Abstract

The increasing interest in cannabinoids, both in hemp plant material and hemp-derived products, has sparked a renewed interest in cannabinoid analysis, mostly by liquid chromatography. A simple isocratic HPLC method for analysing cannabinoids in hemp (Cannabis sativa and Cannabis indica) plant material and its extracts has been developed. It was demonstrated that separation of chromatographically critical cannabinoids can be successfully done by a careful selection of a few parameters like common mobile phase modifiers and column temperature. Column temperature proved to be very critical, even under isocratic elution. Analyses are performed within 8.5 min. The use of 275 nm detection wavelength provided about an order of magnitude better sensitivity compared to the established 228 nm wavelength normally used in cannabinoid analysis. The method was validated for 11 major cannabinoids present in Cannabis samples and products, namely: cannabidivarine, cannabidiolic acid, cannabigerolic acid, cannabigerol, cannabidiol, tetrahydrocannabivarin, cannabinol, Δ9-tetrahydrocannabinol, Δ8-tetrahydrocannabinol, tetrahydrocannabinolic acid, and cannabichromene. The assessed limits of detection and the limits of quantitation range from 7 to 205 ng/mL and from 23 to 684 ng/mL, respectively. Being isocratic, with minimum adaptation, the method can be applied for screening work using a shorter column or for a better performing analysis by employing a longer column.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

The ever increasing interest in growing different hemp varieties (Cannabis sativa and Cannabis indica) and its consequential need for analysis of plant material and plant-derived products have put a lot of demand and pressure on many analytical laboratories during the last decade. Hence, the surge of many analytical applications for cannabinoid analysis in the past years was a logical consequence of these circumstances. Traditionally, the most common approach for cannabinoid analysis was by the use of gas chromatography (GC) with flame ionisation (FID) or mass-spectrometric (MS) detection [1,2,3,4,5,6,7], which is also the prescribed one by some official authorities [8] for regulatory analysis of cultivated and seized samples. In GC, during the injection phase, the majority of cannabinoids in acid form (e.g., cannabidiolic acid, tetrahydrocannabinolic acid, etc.) decarboxylate under high vaporisation temperatures in the injection port, thereby they are detected in the decarboxylated form along with their native decarboxylated counterparts (e.g., cannabidiol, tetrahydrocannabinol, etc.) as the whole amount. However, as has been observed by the author on many occasions (unpublished work), the degree of decarboxylation is largely dependent on many factors like the injector temperature, sample volume, type of solvent, etc., and can never be considered as complete. Such observations have also been made by other researchers. Decarboxylation is also very dependent on the compound. Tetrahydrocannabinolic acid (THCA), for example, is more prone to decarboxylate compared to cannabidiolic acid (CBDA) or cannabigerolic acid (CBGA) [9]. Under no circumstances, a complete decarboxylation of an acidic cannabinoid can, thus, be postulated under GC conditions [10]. Gas chromatography is, therefore, unsuitable for a proper characterisation of hemp samples, unless another labour-intensive step is also taken, namely derivatisation of cannabinoids prior to injection, usually in the form of trimethylsilylated compounds [7, 11,12,13]. High-performance liquid chromatography (HPLC) has clearly become the logical choice for cannabinoid analysis, because the sample preparation is basically restricted to extraction (and eventual dilution) before injection. HPLC, hence, does not require a derivatisation step to speciate cannabinoids between acidic and decarboxylated forms.

Speciation of cannabinoids between the acidic and the decarboxylated form provides important information about the status of the plant material like harvest maturity or storage conditions of the material in question [14, 15]. For hemp-derived extracts, such profiling can provide an indication about the processing steps involved in the production. Nonetheless, medical and other studies confirm that the acidic forms also have a large biochemical and medical potential [16,17,18,19,20]. Especially, CBDA is becoming an important subject of studies, mainly due to its proven anti-cancer activity [21].

