, for isolation of C40 and/or C50 carotenoids. This class of compounds has received considerable attention in the last years because of their potential functions on human health (Heider et al. 2014). Thus, under our experimental conditions, the microorganism can be exploited as EPS and carotenoids producer at the same time. The highest EPS amount was reached in the stationary phase, and only a negligible decrease in the quantity of EPS was observed within the following 100 h of growth, in contrast to other EPSs which amount was considerably reduced after the maximum production, maybe for enzymatic degradation (Mata et al. 2006).

Many halophilic microorganisms have been reported to synthesize EPSs, but the majority that have been described are Eubacteria both moderate and extreme with yields ranging from milligrams to grams per liter of culture medium (Amouric et al. 2014; Cojoc et al. 2009; Llamas et al. 2010). Little is reported about EPSs production from halophilic Archaea with strains from Haloferax being the most described (Nicolaus et al. 2010). H. mediterranei strain R4 produced 300 mg of EPS per liter of culture medium, and three strains of Haloarcula isolated from samples collected in a Tunisian marine saltern (T5, T6 and T7) yielded 370, 45, and 35 mg/l, respectively (Nicolaus et al. 1999; Parolis et al. 1996). Many are the Haloterrigena species isolated, but the ability to produce EPSs has not been investigated to date, apart from our study on the EPS synthesis by H. turkmenica. According to Sutherland (1990) and Bhaskar and Bhosle (2005), the majority of microbial EPSs are generally heteropolymers with two to four or five sugar components. Moreover, microbial EPSs are usually rich in hexoses like glucose and galactose (Sutherland 1999). The EPS from H. turkmenica seems to follow these rules, because it is a heteropolysaccharide constituted by five moieties comprising neutral, acid, and amino sugars. It has sulfate groups like other described EPSs from extreme halophilic Archaea and moderately halophilic Bacteria (Antón et al. 1988; Llamas et al. 2010; Mata et al. 2006; Nicolaus et al. 1999). Sulfated EPSs resemble eukaryotic polymers such as chondroitin sulfate and heparin sulfate, and hence, they are of great potential interest in biomedical applications. They have a number of bioactive properties such as anticoagulant, antiproliferation of cancer cells, antiviral, and wound healing in vitro (Arena et al. 2009; Haroun-Bouhedja et al. 2000; Senni et al. 2011). The presence of an acid sugar (glucuronic acid) was also established for our EPS. The occurrence of acid sugars in the molecule of EPSs is desired in the cosmetic industry as these macromolecules are good hydrating agents to be used as active principle in cosmetic formulations (Thibodeau 2005). Moreover, the occurrence of negative charges could be also useful in biodetoxification and water treatment. A high quantity of hexosamine is unusual among microbial, in general, and archaea, in particular, species. Traces of galactosamine were detected in the EPS from Bacillus licheniformis, isolated from a shallow vent off Panarea Island in Italy (Spanò et al. 2013), and percentages of hexosamine ranging from 2.15 to 2.50 and 2.40 to 2.80 were found in EPSs from H. mediterranei and Halomonas, respectively (Antón et al. 1988; Mata et al. 2006). In contrast, the EPS from H. turkmenica contains high proportion of glucosamine (30.46 %), only second to glucose (46.76 %) as sugar component. This feature is more diffused among marine eukaryotes, such as Amussium pleuronectus which produces an exopolysaccharide, resembling an alternative source of heparin, formed by a repeated disaccharide containing uronic acid and hexosamine (Saravanan and Shanmugam 2010). The EPS of the present study exhibited moderate emulsifying power towards n-hexane while was capable of producing stable emulsions with vegetable oils. EPSs provided with emulsifying ability could be employed in the food industry as emulsifier and stabilizer agents (Duboc and Mollet 2001). Proteins seem to play an important part in the emulsifying capability of several EPSs. It is reported that emulsifying properties of many bioemulsifiers are due to the association of an anionic hydrophilic polysaccharide with proteins. The EPS from the halophilic bacterium Salipiger mucosus A3T, which shows good emulsifying capacity, contains a protein concentration of 1.6 % (w/w) which was comparable to that of the EPS of H. turkmenica (1.4 %) (Llamas et al. 2010). Substances with moisture-retention capacity are usually used in cosmetic, food, and pharmaceutical industries (Augustine et al. 2013). Chitosan, HA, and sodium alginate, employed in several sectors for their good moisture-absorption and retention abilities, were chosen as comparison compounds to test the EPS moisture-absorption and retention capacities. It showed an absorption capacity intermediate between HA and chitosan, as the EPS SM-A87 from Z. profunda (Sun et al. 2014). In contrast, our biopolymer displayed higher retention capacity than HA and sodium alginate, thus placing it among candidates for possible applications in food and cosmetic fields.

