Abstract

In some cities such as Ahvaz-Iran, the solar radiation is very high and the annual-mean-daily of the global solar radiation is about 17.33 MJ m2 d−1. Solar radiation as an external heat source seems to affect the thermal performance of the cooling towers. Usually, in modeling cooling tower, the effects of solar radiation are ignored. To investigate the effect of sunshade on the performance and modeling of the cooling tower, the experiments were conducted in two different states, cooling towers with and without sunshade. In this study, the Merkel’s approach and finite difference technique are used to predict the thermal behavior of cross flow wet cooling tower without sunshade and the results are compared with the data obtained from the cooling towers with and without sunshade. Results showed that the sunshade is very efficient and it reduced the outlet water temperature, the approach and the water exergy of the cooling tower up to 1.2 °C, 15 and 1.1 %, respectively and increased the range and the efficiency of the cooling tower up to 29 and 37 %, respectively. Also, the sunshade decreased the error between the experimental data of the cooling tower with sunshade and the modeling results of the cooling tower without sunshade 1.85 % in average.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

Cooling towers are the heat and mass transfer devices being in the widespread use. Due to their important role, the different kinds of the cooling towers have been introduced to address the various demands of industries. Different mathematical models have been developed to predict the thermal behavior of the wet cooling towers. The first practical model to describe the heat and mass transfer mechanisms in wet cooling towers was proposed by Merkel [1]. The critical differences between Merkel, Poppe and ɛ-NTU models were investigated by Kloppers and Kroger [2]. They concluded that when the outlet water temperature is the only important parameter to the tower designer, the less accurate Merkel and ɛ-NTU approaches can be used but when the heat transfer rates are concerned; they give lower values than that predicted by Poppe approach. Hayashi and Hirai [3] approximated the enthalpy of saturated air by a first order equation with respect to the water temperature and applied the cross flow heat exchanger calculations to obtain the overall enthalpy transfer coefficient by using a chart. Inazumi and Kageyama [4] proposed a graphical method for calculation of the enthalpy driving force in a cross flow cooling tower.

Khan and Zubair [5, 6] investigated the effect of Lewis number and heat transfer resistance in the air–water interface and developed a detailed model for counter flow wet cooling towers. Halasz [7, 8] developed a general mathematical model to describe the thermal characteristics of all types of evaporative cooling devices. The main feature of this model is its non-dimensionality which efficiently reduces the required parameters to analyze an evaporative device. He then applied his model to predict the thermal behavior of wet cooling towers and compared the model results with an accurate model. Kairouni et al. [9] presented a mathematical model for the numerical prediction of the performance of crossflow cooling towers. The mathematical model is based on the heat and mass transfer equations. The leading parameters are the Lewis number, the number of transfer units, the percentage of water evaporation, the water losses and the tower efficiency. The model has been used to predict the performance of cooling towers in terms of the meteorological conditions prevailing in the South of Tunisia. Prasad [10] developed a numerical model for cross flow wet cooling towers and applied the model to estimate the departure of available fill characteristics of the packing of a multi-cell cross flow cooling tower from their values at design state.

Hajidavalloo et al. [11] used the Merkel’s model for predicting the thermal behavior of an existing cross flow tower under variable wet bulb temperature and the results are compared with experimental data in various operating conditions. Finally, the effect of placing an impact separator in front of air louvers on the thermal performance of the tower is investigated.

An interesting method to control the wet bulb temperature is the designing and utilization a desiccant wheel. Desiccant materials attract the moisture based on differences in vapor pressure. Due to their enormous affinity for absorbing the water and considerable ability to hold the water, the desiccant has been widely applied to the marine cargo, pharmaceutical, electronics, plastics, food and storage industries. Banooni and Chitsazan [12] used the Merkel’s model for investigating the effect of the desiccant wheel on the thermal performance of cross flow cooling towers in variable wet bulb temperature. They concluded that by using the optimum parameters of desiccant wheel, the inlet air wet bulb temperature into the cooling tower and the outlet water temperature would decrease significantly.

