Abstract

The target of this paper is the study of anthocyanin and tannin extraction from red grape during maceration, the formation of new pigments, and the evolution profiles of anthocyanin derivatives and tannins during the alcoholic and malolactic fermentations and aging in oak barrels and steel vats. 2 anthocyanins, 38 anthocyanin derivatives and 37 tannins were monitored. Formation of all classes of anthocyanin derivatives starts quickly after anthocyanin extraction from grape. Their maximum levels are reached a few days after apex of anthocyanins during maceration/alcoholic fermentation. Indirect condensation derivatives showed less stable behavior than that of the direct flavanol–anthocyanin products during fermentations and aging. Within pyranoanthocyanins, vitisin B had more instability than vitisin A. Extraction of tannins from grape occurs slower than that of anthocyanins. Major tannins are procyanidin homodimers with B bond (45% of total tannins after fermentations), followed by monomers (around 25%) and mixed B dimers (more than 10%). Tannins suffer a general continuous decrease during aging, with increasing relevance of more oxygenated tannins as aging advances. Fermentations are crucial stages in the formation of anthocyanin derivatives. In contrast, aging causes a continuous degradation for nearly all classes of anthocyanin derivatives and tannins, with a more stable behavior for some of them. Thus, establishing with confidence which enological conditions favor each type of derivative during fermentation is an important goal for future research. This work studies many individual compounds, involves exhaustive sampling and covers the different winemaking stages at an industrial winemaking scale, contributing to a more complete vision.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Anthocyanins and tannins, major phenolic compounds in wine, greatly contribute to wine organoleptic characteristics such as astringency, bitterness and color [1,2,3,4]. Initial anthocyanins are responsible for the red color in young wines and they are extracted to must mainly from grape skin during maceration of red cultivars. These compounds undergo multiple chemical transformations during winemaking, leading to the formation of new anthocyanin derivatives and providing new tones and hues to red wine color. In the last decades, multiple derivatives with new chemical structures have been detected in model solutions and in wine [1, 5,6,7,8]. Most known are anthocyanin derivatives formed by direct condensation [9,10,11] between anthocyanins and flavanols (monomers of condensed tannins) or tannin oligomers as well as by indirect condensation through an acetaldehyde molecule [12,13,14] and pyranoanthocyanins formed by reaction with small molecules present in wine such as pyruvic acid [15,16,17], acetaldehyde [15], acetoacetic acid [18], 4-vinylphenol [19, 20], 4-vinylcatechol [21], 4-vinylguaicol [22] and vinylflavanols [23,24,25].

Tannins extracted from grape also suffer chemical transformations during winemaking processes, contributing to changes in color through condensation derivatives with anthocyanins, but also in astringency and bitterness. Multiple tannin structures have been detected in wine [5, 26]: direct condensed tannins with type B [27] or A bonds [28]; different degree of polymerization; homo- or hetero-oligomers (also known as mixed oligomers) [29, 30]; indirect condensation tannins linked by acetaldehyde [31, 32], glyoxylic acid [33] or furfurals [34]; galloylated tannins [35]; among others.

The multiple structures detected for both anthocyanin derivatives and tannins reflect the high complexity of wine chemistry. A lot is nowadays known about these different chemical structures. However, data about the stability and the evolution of the different classes of anthocyanin derivatives and tannins during the different stages of winemaking are still scarce [8, 36,37,38]. This work aims to present a more complete vision of the extraction of initial anthocyanins and of different tannin classes during maceration and formation and evolution of new species during fermentations and aging stages of winemaking processes at an industrial scale in wineries.

Materials and methods

Reagents and standards

Methanol and acetonitrile (Romil Chemical Ltd, Heidelberg, Germany) were of HPLC grade. Water was purified on a Milli-Q system (Millipore, Bedford, MA, USA). Trifluoroacetic acid (TFA) for spectroscopy quality, acetic acid (HAc) suprapur quality, and concentrated aqueous hydrochloric acid solution (32%), l(+)-tartaric acid, ethyl alcohol, monosodium phosphate, disodium phosphate and sodium hydroxide of analytical reagent grade were from Merck (Darmstadt, Germany) or (Fluka, Steinheim, Germany). NaH2PO4/Na2HPO4 0.1 M solution buffer was adjusted to pH 6.5 with sodium hydroxide 1 M. All HPLC solvents used were previously filtered through 0.45 μm nylon membranes (Lida, Kenosha, WI, USA).

Standards of malvidin-3-O-glucoside (Mv-3O-glc) and (+)-catechin (Cat) were supplied by Extrasynthèse (Genay, France). Stock solutions of standards were prepared in methanol, with HCl 0.1% m/v in the case of Mv-3O-glc in order to get a better stability. Working calibration dilutions of standards were prepared in water.