Many analytical papers dealing with HPLC analysis of cannabinoids have, therefore, appeared in recent years, both in scientific [6, 22,23,24,25,26,27,28,29,30] and commercially oriented [31,32,33,34,35,36] publications. The latter are logically oriented in the promotion of newer stationary phases promising enhanced selectivity towards certain classes of analytes, in such a case cannabinoids. Nevertheless, the vast majority of analytical methods involves the use of reversed-phase stationary phase for obvious practical reasons, by their own, though subtle, differences in separation strategy. Most of the published methods employ gradient elution, since obtaining sufficient selectivity for the more polar cannabinoids proves to be a challenging task, but also due to quite a large span in polarity between cannabinoids (e.g., between cannabidiolic acid and cannabichromene). Not surprisingly, small differences in method strategy can provide quite big differences in method selectivity. The aim of the present work was to develop a robust isocratic HPLC method based on a time-tested and commonly available type of stationary phase, ensuring method reproducibility and ruggedness.

Materials and methods

Instrumentation and analytical conditions

The analyses were performed using a Finnigan Surveyor HPLC system equipped with a photodiode-array UV–Vis detector (Thermo Electron Corporation, San Jose, CA, USA) using a 50 mm light-pipe flow cell and data acquisition software ChromQuest 5.0 (Thermo Electron Corporation). The selected column was Luna C18 (2) (octadecyl silica) with dimensions 150 mm × 3 mm i.d., 3 µm particle size (Phenomenex, Torrance, CA, USA) with temperature set at 37 °C. Sample vials have been thermostatted at 10 °C. Flush solvent was methanol. The selected UV detection wavelength was 275 nm. Comparative tests have been also performed at 228 nm and 306 nm, all at 11 nm bandwidth. Spectra have been also acquired between 210 and 400 nm. Flow rate during analysis was constant with 0.8 mL/min and injection volume was 5 μL. Mobile phase was isocratic and consisted of water/acetonitrile with a ratio of 9:31 (v/v), with 0.1% formic acid (v/v) and 10 mM ammonium formate (without pH adjustment). Run-time length was 8.5 min. During the method development phase, several other HPLC stationary phases have also been tested for selectivity, namely Alltima C18 (Alltech/Grace), Kromasil C18 (Eka Nobel), LiChrosorb RP-18 (Merck), LiChrospher RP-18 (Merck), Pack-pro RS C18 (YMC), Superspher RP-18 (Merck), and Zorbax C18 (Agilent).

Chemicals and materials

Acetonitrile and methanol were HPLC grade; formic acid and absolute ethanol were p.a. grade (Merck, Darmstadt, Germany). Deionised water was obtained from a Milli-Q apparatus (Millipore, Milford, MA, USA). Ammonium formate was LC–MS grade (Sigma-Aldrich, St.Louis, MO, USA). Reference standards cannabidivarine (CBDV), cannabidiolic acid (CBDA), cannabigerolic acid (CBGA), cannabigerol (CBG), cannabidiol (CBD), tetrahydrocannabivarin (THCV), cannabinol (CBN), Δ9-tetrahydrocannabinol (d9-THC), Δ8-tetrahydrocannabinol (d8-THC), cannabichromene (CBC), and tetrahydrocannabinolic acid (THCA) were all of chromatographic purity obtained in solid form or standardised solution from LGC standards (Teddington, Middlesex, UK). Butylhydroxytoluene (BHT) was purchased from Merck and was applied as internal standard (IS). Hemp plant material was obtained from local hemp growers. Hemp resin was purchased locally or produced in the laboratory by evaporating ethanolic hemp extracts.

Preparation of standards

Stock solutions of individual standards obtained in solid form were prepared in the concentration of 1.0 mg/mL in ethanol. The working standard solution consisted of a mix of all cannabinoids standards plus IS at a concentration of 20 µg/mL. Concentrations of CBN, CBC, and THCA were 1.0 µg/mL; CBD and THCV were 2.0 µg/mL; CBGA was 5.0 µg/mL; CBDA, CBG, CBD, d9-THC, and d8-THC were 10.0 µg/mL. For proper dilution, ethanol was used. For determination of linearity, standard solutions have also been prepared by proportionally increasing and decreasing the concentrations from 500 down to 20% relative to working standard solution. Internal standard concentration was kept constant at 20 µg/mL.

