Abstract

Isoelectric precipitation and ultrafiltration were investigated for their potential to produce protein products from lentils. Higher protein concentrations were obtained when ultrafiltration was used (> 90%), whereas isoelectric precipitation resulted in higher contents of dietary fibre and some minerals (i.e., sodium and phosphorus). Differences in the functional properties between the two ingredients were found as the isoelectric precipitated ingredient showed lower protein solubilities over the investigated pH range (from 3 to 9) which can be linked to the slightly higher hydrophobicity values (2688.7) and total sulfhydryl groups (23.9 µM/g) found in this sample. In contrast, the protein ingredient obtained by ultrafiltration was superior with regard to its solubility (48.3%; pH 7), fat-binding capacity (2.24 g/g), water holding capacity (3.96 g/g), gelling properties (11%; w/w), and foam-forming capacity (69.6%). The assessment of the environmental performance showed that both LPIs exhibited promising properties and low carbon footprints in comparison to traditional dairy proteins.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

The expected continued growth of the global population to 9.6 billion people by 2050 is creating a need to identify and develop solutions for the provision of high-quality food [1, 2]. In addition, the high demand for healthy, sustainable and cost-effective food protein ingredients by consumers is driving the investigation of new and innovative protein sources [3, 4]. Agriculture is one of the main contributors to climate change, and cattle farming faces particular sustainability challenges [5]. The conversion factor of feed protein to milk protein is about 14%, while the remaining 86% is “lost” for human nutrition [6]. Plant-based protein ingredients can serve as an alternative to animal-derived protein, due to their contribution to environmental sustainability, their role in addressing food security challenges and their cost-effectiveness [7]. However, replacing animal-based protein ingredients with those of plant origin is not easy, as significant differences exist between ingredients from both sources in composition, taste, digestibility and techno-functional properties. Nevertheless, research is advancing and several plant ingredients have been applied in a wide range of products [8, 9]. For instance, using extrusion, soya protein was processed into a highly fibrous texture simulating that of meat [10]. In addition to soy, other plant-based proteins have been studied as meat replacers such as canola, rapeseed, wheat gluten, peas and beans [11].

In that respect, legumes are gaining increased attention, as they contain high amounts of protein, typically ranging between 20 and 40%, and are rich sources of essential amino acids such as lysine [12, 13]. Traditionally, they are consumed as whole, split or milled products [14] and approximately 5,481,120 ha are harvested and 6,315,858 tonnes of lentils are produced globally each year [15]. Lentil seeds are showing promising results for the preparation of protein flours, concentrates and isolates due to the lack of allergens and anti-nutritional compounds (e.g., isoflavones found in soya) and also as they are an affordable, sustainable and abundant raw material [16]. Various techniques and approaches such as wet fractionation (e.g., ultrafiltration and isoelectric precipitation) are used to separate and concentrate high levels of protein from other constituents [17, 18] in cereals and legumes. The physicochemical properties and functionality of these isolated protein ingredients are essential in the processing and formulation of food products, providing texture, taste and nutrition for a desirable and pleasurable product. These properties depend not only on the nature of the protein but also on the processing and isolation techniques used. Most studies focused on this subject have been conducted on dairy and soya [19, 20] and increasingly also on legumes in recent years [21,22,23,24,25]. The results of these studies indicate that the methods applied for isolation affect the composition and the physicochemical characteristics of the extracted protein ingredients. Jarpa-Parra et al. [26] highlight the need to establish a deeper connection between the extraction conditions of lentil protein and their influence on lentil protein functionality.

The aim of this work was to produce novel lentil protein isolates using two different technological approaches and to study the techno-functional properties (e.g., solubility, emulsifying, gelling properties) and environmental sustainability (life cycle assessment) of the ingredients based on the same raw material. The results obtained in this study will provide much needed information about the sustainability of the two different approaches and potential applications of the resultant ingredients in the development of novel, healthy and sustainable food product formulations.