Samples

An industrial scale winemaking process, using Tempranillo grape cultivar and 10,000 L steel vats, performed in a collaborating Rioja winery, was monitored during maceration–alcoholic fermentation and malolactic fermentation. A total of twenty-five 3 mL samples were obtained, from 0 to 47 days after the start of fermentation. Samples during maceration–alcoholic fermentation were taken after daily pumping-over operations made in Rioja red winemaking, to get more homogeneous samples. Composition of grape must was 21ºBrix, total acidity 6.17 g/L of tartaric acid and pH 3.34. Maceration and alcoholic fermentation (AF) steel vat was maintained at 26–28 °C and was inoculated with 0.15 g/L of a commercial S. cerevisiae yeast strain (Bayanus, Lamothe-Abiet). Once the fermentation of sugars was complete (day 12) and after devatting, spontaneous malolactic fermentation (MLF) was carried out at 17–18 °C. At the end of MLF (day 23), wine was transferred into a stainless steel vat and 50 mg/L of sulfur dioxide was added. For the wine aging study, another industrial scale Tempranillo red wine aging process, using 225 L oak barrels and 10,000 L steel vats, was performed in a collaborating Rioja winery and was monitored, obtaining a total of twenty (nineteen for tannin analysis) 3 mL wine samples during aging, from 0 to 614 days. Samples were taken from the barrel using a very small diameter tube inserted through the barrel stopper and provided with a stopcock, to avoid oxidation of the sample. Composition of wine when entering the barrel (day 0) was alcoholic degree 13.8º, total acidity 5.46 g/L of tartaric acid, pH 3.53, total phenolic index 73 (absorbance at 280 nm of a 1/100 wine dilution multiplied by 100, measured on a 10 mm optical path cell) and color intensity 14 (sum of absorbances at 420, 520 and 620 nm of undiluted wine measured on a 1 mm optical path cell). Barrel cleaning was done with an automatic barrel washer, using peristaltic or mono pumps for transferring wine. Transfers between barrel and steel vat or vice versa were made using also those types of pumps. Samples from both fermentations and aging studies were immediately preserved in an ultrafreezer at − 80 °C until the analysis.

Analysis of anthocyanin derivatives by SPE–HPLC–DAD–ESI(+)–MS/MS

A solid-phase extraction (SPE) methodology was applied to each sample as a cleaning treatment to reduce suppression in the ionization step of further mass spectrometric analysis. 1 mL of must or wine sample was loaded in a polymeric SPE cartridge Strata-X 3 cc-60 mg (Phenomenex, Torrance, USA), previously preconditioned with 2 mL methanol, 2 mL water and 2 mL synthetic wine (a 3.5 g/L water solution of l(+)-tartaric acid, with a 12% ethanol, adjusted to pH 3.5 with sodium hydroxide). Cartridge was washed with 1 mL of 0.1 M pH 6.5 phosphate buffer and 1 mL water. Anthocyanin derivatives were eluted with 4 mL of MeOH:HCl 99.9:0.1 (v/v), evaporated to dryness under a nitrogen stream using a Zimark Turbovap-LV evaporator (Hopkinton, MA, USA) and redissolved in 1 mL of initial mobile phase.

Malvidin-3-O-(6′′-p-coumaroyl)-glucoside, instead of the major one malvidin-3-O-glucoside, was selected as representative for the behavior of all original anthocyanins due to the need for a great amount of solid standard for calibration and also to droplet saturation effects and lower ionization efficiency in electrospray at high concentrations if malvidin-3-O-glucoside was selected. So, quantification of two anthocyanins (malvidin-3-O-(6′′-p-coumaroyl)-glucoside trans and cis isomers) and 38 anthocyanin derivatives was performed by high-performance liquid chromatography (HPLC) in a Waters Alliance 2695 instrument coupled to a Diode Array Detector (DAD) model 2996 and a Micromass Quattro micro triple quadrupole mass spectrometer (MS) equipped with a Z-spray electrospray (ESI) source and coupled to the exit of DAD (Waters Corporation, Milford, Massachusetts, USA). A reversed-phase Phenomenex (Torrance, USA) Onyx Monolithic C18 column (100 × 3.0 mm) with a precolumn of the same material was used. Eluents were H2O:TFA 99.5:0.5 (v/v) (phase A) and acetonitrile (phase B). A gradient program was employed: 0–0.29 min, isocratic, 12% B; 0.29–4.29 min, linear gradient, 12–15% B; 4.29–9.17 min, linear gradient, 15–25% B; 9.17–12.72 min, linear gradient, 25–40% B; 12.72–13.17 min, isocratic, 40% B; 13.17–13.63 min, linear gradient, 40–100% B; 13.63–21.63 min, isocratic, 100% B, followed by column reconditioning. The flow rate and column temperature were set to 0.3 mL/min and 30 °C, respectively. Vial samples were kept in the injector at 4 °C. 50 μL of each sample was injected. Complete UV–vis spectra were collected in the range 250–600 nm each second. Nitrogen was used as desolvation gas at 300 °C and 450 L/h for mass spectrometer. A potential of 3.2 kV was used on the capillary in positive ion mode. The source block temperature was held at 120 °C. The technique used for quantification was the multiple reaction monitoring (MRM) mode. Collision gas (argon) pressure was set to 1.5 × 10−3 mbar. Table 1 collects the cone voltage (CV), the collision energy (CE) and the MRM transition for each anthocyanin derivative studied. External calibration with Mv-3O-glc was carried out in the range 0.001–100 mg/L using MRM signals, so concentrations of each derivative are given as equivalent concentrations of the only standard employed (Mv-3O-glc). The entire SPE–HPLC–DAD–ESI(+)–MS/MS method was previously validated [39]. It is important to remark that the response factor of each compound in the mass spectrometer is quite different. Thus, comparisons of data for each single derivative when discussing within a profile are confident. However, when comparisons are made between different derivatives these concentration values cannot be taken as absolute values and these comparisons are not strictly correct, but they are the only option since standards were not available for every derivative studied.

