Abstract

A domestic cookie baking process was modeled using nonlinear forward and inverse models to predict surface temperature, moisture content and browning index that describe the baking quality of the end product. The baking processes were carried out at different oven temperatures (160, 180, 200 °C) and the changes in surface temperature, moisture content and browning index were determined to construct the identification models namely nonlinear polynomial models (PLN) and nonlinear artificial-neural network (ANN) model. The parameters of the artificial models were optimized using least-squares estimation and Levenberg-Marquardt optimization, respectively. The predicted baking characteristics in both forward and inverse phases were in good agreement with the measured ones even for the browning index which was difficult to model because of the its nonminimum-phase dynamics. The application results indicated that the developed intelligient models were very accurate, having low root mean-squared errors, the ANN model approximated the desired values better than the PLN models for all the state variables. Thus, the designed ANN models are applicable for the automatized industrial and domestic oven designs of the future.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

1 Introduction

Baking process can be considered as a simultaneous heat and mass transfer process where physical changes and highly complex chemical reactions occur in the food product. Convective ovens are widely used for domestic baking purposes and also in the food industry. In a convective oven, heat is transferred to the baking material by convection, conduction and radiation, and simultaneously the moisture in the food diffuses toward the surfaces, then it is removed from the surface by convection [1]. During baking, food materials undergo changes in structure, taste, size, moisture content and color. It is known that surface color is the first property affecting consumer appreciation on baked products. The color of the surface becomes an important factor in determining the acceptability of the product and directly affects the intention of the purchase [2]. Browning index is a useful variable that is defined to express the color change on the surface resulting from caramelization and Maillard reactions [3]. Few researchers modeled the browning of different sweet baked products. [4] proposed a kinetic model in order to predict lightness variation during cracker baking, [5] analyzed the effects of water activity and temperature on browning kinetics of biscuit baking, and [6] suggested a kinetic model for both browning index and acrylamide formation during baking process of cookies in different type domestic ovens. The Maillard reaction is important for development of surface color and flavor, but may also be related to the formation of toxic compounds such as acrylamide [2]. Acrylamide is defined as a potential carcinogenic, reprotoxic and neurotoxic contaminant for humans and usually formed during the heat treatment of starch-rich foods at temperatures above 120 °C in the presence of asparagine [7]. The Maillard reaction, which is the main pathway for acrylamide formation in foods, depends on temperature, pH, moisture content, the presence of metallic cations and the type of sugar. In particular, the reaction is accelerated at medium moisture level and at high temperature [8]. [9] stated that there is a strong relationship between the development of surface color of baked products and acrylamide formation. Accordingly, it is thought that the moisture content and temperature, as well as the browning on the product surface during the baking process might be useful in predicting acrylamide formation. Therefore, the moisture content, surface temperature and browning index were chosen as the state variables in this study.

So far, various conventional methods such as analytical method, numerical methods with finite difference and finite element simulations, and regression methods have been widely used for the modeling of baking processes which are principally heat and mass transfer problems. However, it is difficult to use a standard partial differential equation or model to accurately describe the baking operation because of the complicated thermo-physical properties of foods and uncertainties during processing. Hence, an artificial intelligent model is an alternative and promising tool to overcome these problems and it is widely utilized in nonlinear function approximation [10,11,12,13].

Artificial neural networks (ANN) are one of the popular machine learning methods that provide the empirical solution to the problems from a set of experimental data, and are capable of handling complex systems such as baking processes with nonlinearities and interactions between decision variables [14]. In literature, linear and nonlinear identification methods are developed for modeling of the industrial processes where polynomial models, artificial neural-networks, fuzzy logic systems, extreme learning machines, support vector machines and etc. are often used for nonlinear modeling [15, 16]. Since the physico-chemical changes during the baking process are not completely identified, the ANN modeling is an appropriate model to relate the oven conditions with quality attributes without requiring prior knowledge on the mechanisms involved in the process [17]. Thus, the machine learning methos can eliminate the inflexibility of the baking processes which are complex operations, especially when baking a different type of product in a given oven or baking a given product in a different type of oven [7]. Artificial intelligence modeling has been successfully applied to the heat and mass transfer problems such as predicting heat transfer coefficients in end-over-end processing of cans [18], predicting of porosity during air-drying of some fruits [19], modeling and control of a food extrusion process [20], dynamic modeling of retort processing [21], modeling and optimization of flat bread baking [17], modeling of the hardening process for Swiss-type cheese [22], modeling of the heat and mass transfer during drying of mango and cassava [23], predicting the moisture content during grain drying process [24] and modeling and predicting the moisture content, antioxidant capacity and anthocyanin of mahaleb puree [15].

