Abstract

Angelicae sinensis radix is commonly used in Chinese medicine and is also widely used as a spice and condiment in many countries. Due to the different geographical sources and processing methods, the contents of chemical components are different and affect the quality of Angelica sinensis radix. A simple and efficient method was established to comprehensively evaluate the quality of Angelica sinensis radix by combining HPLC fingerprint and single-standard multi-component quantitative analysis. With ferulic acid as a single marker, the contents of eight main active ingredients, including ferulic acid, senkyunolide I, senkyunolide H, coniferyl ferulate, E-ligustilide, E-butylidenephthalide, Z-ligustilide, and Z-butylidenephthalide, were simultaneously determined in 30 min by reliable relative correction factor. The overall chemical profiles of Angelica sinensis radix were compared by fingerprint similarity evaluation, the specific content level of each component was compared by simultaneous content determination of multiple components of a single standard, and the specific different components of Angelica sinensis radix before and after processing were analyzed by chemometrics. The established method was successfully applied to the quality evaluation of 44 batches of Angelica sinensis radix from 4 different origins and 45 batches of Angelica sinensis radix with different processing methods. This study proposed a simple, rapid, low-cost, and reliable quality comprehensive evaluation method for ASR from different origins and processing methods, which may be readily transferred and applied to other industries.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Angelicae sinensis radix (ASR), the dried root of Angelica sinensis (Oliv.) Diels (family Apiaceae), known as Danggui in China, has protective effects on the circulatory system and treat gynecological diseases [1]. It is also a traditional spice and condiment, widely consumed in China, Japan, the United States, and the European Union [2]. ASR has various cooking and processing methods with different effects. For example, making ASR tea and cooking porridge can regulate menstruation, stewing with ASR can enhance flavors and warm the body to prevent repeated attacks of blood deficiency, wine-processed ASR can enhance ASR to promote blood circulation [3].

More than 168 compounds have been isolated and identified from ASR, mainly including organic acids and their esters (such as ferulic acid and coniferyl ferulate), phthalides (such as ligustilide, butylphthalide, senkyunolide, and butylidenephthalide), and polysaccharides, which account for the main bioactivities and pharmacological properties, such as enhancing immunity, anti-inflammatory, anti-fibrosis, antioxidant activity, anti-platelet aggregation activity, and neuroprotective effect [4,5,6]. The quality of ASR is easily affected by weather, origin, harvesting season, processing technology and other conditions [7]. For example, the ASR genuine origin is recognized as Gansu, and the contents of volatile oil and ferulic acid in Gansu ASR were higher than those in other producing areas [8]. At present, Chinese Pharmacopoeia, European Pharmacopoeia, British Pharmacopoeia, Japanese Pharmacopoeia and Hong Kong Chinese herbal medicine standards have included ASR, most of which use the contents of ferulic acid or ligustilide for quality control. However, ferulic acid is also a quality control index component of Chuanxiong Rhizoma and Ligustici Rhizoma et Radix, which means it lacks specificity for ASR. Another issue of using ferulic acid is that coniferyl ferulate, another major compound in ASR, is only stable in acidizing solvents and easily hydrolyzed to ferulic acid and coniferol. It means the ferulic acid measured in most current methods may come from its prototype in ASR, and the decomposed coniferyl ferulate. Nevertheless, the comprehensive quality control of ASR and its processed form is still insufficient, especially for pharmacopeia. Therefore, more components should be paid attention to in evaluating the quality of ASR, rather than just Z-ligustilide or ferulic acid.