Analysis of tannins by SPE–HPLC–DAD–ESI(+)–MS/MS

The same SPE cleaning procedure as that for anthocyanin derivatives was used, but using polymeric sorbent Oasis HLB 60 mg (Waters Corporation, Milford, MA, USA) cartridges. Eluted extracts were also evaporated to dryness under a nitrogen stream and redissolved in 1 mL of the respective initial mobile phase.

Quantification of thirty-seven tannins was performed with the same HPLC–DAD–ESI–MS/MS equipment and column, but using negative polarity in the ESI and different eluents, H2O:HAc 99:1 (v/v) (phase A) and MeOH:HAc 99:1 (v/v) (phase B). A gradient program was employed: 0–1.03 min, isocratic, 0% B; 1.03–7.47 min, linear gradient, 0–20% B; 7.47–11.25 min, linear gradient, 20–25% B; 11.25–16.03 min, linear gradient, 25–45% B; 16.03–19.92 min, linear gradient, 45–75% B; 19.92–24.70 min, linear gradient, 75–100% B; 24.70–28.00 min, isocratic, 100% B, followed by the column reconditioning. The other chromatographic and mass spectrometric conditions were the same as those for anthocyanin derivatives, except capillary voltage (2.6 kV) and polarity (negative). Table 2 collects the cone voltage (CV), the collision energy (CE) and the MRM transition for each of the tannins studied. External calibration with catechin was carried out in the range 0.01–150 mg/L using MRM signals, so concentrations of each tannin are given as equivalent concentrations of the only standard employed (catechin). The entire SPE–HPLC–DAD–ESI(+)–MS/MS method was previously validated [40].

Results and discussion

Formation of anthocyanin derivatives and their evolution profiles during fermentations

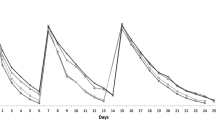

Extraction of anthocyanins from grape to must starts quickly and continuously in the first moments and days of maceration and alcoholic fermentation (AF), as shown in Fig. 1a for coumaroylated malvidin, reaching a maximum level at day 4. Anthocyanin degradation processes (polymerization, oxidation, precipitation/readsorption from pomace, formation of new pigments) also start immediately, if conditions were convenient for each kind of process. From day 4, degradation processes exceed the rate of anthocyanin extraction, so anthocyanin levels begin to decrease. The formation of both direct (Fig. 1b) and indirect (Fig. 1c) flavanol–anthocyanin condensation products starts quickly after anthocyanin extraction. These compounds reach their maximum level during AF at day 6–8, only a few days after anthocyanin apex: Obviously, the formation of condensation derivatives requires that anthocyanins and tannins have been previously extracted from grape to must. Also pyranoanthocyanin formation starts quickly after anthocyanin extraction [36, 41], as shown in Fig. 1d–f for vitisin B (Mv-3-glc-acetaldehyde, pyranoanthocyanin derivative of Mv-3-glc with acetaldehyde), vitisin A (Mv-3-glc-pyruvic, pyranoanthocyanin derivative of Mv-3-glc with pyruvic acid) and pyranoanthocyanin derivative with vinylphenol (Mv-3-glc-vinylphenol), respectively. These compounds reach their maximum levels during AF at day 5–10. Oxygenation/aeration during this stage is significant due to daily pumping-over operations (by pumping must out from the bottom part of vat and over onto the cap) made in Rioja red winemaking.

Evolution profiles of the levels of a trans isomer of malvidin-3-O-(6′′-p-coumaroyl)-glucoside (Mv-3-(6-p-coumglc)), b catechin-malvidin-3-O-glucoside, c malvidin-3-O-glucoside-ethyl-catechin 2, d vitisin B, e vitisin A, and f pyranoanthocyanin derivative with vinylphenol; during fermentations of an industrial scale Rioja red wine winemaking process (concentration values are given as equivalent concentrations in mg/L of Mv-3O-glc)

After a decreasing tendency for all anthocyanin derivatives in the last days of AF, more pronounced in the case of vitisin B (both non-acylated and coumaroylated), a new formation impulse is observed for all compounds when malolactic fermentation (MLF) starts. For most derivatives, this impulse recovers or even increases the maximum levels of AF, except for vitisin B for which the level throughout MLF stays way below from the apex of AF. The second part of MLF produces again a decreasing tendency for all derivatives, except for indirect condensation products, for which this decrease is delayed until the end of MLF. The next 3 weeks after the end of MLF cause new losses for vitisin B and direct (less pronounced) and indirect condensation derivatives, but not for vitisin A and pyranoanthocyanins with vinylphenols, which preserve their levels.