In the present paper, discrete-time nonlinear input-output identification models which are nonlinear polynomial models (PLN) and nonlinear artificial-neural network (ANN) model proposed and designed for the modeling of a domestic cookie baking process in forward and inverse phases. For this purpose, cookies were baked at three different oven temperatures in a conventional domestic oven and the samples were taken out at certain time intervals to determine the moisture content and browning index. Furthermore, the time-temperature history at the top surface of the cookies was obtained during the whole baking period. Then, the artificial models are optimized in off-line sense using least-squares estimation and Levenberg-Marquardt optimization. Consequently, in order to show the modeling accuracies, root-mean squared error (RMSE) criterion is used to test and compare the designed models.

2 Materials and methods

2.1 Materials

The cookies were prepared by mixing 500 g of ready dry cookie mixture (Dr. Oetker), 50 g of homogenized eggs and 175 g of vegetable margarine. The ready cookie mixture was composed of wheat flour, sugar, baking powder and starch. All the commercial ingredients were brought together for ∼10 min by hand kneading to obtain the cookie dough. Then, the cookie dough was rolled into a layer of 1 cm thickness by a roller, and cut by a circular aluminum cookie cutter with a diameter of 5 cm. The initial moisture content of the cookie dough was 19–20%.

2.2 Baking tests

Baking experiments were carried out in a domestic convectional oven (Grundig GEBM 13000X) having 53 L cooking chamber. The prepared dough was placed on the enameled steel tray with a total of 3 pieces and the tray was placed in the middle compartment of the oven. Baking experiments were performed at three different temperatures of 160, 180 and 200 °C and natural convection conditions with upper and lower resistances on. The total baking time was set to 40 min for all oven temperatures and the baking processes were completed in 2 min periods. As the opening of the oven door to sampling had a negative effect on the baking process, the same amount of cookies was prepared using fresh dough for each time interval and successive baking test was performed. Thus, the baking conditions were kept constant by providing the same oven load in each baking process. For all the tests, the oven was preheated until reaching the constant preset temperature.

2.3 Temperature measurement

Surface temperature of the cookies was measured using K-type thermocouple (wire diameter: 1.5 mm) and recorded with a data logger (Testo, 176-T4) every 1 min during the baking tests. The thermocouple was positioned at the top surface of the cookie and fixed to the edge of the tray with the help of a fire resistant sticky tape.

2.4 Moisture content

The moisture content of the cookies were determined using an infrared moisture analyzer (Shimadzu, MOC 63u, Japan) at 130 °C and the results were validated by the standard oven method. The samples were crushed into small pieces using a ceramic mortar before the measurements.

2.5 Browning index

The surface color measurements of the cookie samples were carried out with 3NH Colorimeter NR-200 (Chinese), and CIE L∗,a∗ and b∗ values were detected with 4 parallel readings at each cookie. The browning index (BI value) was calculated as

where, \( {a}_t^{\ast } \),\( {b}_t^{\ast } \) and \( {L}_t^{\ast } \) are the color values at a definite time (t) of baking [25].

3 Artificial modeling of cookie baking process

The modeling of the cookie baking process is achieved in terms of forward and inverse phases. Forward modeling means that the designed models predicts the future output values of the system with respect to system inputs. The cookie baking process is assumed that it has time input and three outputs surface temperature, moisture content and browning index. Therefore, in the forward models, the inputs are the functions of the time, however the output is the state variable of the cooking baking process. Forward models can be written as follows.

where \( \hat{x}(k) \) is the predicted output state variable, fforward(.) is the designed nonlinear artificial model, k is the time variable, n is the delay of the time variable. By doing so the future values of the variable can be predicted at any time instant. In case of different, initial conditions and temperatures, another input variables can be added as the inputs of the model.