Various detection methods have been developed to evaluate the quality of ASR more comprehensively from multiple angles to improve the quality control of ASR, including LC, LC–MS/MS, and GC/MS for fingerprint chromatogram or multi-component determination [9]. For example, Zhang et al. established an HPLC–UV fingerprint with 12 common peaks in 65 min to evaluate the water decoction of ASR [10]. Razmovski-Naumovski et al. quantified three components (caffeic acid, ferulic acid, and Z-ligustilide) using the UPLC-UV method in 30 min to analyze the equivalence between granules and crude drugs of ASR [11]. Using the UHPLC–MS/MS method, 13 components, including 8 phthalides (senkyunolide I, H, A, butylphthalide, Z-ligustilide, butylidenephthalide, neocnidilide, and levistilide A) and 5 phenolic acids (chlorogenic acid, caffeic acid, vanillin, ferulic acid, and coniferyl ferulate), were simultaneously determined to analyze different parts (head, body, and tail) of ASR [12]. A comprehensive two-dimensional gas chromatography (GC × GC) combined with high-resolution time-of-flight mass spectrometry was developed to investigate the effect of sulfur fumigation on the volatile components of ASR [13]. To minimize the expend of standards, a single standard to determine the multi-components (SSDMC) method was developed, on the one hand, to determine four components (ferulic acid, senkyunolide I and H, and Z-ligustilide) for comparing the decoction pieces of Chuanxiong Rhizoma and ASR; on the other hand, to determine three components for discriminating sun-dried and sulfur-fumigated ASR; in addition, reliable markers were screened to identify the amount of excipients added, processing time and temperature in wine-processed ASR [14,15,16].

Among all analytical techniques, HPLC fingerprinting is a convenient and reliable method to evaluate the quality of Chinese herbal medicine and has been widely used in the analysis and identification of traditional Chinese medicine [17]. Therefore, in the current study, a simple and efficient method was developed, in which the content of 8 main components of ASR was determined by HPLC based on the method of fingerprint and SSDMC using ASR from different places of origin and processing methods. Through analyzing and mining the data with the chemometrics method, the main differential components of ASR from different origins and processing methods were identified to provide data support for the overall quality evaluation of ASR beyond the traditional Z-ligustilide or ferulic acid.

Materials and methods

Reagents and materials

As reference substances of ASR, ferulic acid (FA) was obtained from National Institutes for Food and Drug Control (Beijing, China); senkyunolide H (SH) was obtained from Weikeqi Biological Technology Co., Ltd. (Sichuan, China); and Z-ligustilide (ZL) was prepared by Shanghai Standard Technology Co., Ltd. Other reference standards, including senkyunolide I (SI), coniferyl ferulate (CF), E-ligustilide (EL), E-butylidenephthalide (EB), and Z-butylidenephthalide (ZB) were prepared in our lab. The purities of all these substances were > 98%, except for ZL, the purity of which was 90.23%. Acetonitrile of HPLC grade was obtained from Honeywell (NJ, USA). Formic acid for HPLC was purchased from Roe Scientific Inc. (USA). Water for HPLC was purified by a Milli-Q Synthesis A10 System (Bedford, MA, USA). All other reagents were of analytical grade.

Forty-four batches of ASR medicinal materials were purchased from four origins. In addition, 15 batches of ASR medicinal materials were prepared into corresponding 15 batches of ASR raw decoction pieces and 15 batches of wine-processed ASR. ASR raw decoction pieces are to remove impurities from ASR medicinal materials, wash them clean and dull, and then cut thin slices and dry. Wine-processed ASR is to slice Angelica first and then add Huangjiu to mix well, fry dry after a low heat, and cool. The detailed information about these samples is listed in Table S1.

Apparatus and chromatographic parameters

The quantitative assay was performed on an Agilent 1260 series HPLC system (Agilent Technologies, Palo Alto CA, USA), comprising an online vacuum degasser, an autosampler, a column temperature controller, a quaternary gradient pump, and a diode array detector, controlled by Agilent ChemStation software (B.04.03-SP1). An Agilent Eclipse Plus C18 (4.6 × 150 mm, 3.5 μm) column at the temperature of 30 °C was applied for analysis. The detection wavelength was set at 274 nm. The mobile phase consisted of (A) acetonitrile and (B) 0.1% formic acid water solution used a gradient elution of 8% A at 0–3 min, 8–47% A at 3–15 min, 47% A at 15–30 min, 47–100% A at 30–30.1 min, 100% A at 30.1–35 min, 100–8% A at 35–35.1 min, 8% A at 35.1–40 min. The flow rate was 1.2 mL/min and the injection volume was 5 μL. The integration parameter (slope sensitivity/peak width/area reject/height reject) was 5/0.05/5/1.