Two conclusions can be drawn from these observations. On one hand, indirect condensation derivatives are formed in a much smaller amount than direct products and are less stable, losing 50 percent of their level 3 weeks after the end of the MLF. This more unstable behavior of indirect derivatives has been previously referred [37, 42,43,44]. On the other hand, although levels of vitisin B formed were more than double than those of vitisin A, the more unstable behavior of the first has as a consequence that the levels of both 3 weeks after the end of MLF were similar or even greater for vitisin A. This more unstable behavior of vitisin B has also been previously referred [37, 44, 45].

In an overall view, in the monitored red wine at the end of fermentations, direct condensation derivatives, vitisin A, vitisin B and pyranoanthocyanins with vinylphenols, represent about 10%, 40%, 40% and 10% of total anthocyanin derivatives (in terms of Mv-3O-glc equivalent concentration levels), respectively. Indirect condensation derivatives and pyranoanthocyanins with vinylflavanols are minor derivatives.

Evolution profiles of other anthocyanin derivatives during fermentations are shown in Figure ESM1 of Online Resource, confirming conclusions previously explained. A stable behavior for pyranoanthocyanins with vinylphenol after MLF is also observed for derivatives with vinylguaiacol and vinylcatechol. Pyranoanthocyanin derivatives with acetoacetic acid show low levels and have a stable behavior after MLF, similar to vitisin A. Very low levels of pyranoanthocyanin derivatives with vinylflavanols were observed throughout fermentations in this study, despite the relatively high levels of vinyl-tannins during fermentations as shown below.

Evolution profiles of anthocyanin derivatives during aging

Table 3 collects percentage variation of levels of some major anthocyanin derivatives throughout different stages of a red wine aging in stainless steel vats and oak barrels. Aging profiles for Mv-3-(6-p-coum)-glc (Fig. 2a) show big changes when processes such as vat transfers are made to the wine, in contrast to quiet periods in barrel or in stainless steel vat. This is a general behavior in most of the cases and for most anthocyanin derivatives. However, when interpreting the results an important fact should be considered: transfer from barrel (225 L) to steel vat (10,000 L) also involves the mixture of wine from the studied barrel with wine of other barrels from the same lot, but perhaps somewhat different in terms of their phenolic contents. For this reason, changes after those barrel to steel vat transfers do not necessarily correspond to the studied wine. In any case, since the wine belongs to the same lot some probable conclusions could be attained. For steel vat to barrel transfers, this problem does not exist. Also the cleaning barrel process, which involves a transitory wine transfer to a steel vat while barrel is cleaned, implies some wine mixture. However, the main cause for these big changes in the levels of anthocyanin derivatives during transfers is probably due to the great oxygenation of the wine that those transfer operations cause. They increase dissolved oxygen in wine and change concentrations of most derivatives, some being favored and others degraded by oxidative conditions.

Evolution profiles of the levels of a trans isomer of malvidin-3-O-(6′′-p-coumaroyl)-glucoside, b catechin-malvidin-3-O-glucoside, c malvidin-3-O-glucoside-ethyl-catechin 2, d vitisin B, e vitisin A, and f pyranoanthocyanin derivative with vinylphenol; during aging in oak barrels and steel vats of an industrial scale Rioja red wine winemaking process (concentration values are given as equivalent concentrations in mg/L of Mv-3O-glc)

When the cleaning of the barrel is performed losses of 66% are experienced for Mv-3-(6-p-coum)-glc. This great decrease during the cleaning barrel process is also observed for direct (− 40% to − 65%) and ethylidene-bridged (losses of 18–66%) condensation derivatives, and for pyranoanthocyanin derivatives with vinylphenols (− 46%) and vinylflavanols (− 35%), but not for vitisin B (+ 59%), vitisin A (+ 75%) or acetoacetic acid derivatives (+ 54%).

The period in barrel after the oak barrel cleaning produces a slight decrease for direct flavanol–anthocyanin (F–A+) condensation derivatives (− 2% to − 14%, see Fig. 2b for Catechin-Mv-3-glc, the major one). A similar behavior is observed for ethylidene-bridged derivatives (− 35%, see Fig. 2c for Mv-3-glc-8-ethyl-cat 2, the major one) and pyranoanthocyanins (from − 8 to − 34%, see Figs. 2d–f for vitisin B, vitisin A and derivative with vinylphenol, respectively). On the other hand, the second barrel period constitutes a more stable stage with nearly no losses for vitisin A (+ 0%) and pyranoanthocyanin derivatives with acetoacetic acid (+ 0%), slight losses for ethylidene-bridged derivatives (− 6% to − 12%) and for pyranoanthocyanin derivatives with vinylflavanols (− 8%) or vitisin B (− 16%), and increases for pyranoanthocyanin derivatives with vinylphenols (+ 2% to + 17%) and for direct condensation derivatives (+ 21%).

Periods within stainless steel vat in the case of F–A+ direct condensation derivatives show two opposite behaviors: the first steel period implies a slight decrease (+ 2% to − 10%), and the second implies an increasing tendency (+ 27% to + 35%). The cause of the great changes in the last period within steel vat before bottling is unknown, but is probably due to mixtures of wines made at winery before bottling. So, no significant consequences should be considered from the second steel period (the same applies for all derivatives).

