Abstract

In this paper, the sand casting process was evaluated using ProCAST simulating software and practical experience for manufacturing of the high chromium stainless steel outlet diaphragms used in iron ore ball mill. In the simulation practice, the effects of feeding and gating designs on the liquid flow, heat transfer and solidification phenomenon were evaluated to minimize the liquid surface turbulence during filling of the mold cavity and the shrinkage porosity formation during the liquid solidification in the mold. The effects of different gating ratios and number of feeders were numerically studied using different indicators in the software such as linear velocity, niyama criteria, fraction solid and shrinkage porosity. Further, the optimal design obtained by simulating process was empirically examined. The simulation results showed that the 1:3:4 gating ratio is the proper gating system that it obtains an unpressurized fluid flow without any surface turbulent of the liquid steel in the filling step. In addition, the simulation of solidification phenomenon was indicated that four feeders are required to eliminate of the shrinkage porosities. The empirical casting examination shown the optimal design by the simulation is proper for manufacturing of the steel part without critical defects.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

Casting is the exclusive process for manufacturing of the complex steel parts. Contrary to the simple appearance, designing of the process is extremely complex for the production of high performance components. Many of casting parameters have significantly effects on the appearance of different defects and variations of mechanical properties. The chemical composition, size and shape of cast parts, it’s molding and melting technologies are key parameters for casting design. Nevertheless, all casting process have concluded two main experiences or concepts: filling and feeding [1, 2]. In the filling practice (according to fluid dynamics of liquid metals), the gating system composed of sprue, runner and gates, is designed to guide the liquid metal for whole filling of mold cavity with a proper velocity, lowest surface turbulent and in a short period [3]. On the other hand, in the feeding practice (according to the heat transfer and mold dynamics), the feeder (or riser) is designed for compensation of the contraction of the liquid metal in mold cavity that takes place on freezing and solidification in order to prevention of the shrinkage defects. The feeding is the long and slow process that takes minutes or hours depending on the size of the casting part. Therefore many of the casting defects such as film oxides, non-metallic inclusion, gas porosities, shrinkage porosities and hot tears can be related to pouring and solidification conditions of the liquid metal in the mold cavity [4].

Nowadays, with the development of computer science technology, it is possible to solve and predict many problems in the casting processes. These improvements save time and money, as well as provide the optimal design for casting. Generally, foundries usually optimize casting process depending on experiences. However, it is difficult to know the metal flow and temperature distribution during mold filling and solidification, which are undoubtedly important to obtaining high quality castings. For this reason, to select a production method of a casting part had to test in different methods and design for choosing an appropriate production method. In fact, this continuous operation is called trial and error, in practical condition; it will cause loss of money, materials, time and energy. But, by using simulation techniques for optimization casting conditions, it is possible for a specific casting part the simulations run to be performed at the least amount of time, cost, and energy to select the optimal design [5,6,7].

A number of casting simulation programs is available today, such as MAGMA, NovaCAST, ProCAST, SUTCAST and SolidCAST. The simulation ProCAST software by solving equations based on finite element method (FEM), will be able to solve complex geometries and allows the user to simulate heat transfer [8], fluid flow [9], stress conditions [10], microstructure [11] and shrinkage porosity [12, 13]. There have been researches in this field, Wang et al. [14], use the niyama criteria for Shrinkage porosity and optimized design of a large forging steel ingot, Li et al. [15], prediction of micro porosity defect in sand cast magnesium alloy by using ProCAST result. Sabau [16], evaluation the shrinkage porosities of step block in investment casting A356 alloy. Panchal et al. [17], studied on design of gating system for casting of ball valves with numerical simulation and could increase the casting yield by 8%.