Data processing and chemometric analysis

Sample similarity was calculated using the Similarity Evaluation System of Traditional Chinese Medicine Chromatographic Fingerprint software (Version 2012.130723, Chinese Pharma-copoeia Commission, Beijing, China). SIMCA software (Version 14.1 Umetrics, Umea, Sweden) was used for principal component analysis (PCA) and partial least squares discriminant analysis (PLS-DA) chemometric analysis of the samples.

Preparation of solutions

Preparation of standard solutions

Eight standard stock solutions were prepared for standard curve test by dissolving reference standards respectively in methanol–formic acid (95:5, v/v), and a series of the mixed standard solutions were diluted.

Preparation of sample solution

All samples were coarsely powdered and prepared as follows: To 1.00 g of powered raw or wine-processed ASR samples, 25 mL of a mixture of methanol and formic acid (95:5, v/v) was added and weighed. Then, the mixture was sonicated (42 kHz, 135 W, BRANSON 5510E-DTH) for 30 min and allowed to cool, weighed the mixture again and replenished the weight with the same solvent, and last, mixed well, and then passed through a membrane filter with 0.45-μm pore size, discarded the first 1 mL of the filtrate, and collected the successive filtrate as the sample solution.

Calculation of conversion factors and relative retention time

For the SSDMC method, conversion factor (F) and relative retention time (RRT) of each analyte were calculated according to the equations reported previously [18]. Specifically, three independent calibration curves covering seven gradient concentrations were used, and FA was chosen as the single standard. Thus, the F value of other analytes was calculated by the ratio of the average slope value of FA and the analyte in the equation of linear regression (Eq. 1).

To identify the peaks in the chromatogram, the relative retention time (RRT) was calculated by the ratio of retention times of the analyte and FA (Eq. 2):

Validation of the method

The method was validated for linearity, accuracy, precision (intra-day and intermediate precisions), specificity, and robustness. The results of the precision and accuracy calculated by the SSDMC method were compared with the results calculated by the traditional external standard method (ESM) using the following equation (Eq. 3):

Results and discussion

Optimization of sample preparation

Different solvent compositions, extraction methods, extraction volume, extraction time, and extraction frequency were investigated to obtain optimal and robust sample preparation methods (Table S2). Among them, the solvent composition was the most important factor which would affect the stability of the sample solution. The results showed that the peak area of FA and CF would only be stable when formic acid was added to the extraction solvent by inhibiting the hydrolysis of CF into FA, and can better reflect the actual content of the original components in ASR. (Table S3 and S4). Thus, a mixture of methanol and formic acid at a ratio of 95:5 was optimized as the solvent. Other factors with different levels could produce similar effects, and ultrasonication once time with 25 mL solvent in 30 min was selected as the optimal sample preparation method.

In this study, ferulic acid was used as a single marker, and SSDMC was used to determine the contents of 8 components simultaneously, which was simpler and more efficient and minimized the cost of standard products. The eight components concerned in this study were ferulic acid, ligustrone I, ligustrone H, coniferyl ferulate, E-ligustilide, e-butenylphthalein, Z-ligustilide and Z-butenylphthalein, which included the main chemical components in ASR. The content of the ingredients changed significantly with different origins and before and after wine production, and the content of these ingredients reflected the quality of ASR.