Comparing the levels between the start of the first barrel period and the end of the second barrel period, direct F–A+ condensation derivatives suffered an increase of 6–39% (− 10% to − 52% from the start of aging, t = 0 days), whereas ethylidene-bridged derivatives had losses of 44–46% (− 85 to − 89%, from t = 0 days). This shows the more unstable behavior of indirect condensation derivatives as previously reported [37, 42,43,44]. Concerning pyranoanthocyanins, differences in the levels between the start of the first and the end of the second barrel periods are + 9% (+ 38%, from t = 0 days), + 9% (+ 21%, from t = 0 days), + 14% (− 13%, from t = 0 days), − 34% (− 77%, from t = 0 days) and − 41% (− 29%, from t = 0 days) for vitisin A, derivatives with acetoacetic acid, vinylflavanols, vinylphenol, and vitisin B, respectively. This order could be regarded as the stability order of pyranoanthocyanins, being vitisin A and derivatives with acetoacetic acid more stable than those with vinylflavanols, vinylphenols and vitisin B.

During the period inside the steel vat ethylidene-bridged derivatives significantly decrease (− 62%, Fig. 2c), in contrast to direct F–A+ condensation derivatives (+ 2% to − 10%, Fig. 2b). This shows again the more unstable behavior above mentioned, also during steel vat periods. Moreover, the levels of ethylidene-bridged derivatives throughout the second barrel period are very low, twenty times lower than those of direct condensation derivatives. They sligthly decrease (− 6% to − 12%) during this period, whereas the amounts of direct condensation derivatives suffer a significant increase (+ 6% to + 21%), confirming instability of ethylidine-bridged derivatives against direct condensation ones even when aging process is advanced.

Evolution profiles of other anthocyanin derivatives during aging are given in Figure ESM2 of Online Resource, confirming the conclusions previously exposed.

Levels of derivatives with vinylphenol and vinylguaiacol are much higher than those of derivatives with vinylcatechol and vinylsyringol during first years of aging and also throughout fermentations. This is a consequence of their quick formation during the first stages of winemaking from enzymatic decarboxylation of hydroxycinnamic acids, which is specific for p-coumaric and ferulic acids [6, 46].

Within direct F–A+ condensation derivatives, those containing (epi)catechin were more abundant than those formed from (epi)gallocatechin. Also, those originated from the epi-isomers were less abundant throughout aging (and also during fermentations), as found by Alcalde-Eon et al. [37]. Figure ESM2 of Online Resource shows that the more unstable behavior of coumaroylated vitisin A against non-acylated vitisin A during aging [47] is also observed for other classes of pyranoanthocyanins.

Evolution profiles of tannins during fermentations

In general, extraction of tannins from grape occurs slower than that of anthocyanins and their contents in must increase during maceration–alcoholic fermentation: tannins start to be extracted from day 3 to 4 (Fig. 3), whereas grape anthocyanins start to be extracted from day 0 to 1 and at day 4 have already reached their maximum levels (Fig. 1a).

Evolution profiles of the levels of a catechin, b procyanidin B1, c procyanidin B2, d ((epi)gallocat)2A, the major prodelphinidin homodimer with A bond, e ((epi)cat-(epi)gallocat)A 2, the major mixed dimer with A bond, f sums of homo and heterodimers A and B, g ((epi)cat)2 1, a procyanidin homodimer B, and h (epi)gallocat-(epi)cat 2, a prodelphinidin heterodimer B; during fermentations of an industrial scale Rioja red wine winemaking process (concentration values are given as equivalent concentrations in mg/L of catechin)

In the case of flavan-3-ol monomers, concentrations increase in the first days of maceration and AF, remaining quite stable or even showing a slight increase from the middle toward the end of AF. During the first part of MLF, monomers remain quite stable, showing a significant increase from the middle toward the end of MLF, as shown in Fig. 3a for catechin, the major monomer. This increase is not so pronounced for gallocatechin and epigallocatechin (Fig. ESM3 of Online Resource). After the end of MLF, monomer levels remain quite stable or even show a slight increasing tendency. This profile during fermentations is observed for most tannins within this study, with the only exception that the significant increase from the middle to the end of MLF (e.g., procyanidin B2, Fig. 3c) is advanced in some cases such as procyanidin B1 (Fig. 3b), the major B dimer, reaching a maximum level at the middle of MLF and showing also an intense decrease until the end of MLF.

Kinetics of extraction of prodelphinidin B homodimers and mixed B dimers are similar to those of procyanidin B homodimers (Fig. ESM3 of Online Resource). Of more interest is the fact that kinetics of A dimers are also similar to those of B dimers (Fig. 3d, e). The extraction starts at days 3–4 and shows high increases until day 6–8. This indicates that A dimers are extracted to must from grape and are not formed from B dimers by oxidation, at least in those first days of AF. Thus, A dimers are also present in grape, as stated by some authors [48].

Major tannins are procyanidin homodimers with B bond (45% of total tannins after fermentations), followed by monomers (near 25%) and mixed B dimers (more than 10%). Within dimers with B bond, mixed ones have higher levels than those of prodelphinidin B homodimers (Fig. ESM3 of Online Resource). In a similar fashion, mixed dimers with A bond are more abundant than prodelphinidin homodimers with A bond (Fig. 3e, d). Interestingly, mixed B dimers with (epi)gallocatechin as upper unit show a more unstable behavior than those with (epi)catechin as upper unit during MLF (Fig. ESM3 of Online Resource), suggesting a favored breakage of interflavonoid linkage during MLF when (epi)gallocatechin is the upper unit. However, this more unstable behavior during MLF is confirmed for only two of the three prodelphinidin dimers and this different behavior is also observed between procyanidins B1 against B2 and procyanidins B1 against ((epi)cat)2 1 (probably B3). This suggests that this more unstable behavior during MLF should have a more complex origin.