Solar radiation always affects the thermal performance of the industrial equipment, especially in countries with very high temperature and strong solar radiation in summers. Rahimikhoob [13] tested an artificial neural network for estimating the global solar radiation as a function of air temperature data in a semi-arid environment. The data used in the network training were obtained from a historical series (1994–2001) of daily climatic data collected in weather station of Ahvaz located in Khuzestan plain in the southwest of Iran. Kramer et al. [14] showed the aerial photographs of the shadowing effect of a plume from a natural draft cooling tower. Ryznar’s [15] measurements of solar radiation were made on 7 March 1977. The sky was cloudless, but a cooling tower plume occasionally came between the sun and the pyranometer that was used. These measurements of solar radiation resulted in values that were greater than those expected with a cloudless sky. It is likely that reflections from the plume, whose average position was slightly north of an imaginary sun-pyranometer line, were responsible. Hajidavalloo and Mohamadianfard [16] investigated the effect of sunshade on the transformer by using the experimental and analytical methods. Transformer oil temperature was measured in two different modes, with and without sun shield. It was found that a sun shield has an important effect on the oil temperature reduction in summer which could be as high as 7 °C depending on the load ratio. Li and Zhang [17] used the energy consumption unit building area of the same building as an index for measuring the effect of sun shade. Combined with the climatic characteristics of Chongqing, the effect of Low-E glass and the sun shade performance of horizontal sunshade board on building energy consumption were analyzed. And the optimal configuration dimensions of Low-E glass and the horizontal sunshade board for Chongqing were recommended on the basis of different requirements for building energy saving in winter and in summer. Gupta and Ralegaonkar [18] proposed the design development of a new static sunshade depending on solar angles, whose efficiency has been experimentally verified using a small-scale modeling technique. Three experimental models of insulating material were prepared with varying the aspect ratio of windows and static sunshades. Sunlit area, which in turn controls the temperature inside the models, has been made the criteria for deciding the effectiveness of the proposed sunshade over existing horizontal sunshade. The proposed technique can be applied at any geographic location over the world for which sunshade can be designed as per the climatic requirements of the place. Raheem et al. [19] presented the findings of a comparative study for evaluating the effects of different solar shading devices on the solar transmittance properties of windows with different orientations in the city of Miami, Florida. The simulation results were compared to determine a performance metric for the primary and the total solar transmittance of each window-shade system. After selecting the most efficient solar devices, a thermal analysis was performed to estimate the reduction in cooling loads generated by improving the internal operative environment. Mackay and Donn [20] identified the features of best practice in shade design for protecting children from UVR exposure in 10 schools throughout New Zealand. The varied New Zealand climate means the different sunshade solutions are appropriate for the different locations. Translucent materials can create much needed warm shade for coastal areas. Solid or green shade can shield the heat of the sun in hotter inland areas. Where the rainfall is frequent, the impermeable materials create the useful wet-weather play space. Soma et al. [21] clarified the reduction effect of the indoor heat load and the improvement of the indoor thermal environment by thermal shielding over the folded-plate roof through a year. A heat transfer model which can predict the heat flux through the roof with sheets and ceiling is proposed. This model is formulated using the heat balance of conduction, convection and indirect radiation on the folded-plate roof. It is clarified that using the sunshade sheets leads to decrease the cooling load for air-conditioning at daytime in summer. Meanwhile, it is found that the sunshade sheets can decrease the heat loss from the roof in winter.

Since the cooling towers should be installed in the free space, they are strongly influenced by the sunshine in hot climate. Researchers for simplicity have ignored the effect of the solar radiation in modeling cooling tower. It seems that neglecting the effect of the solar radiation in modeling cooling towers affects the model’s error, especially in hot climate. In spite of the vast application of the cooling towers in industries, there is no significant research to address the effect of the solar radiation on the thermal behavior of cooling tower.

In this paper, the experimental and analytical methods are used to estimate the effect of solar radiation on the cooling tower performance of Ahvaz Urban Railway, Iran. For this purpose, the experiments are conducted on the two cooling towers with the same weather conditions and structure, one cooling tower with sunshade and another without sunshade. The outlet water temperature from the cooling towers is measured to determine the effect of the solar radiation. Then, the modeling results of the cooling tower without sunshade are compared with the experimental results of the cooling towers, with and without sunshade. Knowing the role of the solar radiation on the performance of the cooling tower will help us to decide if a sunshade should be used around the cooling tower or not.