Optimization of chromatographic parameters

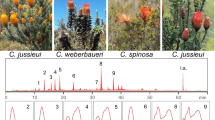

For the fingerprint chromatogram and SSDMC method, detection wavelength was one of the key factors that would influence the value of conversion factors. In this study, the UV spectrums of the eight analytes were different (Fig. 1A). For FA, CF, ZL, and EL, the maximum absorption wavelength was 312–328 nm, while for SI, SH, ZB, and EB, it was 260–280 nm. To obtain the best fingerprint chromatogram, 274 nm was selected as a compromise to balance the chromatographic response of peaks.

Seven different C18 columns with the same size (4.6 × 150 mm) were selected and compared with acetonitrile–0.1% formic acid as mobile phase. All seven columns obtained similar chromatograms and showed good robustness, and finally, the Agilent Eclipse Plus C18 (4.6 × 150 mm, 3.5 μm) was selected (Table S5).

Other chromatographic parameters, such as mobile phase system, flow rate, and column temperature, were also analyzed for the optimized fingerprint chromatogram.

Conversion factors

The single reference standard used in the SSDMC method is generally selected from the constituents of the medicinal preparation being investigated. The standard should meet four requirements, namely (1) abundant in the sample, (2) stable, (3) easy to access, and (4) have a maximum UV absorption [19]. Comparing the chemical structures and the UV absorption of the eight analytes (Fig. 1), FA and ZL were the best candidates. Considering the stability of ZL [20], FA, one of the most pharmacologically active components, was chosen as the single standard.

In this study, eight components were assayed, but their peak area varied greatly. The peak areas of FA, SI, SH, EL, EB, and ZB varied in a range of 10–500, while it varied in a range of 200–5000 for CF and ZL. Therefore, the single marker of FA must be tested in two ranges. The linear range of each analyte was decided by the range of peak area, and the test range for the eight analytes was shown in Table 1. A series of standard solutions for the eight analytes was used to determine the linear regression equation. The results were summarized in Table 1. All the correlation coefficients exceeded 0.9996, except for EB. To calculate and validate the ruggedness of FA, three independent chromatography systems (Table S6) were investigated using a series of standard solutions. The experiments were repeated three times for each system. Thus total of nine standard curves were obtained for each analyte, except for FA, which obtained 18 standard curves. As shown in Table 1, the Fs were in the range of 0.4–1.0 indicating good robustness of Fs.

Relative retention time

The relative retention time of the eight components is shown in Table 1. Three independent chromatographic systems were used to detect the relative retention time, and the results were shown in Table S7. There was no significant difference in the relative retention time measured by different instruments (RSD < 2.0%).

Validation of the method

For accuracy, three different levels, which are 50% (5 mL), 100% (10 mL), and 150% (15 mL) of the standard solutions of FA (10 μg/mL) and ZL (341.5 μg/mL), were added into the flasks with the moderately fine powder of ASR (500 mg), followed by the preparation of sample solutions using optimized extraction method and analysis. Triplicate experiments at each level were established to conduct the recovery test. The results showed that the recovery of FA was in the range of 96–103% (RSD < 3.0%). And the recovery of ZL was in the range of 96–104% (RSD < 3.0%) and 95–104% (RSD < 3.0%) when calculated by ESM and SSDMC methods, respectively. The results in Table 2 showed that the SSDMC method could achieve an accuracy identical to that achieved with the ESM method.

The intra-day and intermediate precisions were chosen to determine the precision of the method. Intra-day precision was assessed by the repeatability using nine test solutions of the same sample, covering three different concentration levels (0.5 g, 1.0 g, and 1.5 g) and triplicate experiments at each level. The results (Table 2) showed excellent repeatability with the RSD of each analyte less than 3.0%, and the difference between the sum value for eight components calculated by the ESM and SSDMC method was less than 1.0%, which showed the SSDMC method could achieve intra-day precision identical to those achieved with the ESM method.