In this study, a casting process is carried out followed by through ProCAST simulation in combination with the experimental of outlet diaphragms used in iron ore ball mill. The main objectives of the present work are: a) to effect of position and number of feeder and evaluation of these designs in numerical simulation and experimental condition. b). to compare ProCAST results such as solid phase fraction percentage, shrinkage porosity and niyama criterion to experimental results c) to analyze whether effect on melt flow behavior in different gating system ratios were simulated by ProCAST software, d) to evaluate the new concept in gating design developed by Prof. John Campbell (unpressurized gating system for controlling of surface turbulence of the liquid metal) [1, 2].

2 Experimental

2.1 Materials and characterization

Figure 1 shows a used outlet diaphragm and inner image from outlet diaphragms network in iron ore ball mill (during productivity maintenance (PM) at Golgohar Mining and Industrial Company in Iran). The low carbon-high chromium steel (called FMU 27) was used for production of the outlet diaphragms. Table 1 presents the chemical composition of FMU 27.

The steelmaking was performed in 1000 kg high frequency induction furnace accordance. Molding and casting was performed using the silica sand and silicate sodium as binder (called CO2 sand). The pouring of the liquid steel was performed at 1620 °C in 7 s.

2.2 Feeder design

In this study, the number and position of feeders in the casting process were selected for simulation of solidification and predication of shrinkage cavities. Figure 2 shows the scheme of outlet diaphragms of iron ore ball mill according to the number and position of feeder (designs of W1 and W2). The first part designed with two feeders (W1) (preliminary design) and the second part designed with four feeders (W2). The dimensions and sizes of feeders were constant and equal in both parts. Weight of each part (with feeders) in order for W1 was 164 kg and W2 was 201 kg.

2.3 Gating system design

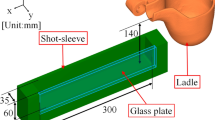

In the another part of this research, the effect of different gating systems ratios on the fluid dynamics of molten metal and the condition of filling the mold were investigated. Figure 3 shows the X part was designed in defferent gating system ratios. For this purpose, four different gating systems ratios were used. The bottom gating system was selected for all of designs. In the each design, the certain proportion between the cross sections of the components of a gating system (called SRG ration) was used for the gating design. The smallest cross-section in a gating system is called a Chock that determines the filling time. Table 2, shows the SRG ratios were used in this research. For designing of gating system, relationships (1), (2) and (3) were used to calculate the dimensions of the system [4].

2.4 Numerical simulation

The mold filling and solidification processes have been simulated using the ProCAST 2016 software. The Details of the numerical model are shown in Table 3. Input mesh data, step number and time step provided for W1 and W2 models. Step number Specifies the number of time steps to take in the current run and ProCAST will terminate the run when it reaches this limit. Time step consists of 3 steps, the initial time step size, the maximum time step size (which will be used during the filling stage only) and the maximum time step size. In this research, their value was determined by the software default 0.001, 0.1 and 1, respectively.

The main inputs including the part design, feeders, and gating system, thermo-physical properties of material such as; density, specific heat, and thermal conductivity, description of boundary conditions and import of process parameters such as pouring rate, time and temperature. Figure 4 shows the geometry and boundary conditions of the model were used in this study. The finite element mesh of the mold (30 mm) and part (10 mm) and feeders and gating systems (15 mm) were selected. The mesh was selected based on several mesh refinements. The casting parameters were the same as those in the simulation. As it can be seen, sleeves were assigned over the molten metal surface at the hot top. Other information and simulation related parameters are shown in Table 4.

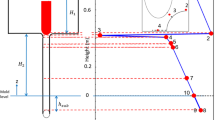

In ProCAST user manual, to analyze the porosity in a casting, several options are available: Temperature field with the cut-off option, fraction of solid field with the cut-off option, shrinkage porosity field, niyama criteria, hot spot and Specific RGL criteria. The RGL function is able to calculate the solidification rate (R), the temperature gradient (G) and the cooling rate (L). In ProCAST, there are ways to combine the R, G and L variables together so as to obtain a combined criterion function (called Mapping factor) as follows. The values of the coefficients a = 1, b = 0, c = 1 and d = −0.5 were considered [14, 19]:

For calculation of the niyama criterion, suggested values are [18]:

3 Result and discussion

3.1 Solidification evaluation

Figure 5 shows the filling and solidification sequences of the W1 part with the melt flow rate of 25 kg/s. The pictures demonstrate the filling and solidification process. In the thermal simulation, solidification starts from the edges and sharp corners and moves towards the center of the part, and finally the solidification ends in the feeding. Use of insulation around the feeders and the addition of exothermic materials at the top of the feeder were considered for the formation of directed solidification. The simulation time for W1 5666 s. and W2 6197 s. were obtained.