In contrast to dimers with B bond, levels of procyanidin A homodimers are much lower than those of prodelphinidin homodimers and mixed dimers with A bond (Fig. ESM3 of Online Resource). This suggests a favored formation of additional A bond when an (epi)gallocatechin unit is involved. In fact, within A trimers those with A bond implying one or two (epi)gallocatechin units are easily detected (Fig. ESM3 of Online Resource) unlike those with A bond between two units of (epi)catechin (data not shown). Moreover, mixed A dimers with (epi)gallocatechin as the lower unit are more easily detected when compared to those with (epi)gallocatechin as upper unit (data not shown).

In contrast to ethylidene-bridged tannins, vinyl-tannins were present at very high levels (Fig. ESM3 of Online Resource), suggesting that depolymerization of the former to produce the last is favored throughout fermentations for the studied tempranillo wine.

As previously referred [38, 49], skin tannins have larger proportion of (epi)gallocatechin units than seed tannins. Thus, extraction of tannins from the skin exceeds that from the seed during the early stages of maceration/AF, while extraction of seed tannins predominates in the later stages of maceration. So, as maceration advances the ratio of the levels of tannins with (epi)gallocatechin units to those with (epi)catechin units should decrease, as shown in Fig. 3f for sums of homo and heterodimers A and B. The same decreasing tendency is also observed for sums of monomers (excluding galloylated units) and sums of monomers, dimers and trimers (Fig. ESM3 of Online Resource). As stated [38, 50, 51], skin tannins, mainly extracted in the firsts maceration stages, appear to follow a Boltzmann sigmoid extraction model reaching a plateau, while extraction of seed tannins, predominating in the latter stages when hydration of seeds is complete and ethanol content is higher, follows a linear model. These two stages can be seen for most of the analyzed tannins, as shown in Fig. 3g, h for a procyanidin homodimer B and a prodelphinidin heterodimer B. However, lower extraction rates were observed in this industrial fermentation for other tannins in the latter stages, maintaining nearly plateau behaviors (Fig. ESM3 of Online Resource), and indicating little seed tannin extraction.

Evolution profiles of tannins during aging

Tannins suffer a general continuous decrease throughout aging (Fig. ESM4 of Online Resource and Table 4). However, some major contribution of mixed trimers with A bond can be observed as aging process advances, which is also produced for mixed dimers with B bond. Both facts seem to point out an increasing relevance of more oxygenated tannins as aging advances. Moreover, although the level of furfuryl bridged tannins during fermentations is very low, some higher levels were found for the studied wine during aging due to oak contact. However, a much higher content of furfuryl bridged tannins has been found in other aged Rioja wines (data not shown).

Conclusions

Fermentations are essential stages in the formation of anthocyanin derivatives. In contrast, aging causes a continuous degradation for nearly all classes of anthocyanin derivatives and tannins, with more stable behavior for some of them, such as non-acylated pyranoanthocyanin derivatives with pyruvic acid (vitisin A), vinylflavanols and vinylphenols and non-epi-isomers of direct F–A+ condensation derivatives. Thus, establishing with confidence which enological conditions during fermentation favors each type of derivative is an important goal for future research.

References

Cheynier V, Dueñas-Paton M, Salas E, Maury C, Souquet JM, Sarni-Manchado P, Fulcrand H (2006) Structure and properties of wine pigments and tannins. Am J Enol Vitic 57:298–305

Kennedy JA, Saucier C, Glories Y (2006) Grape and wine phenolics: history and perspective. Am J Enol Vitic 57:239–247

Harrison R (2018) Practical interventions that influence the sensory attributes of red wines related to the phenolic composition of grapes: a review. Int J Food Sci Technol 53:3–18

Sener H (2018) Effect of temperature and duration of maceration on colour and sensory properties of red wine—a review. S Afr J Enol Vitic 39:227–234

Monagas M, Bartolomé B, Gómez-Cordovés C (2005) Updated knowledge about the presence of phenolic compounds in wine. Crit Rev Food Sci Nutr 45:85–118

Rentzsch M, Schwarz M, Winterhalter P (2007) Pyranoanthocyanins—an overview on structures, occurrence, and pathways of formation. Trends Food Sci Technol 18:526–534

De Freitas V, Mateus N (2011) Formation of pyranoanthocyanins in red wines: a new and diverse class of anthocyanin derivatives. Anal Bioanal Chem 401:1463–1473

Quaglieri C, Jourdes M, Waffo-Teguo P, Teissedre PL (2017) Updated knowledge about pyranoanthocyanins: impact of oxygen on their contents, and contribution in the winemaking process to overall wine color. Trends Food Sci Technol 67:139–149