The intermediate precision was evaluated by changing the main factors: different days, different analysts, different equipment (Agilent 1260, 1100, and 1200), and different columns (Agilent Extend C18, Agilent Plus C18, and Waters SunFire C18), with triplicate experiments for each analysis conditions. The results showed that ESM and SSDMC methods were repeatable at different analysis conditions (Table 2) and interchangeable with the difference of the sum value of less than 0.21% (data not shown).

The specificity of the method was assessed by comparing the chromatograms of the blank solvent, standard solution, and sample solution. The results (Fig. 2) showed that the peaks in the chromatogram of the sample solution corresponded in time with the peaks in the chromatogram of the standard solution.

The stability of the standard and sample solutions was investigated. It was carried out by comparing the peak areas of eight analytes in the chromatograph of the same standard or sample solution at different times at room temperature. Stability was evaluated by calculating the RSD (%) of the peak area obtained. The standard solution and the sample solution were stable within 48 h (RSD% < 3.0) (Table 2).

The robustness of the established method was evaluated by examining its stability with the small variations of procedural parameters, including column, flow rate (± 0.2 mL/min), column temperature (± 5 °C), and equipment, using a single-factor experiment. The sample solution, the mixed standard solution, and the single standard solution of ZL (40 μg/mL) were respectively injected with 5 µL in triplicate. The RSD of both the content of ZL and the eight analytes was less than 3.0%, which showed the robustness of the method in all designed ranges of the HPLC parameters. The content differences of both ZL and the eight analytes calculated by the ESM and the SSDMC method were less than 2.0%, which showed that the SSDMC method was practicable (data not shown).

The reference standard extract solution of ASR (15 mg/mL) was injected with 5 µL five times to evaluate the system suitability parameters, which were specified as follows: the tailing factor of ZL should be less than 1.5%, the relative standard deviation should be less than 3.0%, the number of theoretical plates should be more than 60000, and the resolution between ZL and ZB should be more than 1.5.

Fingerprint analyses of Angelica sinensis radix in different producing areas and processing methods

Forty-four batches of ASR fingerprint data from four producing areas were imported into the software Similarity Evaluation System of Traditional Chinese Medicine Chromatographic Fingerprint in AIA format for processing, and corresponding control fingerprints were obtained. The fingerprint similarity of 21 batches of ASR from Gansu provenance was above 0.975, the fingerprint similarity of 7 batches of ASR from Sichuan provenance was above 0.982, the fingerprint similarity of 6 batches of ASR from Hubei provenance was above 0.982, and the fingerprint similarity of 10 batches of ASR from Yunnan provenance was above 0.985, indicating relatively high sample similarity (Table 3). From the control fingerprints of the four producing areas, it can be seen that the content of SI in ASR from Gansu and Yunnan provinces is higher than that of FA, while the content of SI in ASR from Hubei and Yunnan provinces is opposite (Fig. 3). It may be because Yunnan ASR is the result of the introduction of Gansu ASR to form a certain planting scale, so it is more similar to Gansu ASR. The contrast fingerprint of ASR from non-genuine origin in Sichuan and ASR sinensis from genuine origin in Gansu was compared, and the similarity was above 0.968 (Table 4), indicating that the similarity was not the best method to distinguish the origin, and then we could try to distinguish by stoichiometric method.

The influence of different processing methods on the quality of ASR was evaluated using the Similarity Evaluation System of Traditional Chinese Medicine Chromatographic Fingerprint software to analyze the data of ASR and corresponding raw decoction pieces and wine-processed ASR. The fingerprint similarity of 15 batches of ASR medicinal materials was above 0.999, the fingerprint similarity of 15 batches of ASR raw decoction pieces was above 0.989, and the fingerprint similarity of 15 batches of wine-processed ASR was above 0.986, and the similarity was high (Table 5). As can be seen from the control fingerprint, CF and ZL contents in raw slices and wine-processed are significantly lower than those in ASR medicinal materials, which may be due to the unstable nature of ASR and the loss of components during processing (Fig. 4). The similarity of fingerprints between ASR raw decoction pieces and ASR was above 0.960 (Table 4), indicating that the similarity could not distinguish different processing methods of ASR.