Materials and methods

Raw materials and chemicals

For extraction of lentil proteins, brown lentils of commercial quality (Lens culinaris cv. Itaca), provided by Agroservice Spa, San Severino Marche, Italy, were used as raw material. All chemicals used were purchased from Sigma-Aldrich (St Louis, Missouri, USA), unless otherwise stated.

Preparation of protein isolates

Lentil seeds were dehulled in an underrunner disc sheller (Streckel & Schrader GmbH, Germany) and the kernels and hulls were separated in an air classifier (Turboplex, Hosokawa Alpine AG, Augsburg, Germany). Kernels were milled using an impact mill (UPZ, Hosokawa Alpine AG, Germany) to a mean particle size (D50) of 21 µm. For extraction of protein, lentil flour was suspended in water at pH 7.5 to extract the high molecular weight proteins. The insoluble dietary fibre and lentil starch were then separated from the soluble high molecular weight proteins by decanting. Lentil protein isolate (LPI) was recovered from the resulting protein extract either by isoelectric precipitation (IEP) or by ultrafiltration (UF), as shown in Fig. 1. LPI–IEP was isolated from the aqueous protein extract by acid precipitation at pH 4.5, which coincides with minimum solubility of lentil proteins [27]. Subsequently, the precipitated proteins were separated in a disc separator and the sediment was neutralized with 3 M NaOH, pasteurised (65 °C, 30 min) and spray dried (Tin: 180 °C, Tout: 75 °C) to obtain the protein isolate powder. LPI–UF was extracted at 50 °C using a polysulfone membrane with a molecular weight cutoff of 10 kDa followed by diafiltration with demineralized water (retentate:water; 1:1.7) to enrich the protein content of the retentate. The resulting retentate was pasteurized (65 °C, 30 min) and spray dried (Tin: 180 °C, Tout: 75 °C). The protein isolates were stored at room temperature until further analysis.

Compositional analysis

Total nitrogen content of the LPIs was analysed according to the Kjeldahl method (MEBAK 1.5.2.1) [28] using a nitrogen-to-protein conversion factor of 6.25. Fat content was measured following the Soxhlet method (AACC Method 30-25.01) [29]. Ash content was determined by dry ashing in a muffle furnace at 500 °C for 5 h (AOAC 923.03) [30]. Moisture was determined by oven drying at 103 °C for 5 h (AOAC 925.10) [31]. Total starch (AOAC Methods 996.11 and AACC Method 76-13.01) [32, 33] content was determined using an enzymatic kit (Megazyme, Bray, Co. Wicklow, Ireland). Minerals were analysed using inductively coupled plasma-optical emission spectrophotometry [34]. The soluble and insoluble fibre content of the samples was analysed in accordance with the AOAC method 991.43 [35].

Protein profile analysis

Protein profile was assessed using sodium dodecyl sulphate–polyacrylamide gel electrophoresis (SDS-PAGE) using precast gels (Mini-PROTEAN TGX, Bio-Rad Laboratories, CA, USA) under non-reducing and reducing conditions as described by Alonso-Miravalles and O’Mahony [36]. The sample loading buffer contained 65.8 mM Tris–HCl (pH 6.8), 26.3% (w/v) glycerol, 2.1% SDS and 0.01% bromophenol blue. The running buffer (10 × Tris/Glycine/SDS, Bio-Rad Laboratories, CA, USA) had a composition of 25 mM Tris, 192 mM glycine and 0.1% SDS (w/v), pH 8.3. The staining solution used was Coomassie Brilliant Blue R-250 (Bio-Rad Laboratories, CA, USA). The target final protein concentration was 1 mg/mL and 8 µL of sample solution was loaded into each well of the gel and run at a constant voltage of 150 V.