Somers TC (1971) The polymeric nature of wine pigments. Phytochem 10:2175–2186

Remy S, Fulcrand H, Labarbe B, Cheynier V, Moutounet M (2000) First confirmation in red wine of products resulting from direct anthocyanin-tannin reactions. J Sci Food Agric 80:745–751

Salas E, Atanasova V, Poncet-Legrand C, Meudec E, Mazauric JP, Cheynier V (2004) Demonstration of the occurrence of flavanol-anthocyanin adducts in wine and in model solutions. Anal Chim Acta 513:325–332

Timberlake CF, Bridle P (1976) Interactions between anthocyanins, phenolic compounds, and acetaldehyde and their significance in red wines. Am J Enol Vitic 27:97–105

Bakker J, Picinelli A, Bridle P (1993) Model wine solutions: colour and composition changes during ageing. Vitis 32:111–118

Rivas-Gonzalo JC, Bravo-Haro S, Santos-Buelga C (1995) Detection of compounds formed through the reaction of malvidin-3-monoglucoside and catechin in the presence of acetaldehyde. J Agric Food Chem 43:1444–1449

Bakker J, Timberlake CF (1997) Isolation, identification, and characterization of new color-stable anthocyanins occurring in some red wines. J Agric Food Chem 45:35–43

Fulcrand H, Benabdeljalil C, Rigaud J, Cheynier V, Moutounet M (1998) A new class of wine pigments generated by reaction between pyruvic acid and grape anthocyanins. Phytochem 47:1401–1407

Mateus N, Silva AMS, Vercauteren J, De Freitas V (2001) Occurrence of anthocyanin-derived pigments in red wines. J Agric Food Chem 49:4836–4840

He J, Santos-Buelga C, Silva AMS, Mateus N, De Freitas V (2006) Isolation and structural characterization of new anthocyanin-derived yellow pigments in aged red wines. J Agric Food Chem 54:9598–9603

Cameira-dos-Santos PJ, Brillouet JM, Cheynier V, Moutounet M (1996) Detection and partial characterization of new anthocyanin-derived pigments in wine. J Sci Food Agric 70:204–208

Fulcrand H, Cameira Dos Santos PJ, Sarni-Manchado P, Cheynier V, Favre-Bonvin J (1996) Structure of new anthocyanin-derived wine pigments. J Chem Soc Perkin Trans 1:735–739

Schwarz M, Jerz G, Winterhalter P (2003) Isolation and structure of pinotin A, a new anthocyanin derivative from Pinotage wine. Vitis 42:105–106

Hayasaka Y, Asenstorfer RE (2002) Screening for potential pigments derived from anthocyanins in red wine using nanoelectrospray tandem mass spectrometry. J Agric Food Chem 50:756–761

Francia-Aricha EM, Guerra MT, Rivas-Gonzalo JC, Santos-Buelga C (1997) New anthocyanin pigments formed after condensation with flavanols. J Agric Food Chem 45:2262–2266

Asenstorfer RE, Hayasaka Y, Jones GP (2001) Isolation and structures of oligomeric wine pigments by bisulfite-mediated ion exchange chromatography. J Agric Food Chem 49:5957–5963

Mateus N, Silva AMS, Santos-Buelga C, Rivas-Gonzalo JC, de Freitas V (2002) Identification of anthocyanin-flavanol pigments in red wines by NMR and mass spectrometry. J Agric Food Chem 50:2110–2116

McRae JM, Bindon KA, Hixson JL, Smith PA (2016) Wine tannin structure and extraction: Review of current research. In: Combs CA (ed) Tannins: biochemistry, food sources and nutritional properties. Nova Science Publishers, Hauppauge, pp 85–119

Bourzeix MD, Weyland D, Heredia N (1986) Étude des catéchins et des procyanidols de la grappe de raisin, du vin et d’autres dérivés de la vigne. Bull OIV 669–670:1171–1254

Vivas de Gaulejac N, Vivas N, Absalon C, Nonier MF (2001) Identification of procyanidin A2 in grape and wine of Vitis vinifera L. cv. Merlot Noir and Cabernet Sauvignon. J Int Sci Vigne Vin 35:51–56

Fulcrand H, Remy S, Souquet JM, Cheynier V, Moutounet M (1999) Study of wine tannin oligomers by on-line liquid chromatography electrospray ionization mass spectrometry. J Agric Food Chem 47:1023–1028

De Pascual-Teresa S, Rivas-Gonzalo JC, Santos-Buelga C (2000) Prodelphidins and related flavanols in wine. Int J Food Sci Technol 35:33–40

Cheynier V, Doco T, Fulcrand H, Guyot S, Le Roux E, Souquet JM, Rigaud J, Moutounet M (1997) ESl-MS analysis of polyphenolic oligomers and polymers. Analusis 25:M32–M37

Saucier C, Little D, Glories Y (1997) First evidence of acetaldehyde-flavanol condensation products in red wine. Am J Enol Vitic 48:370–373

Es-Safi NE, Le Guernevé C, Fulcrand H, Cheynier V, Moutounet M (2000) Xanthylium salts formation involved in wine colour changes. Int J Food Sci Technol 35:63–74

Es-Safi NE, Cheynier V, Moutounet M (2000) Study of the reactions between (+)-catechin and furfural derivatives in the presence or absence of anthocyanins and their implication in food color change. J Agric Food Chem 48:5946–5954