One of the parameters for evaluating the porosity location is the percentage of solid phase fraction. The fraction of solid and liquid metal in the mushy zone is a function of time and temperature [20]. In Fig. 6, this criterion represents the percentage of solid phase formation with decreasing temperature. As shown in this figure, the area shown with the black arrow is related to the presence of feeders, and the areas shown with the blue strip in the W1 are related to the formation of hot areas. As seen, hot areas are formed in areas that are far from the feeders and then the feeding operation in those areas is not well done. It is anticipated, leads to a delay in solidification and creating shrinkage porosity at these points [21]. In W1 part it is expected that these problems will be overcome by adding feeders.

Figure 7 shows the results of the shrinkage porosity, niyama and temperature gradient criterions for models. In shrinkage porosity criterion pictures, the probable areas with their probability of formation are shown. As shown in the figure, the formation areas of porosity with probability 3% are specified. The results of the porosity criterion are equal to the results of the solid phase fraction percentage and indicates that the probable hot areas are prone sources for forming shrinkage porosity [1]. The niyama criterion according to Eq. (10) is defined as the local thermal gradient divided by the square root of the local cooling rate [14, 22]:

The niyama criterion is measured near the end of solidification, when shrinkage porosities form. The choice of niyama evaluation temperature can significantly influence the resulting niyama values. When the constant temperature is low, the heat transfer or gradient temperature is decreases and so probability of formation the shrinkage porosity is increases. The constant temperature is dependent on the material and size of the castings.

Figure 8 shows the shrinkage porosity in parts in the practical conditions for W1 part. As shown in the simulation results, in areas where feeders are far away or feeding are not well performed, the shrinkage porosities defects are formed at the surface and below the surface. Therefore, it is expected that these defects will be eliminated by increasing the number of feeders in these regions, which is shown in simulation results that this defect is not observed in W2 part and the probability of formation of shrinkage porosities defects decreases from 40% to less than 2%.

3.2 Gating system evaluation

In the present case, we compare the metal flow simulation results of the parts at different gating systems. One of the requirements for good operation of a gating system is that, the cross section of the sprue, runner and gates should have an appropriate ratio among themselves [2]. This ratio is called gating system ratio and it is expressed as AS: AR: AG. AS is cross section of sprue, AR is cross section of runner and AG is summed cross sections of the gates [23, 24].

The gating systems ratios are divided into two categories: pressure and unpressurized system. If the total level of the cross sections of the gates is less than the cross section of the sprue, the system called pressure system (such as 1: 3: 4 ratio) and if the opposite of the above mode is present, the system called unpressurized. So the cross sections of the gates are high in unpressurized systems [9].

In Fig. 9, shown the results obtained from ProCAST software consist of analyses of the melt speed flow into the mold in Y vector for all ratios. As shown in the images, as the cross sections of the gates are increases, the speeds of the melt are decreases. Also, with increases in cross sections of the gates, the filling state of the molten metal is stable when compared to the other gating systems [25]. Figure 10 shows the disturbance of melt flow with white vector in the mold. The higher density of the vectors shown the more pressure of the molten metal to the walls, which can lead to corrosion, abrasion. With this parameter, melt motion can be optimized in different parts area. In the unpressurized system 1: 3: 4, the molten metal is entering into the mold by four channels, which reduces the vector density in this section, but it is not seen in other systems, especially in pressure systems.