On the other hand, inverse modeling accepts the state variables as in functional form, however the time variable is predicted to corresponding inputs. Inverse model can be functioned as follows.

where \( \hat{k} \) is the predicted time variable, finverse(.) is the designed nonlinear inverse model, xk is the state variable, n is the delay of the state variable. By using the inverse models, any future values of the time variable can be predicted at any desired value of the states. Similarly here, the initial condition and temperature are assumed same, if not, they can be also added as one of the input parameters in the nonlinear regressor models.

3.1 Polynomial Regressor model

The nonlinear polynomial regressor model (PLN) is designed for forward modeling as follows.

where the \( \hat{x} \) is the approximated state output, \( {\hat{\theta}}_{i,j} \) is the parameter or weighting factors of the inputs. The n represents the order of the polynomial, m is the largest delay of the inputs. \( \hat{x} \) can be any state of the cookie baking process. For instance, when the m = n = 2, then model becomes as

where θij indices are simplified to prevent misunderstanding. The inverse polynomial regressor model is designed as

where the\( \hat{k} \)is the approximated time output, \( {\hat{\theta}}_{i,j} \) is the parameters. The \( \hat{\theta} \) parameters are estimated using the least-squares estimation which is explained later.

3.2 Artificial neural-network

In this section, the state variables or the outputs of the cookie baking process are modeled as in nonlinear static function using artificial neural networks (ANN). So that each state has been represented as a function of previous states with one neural-network model. The state vector is considered as directly output of the neural-networks as follows.

The \( {\hat{x}}_k \) are approximated or predicted outputs for the forward model that is one of the temperature, moisture content and browning index, respectively. The k, k − 1, , k − n are the time indices. The \( \hat{k} \) is the predicted time variable for the inverse model. The designed artificial neural networks are independent models for each state.

The ANNs are basically inspired by the neuron models and learned by human learning mechanisms that are used for nonlinear function mapping. Therefore, according to function approximation theorem of neural networks, by using the enough number of neurons and hidden layers, any linear and nonlinear function can be approximated. A one hidden layer, multi-input multi-output artificial neural network with H number of neuron is shown in Fig. 1. In implicit form, the ANN model in Fig. 1 can be formulated as

where the wi, i = 0, 1 parameter matrices and the b1 parameter vector are to be optimized for regression. The wo andw1 are the output-layer and input-layer weighting matrices, respectively. The b1 is hidden layer bias values. The bias values were used to prevent the sleeping of the neurons. The ϕ(.) is an activation function of a neuron in a layer. In this paper, sigmoid function,

was used as an activation function of the neurons. They were optimized by Levenberg-Marquardt (LM) optimization in off-line sense. The LM optimization is a nonlinear least-squares and gradient-based method and one of the fastest optimization methods which is given in detail [26].

It is important to notice that two models are designed and applied for the modeling of the cookie baking process. A linear auto-regressive with exogenous (ARX) model and nonlinear support vector machine (SVM) could be designed. The linear ARX model is not employed since the data are nonlinear and have nonminimum phase dynamics. In addition, from our previous study [15], we have seen that ANN model is preferable compared to the SVM model for the less number of data.

3.3 Optimization of nonlinear models

The parameters of the nonlinear regressor models can be trained in off-line sense. They are constructed as casual models and the parameters are conventionally estimated using linear and nonlinear least-squares methods.