2 Materials and methods

2.1 Study area and data

Measured daily weather data for a 10-year period from 1994 to 2003 were obtained from the Ahvaz weather station (Latitude 31°200′N, longitude 48°40′E, elevation 22.5 m) located in the Khuzestan plain in the southwest of Iran (Fig. 1). The climate in the study area is semi-arid with an average annual rainfall of 220 mm, approximately 80 % of which occurs during November through April. The minimum and maximum air temperature range from 23.4 to 48.2 and 6.48 to 30.2 °C in summer and winter months, respectively. The average annual temperature is around 26.4 °C, the annual average sunshine is about 3209 h and the daily mean relative humidity ranges from 17 to 85 % with an annual average of 41.5 %. The Global solar radiation was found to vary between a minimum of 0.01 to a maximum of 36.43 MJ m2 d−1 and the annual-mean-daily is about 17.33 MJ m2 d−1 [13].

2.2 Cooling tower specifications

Figure 2 shows a schematic diagram of the cooling tower of Ahvaz Urban Railway that is used to cool the different parts of the tunneling machine. It is a cross flow cooling tower with one cell (two cell halves). The fills are splash type with the rectangular cross section and made from Unplasticised Poly Vinyl Chloride. The design parameters of the tower are listed in Table 1. These parameters have been extracted from the catalog of the cooling tower manufacturer. Fill performance characteristic, called here as fill characteristic (FC), is a single composite nondimensional parameter involving the dimensions of the cell half, the configuration of the packing and the water flow rate through it. The FC value represents the overall potential of the existing packing to cool the water and is a sole function of the mass flow ratio of water to air, called FR [10]. In Fig. 3, the effect of FR on the water temperature along the tower has been shown. The figure shows that the water temperature is increased when FR is increased. This can be explained from this fact that an increase in FR means more water should be cooled for a given tower volume. Therefore, one would expect that the surface area required both for convection and evaporation will be reduced, resulting in the higher outlet water temperature [12].

Inlet air wet bulb temperature against the outlet water temperature at different FR ratios [12]

2.3 Measuring devices

Thermocouples were used to measure the dry bulb temperature of the environment; inlet and outlet water temperatures of the cooling tower with shade and without shade. The relative humidity of environment is recorded with a digital hygrometer. A mathematical model [23] is used to obtain the ambient wet bulb temperature by measuring the ambient dry bulb temperature and the relative humidity. The specifications of the measuring devices are listed in Table 2. We considered the inlet dry bulb temperature and the inlet wet bulb temperature into the cooling towers with sunshade and without sunshade the same as those of the ambient dry bulb temperature and the ambient wet bulb temperature.

2.4 Mathematical modeling

Merkel’s model is used to investigate the behavior of the cooling tower. The basic assumptions of this model are:

-

1.

The heat transfer resistance of the liquid film is negligible.

-

2.

The mass flow rate of water per unit cross-sectional area of the tower is constant (neglecting the mass of evaporated water).

-

3.

The specific heat of moist air at constant pressure is the same as that of dry air.

-

4.

Lewis number for moist air is unity.

According to the Merkel’s theory, all the heat and mass transfer occurring at each point of the cooling tower can be treated as a single transfer process with enthalpy difference as the driving force. Unlike the analysis of counterflow tower which is one dimensional, the crossflow tower must be treated as a two dimensional system, because there is the variation of temperature and humidity both in vertical and horizontal directions. Considering a differential element of a cross flow cooling tower (Fig. 4), the energy balance equation inside the tower is [11]:

where, dxdy is the volume of the element, with its width assumed unity.Rearranging Eq. (1), results in the following set of PDEs for the variations of water temperature and air enthalpy throughout the tower:

The boundary conditions are:

The relation between the water temperature and the enthalpy of saturated air is [24]:

The governing equations (Eqs. 2 and 3) in conjunction with Eq. (6) are coupled and non-linear, which should be solved, simultaneously. Finite difference technique is used to solve the set of governing equations to find air and water properties in each point of the tower [10].

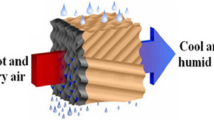

2.5 Sunshade design system

There are several restrictions in the design and installation of the sunshade. These restrictions are as follows:

-

1.