Protein secondary structure

Information about secondary structure of the proteins was obtained using circular dichroism (CD) spectrophotometry (Chirascan, Applied Photophysics, Leatherhead, UK). Protein solutions of 1 mg/mL were prepared in 10 mM sodium phosphate buffer (pH 7) and solubilized overnight at 4 °C using magnetic stirring at 250 rpm. Subsequently, samples were filtered (0.25 μm) and the CD spectra was measured with a path length of 0.1 mm in the range 180–260 nm at a bandwidth of 1 nm and spectral resolution of 1 nm and data acquisition rate of 1 point/s. The average of three spectra was obtained and a 5-point smoothing algorithm was applied.

Scanning electron microscopy

Protein powders were mounted on aluminium stubs using double-sided adhesive carbon tape, and sputter-coated with a 5 nm layer of gold/palladium (Au:Pd = 80:20) using a Quorum Q150R ES Sputter Coating Unit (Quorum Technologies Ltd., Sussex, UK). The coated samples were loaded into a sample tube and examined using a JSM-5510 scanning electron microscope (JEOL Ltd, Tokyo, Japan), operated at an accelerating voltage of 5 kV.

Particle size distribution

Particle size distribution of protein dispersions was measured using static laser light diffraction (Mastersizer 3000, Malvern Instruments Ltd, Worcestershire, UK). For the preparation of samples, the protein isolate powders were mixed with ultrapure water at a concentration of 1% protein (w/v), pH adjusted to 7, and stirred overnight at 4 °C. The refractive index of protein was set at 1.45 [27] and the absorption and dispersant refractive indices used were 0.1 and 1.33, respectively. LPI dispersions, equilibrated at 22 °C, were introduced into the dispersing unit using ultrapure water as dispersant until a laser obscuration of 12% was achieved.

Hydrophobicity

Surface hydrophobicity (S0) of protein particles was measured according to Hayakawa and Nakai [37] using 1-anilino-8-naphthalenesulfonate (ANS) with slight modifications as described by Karaca et al. [16]. Protein solutions were serially diluted with 10 mM phosphate buffer (pH 7) ranging from 0.0006 to 0.015% (w/v). ANS (10 µL; 8.0 mM in 0.1 M phosphate buffer, pH 7) were mixed with 2 mL of diluted sample and left in darkness for 15 min. Fluorescence was measured (λexcitation 390 nm, λemission 470 nm) and corrected by a blank measured without ANS. The results are presented as the slopes (R2 ≥ 0.98) of the absorbance versus protein concentration.

Sulfhydryl groups

Sulfhydryl groups were determined using Ellman’s reagent [5,5′-dithio-bis-(2-nitrobenzoic acid)] according to the method of Van der Plancken et al. [38]. The protein samples were diluted to 2 mg/mL with 10 mM phosphate buffer (pH 7) for free sulfhydryl groups, while for total sulfhydryl groups a buffer containing 6 M urea and 0.5 M SDS was used. Ellman’s reagent (80 µL) was added to 2.5 mL of diluted sample and absorbance was measured at 412 nm after 15 min. For the reagent blank, the protein samples were replaced by the sodium phosphate buffer and mixed with 80 µL of Ellman’s reagent. Sulfhydryl groups were quantified as follows:

where A412 is the absorbance at 412 nm, A412B is the absorbance at 412 nm for the blank, ε is the extinction coefficient, which was taken as 13,600 M−1 cm−1, and C is the protein concentration in mg/mL of the diluted sample.

Protein solubility

The solubility of proteins as influenced by pH, was determined by adjusting the pH of protein dispersions from 3.0 to 8.0 at 0.5 units intervals using 0.1 and 1 M HCl or NaOH. Protein samples (1% w/v) were hydrated at 4 °C. The pH was re-adjusted before measurements. Samples were centrifuged at 5000 g for 30 min. The protein contents of the supernatants were analysed using the Kjeldahl method as described in Sect. 2.3. The results were expressed as % of the total protein content.