3.3.1 Least-squares estimation of polynomial models

Though the polynomial models are nonlinear, they are in linear-in-parameters form. Therefore, for off-line sense, least-squares estimation method can be used to optimize its parameters. Assume that a model output is calculated as \( \hat{y}(k)=\boldsymbol{\phi} {(k)}^T\hat{\boldsymbol{\theta}} \) where ϕ(k) is the regressor matrix and \( \hat{\boldsymbol{\theta}} \) is the parameter vector. Then using least-squares estimation as

where y is the system output to optimize model parameters and also ϕ is the regressor matrix that is found using training inputs from the system. The least-squares optimization is one of the optimal unbiased estimators for linear estimation problems.

3.3.2 Levenberg-Marquardt optimization of neural-networks

The parameters of the designed neural-networks are trained or optimized using well-known conventional Levenberg-Marquardt optimization. It is a gradient-based off-line optimization method. Instead of applying true inverse Hessian matrix, LM employees the approximate Hessian approach. Its parameter adaptation is given as follows.

where \( \hat{\boldsymbol{\theta}}(k) \) is the complete parameter vector, e(k) is the identification error vector, J(k) is the Jacobian matrix of the output with respect to each parameter, μ is the regularization parameter of the LM method to guarantee the batch error performance. I is an identity matrix in the dimension of parameter vector.

3.4 Performance criterion and data preprocessing

In order to test the model performance, testing inputs are used to find the regressor matrix for testing part. Then, using estimated \( \hat{\boldsymbol{\theta}} \) parameters, testing approximation outputs can be estimated. To see the performance of the model compared to system outputs, root-mean squared error criterion (RMSE) can be used as

where N is the total number of the data and \( \hat{e}(k)=y(k)-\hat{y}(k) \) is the identification error of kth index. The input-output dataset is normalized to small scales for the forward and inverse modeling since neural-networks do not work with large values. The normalization of a x(k) variable between [−β, β] is performed as

where β is the normalization scale. xmin and xmax are the minimum and maximum values of the x variable. Normalization process is performed before applying the inputs to the nonlinear models. Therefore, the predictions are obtained in normalized scale. In order to calculate the RMSE performances and show the prediction results in real space, the predictions are denormalized to the original scale as

In this study, the dataset is first normalized to [−1, 1] interval.

4 Computational results and discussion

The baking is a complex process resulting in a number of physical, chemical and biochemical changes such as volume expansion, water evaporation, formation of a porous structure, denaturation of the protein, gelatinization of starch, crust formation and browning reaction [27]. In particular, the browning degree is very important to define the acceptance of the baked foods by the consumer as well as the flavor of the final product. It can also be used to determine the degree of completion of the baking process, since the color development takes place substantially in the final stages of the baking [5]. A wide range of quality changes during baking and potential interactions between the process parameters (i.e. time, temperature, air velocity, relative humidity) make difficult to control the operation by the user. From this point of view, the product quality can be estimated by artificial modeling without a priori putting forward hypotheses on the underlying physico-chemical mechanisms involved.

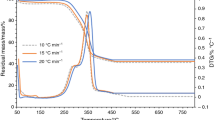

From the experimental cookie baking process, the state variables, which are temperature, moisture content and browning index, were measured in time and the collected data from the experiments are shown in Fig. 2 (a), (b) and (c), respectively. The state variables dynamically change when the heating is continued and the baking process was ended in two-minute periods. It is seen in Fig. 2(c) that the browning index has nonlinear and nonminimum phase dynamics. Practically nonminimum phase dynamics mean that even though the input variable is increased and applied in the right direction, the observed output first goes to the inverse direction then comes back to the right direction. This property makes difficult to model a nonlinear process. In the following subsections, the forward and inverse modeling results are demonstrated and performance results are given using MATLAB environment. For completeness of the identification models, the measured data is used for modeling where 60% of dataset is used for training and 40% of dataset is used for testing the models. Even though both models are applied for modeling, due to the better modeling results of ANN, its identification results are plotted in the figures.

4.1 Forward modeling of baking process

Figure 3 shows the artificial neural-network based forward modeling of the cookie baking process. The predicted surface temperature profile of the cookies identified at different oven temperatures is seen in Fig. 3(a). Known from the Fig. 3(a) that the behavior of the surface temperature has a nonlinear behavior with oscillations. The ANN model approximates well the surface temperature at low oven temperatures in early stages of baking. Besides, much oscillations were observed at the high surface temperatures, so the ANN model did not catch the all oscillating behavior. Therefore, the RMSE performances were obtained relatively large compared to other forward modeling results where its RMSE performances can be seen in Table 1.