The sunshade should not be an obstacle in front of air louvers.

-

2.

A suitable place should be embedded for the outlet hot and humid air from the cooling tower.

-

3.

The sunshine direction should be considered.

-

4.

The sunshade should be made from the material that is the lightweight and resistant to the sun and rain.

In Fig. 5, a three-dimensional view of the sunshade design is provided. As it is shown in the upper part of the sunshade, a hole with the diameter of the diffuser is created that will let the warm and moist air exists from the tower. On the other hand, in order to remove the direct solar radiation, the length and width of the sunshade is considered one meter greater than each side of the cooling tower. The sunshade is made from the sandwich panels and foam in the sandwich panels is made from polyurethane with the specific weight equivalent to 25–60 kg/m3.

Since the sun shines almost vertically at around noon, the hottest hours are at this time [22]. On the other hand, when the surface is perpendicular to the sunshine, the surface will receive the maximum solar radiation [25]. Therefore, the roof of the cooling tower absorbs more the solar radiation than the other surfaces and the roof of the cooling tower should be protected against the solar radiation [21]. That’s why; we installed the sunshade on the roof of the cooling tower horizontally, and we measured the required data approximately at 14:00 h. Due to the dependence of the solar radiation to the air temperature, humidity and dust, the tests have been carried out on the sunny and smooth days. Figure 6 shows a view of the cooling tower without sunshade and Fig. 7 shows a view of the cooling tower with sunshade.

2.6 Assessment of cooling tower

2.6.1 Range

The range is the temperature difference between the hot water entering the cooling tower and the cold water leaving the cooling tower. A high cooling tower range means that the tower has been able to reduce the water temperature effectively, and thus performance is well.

2.6.2 Approach

The approach is the temperature difference between the cold water leaving the cooling tower and the ambient wet bulb. The best approach value for a cooling tower is zero and the cooling tower efficiency will be maximum in this situation. Figure 8 provides a visual representation of the relationship between the range and approach.

2.6.3 Efficiency

It is the ratio between the range and the ideal range, i.e. the temperature difference between the hot water entering the cooling tower and the ambient wet bulb, or in other words, it is:

2.6.4 Exergy

Water exergy defined as the available energy carried by supplying water decreases continuously from top to bottom. It can be explained from the fact that the water temperature decreases from top to bottom as a result of supplying its exergy to air. Water exergy shows that the supplying rate is nearly constant until approaching the bottom. Equation (10) explains the water exergy Xw in environment when the water is considered as an incompressible fluid where the first two terms are known as thermal exergy and the last is chemical exergy. Thermal exergy is the exergy associated with difference in temperatures, and chemical exergy is the one that associated with ambient humidity, θ0. Because the chemical exergy at ambient is constant, the water temperature can be used as an indicator of the water exergy [26].

3 Results and discussion

3.1 Validity of mathematical model

It may be mentioned that the air mass flow rate is kept constant at the simulation condition [27]. Since the volume flow rate of water and air from the selected cooling towers are constant, therefore, we considered the mass flow ratio of water to air (FR) constant and equal to its value at design condition. Since the FC value is a sole function of FR [10], considering the FR as a constant parameter, the FC value as a sole function of FR will be constant. Considering the FC and FR at design condition, the performance of the cooling tower can be predicted at the different conditions using the mathematical model.

Table 3 presents the model predictions and experimental data from the cooling tower without sunshade at eight various operating conditions. The relative error of the model predictions when compared with experimental results is <7 %. We calculated the relative error of the model predictions with Eq. (11).

Figure 9 shows the model predictions and the experimental data for the water outlet temperatures. Having confirmed the accuracy of the model and the cooling tower characteristics, we can use this model to study the effect of other parameters on the performance of the existing cooling tower.

3.2 Effect of sunshade on the cooling tower performance

The outlet water temperature of the cooling towers with and without sunshade is measured and its results are given in Table 4. According to Fig. 10, the outlet water temperature of the cooling tower with sunshade is less than that of the cooling tower without sunshade and the difference in outlet water temperature between these two situations is up to 1.2 °C. Moreover, the range value for the cooling towers with and without sunshade and the enhancement of range are given in Table 5. It can be seen clearly from Fig. 11 that the range value for the cooling tower with sunshade is greater than that of the cooling tower without sunshade. This enhancement in the range of the cooling tower could be as high as 29 %. Therefore, the sunshade prevents the cooling tower from the extra heat absorption of the sun and improves the heat and mass transfer process between the hot water droplets and the ambient air considerably.