Oxidative reactions produced by reactive oxygen species may cause human tissue damages and many diseases such as cancer and inflammation (Thanan et al. 2014). In last years, research of natural antioxidants, both small or large molecules, has been greatly promoted with the aim to replace synthetic antioxidants used in the pharmaceutical, cosmetic, and food industries, whose safety has been questioned. It is preferable to ascertain the antioxidant capacity of a compound by testing different substrates since a molecule can exert its own antioxidant power by different mechanisms. DPPH is a useful reagent to evaluate the free radical scavenging ability of a hydrogen-donating antioxidant, which can transfer hydrogen atoms or electrons to DPPH radicals. Our results indicated that the EPS showed a modest capacity for scavenging DPPH but displayed antioxidant power also when tested with FRAP and TAC assays. The data demonstrated a dose-dependent linear increase of the EPS indicating its ability to change the oxidation state or to chelate transition metal ions (Priyanka et al. 2014). As a conclusion, the EPS of H. turkmenica is the first exopolysaccharide produced by halophilic archaea to be characterized in terms of properties that can have potential biotechnological applications. However, although its properties make the EPS a possible candidate for use in several areas, its yield is still inadequate for wide applications in industrial sectors. Studies aiming to get a higher production of the biopolymer through optimization of culture conditions, such as changes in nutrient medium composition (sodium chloride concentration, carbon source) and control of growth parameters in a fermenter, are under way.

References

Allison DG, Sutherland IW (1984) A staining technique for attached bacteria and its correlation to extracellular carbohydrate production. J Microbiol Meth 2(2):93–99

Amouric A, Liebgott PP, Joseph M, Brochier-Armanet C, Lorquin J (2014) Halomonas olivaria sp. nov., a moderately halophilic bacterium isolated from olive-processing effluents. Int J Syst Evol Microbiol 64(1):46–54

Antón J, Meseguer I, Rodríguez-Valera F (1988) Production of an extracellular polysaccharide by Haloferax mediterranei. Appl Environ Microbiol 54(10):2381–2386

Arena A, Maugeri TL, Pavone B, Jannello D, Gugliandolo C, Bisignano G (2006) Antiviral and immunoregulatory effect of a novel exopolysaccharide from a marine thermotolerant Bacillus licheniformis. Int Immunopharmacol 6(1):8–13

Arena A, Gugliandolo C, Stassi G, Pavone B, Iannello D, Bisignano G, Maugeri TL (2009) An exopolysaccharide produced by Geobacillus thermodenitrificans strain B3-72: antiviral activity on immunocompetent cells. Immunol Lett 123(2):132–137

Arias S, Ferrer MR, Del Moral A, Quesada E, Béjar V (2003) Mauran, an exopolysaccharide produced by the halophilic bacterium Halomonas maura, with a novel composition and interesting properties for biotechnology. Extremophiles 7(4):319–324

Augustine R, Rajendran R, Cvelbar U, Mozetič M, George A (2013) Biopolymers for health, food, and cosmetic applications. In: Thomas S, Durand D, Chassenieux C, Jyotishkumar P (eds) Handbook of biopolymer-based materials: from blends and composites to gels and complex networks. Wiley-VCH Verlag GmbH & Co. KGaA, Weinheim, pp 801–849