Ricardo da Silva JM, Cheynier V, Souquet JM, Moutounet M, Cabanis JC, Bourzeix M (1991) Interaction of grape seed procyanidins with various proteins in relation to wine fining. J Sci Food Agric 57:111–125

Asenstorfer RE, Markides AJ, Iland PG, Jones GP (2003) Formation of vitisin A during red wine fermentation and maturation. Austr J Grape Wine Res 9:40–46

Alcalde-Eon C, Escribano-Bailón MT, Santos-Buelga C, Rivas-Gonzalo JC (2006) Changes in the detailed pigment composition of red wine during maturity and ageing. A comprehensive study. Anal Chim Acta 563:238–254

Smith PA, McRae JM, Bindon KA (2015) Impact of winemaking practices on the concentration and composition of tannins in red wine. Austr J Grape Wine Res 21:601–614

Sánchez-Ilarduya MB (2010) Pigmentos derivados antociánicos de los vinos tintos de Rioja. Estudio analítico, influencia en el color y evolución durante la crianza. PhD Thesis, Universidad del País Vasco/Euskal Herriko Unibertsitatea UPV/EHU, Bilbao (Spain). https://www.educacion.es/teseo/mostrarRef.do?ref=902685. Accessed 3 Sep 2019

Sánchez-Fernández C (2012) Búsqueda de marcadores de tipo tanino en vinos tintos de Rioja: Estudio cualitativo y cuantitativo por HPLC-MS/MS. PhD Thesis, Universidad del País Vasco/Euskal Herriko Unibertsitatea UPV/EHU, Bilbao (Spain). https://www.educacion.es/teseo/mostrarRef.do?ref=346281. Accessed 3 Sep 2019

Benito S, Morata A, Palomero F, González MC, Suárez-Lepe JA (2011) Formation of vinylphenolic pyranoanthocyanins by Saccharomyces cerevisiae and Pichia guillermondii in red wines produced following different fermentation strategies. Food Chem 124:15–23

Fulcrand H, Atanasova V, Salas E, Cheynier V (2004) The fate of anthocyanins in wine: are there determining factors?. In: Waterhouse AL, Kennedy JA (eds) Red Wine Color. Exploring the mysteries. ACS Symposium Series 886, American Chemical Society, Washington, pp 68–88

Cano-López M, Pardo-Mínguez F, Schmauch G, Saucier C, Teissedre PL, López-Roca JM, Gómez-Plaza E (2008) Effect of micro-oxygenation on color and anthocyanin-related compounds of wines with different phenolic contents. J Agric Food Chem 56:5932–5941

Arapitsas P, Perenzoni D, Nicolini G, Mattivi F (2012) Study of Sangiovese wines pigment profile by UHPLC-MS/MS. J Agric Food Chem 60:10461–10471

Rentzsch M, Schwarz M, Winterhalter P, Hermosín-Gutiérrez I (2007) Formation of hydroxyphenyl-pyranoanthocyanins in Grenache wines: precursor levels and evolution during aging. J Agric Food Chem 55:4883–4888

Chatonnet P, Dubourdieu D, Boidron JN, Lavigne V (1993) Synthesis of volatile phenols by Saccharomyces cerevisiae in wines. J Sci Food Agric 62:191–202

Romero C, Bakker J (2001) Anthocyanin and colour evolution during maturation of four port wines: effect of pyruvic addition. J Sci Food Agric 81:252–260

Passos CP, Cardoso SM, Domingues MRM, Domingues P, Silva CM, Coimbra MA (2007) Evidence for galloylated type-A procyanidins in grape seeds. Food Chem 105:1457–1567

Peyrot des Gachons C, Kennedy JA (2003) Direct method for determining seed and skin proanthocyanidin extraction into red wine. J Agric Food Chem 51:5877–5881

Cerpa-Calderón FK, Kennedy JA (2008) Berry integrity and extraction of skin and seed proanthocyanidins during red wine fermentation. J Agric Food Chem 56:9006–9014

Hernández-Jiménez A, Kennedy JA, Bautista-Ortín AB, Gómez-Plaza E (2012) Effect of ethanol on grape seed proanthocyanidin extraction. Am J Enol Vitic 63:57–61

Acknowledgements

This research was supported by the Agricultural Department of Basque Government. Z. Rasines-Perea and C. Asensio-Regalado thank Gobierno Vasco/Eusko Jaurlaritza for their Ph.D. grants. The authors also thank the wineries Faustino, Cvne, Coto de Rioja, Torre de Oña and Unión de Cosecheros de Labastida, for their collaboration. Technical and staff support provided by SGIker (UPV/EHU, MICINN, GV/EJ, ESF) is gratefully acknowledged.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that there are no conflicts of interest associated with this publication.

Humans or animal rights

This article does not contain any study with humans or animal subjects.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Electronic supplementary material

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Berrueta, L.A., Rasines-Perea, Z., Prieto-Perea, N. et al. Formation and evolution profiles of anthocyanin derivatives and tannins during fermentations and aging of red wines. Eur Food Res Technol 246, 149–165 (2020). https://doi.org/10.1007/s00217-019-03405-x

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00217-019-03405-x