The approach value for the cooling towers with and without sunshade and the reduction of approach are given in Table 6. We can observe from Fig. 12 that the approach value for the cooling tower with sunshade is lower than that of the cooling tower without sunshade at the same wet bulb temperature. Indeed, the outlet water temperature of the cooling tower with sunshade is approaching to the ambient wet bulb temperature more than that of the cooling tower without sunshade. This approaching may reach up to 15 %. Thus, the effect of solar radiation on the performance of cooling towers is more considerable in hot climate.

The efficiency for the cooling tower with and without sunshade and the enhancement of efficiency are given in Table 7. According to Eq. (9), the reduction of approach and the enhancement of range will increase the efficiency of the cooling tower. As expected, it can be observed from Fig. 13 that the efficiency for the cooling tower with sunshade is greater than that of the cooling tower without sunshade. This enhancement in the efficiency of the cooling tower could be as high as 37 %.

Since the water temperature can be used as an indicator of the water exergy, we used Eq. (10) to calculate the water exergy of both cooling towers with sunshade and without sunshade at the outlet water temperature. The ambient conditions used for the exergy analysis are at T0 = 25 °C, P0 = 1 atm, and θ0 = 50 %RH [26]. The calculation results of the water exergy for the cooling towers with and without sunshade are given in Table 8. Figure 14 shows the comparison between the water exergy of cooling towers with sunshade and without sunshade. Since the sunshade decreased the outlet water temperature of the cooling tower, we observe that the cooling tower with the sunshade has the water exergy less than that of the cooling tower without sunshade and the water exergy of the cooling tower with sunshade could be decreased up to 1.1 %.

3.3 Effect of the solar radiation on the process of modeling

Table 9 shows the modeling results of the cooling tower without sunshade which has been ignored the impact of solar radiation in modeling cooling tower and the experimental results for two cooling towers; one of them is exposed to the solar radiation and the other shaded by the installed sunshade. As shown in Fig. 15, the error between the modeling and experimental results for the cooling tower with sunshade is less than that of the cooling tower without sunshade and the installation of sunshade decreases the error rate 1.85 % in average and its reason is the ignoring of the solar radiation effect in modeling cooling tower. Thus, it is very important to enter the impact of solar radiation in modeling cooling tower in order to predict the effect of solar radiation on the performance of cooling tower and increase the accuracy of Merkel’s model or the other models which have been ignored the solar radiation effect in modeling cooling tower.

3.4 Economical aspects of the sunshade system

We observed that the sunshade system can improve the thermal performance of cooling tower in hot climate considerably. To evaluate the economic concerns about the sunshade utilization on the cooling tower, some important criteria such as initial cost, repair and maintenance cost and payback period should take into account. Table 10 demonstrates a simple comparison in three important criteria. The cost of installing the sunshade on the cooling tower is very low because it has very simple construction and does not need any expensive equipment. It is estimated that the cost of sunshade would be around 3 % of the cooling tower cost. Therefore, it seems that using the sunshade around the cooling tower in region with high solar radiation can be a cost-effective method.

3.5 Cooling tower performance in different environmental conditions

Since the heat is transferred from the process water to the ambient air, the environmental conditions strongly influence the heat and mass transfer process. One of the most important parameters that should be considered in the design and operating of wet cooling towers in mixed weather conditions, like Ahvaz climate, is the effect of wet bulb temperature on the cooling tower performance. Ahvaz city has a hot and humid climate with variable wet bulb temperature due to its closeness to the Persian Gulf in the Middle East. When the weather gets humid, the wet bulb temperature enhances and the performance of cooling towers deteriorates considerably. The desiccant wheel utilization can improve the cooling duties by controlling the inlet wet bulb temperature [12]. The combination of the desiccant wheel to reduce the inlet air wet bulb temperature into the cooling tower and the sunshade system to prevent the cooling tower from the extra heat absorption of the sun can be a beneficial method in hot and humid climate (Fig. 16).