Becker A, Katzen F, Pühler A, Ielpi L (1998) Xanthan gum biosynthesis and application: a biochemical/genetic perspective. Appl Microbiol Biotechnol 50(2):145–152

Béjar V, Llamas I, Calvo C, Quesada E (1998) Characterization of exopolysaccharides produced by 19 halophilic strains included in the species Halomonas eurihalina. J Biotechnol 61(2):135–141

Benzie IFF, Strain JJ (1996) The ferric reducing ability of plasma (FRAP) as a measure of “antioxidant power”: the FRAP assay. Anal Biochem 239(1):70–76

Bhaskar PV, Bhosle NB (2005) Microbial extracellular polymeric substances in marine biogeochemical processes. Curr Sci 88(1):45–53

Blois MS (1958) Antioxidant determination by the use of a stable free radical. Nature 181(4617):1199–1200

Blumenkrantz N, Asboe-Hansen G (1973) New method for quantitative determination of uronic acids. Anal Chem 54(2):484–489

Bradford MM (1976) A rapid and sensitive method for the quantification of microgram quantities of protein utilizing the principle of protein dye binding. Anal Biochem 72(1–2):248–254

Cerning J, Renard CMGC, Thibault JF, Bouillanne C, Landon M, Desmazeaud M, Topisirovic L (1994) Carbon source requirements for exopolysaccharide production by Lactobacillus casei CG11 and partial structure analysis of the polymer. Appl Environ Microbiol 60(11):3914–3919

Chen L, Du Y, Zeng X (2003) Relationships between the molecular structure and moisture-absorption and moisture-retention abilities of carboxymethyl chitosan. II. Effect of degree of deacetylation and carboxymethylation. Carbohydr Res 338(4):333–340

Cojoc R, Merciu S, Oancea P, Pincu E, Dumitru L, Enache M (2009) Highly thermostable exopolysaccharide produced by the moderately halophilic bacterium isolated from a man-made young salt lake in Romania. Pol J Microbiol 58(4):289–294

Cooper DG, Goldenberg BG (1987) Surface active agents of two Bacillus species. Appl Environ Microbiol 53(2):224–229

Duboc P, Mollet B (2001) Applications of exopolysaccharides in dairy industry. Int Dairy J 11(9):759–768

Dubois MK, Gilles A, Hamilton JK, Rebers PA, Smith F (1956) Colorimetric methods for determination of sugars of related substances. Anal Chem 28(3):350–356

Fang CJ, Ku KL, Lee MH, Su NW (2010) Influence of nutritive factors on C50 carotenoids production by Haloferax mediterranei ATCC 33500 with two-stage cultivation. Bioresour Technol 101(16):6487–6493

Freitas F, Alves VD, Reis MA (2011) Advances in bacterial exopolysaccharides: from production to biotechnological applications. Trends Biotechnol 29(8):388–398

Gorret AU, Maubois N, Engasser JL, Ghoul JM (2001) Study of the effects of temperature, pH and yeast extract on growth and exopolysaccharide production by Propionibacterium acidi-propionici on milk microfiltrate using a response surface methodology. J Appl Microbiol 90(5):788–796

Guo S, Mao W, Han Y, Zhang X, Yang C, Chen Y, Xu J, Li H, Qi X (2010) Structural characteristics and antioxidant activities of the extracellular polysaccharides produced by marine bacterium Edwardsiella tarda. Bioresour Technol 101(12):4729–4732

Haroun-Bouhedja F, Ellouali M, Sinquin C, Boisson-Vidal C (2000) Relationship between sulfate groups and biological activities of fucans. Thromb Res 100(5):453–459

Hartzell PL, Millstein J, Lapaglia C (1999) Biofilm formation in hyperthermophilic Archaea. Methods Enzymol 310:335–349

Heider SAE, Peters-Wendisch P, Wendisch VF, Beekwilder J, Brautaset T (2014) Metabolic engineering for the microbial production of carotenoids and related products with a focus on the rare C50 carotenoids. Appl Microbiol Biotechnol 98(10):4355–4368