In Table 5, the other results obtained from the simulation of different gating system ratios are shown. The filling time is slightly longer for the casting with the unpressurized ratio gating system. It means that the filling velocity is slower than that of the pressure ratio. The faster filling velocity of the molten metal will increase the gas involvement and nonstationarity and result in porosity defects and surface enters the oxide [2, 24]. Also, in the pressure gating system, there is always a pressure behind the melt, but in unpressurized gating system, the pressure of the melt is taken over at the sprue section. In this case, the gas will not be easily involved in the molten metal, so the porosity defects can be avoided. However, it has been reported that at speeds above 1 (m/s), surface corrosion is observed in the molten metal, which causes the surface enters the oxide to the molten metal.

4 Conclusion

The different gating and feeding designs were evaluated for casting of the high chromium stainless steel outlet diaphragms using ProCAST simulating software. Then, the optimal design was empirically examined. It can be concluded that:

-

1.

ProCAST simulating software is useful for predication of surface turbulence and shrinkage porosities at different gating and feeding designs.

-

2.

The simulation results showed that the unpressurized fluid flow by 1:3:4 gating ratio is the proper gating system that obtains mold filling without any surface turbulent.

-

3.

The simulation of solidification steps was indicated that four feeders are required to eliminate of the shrinkage porosities.

-

4.

The empirically studies indicates that the selected gating and feeding designs has good agreement by the simulation results.

Abbreviations

- Ac:

-

Chock (cm2)

- m :

-

Weight of Steel Part (gr)

- t :

-

Filling Time (s)

- he :

-

Effective Height of Part (cm)

- g :

-

981 (\( \frac{cm}{s^2} \))

- H :

-

Height of Sprue (cm)

- hc :

-

Height of Part (cm)

- S :

-

Thickness of Part (cm)

- G :

-

Weight of Steel Part (gr)

- μ :

-

Casting Factor for Steel (0.3–0.4)

- ρ :

-

Density (\( \frac{gr}{m^3} \))

- Ny :

-

Niyama \( \frac{\sqrt{K. Sec}}{cm.} \)

- G:

-

Temperature Gradient (\( \frac{k}{cm} \))

- L:

-

Cooling Rate

References

Campbell J (2003) Castings, 2nd ed. Butterworth-Heinemann, Oxford

Campbell J (2004) Castings practice: the ten rules of castings. Butterworth-Heinemann [Imprint] Elsevier Science & Technology Books Available via http://worldcat.org. http://public.eblib.com/choice/publicfullrecord.aspx?p=226698

Jezierski J, Dojka R, Janerka K (2018) Optimizing the gating system for steel castings. Metals 8(4):266–279

ASM International (2008) ASM Handbook Volume 15: Casting. ASM International

Bahmani A, Baghani A, Mirbagheri MH, Davami P (2017) Simulation of casting processes. Amirkabir University of Technology, Tehran (in persian)

Chudasama BJ (2013) Solidification analysis and optimization using pro-cast. International Journal of Research in Modern Engineering and Emerging Technology 1(4):9–19

Kotas P, Tutum CC, Thorborg J, Hattel JH (2012) Elimination of hot tears in steel castings by means of solidification pattern optimization. Metall Mater Trans B Process Metall Mater Process Sci 43(3):609–626. https://doi.org/10.1007/s11663-011-9617-z

Zhang L, Tan W, Hu H (2016) Determination of the heat transfer coefficient at the metal–sand mold interface of lost foam casting process. Heat Mass Transf 52(6):1131–1138. https://doi.org/10.1007/s00231-015-1632-1

Wenming J, Zitian F (2014) Gating system optimization of low pressure casting A356 aluminum alloy intake manifold based on numerical simulation. China Foundry Research & Development 11(2):119–124 https://doaj.org/article/041f71a010144dd58d4a2f4214967235

Mingguang W, Yong P (2017) Numerical simulation and analysis of hot cracking in the casting of fork. Rare Metal Mater Eng 46(4):946–950. https://doi.org/10.1016/S1875-5372(17)30127-3