Cooling towers operating in sub-freezing temperatures are prone to ice formations at the exposed louvers and lower regions of the fill. Under extreme conditions, such as very cold temperatures or cold temperatures combined with a strong wind, the build-up of ice can become so large that the structural damage may occur. Procedures to remove ice formations typically require the cooling tower to cease operation, thus disrupting the supply of cooled water [28]. Since the air intake louver of the cooling tower with sunshade is in the shade, therefore the inlet dry bulb temperature into the cooling tower with sunshade is less than that of the cooling tower without sunshade. For this reason, the sunshade will speed up ice formations in the winter season and this is a negative effect of the sunshade system on the cooling tower performance in this season.

4 Conclusion

In this study, the Merkel’s approach and finite difference technique are used to predict the thermal performance of the cooling tower exposed to the solar radiation in hot climate. A sunshade was proposed to prevent the cooling tower from the extra heat absorption of the sun. Experimental tests were performed at two different modes to measure the effect of sun radiation. The modeling results from the cooling tower without sunshade are compared with the experimental data of cooling towers with and without sunshade.

-

The influence of the sunshade on the performance of the cooling tower is significant and it affects the outlet water temperature of the cooling tower.

-

The range and efficiency for the cooling tower with sunshade are greater than that of the cooling tower without sunshade.

-

The approach and exergy for the cooling tower with sunshade are less than that of the cooling tower without sunshade.

-

The model’s error for the cooling tower with sunshade is less than that of the cooling tower without sunshade.

-

The combination of the desiccant wheel and the sunshade system to reduce the impact of solar radiation and the inlet air wet bulb temperature into the cooling tower can be a beneficial method in hot and humid climate.

-

Sunshade system will speed up ice formations in the winter season and this is a negative effect of the sunshade system on the thermal behavior of cooling tower in this season.

These results are extracted by ignoring the effect of the solar radiation on the input boundary conditions. Thus, in order to increase the accuracy of results, it is necessary to measure the effect of solar radiation on the input boundary conditions.

Abbreviations

- av :

-

Surface area of water droplets per unit volume of tower (m2 m−3)

- cw :

-

Specific heat of water at constant pressure (J kg−1 °C−1)

- FC:

-

Fill characteristic = \({\text{h}}_{\text{m}} {\text{A}}_{\text{v}} {\text{V}}/{\dot{\text{m}}}_{\text{w}}\)

- FR:

-

Flow ratio, water to air = \(\dot{m}_{w} /\dot{m}_{a}\)

- hm :

-

Mass transfer coefficient (Kg m−2 h−1)

- h:

-

Enthalpy (kJ kg−1)

- hf,w :

-

Enthalpy of saturated liquid water evaluated at Tw, (kJ/kg)

- L:

-

Length of the tower (m)

- \({\dot{\text{m}}}\) :

-

Mass flow rate per square meter of the tower (Kg m−2 h−2)

- P:

-

Pressure (kPa)

- R:

-

Gas constant (kJ/kg K)

- s:

-

Entropy (kJ/kg K)

- sf,w :

-

Entropy of water (kJ/kg K)

- T:

-

Temperature (°C)

- V:

-

Volume of the selected tower (m3)

- x,y:

-

Coordinates shown in Fig. 4

- Xw :

-

Water exergy (kW)

- θ:

-

Relative humidity

- a:

-

Air

- db:

-

Dry bulb

- i :

-

Inlet

- o:

-

Outlet

- 0:

-

Restricted dead state

- s:

-

Refers to standard air

- v:

-

Water vapor

- w:

-

Water

- wb:

-

Wet bulb

- ws:

-

With sunshade

- wos:

-

Without sunshade

References

Merkel F (1925) Evporative cooling. Z Verein Deutsch Ingen (VDI) 70:123–128

Kloppers JC, Kroger DG (2005) Cooling tower performance evaluation: Merkel, Poppe, and ɛ-NTU methods of analysis. J Eng Gas Turbines Power 127:1–7

Hayashi Y, Hirai E (1974) Analysis of a multi-unit co-current cross flow cooling tower. J Heat Transf 3:67–74

Inazumi H, Kageyama S (1974) A successive graphical method of design of a cross flow cooling tower. Chem Eng Sci 30:717–721