Johnson AR (1971) Improved method of hexosamine determination. Anal Biochem 44(2):628–635

Krüger M, Blumenberg M, Kasten S, Wieland A, Känel L, Klock JH, Michaelis W, Seifert R (2008) A novel, multi-layered methanotrophic microbial mat system growing on the sediment of the Black Sea. Environ Microbiol 10(8):1934–1947

La Gatta A, De Rosa M, Marzaioli I, Busico T, Schiraldi C (2010) A complete hyaluronan hydrodynamic characterization using a size exclusion chromatography-triple detector array system during in vitro enzymatic degradation. Anal Biochem 404(1):21–29

Llamas I, Mata JA, Tallon R, Bressollier P, Urdaci MC, Quesada E, Béjar V (2010) Characterization of the exopolysaccharide produced by Salipiger mucosus A3T, a halophilic species belonging to the Alphaproteobacteria, isolated on the Spanish Mediterranean seaboard. Mar Drugs 8(8):2240–2251

Mata JA, Béjar V, Llamas I, Arias S, Bressollier P, Tallon R, Urdaci MC, Quesada E (2006) Exopolysaccharides produced by the recently described halophilic bacteria Halomonas ventosae and Halomonas anticariensis. Res Microbiol 157(9):827–835

Nichols CA, Guezennec J, Bowman JP (2005) Bacterial exopolysaccharides from extreme marine environments with special consideration of the southern ocean, sea ice, and deep-sea hydrothermal vents: a review. Mar Biotechnol 7(4):253–271

Nicolaus B, Manca MC, Romano I, Lama L (1993) Production of an exopolysaccharide from two thermophilic archaea belonging to the genus Sulfolobus. FEMS Microbiol Lett 109(2–3):203–206

Nicolaus B, Lama L, Esposito E, Manca MC, Improta R, Bellitti MR, Duckworth AW, Grant WD, Gambacorta A (1999) Haloarcula spp. able to biosynthesize exo-endopolymers. J Ind Microbiol Biotechnol 23(6):489–496

Nicolaus B, Panico A, Manca MC, Lama L, Gambacorta A, Maugeri T, Gugliandolo C, Caccamo D (2000) A thermophilic Bacillus isolated from an Eolian shallow hydrothermal vent, able to produce exopolysaccharides. Syst Appl Microbiol 23(3):426–432

Nicolaus B, Kambourova M, Oner ET (2010) Exopolysaccharides from extremophiles: from fundamentals to biotechnology. Environ Technol 31(10):1145–1158

Paramonov NA, Parolis LA, Parolis H, Boán IF, Antón J, Rodríguez-Valera F (1998) The structure of the exocellular polysaccharide produced by the archaeon Haloferax gibbonsii. Carbohydr Res 309(1):89–94

Parolis H, Parolis LA, Boán IF, Rodríguez-Valera F, Widmalm G, Manca MC, Jansson PE, Sutherland IW (1996) The structure of the exopolysaccharide produced by the halophilic Archaeon Haloferax mediterranei strain R4 (ATCC 33500). Carbohydr Res 295:147–156

Poli A, Kazak H, Gürleyendağ B, Tommonaro G, Pieretti G, Toksoy Öner E, Nicolaus B (2009) High level synthesis of levan by a novel Halomonas species growing on defined media. Carbohydr Polym 78(4):651–657

Poli A, Anzelmo G, Nicolaus B (2010) Bacterial exopolysaccharides from extreme marine habitats: production, characterization and biological activities. Mar Drugs 8(6):1779–1802

Prieto P, Pineda M, Aguilar M (1999) Spectrophotometric quantitation of antioxidant capacity through the formation of a phosphomolybdenum complex: specific application to the determination of vitamin E. Anal Biochem 269(2):337–341

Priyanka P, Arun AB, Rekha PD (2014) Sulfated exopolysaccharide produced by Labrenzia sp. PRIM-30, characterization and prospective applications. Int J Biol Macromol 69:290–295