The forward moisture content modeling results are illustrated in Fig. 3(b) at different oven temperatures. The moisture change has a nonlinear behavior with relatively easy characteristics. It has a similar behavior with exponential decay. The oven temperature changes the speed of the decay function. The decline in the tangent of the surface temperature between 10 and 15 min directly affects the change in moisture content. Therefore, there exist large errors in the approximations.

Figure 3(c) presents the forward modeling of the browning index at different oven temperatures. From modeling point of view, the nonlinear and nonminimum phase behavior of the data set is the most difficult to approximate for approximation models. As seen from the results, the modeling of browning index is much accurate at low oven temperature. However, it is not so good at high oven temperatures. The high oven temperature causes oscillating and more nonlinear behavior of the baking dynamics. In fact, this results are very important for the standardization of the baked cookies. The last columns of Table 1 shows the RMSE performance of the designed models for browning index.

In the design of neural-networks, the number of the neurons and training epoch are very important for a qualified model. To define optimal number of the neurons, validation set of the data is required. Since it is known that using much number of the neurons and too much training of the neural-network are not good for the generalization performance of the neural-networks. For our experiments, it is evidently seen that the difficulty of the data brings a relevant number of the hidden-layer neurons. For the modeling of the surface temperature, the best number of the neurons are found as 9 for the best modeling performance. There exist small oscillations on the data that needs a few neurons to solve it. But, for the modeling of the moisture content, its behavior is very smooth and monotone decreasing. Therefore, there is determined that 3 neurons are the best number of the network for such a good performance. The last data, browning index, is the relatively difficult data due to its nonlinear and nonminumum phase dynamics. Therefore, to solve this inverse dynamics, there is determined that 30 neurons are needed in the neural-network. With these number of the neurons, accurate results are obtained which are seen in the application results in Fig. 3.

4.2 Inverse modeling of cookie baking process

Remember that the modeling of a nonlinear process provides to user a functional relationship or computational model between inputs and outputs. Therefore, we had time inputs to predict the surface temperature, moisture content and browning index as the outputs in the forward modeling. In this section, inverse modeling can be described as the prediction of required time for baking with respect to desired moisture content and browning index. It means that construction of a computational nonlinear model imitate inverse functional of the cookie baking process. The inverse model directly calculates the required time for the given or preferred cookie properties. This property will help to automatize and standardize the domestic and industrial ovens which is the main goal of this paper. The behavior of the collected input-output data is more suitable for forward modeling since the real-time system integrates the outputs via a differential equation with time dependency. But inverse modeling forces to model its inverse behavior. Therefore, the inverse modeling is not an easy task compared to the forward modeling.

For the polynomial modeling, after several modeling experiments, the best regressor function is determined as ϕ(k) = [1 x(k − 1) x(k − 1)2 x(k − 1)3]T. For the neural-network design, 30 neurons are employed in the hidden-layer. To improve the inverse modeling performances, a feature extraction layer is used for the inputs. Three cases are considered for inverse modeling. In those cases, the moisture content and browning index are considered as the preferable properties of the cookies after baking process. Therefore, surface temperature is not used as the input of the inverse models.

- Case 1:

Preferred moisture predicts baking time

The inverse model is constructed again using polynomial model and artificial neural networks. The input of the nonlinear models are used preferred moisture content of the cookies. Then, the required time duration for the given moisture content is predicted using nonlinear models. Consider that the x2(k) (preferred moisture) and in order to improve the inverse model performance, the input is passed through a feature selection layer given as \( \left[{x}_2(k)\sqrt{0.1{x}_2(k)}\ \mathit{\sin}\left(2{x}_2(k)\right)\right] \) then features are used as the inputs of the nonlinear models. Figure 4 shows the artificial neural-networks based inverse identification results for the moisture content. Due to the moisture characteristics, the inverse model can accurately be designed and time output is predicted with very small errors at different temperatures. Table 2 presents the corresponding RMSE results. At low oven temperature, very small errors of time predictions are obtained. At the highest oven temperature, 0.495 min of prediction error is obtained.