Khan JR, Zubair SM (2002) Performance characteristics of counter flow wet cooling towers. Energy Convers Manag 44:2073–2091

Khan JR, Zubair SM (2001) An improved design and rating analysis of counter flow wet cooling towers. J Heat Transf ASME 123:770–778

Halasz B (1998) A general mathematical model of evaporative cooling devices. Int J Therm Sci 37:245–255

Halasz B (1999) Application of a general non-dimensional mathematical model to cooling towers. Int J Therm Sci 38:75–88

Kairouani L, Hassairi M, Tarek Z (2004) Performance of cooling tower in south of tunisia. Build Environ 39:351–3555

Prasad M (2003) Economic upgradation and optimal use of multi-cell cross flow evaporative water cooling tower through modular performance appraisal. Appl Therm Eng 24:579–593

Hajidavalloo E, Shakeri R, Mehrabian MA (2010) Thermal performance of cross flow cooling towers in variable wet bulb temperature. Energy Convers Manag 51:1298–1303

Banooni S, Chitsazan A (2014) Economic and technical assessment of the desiccant wheel effect on the thermal performance of cross flow cooling towers in variable wet bulb temperature. Heat Mass Transf 50:1587–1596

Rahimikhoob A (2010) Estimating global solar radiation using artificial neural network and air temperature data in a semi-arid environment. Renew Energy 35:2131–2135

Kramer ML, Smith ME, Butler MJ, Seymour DE, Frankenberg TT (1976) Cooling towers and the environment. J Air Pollut Control Assoc 26:582–584

Ryznar E (1978) An observation of cooling tower plume effects on total solar radiation. Atmos Environ 12:1223–1224

Hajidavalloo E, Mohamadianfard M (2010) Effect of sun radiation on the thermal behavior of distribution transformer. Appl Therm Eng 30:1133–1139

Li J, Zhang Q (2007) Influence of the sunshade structure on building energy consumption in Chongqing district. Constr Conserv Energy 10:1–8

Gupta R, Ralegaonkar R (2006) New static sunshade design for energy-efficient buildings. Energy Eng 132:27–36

Raheem AA, Issa RR, Olbina S (2014) Solar transmittance analysis of different types of sunshades in the Florida climate. Build Simul 7:3–11

Mackay C, Donn M (2003) Sunshade design in New Zealand primary schools. PLEA Conf Proc 2003:143–148

Soma M, Yamanaka T, Lim E, Kotani H, Momoi Y, Sagara K (2011) Solar shielding performance of sunshade sheets over roof through a year. Measurement 2:3–23

Mokhtari E (2010) Yearbook of Ahvaz metrological parameters. Khuzestan Metrological Center Publication, Ahwaz

Al-Nimr MA, Abu Nabah BA, Naji M (2002) A novel summer air conditioning system. Energy Convers Manag 43:1911–1921

Stoecker WP, Jones JW (1983) Refrigeration and air conditioning. McGraw-Hill, New York

Keshavarz SA, Talebizadeh P, Adalati S, Mehrabian MA, Abdolzadeh M (2012) Optimal slope angles to determine maximum solar energy gain for solar collectors used in Iran. Int J Renew Energy Res 2:665–673

Muangnoi T, Asvapoositkul W, Wongwises S (2007) An exergy analysis on the performance of a counterflow wet cooling tower. Appl Therm Eng 27:910–917

Sarker MMA, Kim E, Moon CG, Yoon JI (2008) Numerical simulation of the performance characteristics of the hybrid closed circuit cooling tower. Nonlinear Anal Model Control 13:89–101

Derksen DD, Bender TJ, Bergstrom DJ, Rezkallah KS (1996) A study on the effects of wind on the air intake flow rate of a cooling tower: Part 1. Wind tunnel study. J Wind Eng Ind Aerody 64:47–59

Acknowledgments

We would like to thank personnel and management of Scetiran Consulting Engineers for their great help to do this research.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Banooni, S., Chitsazan, A. Effect of solar radiation on the performance of cross flow wet cooling tower in hot climate of Iran. Heat Mass Transfer 52, 2551–2562 (2016). https://doi.org/10.1007/s00231-016-1766-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00231-016-1766-9