Zeta potential

The zeta potential of protein solutions at the same pH values as for protein solubility analysis was determined using a Zetasizer nano-Z (Malvern Instruments Ltd; UK). Samples were prepared as described for the protein solubility, excluding the centrifugation step, and diluted with ultrapure water to a concentration of 0.1% (w/v) and pH was readjusted. The measurement was performed using an automatic voltage selection and zeta potential was calculated using the Smoluchowski model. Refractive and absorption indices of 1.45 and 0.001 were used, respectively.

Water holding capacity

Analysis of water holding capacity (WHC) of proteins was determined according to AACC method 56-30.01 [39] with some modifications. Samples (1.000 g ± 0.005 g) were mixed with 30 mL of distilled water using an Ultra-Turrax equipped with a S10N-5G dispersing element (Ika-abortechnik, Janke and Kunkel GmbH, Staufen, Germany) for 15 s and then shaken for 30 min at 1000 rpm using a platform shaker (UNI MAX 1010, Heidolph, Schwabach, Germany). Subsequently, the mixture was centrifuged at 2000g for 10 min. WHC was expressed as grams of water retained per gram of protein isolate.

Fat absorption capacity

Fat absorption capacity (FAC) was determined following the method described by Boye et al. [13] with slight modifications. Powder (1 g) and sunflower oil (6 g) were weighted into a 15 mL centrifuge tube (Sarstedt, Nümbrecht, Germany), mixed with a vortex for 3 min and centrifuged at 4000g for 30 min. The oil was removed from the tube carefully and weighed again. FAC was expressed as grams of fat retained per gram of protein isolate.

Foaming properties

Protein dispersions (20 mL) with a protein concentration ranging from 0.1 to 3.3% (w/v) in ultrapure water were frothed using an Ultra-Turrax equipped with a S10N-10G dispersing element (Ika-Labortechnik, Janke and Kunkel GmbH, Staufen) at high speed for 30 s. The height of the sample (liquid and foam phase) was measured over 60 min. The foaming capacity was taken as sample expansion at 0 min, while foam stability was expressed as sample expansion after 60 min. Foam expansion was calculated according to the following equation:

Emulsifying properties

Protein solutions (1%, w/v) were hydrated with ultrapure water using a magnetic stirrer at 250 rpm overnight at 4 °C and pH 7. The next day samples were adjusted to room temperature and the pH was re-adjusted if necessary and pre-emulsions were prepared as follows: 20 mL of sunflower oil was added to 180 mL of 1% protein (w/v) solution and homogenized for 3 min at 10,000 rpm using an ultraturrax (T 25 digital Ultra-Turrax, Staufen, Germany). Emulsifying activity (EAI) and stability (ESI) indices were determined using the method described by Pearce and Kinsella [40], with slight modifications. In brief, 250 µL emulsion was taken from the bottom of the homogenized sample after 0 and 120 min and diluted (1:100, v/v) in 0.1% sodium dodecyl sulphate (SDS) solution. The absorbance at a wavelength of 500 nm was read using a spectrophotometer. EAI and ESI were calculated using the following equations:

where DF is the dilution factor (100), C is the initial concentration of protein (0.01 g/mL), θ is the fraction of oil used to form the emulsion (0.1), and A0 and A120 are the absorbance of the diluted emulsion at 0 and 120 min, respectively.

Gelation characteristics

Least gelling concentration

The least gelling concentration (LGC) is defined as the lowest concentration required to form a self-supporting gel. The LGC test was performed according to the method of Sathe et al. [41] with some modification. LPI dispersions ranging from 6 to 16% (w/v) were prepared in 0.01 M phosphate buffer at pH 7.0. These suspensions were heated in 15 mL test tubes (Sarstedt, Nümbrecht, Germany) in a water bath at 90 °C for 30 min, after which they were cooled rapidly under running water and stored at 4 °C overnight. LGC was determined visually as the minimum concentration of protein at which the contents of the tube did not flow.