- Case 2:

Preferred browning index predicts baking time

Consider in this case that the x3(k) (preferred browning index) and the inverse modeling performance of the nonlinear models are enhanced using the feature selection layer given as \( \left[{x}_3{(k)}^2\ {e}^{-0.1{x}_3(k)}\ \mathit{\sin}\left(0.5{x}_3(k)\right)\right] \). Then these features are used as the inputs of the nonlinear inverse models. Figure 5 shows the artificial neural-networks based inverse identification results and the RMSE performances are given in Table 2. We know that the browning index has nonminimum phase dynamics, therefore forward modeling results have relatively large prediction errors when oven temperature is increased. For the inverse modeling, the time prediction errors are also relatively large; however in this case, when the oven temperature increases the modeling performance is increased and the prediction errors are decreased.

- Case 3:

Preferred moisture and browning index together predicts baking time

In the last case, the inverse models are constructed based on the moisture content and browning index. To visualize the results, both inputs and output are plotted in the three dimensional plot seen in Fig. 6. The feature extraction layer is designed as \( \left[{x}_3{(k)}^2{e}^{-0.2{x}_1(k)}\ \mathit{\sin}\left(0.5{x}_2(k)\right)\right] \) where x2(k): preferred moisture content and x3(k): preferred browning index. The obtained inverse models predicts required time accurately for all the oven temperatures. The RMSE performance results are given in Table 2. The models can produce time predictions according to correlated moisture and browning index values. However, if there is applied low moisture content and low browning index values as the inputs of the inverse models, the inverse models can not produce true time predictions, since these input values are physically not occur together.

5 Conclusion

In this paper, surface temperature, moisture and browning index of cookies are assumed as the state variables and used for the modeling by machine learning based nonlinear polynomial (PLN) and artificial-neural network (ANN) models in forward and inverse phases. For the both phases, the ANN model approximated the desired values better than the PLN models for all the state variables. The best number of the neurons were found as 9, 3 and 30 for the surface temperature, moisture content and browning index, respectively. Three different cases were considered for inverse modeling which directly calculates the required time for the preferred moisture content and browning index. The computational results showed that the proposed ANN model predicted well the selected quality characteristics of the cookie for the inverse phase which might give a more useful information to the operator and would help to standardize the products. Therefore, the designed ANN models can be embedded to the automatized industrial and domestic ovens in the future.

References

Özilgen M, Heil J (1994) Mathematical modeling of transient heat and mass transport in a baking biscuit. Journal of food processing and preservation 18(2):133–148

Ahrné L, Andersson C-G, Floberg P, Rosén J, Lingnert H (2007) Effect of crust temperature and water content on acrylamide formation during baking of white bread: steam and falling temperature baking. LWT-Food Scie Technol 40(10):1708–1715

Ureta MM, Olivera DF, Salvadori VO (2014) Quality attributes of muffins: Effect of baking operative conditions. Food and Bioprocess Technology 7(2):463–470

Broyart B, Trystram G, Duquenoy A (1998) Predicting colour kinetics during cracker baking. J Food Eng 35(3):351–368

Sandra Mundt and Bronislaw L Wedzicha. A kinetic model for browning in the baking of biscuits: effects of water activity and temperature. LWT-Food Sci Technol, 40(6):1078–1082, 2007

Isleroglu H, Kemerli T, Sakin-Yilmazer M, Guven G, Ozdestan O, Uren A, Kaymak-Ertekin F (2012) Effect of steam baking on acrylamide formation and browning kinetics of cookies. J Food Sci 77(10):E257–E263

Broyart B, Trystram G (2003) Modelling of heat and mass transfer phenomena and quality changes during continuous biscuit baking using both deductive and inductive (neural network) modelling principles. Food Bioprod Process 81(4):316–326