Determination and stoichiometric analysis of Angelica sinensis radix content in different producing areas and processing methods

ESM method and SSDMC method were used to determine 44 batches of ASR samples from different origins. The results (Table 6) also showed that the total content obtained by SSDMC was similar to that obtained by ESM, with differences of less than 2.0% between the two methods. The total content of the eight analytes was in the range of 0.4–2.0%.

By further comparing the scatterplot of the contents of 8 analytes in ASR samples from four producing areas, it can be seen that the contents of each component are different in different producing areas, among which the average contents of FA, SI, SH, and ZB are the lowest in Sichuan producing area, and the average contents of CF, EL, EB and ZL are the lowest in Hubei producing area. Gansu as a genuine producing area, the content is higher and the quality is better (Fig. 5).

Further stoichiometric analysis was carried out for different origins. In order to observe the overall profile of the data and whether there were abnormal data, unsupervised PCA was performed on the data. The results showed that the samples could be divided into four categories according to the origin of ASR. PCA only gave a preliminary overview of the similarities and differences between samples and did not show the main differences. In order to further understand the differences between the different origins of ASR, a supervised PLS-DA model was established. According to the three-dimensional score chart, the four producing areas of ASR can be clearly distinguished, and the results are consistent with PCA. According to the VIP value in the PLS-DA model, the main difference in components is screened. There are three components with VIP value greater than 1, namely SI, ZL, and CF (Fig. 6).

In addition, the method can also be used to identify the quality of different processing methods, and the contents of 8 components in 15 batches of ASR medicinal materials, corresponding to 15 batches of ASR raw decoction pieces and wine ASR were determined (Table 7). The scatterplot shows that the contents of SI, SH, and ZB in ASR medicinal materials, ASR raw decoction pieces, and wine ASR were gradually increasing, and the difference between SI and ZB is the most significant. The limit of SI content is 0.044%, and the limit of ZB content is 0.032%, which can distinguish ASR medicinal materials and wine ASR decoction pieces. The contents of CF, ZL and EL in ASR medicinal materials, ASR raw decoction pieces and wine ASR decreased gradually (Fig. 7), which may be due to the instability of heat during processing. For example, CF is easily decomposed into FA and coniferyl alcohol by heat, and the content of CF decreases. Due to the low polarity and the volatility of ligustilide, the content of ligustilide may be reduced during processing due to thermal instability. In addition, the reduction of its content may also be related to storage time because the ligustilide is unstable, so with the extension of storage time even the content of ligustilide in medicinal materials will decrease. The contents of senkyunolide and Z-butylidenephthalide increased may be due to the solubility of the added Huangjiu.

PCA and PLS-DA were performed on the data combined with the stoichiometric method, and the results showed that ASR, raw decoction pieces, and wine-processed ASR were obviously divided into three groups (Fig. 8). The PLS-DA results showed that the data were reliable and not saturated after 200 predictions. According to the VIP value in the PLS-DA model, the main differential components were screened. There were three components with VIP values greater than 1, namely ZL, SI, and ZB.