Sample preparation

Finely pulverised hemp plant material was extracted by sonication for 30 min in ethanol containing IS (20 µg/mL) at a rate of 0.5 g/50 mL. The extracts were further diluted 10- to 20-fold with ethanolic IS solution (20 µg/mL). Hemp resin extracts were firstly dissolved in 2-propanol at 0.5 g/10 mL and then diluted with IS solution 500- to 1000-fold. Working sample solutions were then centrifuged at 16.000g for 10 min and the supernatant transferred into HPLC vials. Results from a few selected sample analyses are summarised in Table 1.

Quantitation, method precision, accuracy, sensitivity, linearity, and stability

Injection precision was determined by four injections of working standard solution. Extraction efficiency was assessed by three consecutive extractions of selected plant samples and then compared the analyte recovery with the combined recovery of all extraction steps. Accuracy was determined by spiking sample solution with standards at 50% concentration relative to working standard solution. Repeatability and intermediate precision were also tested on a homogeneous plant sample. Four replicates were assayed for repeatability, while three replicates were assayed on each of the 3 consecutive days for intermediate precision.

Limits of detection (LOD) and quantitation (LOQ) have not been tested directly because beyond the scope of the work. The assessment of LOD and LOQ was based on the criteria of expected signal-to-noise ratios of 3 and 10, respectively, based on the signal-to-noise data obtained from standard solutions. Linearity was checked in two replicates in the range between 20 and 500% concentration relative to the working standard solution, at least in six points. Correlation coefficients were calculated with intercept values set at zero. Analyte peak areas were normalised by dividing them with IS peak area. For stability tests, a spiked sample solution has been refrigerated at 4 °C in the dark for 48 h. The validation results are shown in Table 2.

Compliance with ethics requirements

This article does not contain any studies with human or animal subjects.

Results and discussion

Stationary and mobile phase selection

The initial selection for a proper column phase began among the more traditional stationary phases with relatively high carbon load values. Phases with carbon load content between 16 (Alltima C18) and 22% (YMC Pack-Pro RS C18) have been taken into consideration. Newer stationary phases (e.g., sub 3 µm particles and core–shell) have been deliberately omitted. The need for a column with high carbon load was dictated by at least two factors. First, cannabinoid sample (and standard) solutions need to be made in high-strength solvents (in terms of reversed-phase conditions) like pure methanol or ethanol to prevent analyte precipitation. The sample solution must, therefore, be comparable in elution strength with mobile phase to prevent peak distortion or excessive peak width [37]. With high carbon load stationary phases, mobile phases with higher elution strength are thus used. Second, the most challenging part of cannabinoid analysis is the separation between peaks of CBDA, CBGA, CBG, and CBD, based on the published data [22,23,24,25,26,27,28,29,30,31,32,33,34,35,36]. When acetonitrile is used as eluent, these four analyte occur as a quartet of peaks. It was, therefore, the primary task to choose among a set of columns the most appropriate one for this purpose. The best candidates proved to be Phenomenex Luna C18 (2) and YMC Pack-Pro RS C18. Selectivity tests have been also done with methanol as eluent instead of acetonitrile, since it is known that methanol produces a different elution pattern of cannabinoids [36]. The elution pattern, however, is also very dependent on the stationary phase [22,23,24,25,26,27,28,29,30,31,32,33,34,35,36]. Within the two selected columns, no satisfactory results have been obtained with methanol as eluent for the purpose of an isocratic mobile phase. In addition, methanol mobile phase gave expectedly much higher column backpressure. Tests have also been performed by mixing a smaller percentage of methanol (2–10%, v/v) into the mobile phase to modify the elution order, without tangible success. Acetonitrile and Luna C18 (2) with dimensions 150 mm × 3.0 mm (3 µm particle size) were finally chosen as organic modifier and separation column, respectively.