Rinker KD, Kelly RM (1996) Growth physiology of the hyperthermophilic archaeon Thermococcus litoralis: development of a sulfur-free defined medium, characterization of an exopolysaccharide, and evidence of biofilm formation. Appl Environ Microbiol 62(12):4478–4485

Saravanan R, Shanmugam A (2010) Isolation and characterization of low molecular weight glycosaminoglycans from marine mollusc Amussium pleuronectus (linne) using chromatography. Appl Biochem Biotechnol 160(3):791–799

Senni K, Pereira J, Gueniche F, Delbarre-Ladrat C, Sinquin C, Ratiskol J, Godeau G, Fischer AM, Helley D, Colliec-Jouault S (2011) Marine polysaccharides: a source of bioactive molecules for cell therapy and tissue engineering. Mar Drugs 9(9):1664–1681

Severina LO, Usenko IA, Plakunov VK (1990) Exopolysaccharide biosynthesis by the extreme halophilic archaebacterium Halobacterium volcanii. Mikrobiologiia 59:437–442

Song YR, Song NE, Kim JH, Nho YC, Baik SH (2011) Exopolysaccharide produced by Bacillus licheniformis strains isolated from Kimchi. J Gen Appl Microbiol 57(3):169–175

Spanò A, Gugliandolo C, Lentini V, Maugeri TL, Anzelmo G, Poli A, Nicolaus B (2013) A novel EPS-producing strain of Bacillus licheniformis isolated from a shallow vent off Panarea Island (Italy). Curr Microbiol 67(1):21–29

Sun ML, Liu SB, Qiao LP, Chen XL, Pang X, Shi M, Zhang XY, Qin QL, Zhou BC, Zhang YZ, Xie BB (2014) A novel exopolysaccharide from deep-sea bacterium Zunongwangia profunda SM-A87: low-cost fermentation, moisture retention, and antioxidant activities. Appl Microbiol Biotechnol 98(17):7437–7445

Sutherland IW (1982) Biosynthesis of microbial exopolysaccharides. Adv Microb Physiol 23:79–150

Sutherland IW (1990) Biotechnology of microbial exopolysaccharides, Cambridge study in Biotechnology, vol 9. Cambridge University Press, Cambridge

Sutherland IW (1999) Polysaccharases in biofilms-source-action-consequences! In: Wingender J, Neu TR, Flemming HC (eds) Microbial extracellular polymeric substances. Springer, Berlin, pp 201–230

Sutherland IW (2001) Biofilm exopolysaccharides: a strong and sticky framework. Microbiology 147(1):3–9

Thanan R, Oikawa S, Hiraku Y, Ohnishi S, Ma N, Pinlaor S, Yongvanit P, Kawanishi S, Murata M (2014) Oxidative stress and its significant roles in neurodegenerative diseases and cancer. Int J Mol Sci 16(1):193–217

Thibodeau A (2005) Protecting the skin from environmental stresses with an exopolysaccharide formulation. Cosmet Toiletries 120:81–86

Van Fossen AL, Lewis DL, Nichols JD, Kelly RM (2008) Polysaccharide degradation and synthesis by extremely thermophilic anaerobes. Ann NY Acad Sci 1125:322–337

Ventosa A, Gutierrez MC, Kamekura M, Dyall-Smith ML (1999) Proposal to transfer Halococcus turkmenicus, Halobacterium trapanicum JCM 9743 and strain GSL-11 to Haloterrigena turkmenica gen. nov., comb. nov. Int J Syst Bacteriol 49(1):131–136

Acknowledgments

The authors gratefully acknowledge the Integrated Microscopy Facility of the Institute of Genetics and Biophysics, CNR, Naples, in particular, Dr. Rosarita Tatè.

Conflict of interest

The authors declare that they have no competing interests.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Squillaci, G., Finamore, R., Diana, P. et al. Production and properties of an exopolysaccharide synthesized by the extreme halophilic archaeon Haloterrigena turkmenica . Appl Microbiol Biotechnol 100, 613–623 (2016). https://doi.org/10.1007/s00253-015-6991-5

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00253-015-6991-5