Hogervorst JGF, Van Den Brandt PA, Godschalk RWL, van Schooten F-J, Schouten LJ (2016) The influence of single nucleotide polymorphisms on the association between dietary acrylamide intake and endometrial cancer risk. Scie Rep 6:34902

Fennema OW (1993) Quimica de los alimentos. Editorial Acribia, S. A

Chen CR, Ramaswamy HS, Marcotte M (2007) Neural network applications in heat and mass transfer operations in food processing. WIT Trans State-of-the-art in Sci Eng 13:39–59

Shahpour Jahedi Rad, Mohammad Kaveh, Vali Rasooli Sharabiani, and Ebrahim Taghinezhad. Fuzzy logic, artificial neural network and mathematical model for prediction of white mulberry drying kinetics. Heat Mass Transf, 54(11):3361–3374, Nov 2018

Alam MA, Saha CK, Alam MM, Ashraf MA, Bala BK, Harvey J Neural network modeling of drying of rice in bau-str dryer. Heat Mass Transf 54(11):3297–3305 Nov 2018

Çebi A, Akdoğan E, Celen A, Dalkilic AS (Feb 2017) Prediction of friction factor of pure water flowing inside vertical smooth and microfin tubes by using artificial neural networks. Heat Mass Transf 53(2):673–685

Ljung L (1999) System identification theory for the user. Prentice Hall PTR

Isleroglu H, Beyhan S (2018) Intelligent models based nonlinear modeling for infrared drying of mahaleb puree. J Food Process Eng 41(8):e12912

Beyhan S, Kavaklioglu K (2015) Comprehensive modeling of u-tube steam generators using extreme learning machines. IEEE Trans Nucl Sci 62(5):2245–2254

Banooni S, Hosseinalipour SM, Mujumdar AS, Taherkhani P, Bahiraei M (2009) Baking of flat bread in an impingement oven: modeling and optimization. Dry Technol 27(1):103–112

Sablani SS, Ramaswamy HS, Sreekanth S, Prasher SO (1997) Neural network modeling of heat transfer to liquid particle mixtures in cans subjected to end-over-end processing. Food Res Int 30(2):105–116

Hussain MA, Shafiur M (2002) Rahman, and CW Ng. Prediction of pores formation (porosity) in foods during drying: generic models by the use of hybrid neural network. J Food Eng 51(3):239–248

Popescu O, Popescu DC, Wilder J, Karwe MV (2001) A new approach to modeling and control of a food extrusion process using artificial neural network and an expert system. J Food Process Eng 24(1):17–36

Chen CR, Ramaswamy HS, Prasher SO (2002) Dynamic modeling of retort processing using neural networks. Journal of Food Processing and Preservation 26(2):91–111

Vasquez N, Magin C, Oblitas J, Chuquizuta T, Avila-George H, Castro W (2018) Comparison between artificial neural network and partial least squares regression models for hardness modeling during the ripening process of swiss-type cheese using spectral profiles. J Food Eng 219:8–15

Hernández JA (2009) Optimum operating conditions for heat and mass transfer in food stuffs drying by means of neural network inverse. Food Control 20(4):435–438

Liu X, Chen X, Wu W, Peng G (2007) A neural network for predicting moisture content of grain drying process using genetic algorithm. Food Control 18(8):928–933

Dadalı G (2007) Dilek Kılıç Apar, and Belma Özbek. Color change kinetics of okra undergoing microwave drying. Dry Technol 25(5):925–936

Scales LE (1985) Introduction to non-linear optimization. Springer-Verlag New York, Inc.

Purlis E, Salvadori VO (2009) Bread baking as a moving boundary problem. part 1: mathematical modelling. Journal of Food Engineering 91(3):428–433

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

On behalf of all authors, the corresponding author states that there is no conflict of interest.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Isleroglu, H., Beyhan, S. Prediction of baking quality using machine learning based intelligent models. Heat Mass Transfer 56, 2045–2055 (2020). https://doi.org/10.1007/s00231-020-02837-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00231-020-02837-6