Selectivity fine tuning

Since column temperature has also a large influence on analyte partitioning [38], test has been done with an isocratic binary mobile phase (80% acetonitrile (v/v) with 0.1% formic acid) over a large temperature range. The tests demonstrated a substantial improvement in selectivity among the CBDA, CBGA, CBG, and CBD group of peaks when column temperature is kept between 35 and 40 °C. The optimal temperature proved to be 37 °C. This fact at least partially explains why Gul et al. [25] have obtained a lower selectivity and resolution even under gradient elution for the mentioned analytes, using the same type of column and mobile phase, since column temperature was kept at 28 °C. Above 40 °C, however, a significant loss of selectivity was observed. Slight adjustments in the acetonitrile:water ratio have been also needed. The optimal acetonitrile:water ratio has, therefore, been determined at 31:9 (v/v). Such a composition enabled the best resolution attainable among the mentioned analytes (under given conditions) while keeping analysis time reasonable. The addition of 10 mM ammonium formate to the mobile phase was then finally allowed a further improvement in selectivity by slightly shortening the retention of CBDA and CBGA and slightly increasing of retention of CBG and CBD without any change in elution order. Retention of other analytes was also affected, but basically without changing the elution pattern (with the exception of CBC and THCA) or otherwise influencing the chromatographic performance. Measurement of pH of the mobile phase water component has shown an increase in pH of about 0.6 units when ammonium formate is added to formic acid solution, thereby yielding a pH value of about 3.3. Acidic cannabinoids have their pKa values around 3.4 [39]. This might be part of the explanation why retention times of CBDA and CBGA decreased. A slight increase in retention times of CBG and CBD was then might be due to a weak ion-pairing effect or enhanced non-hydrophobic interactions with the stationary phase. Chromatograms of standard and sample solution are depicted in Fig. 1.

Detection

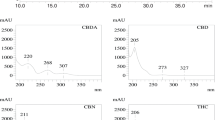

Cannabinoids have two or more absorption maxima in the UV region [40]. The largest absorption maximum for most of them is at 228 nm or close to it. Most of HPLC methods for cannabinoids, therefore, use this wavelength (or a close one) for detection. Optionally, a wavelength of 306 nm is applied for selective detection of acidic cannabinoids. However, virtually, all cannabinoids have another absorption maximum at 250–300 nm. During method development, it was discovered that the detection wavelength of 275 nm gave much better performance. Compared to the established 228 nm wavelength, at 275 nm under the given mobile phase conditions, there is about a tenfold less signal noise. The overall sensitivity in terms of signal-to noise ratio is at 275 nm about 8.5- to 33-fold higher compared to 228 nm, depending on the analyte. A plausible explanation is the interference by UV absorption of formic acid in the mobile phase, since its absorption is considerable already at 240 nm, and increases with temperature [41]. UV spectra of CBDA and CBD under given mobile phase conditions are shown in Fig. 2. Another practical advantage of UV detection at 275 nm is the fact that some pairs of analytes have a nearly identical detection response; CBDA and CBGA; CBG and CBD; d9-THC and d8-THC.

Method performance and validation

The developed isocratic method exhibits good overall analytical performance within a relatively short analysis time. Despite the fact that mobile phase flow is relatively high given the column diameter, the operating backpressure is kept about 150 bar. Therefore, even older, less performing HPLC instruments can be used for cannabinoid analysis, provided that there is a proper temperature control of the column. Separation-wise, the most challenging part still remains the resolution between peak pairs CBDA–CBGA and CBN–IS, since they are not fully baseline resolved. Validation and stability data (Table 2), on the other hand, confirm the feasibility of the method for its purpose, indicating that even partially resolved peaks can be successfully quantified. Should be a full baseline resolution needed, the method can be implemented with a 250 mm column length instead, with accordingly prolonged analysis time. The exhibited sensitivity limits which are in the sub-ppm range for most analytes (and even in the ppb-range for cannabinoid acids and CBN) make it practical to use highly diluted working sample solutions which might be beneficial in prolonging column lifetime. In addition, due to the similarities in detection responses observed for some of the analytes, a practical approach can be used when ultimate accuracy and precision are not required, namely a limited use of cannabinoid standards, thus reducing the expense of (usually) very costly standards.