Conclusion

In this study, a fingerprint-based method for identifying chemical component data with a single standard to determine the multi-component quantitative analysis method was established by combining data analysis and chemometrics. The content variation of each component was clarified, which provided data support for the quality control of ASR. From fingerprints of ASR of different places of origin, the results showed that the ratio of FA and SI peaks from Gansu and Yunnan Provinces is opposite to that in Hubei and Sichuan, which may be the result of the introduction of Gansu cultivation in Yunnan, indicating chemical composition of ASR from Gansu and Yunnan Provinces was similar. The content of ASR components in Gansu Province was significantly higher than that in the other three regions, indicating that the quality of the genuine producing areas was the best. The differential components were SI, ZL, and CF by stoichiometric analysis. The contents of CF, EL, and ZL in ASR, raw decoction pieces, and wine-processed ASR were gradually decreased, which may be related to the addition of yellow rice wine. Through stoichiometric analysis, ASR with different processing methods could be distinguished, and the main difference components were ZL and CF. It was shown that fingerprint chromatography and a single standard to determine the multi-components method combined with chemometrics analysis are practical and efficient. It provides strategies for the quality control of the main characteristic components of ASR of different origins and processing methods and also provides references for the overall quality control of similar edible and medicinal materials.

Data availability

The data that support the findings of this study are available from the authors, upon reasonable request.

References

National Administration of Traditional Chinese Medicine Editorial Committee (1999) Chinese Materia Medica. Shanghai Scientific and Technical, Shanghai

Chen XP, Li W, Xiao XF et al (2013) Phytochemical and pharmacological studies on Radix Angelica sinensis. Chin J Nat Med 11(6):577–587. https://doi.org/10.3724/SP.J.1009.2013.00577

Chinese Pharmacopoeia Commission (2020) Pharmacopoeia of the People's Republic of China. Chinese Medical Science and Technology, Beijing

Wei WL, Zeng R, Gu CM, Qu Y, Huang LF (2016) Angelica sinensis in China-A review of botanical profile, ethnopharmacology, phytochemistry and chemical analysis. J Ethnopharmacol 190:116–141. https://doi.org/10.1016/j.jep.2016.05.023

Zhou SS, Xu J, Tsang CK et al (2018) Comprehensive quality evaluation and comparison of Angelica sinensis radix and Angelica acutiloba radix by integrated metabolomics and glycomics. J Food Drug Anal 26:1122–1137. https://doi.org/10.1016/j.jfda.2018.01.015

Zhang K, Shen X, Yang L et al (2022) Exploring the Q-markers of Angelica sinensis (Oliv.) Diels of anti-platelet aggregation activity based on spectrum–effect relationships. Biomed Chromatograp 36(9):e5422. https://doi.org/10.1002/bmc.5422

Wei WL, Huang LF (2015) Simultaneous determination of ferulic acid and phthalides of Angelica sinensis based on UPLC-Q-TOF/MS. Molecules 20:4681–4694. https://doi.org/10.3390/molecules20034681

Xie TP, Liu N, Wang YL, Jing M (2020) Quality research progress of Angelica sinensis from different regions. Acta Chinese Medi Pharmacol 48(1):72–75. https://kns.cnki.net/kcms/detail/23.1193.r.20200113.1545.018.html

Gui QD, Zheng J (2019) Simultaneous determination of eight components in Angelica sinensis based on UHPLC-ESI-MS/MS method for quality evaluation. Biomed Chromatogr 33:e4326. https://doi.org/10.1002/bmc.4326

Zhang Q, Chen YY, Ma LX et al (2020) Study on the fingerprints and quality evaluation of Angelica Sinensis Radix by HPLC coupled with chemometrics based on traditional decoction process of ACPTCM. Dose-Response. https://doi.org/10.1177/1559325820951730

Razmovski-Naumovski V, Zhou X, Wong HY, Kam A, Pearson J, Chan K (2020) Chromatographic, chemometric and antioxidant assessment of the equivalence of granules and herbal materials of Angelicae Sinensis Radix. Medicines 7(6):35. https://doi.org/10.3390/medicines7060035

Li X, Yao YX, Wang XX, An C et al (2020) Quantification analysis of 13 organic components and 8 inorganic elements in Angelica Sinensis Radix and its different parts combined with chemical recognition pattern. J Anal Methods Chem. https://doi.org/10.1155/2020/8836184