Szeliga D, Kubiak K, Burbelko A, Motyka M, Sieniawski J (2014) Modeling of directional solidification of columnar grain structure in CMSX-4 nickel-based Superalloy castings. J Mater Eng Perform 23(3):1088–1095. https://doi.org/10.1007/s11665-013-0820-8

Kang M, Gao H, Wang J, Ling L, Sun B (2013) Prediction of microporosity in complex Thin-Wall castings with the dimensionless Niyama criterion. Materials 6(5):1789–1802. https://doi.org/10.3390/ma6051789

Zhang C, Bao Y, Wang M, Zhang L (2016) Shrinkage porosity criterion and its application to a 5.5 ton steel ingot. Archives of Foundry Engineering 16. https://doi.org/10.1515/afe-2016-0021

Wang J, Fu P, Liu H, Li D, Li Y (2012) Shrinkage porosity criteria and optimized design of a 100-ton 30Cr2Ni4MoV forging ingot. Mater Des 35:446–456. https://doi.org/10.1016/j.matdes.2011.09.056

Li J, Chen R, Ma Y, Ke W (2014) Characterization and prediction of microporosity defect in sand cast WE54 alloy castings. J Mater Sci Technol 30(10):991–997. https://doi.org/10.1016/j.jmst.2014.03.011

Sabau AS (2006) Alloy shrinkage factors for the investment casting process. Metall Mater Trans B Process Metall Mater Process Sci 37(1):131–140. https://doi.org/10.1007/s11663-006-0092-x

Panchal P, Joshi S, Ghetiya N (2015) Design and analysis of gating and Risering system for casting of ball valves. Nirma University Journal of Engineering and Technology 4(1):1–5

ProCast 2016 User's Guide, ESI group. www.esi-group.com

Fu PX, Kang XH, Ma YC, Liu K, Li DZ, Li YY (2008) Centrifugal casting of TiAl exhaust valves. Intermetallics 16(2):130–138. https://doi.org/10.1016/j.intermet.2007.08.007

Lakum PM, Gondaliya RD, Chauhan HN (2016) Shrinkage Porosity & Temperature Distribution analysis of air cooled cylinder liner block of Grey cast iron - ASTM class 35. Internation Journal Of Advance Research And Innovative Ideas In Education 2(3):569–577

Tavakoli R (2014) On the prediction of shrinkage defects by thermal criterion functions. Int J Adv Manuf Technol 74(1):569–579. https://doi.org/10.1007/s00170-014-5995-0

Carlson KD, Beckermann C (2009) Prediction of shrinkage pore volume fraction using a dimensionless Niyama criterion. Metall Mater Trans A 40(1):163–175. https://doi.org/10.1007/s11661-008-9715-y

Nimbulkar SL, Dalu RS (2016) Design optimization of gating and feeding system through simulation technique for sand casting of wear plate. Perspect Sci 8:39–42. https://doi.org/10.1016/j.pisc.2016.03.001

Masoumi M, Hu H, Hedjazi J, Boutorabi MA (2005) Effect of gating design on Mold filling. AFS Transactions 05-152(2):1–12

Jezierski J, Dojka R, Kubiak K, Zurek W (2016) Experimental approach for optimization of gating system in castings. Paper presented at the in proceedings of the 25th anniversary international conference on metallurgy and materials, Brno

Acknowledgements

This research is financial supported by Gol-Gohar Iron Ore and Steel Research Institute. In addition, the authors greatly appreciate Babol Noshirvani University of Technology and Foolad Tanbour Company (Foundry industry) for their assists.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Javahery, M., Abbasi, M. Simulation of casting process: case study on the gating and feeding design for outlet diaphragms of iron ore ball mill. Heat Mass Transfer 55, 1959–1967 (2019). https://doi.org/10.1007/s00231-018-2447-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00231-018-2447-7