Method applicability

The method in its presented version is applicable to both hemp plant material (Cannabis sativa and Cannabis indica), plant-derived extracts, and products. For merely screening work, a shorter column can also be used when peak resolution is not a priority. The method avails on a volatile mobile phase, and it is, therefore, directly applicable for mass-spectrometric detection, gaining in detection selectivity and sensitivity if needed. Based on the elution pattern and retention factors of the analytes and by comparing them to some others from the references [26, 32, 36], it can be inferred that the method should be also amenable for the analysis of other cannabinoids like cannabidivarinic acid (CBDVA), cannabinolic acid (CBNA), tetrahydrocannabivarinic acid (THCVA), cannabicyclol (CBL), and cannabichromenic acid (CBCA). However, due to the current unavailability of mentioned standards (to the author), this has yet to be tested in future work.

References

Gambaro VE, Froldi R, Saligari E, Dell’Acqua L, Salomone E, Roses OE (1995) Acta Toxicol Argent 3:11–13

Gibson CR, Williams RD, Browder RO (1998) J Anal Toxicol 22:179

Ross SA, Mehmedic Z, Murphy TP, Elsohly MA (2000) J Anal Toxicol 24:715–717

Raharjo TJ, Verpoorte R (2004) Phytochem Anal 15:79–94

Pellegrini M, Marchei E, Pacifici R, Pichini S (2005) J Pharm Biomed Anal 36:939–946

Gambaro V, Dell’Acqua L, Fare F, Froldi R, Saligari E, Tassoni G (2002) Anal Chim Acta 468:245–254

Cardenia V, Toschi TG, Scappini S, Rubino RC, Rodriguez-Estrada MT (2018) J Food Drug Anal 26:1283–1292

United Nations Office on Drugs and Crime (2009) Recommended methods for the identification and analysis of cannabis and cannabis products. United Nations Publications, New York

Wang M, Wang Y-H, Avula B, Radwan MM, Wanas AS, van Antwerp J, Parcher JF, ElSohly MA, Khan IA (2016) Cannabis Cannabinoid Res 1:262–271

Dussy FE, Hamberg C, Luginbühl M, Schwerzmann T, Briellmann TA (2005) Forensic Sci Int 149:3–10

Kemp PM, Abukhalaf IK, Manno JE, Manno BR, Alford DD, Abusada GA (1995) J Anal Toxicol 19:285–291

Steinmeyer S, Bregel D, Warth S, Kraemer T, Moeller MR (2002) J Chromatogr B 772:239–248

Leghissa A, Hildenbrand ZL, Foss FW Jr, Schug KA (2017) J Sep Sci 41:459–468

Pacifico D, Miselli F, Carboni A, Moschella A, Mandolino G (2007) Euphytica 160:231–240

Zuk-Golaszewska K, Golaszewski J (2018) J Elem 23:971–984

Burstein SH (2014) Bioorg Med Chem 22:2830–2843

Maurya N, Velmurugan BK (2018) Chem Biol Interact 293:77–88

Izzo AA, Capasso R, Aviello G, Borrelli F, Romano B, Piscitelli F, Gallo L, Capasso F, Orlando P, Di Marzo V (2012) Br J Pharmacol 166:1444–1460

Brierley DI, Samuels J, Duncan M, Whalley BJ, Williams CM (2016) Psychopharmacology 233:243–254

Velasco G, Hernández-Tiedra S, Dávila D, Lorente M (2016) Prog Neuro-Psychopharmacol Biol Psychiatry 64:259–266

Takeda S, Okajima S, Miyoshi H, Yoshida K, Okamoto Y, Okada T, Amamoto T, Watanabe K, Omiecinski CJ, Aramaki H (2012) Toxicol Lett 214:314–319

De Backer B, Debrus B, Lebrun P, Theunis L, Dubois N, Decock L, Verstraete A, Hubert P, Charlier C (2009) J Chromatogr B 877:4115–4124