Cai H, Cao G, Zhang HY (2017) Qualitative analysis of a sulfur-fumigated Chinese herbal medicine by comprehensive two-dimensional gas chromatography and high-resolution time of flight mass spectrometry using colorized fuzzy difference data processing. Chin J Integr Med 23:261–269. https://doi.org/10.1007/s11655-015-1966-z

Tian L, Yan HX, Fu XT et al (2014) Simultaneous determination of multiple components in decoction pieces of Chuanxiong Rhizoma and Angelicae Sinensis Radix by quantitative analysis of multi-components by single maker. Chinese J Pharm Anal 34(5):848–854. https://doi.org/10.16155/j.0254-1793.2014.05.018

Lou YJ, Cai H, Liu X et al (2014) Multi-component analysis in sun-dried and sulfur-fumigated Angelicae Sinensis Radix by single marker quantitation and chemometric discrimination. Pharmacogn Mag 10:S189–S197. https://doi.org/10.4103/0973-1296.127374

Yin HR, Ni H, Zhang LL et al (2021) Untargeted metabolomics coupled with chemometric analysis deducing robust markers for discrimination of processing procedures: Wine-processed Angelica sinensis as a case study. J Sep Sci 44(22):4092–4110. https://doi.org/10.1002/jssc.202100566

Liu C, Long HL, Wu XD et al (2021) Quantitative and fingerprint analysis of proanthocyanidins and phenylpropanoids in Cinnamomum verum bark, Cinnamomum cassia bark, and Cassia twig by UPLC combined with chemometrics. Eur Food Res Technol 247:2687–2698. https://doi.org/10.1007/s00217-021-03795-x

Lu WY, Niu YG, Yang HS et al (2014) Simultaneous HPLC quantification of five major triterpene alcohol and sterol ferulates in rice bran oil using a single reference standard. Food Chem 148:329–334. https://doi.org/10.1016/j.foodchem.2013.10.027

Hou JJ, Wu WY, Liang J et al (2014) A single, multi-faceted, enhanced strategy to quantify the chromatographically diverse constituents in the roots of Euphorbia kansui. J Pharm Biomed Anal 88:321–330. https://doi.org/10.1016/j.jpba.2013.08.049

Duric K, Liu Y, Chen SN et al (2019) Studying mass balance and the stability of (Z)-Ligustilide from Angelica sinensis helps to bridge a botanical instability-bioactivity chasm. J Nat Prod 82:2400–2408. https://doi.org/10.1021/acs.jnatprod.8b00962

Acknowledgements

This work was supported by Organizational Key Research and Development Program of Shanghai University of Traditional Chinese Medicine [Number 2023YZZ02]; Sanming Project of Medicine in Shenzhen (grant number SZZYSM202106004); National Key R&D Program of China under Grant [Number 2018YFC1707900 and 2018YFC1707001]; Research Project of Science and Technology Commission of Shanghai Municipality under Grant [Number 19DZ2200400].

Author information

Authors and Affiliations

Corresponding authors

Ethics declarations

Conflict of interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Compliance with ethics requirements

This article does not contain any research conducted by any author on human participants or animals.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Supplementary file 1: Table S1.

The information of 89 batches of medicinal materials, raw decoction pieces and wine-processed Angelicae Sinensis Radix samples. Table S2. The parameters of the optimization for sample preparation. Table S3. The content (%) of the eight analytes with different extraction solvents. Table S4. The stability (%) of the eight analytes in 34 hours. Table S5. The system suitability parameters of different columns. Table S6. The information about the three chromatographic systems. Table S7. The RRT of each component in three chromatographic systems

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Sun, Y., Zhou, J., Hu, Y. et al. Comprehensive analysis of phenylpropanoids and butylidenephthalides in Angelica sinensis (Oliv.) Diels from different regions and processing methods by high-performance liquid chromatography combined with chemometrics. Eur Food Res Technol 250, 983–998 (2024). https://doi.org/10.1007/s00217-023-04422-7

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00217-023-04422-7