Aizpurua-Olaizola O, Omar J, Navarro P, Olivares M, Etxebarria N, Usobiaga A (2014) Anal Bioanal Chem 406:7549–7560

Zgair A, Wong JCM, Sabri A, Fischer PM, Barrett DA, Constantinescu CS, Gershkovich P (2015) J Pharm Biomed Anal 114:145–151

Gul W, Gul SW, Radwan MM, Wanas AS, Mehmedic Z, Khan II, Sharaf MH, ElSohly MA (2015) J AOAC Int 98:1523–1528

Giese MW, Lewis MA, Giese L, Smith KM (2015) J AOAC Int 98:1503–1522

Citti C, Ciccarella G, Braghiroli D, Parenti C, Vandelli MA, Cannazza G (2016) J Pharm Biomed Anal 128:201–209

Patel B, Wene D, Fan Z (2017) J Pharm Biomed Anal 146:15–23

Ciolino LA, Ranieri TL, Taylor AM (2018) Forensic Sci Int 298:438–447

Mudge EM, Murch SJ, Brown PN (2017) Anal Bioanal Chem 409:3153–3163

Cannabinoids for potency testing in two methods with alternate elution orders by LC-UV. https://www.phenomenex.com/ViewDocument/?id=12+cannabinoids+for+potency+testing+in+two+methods+with+alternate+elution+orders+by+lc-uv+(tn-1225). Accessed 21 Jan 2019

Cannabinoids on raptor ARC-18 1.8 μm by LC-UV. https://www.restek.com/chromatogram/view/LC_GN0579/ARC-18. Accessed 21 Jan 2019

Qualitative and quantitative determination of cannabinoid profiles and potency in CBD hemp oil using LC/UV and mass selective detection. https://www.agilent.com/cs/library/applications/5991-8313EN_Cannabis_AppNote.pdf. Accessed 21 Jan 2019

Cannabinoids by LC-MS/MS using Kinetex 2.6 μm Biphenyl LC Column. https://www.phenomenex.com/ViewDocument/?id=10+cannabinoids+by+lc-ms_ms+using+kinetex+2.6+%u03bcm+biphenyl+lc+column. Accessed 21 Jan 2019

Eight cannabinoids by HPLC-UV. https://www.conflabs.com/wp-content/uploads/2018/03/EIght-Cannabinoids-by-HPLC-UV-v1.1.pdf. Accessed 21 Jan 2019

Separation of 12 natural cannabinoids using a Kinetex® Polar C18 column under methanol and acetonitrile conditions. https://www.phenomenex.com/ViewDocument/?id=separation+of+12+natural+cannabinoids+using+a+kinetex+polar+c18+column+under+methanol+and+acetonitrile+conditions. Accessed 21 Jan 2019

Neue UD (1997) In: Neue UD (ed) HPLC columns: theory, technology and practice. Wiley-VCH, New York, pp 351–379

Dolan JW (2002) J Chromatogr A 965:195–205

Analysis of biologically active compounds: cannabinoids. http://www.uct-uit-cooperation.eu/docs/stranska_rafa_interactive_seminar.pdf. Accessed 25 Jan 2019

Hazekamp A, Peltenburg A, Verpoorte R, Giroud C (2005) J Liq Chromatogr R T 28:2361–2382

Ramsperger HC, Porter CW (1926) J Am Chem Soc 48:1267–1273

Hillig KW, Mahlberg PG (2004) Am J Bot 91:966-975

Acknowledgement

The author acknowledges the financial support from the Slovenian Research Agency (research core funding No. P1-0005).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The author declares that he has no conflict of interest.

Compliance with ethics requirements

This article does not contain any studies with human or animal subjects.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

This manuscript is based on a contribution given at CHIMALI 2018, Italian Food Chemistry Congress, Camerino, September 24–27, 2018.

Rights and permissions

About this article

Cite this article

Križman, M. A simplified approach for isocratic HPLC analysis of cannabinoids by fine tuning chromatographic selectivity. Eur Food Res Technol 246, 315–322 (2020). https://doi.org/10.1007/s00217-019-03344-7

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00217-019-03344-7