Texture profile analysis

Texture profile analysis (TPA) of the LPI gels was performed using a TA.XT Plus™ texture analyser (Stable Microsystems Ltd., Crawley, UK) to determine their mechanical properties. Protein gels (25%; w/v) were prepared by heating LPI dispersions as described above. Gels were cut into small cylinders of 8.2 mm in diameter and 8.0 mm in height. The gel pieces were compressed twice to 30% of their original height at a constant speed of 0.3 mm/s using a cylindrical probe with 20 mm diameter. The TPA parameters of hardness, cohesiveness, adhesiveness, gumminess and springiness were calculated according to the definitions of Bourne [42].

Life cycle assessment

Environmental performance of LPIs was examined by means of life cycle assessment (LCA) using Umberto 5.5 software. LCA is carried out as an attributional cradle-to-gate LCA and includes the individual processes associated with LPIs shown in Fig. 1. Impact assessment methods are based on Umweltbundesamt Berlin [43].

Statistical analysis

All analyses were carried out in triplicate, with exception of analyses of fibre and minerals, which are performed following a validated method and therefore analysed just once and reported without standard deviation. The other data generated were subjected to student’s T test to determine statistically significant differences (p < 0.05) between mean values for the different samples, at a 95% confidence level. The statistical program used was Excel (Microsoft Office 365 ProPlus, version 1809).

Results and discussion

Compositional analysis

The macro- and micro-nutrient compositions of the LPIs are shown in Table 1. The protein content of LPI–UF (93.7%) was significantly higher (p < 0.05) than that obtained for LPI–IEP (85.1%). The reason for this higher protein content can be explained by the ultrafiltration process, where specific pore-sized membranes are used leading to higher protein levels in the final ingredient [25]. Additionally, by diafiltration more soluble substances (e.g. sugars, minerals) permeate the membrane thereby further purifying the protein. (4.49%). Regarding the fat content, no significant differences (p < 0.05) were found between LPI–UF (4.40%) and LPI–IEP (4.49%). The ash content for LPI–IEP (5.46%) was significantly higher than for LPI–UF (3.51%) which was expected since, with the former approach, NaOH and HCl are used to solubilize and precipitate the proteins [17]; this can be seen in the determined sodium content of LPI–IEP. Interestingly, high values of magnesium and calcium were obtained in LPI–UF. An explanation for these high values might be the retention of these minerals in the retentate along with the protein during the UF process. These differences in the mineral profile can play an important role in the functionality of these protein ingredients such as the solubility, emulsifying and gelling properties [44]. For example, in dairy proteins, especially caseins, calcium plays an important role in determining their gelation behaviour, facilitating linkages between proteins [45]. Also, other authors have studied the role of calcium on gelation properties of a soya drink, finding coagulation of soya proteins when the ionic calcium concentration was increased [46, 47]. The fibre content, mostly soluble dietary fibre, was higher in the LPI–IEP (1.8%) than in LPI–UF (< 0.1%). A reason for the higher fibre content in LPI–IEP could be that a part of the fibres was precipitated together with the protein and/or were only partially removed by the centrifugation step; the lower protein content of LPI–IEP is an indicator of this.

Structural properties

SDS-PAGE

SDS-PAGE analyses under non-reducing and reducing conditions of the two LPIs are shown in Fig. 2. Both samples showed similar protein profiles, with several common bands under non-reducing and reducing conditions. Proteins with molecular weight (MW) of ~ 50, ~ 37 and ~ 20 kDa under non-reducing conditions were observed. The bands at MW ~ 50 kDa may correspond to vicilin subunits, which compose a 7S trimeric protein, one of the major globulins, together with legumin found in many pulses. Each trimer of vicilin has a MW of 150 kDa without disulphide bridging [48]. The bands at 37 kDa and 25 kDa correspond to the acidic and basic subunits of legumin, in accordance with previous studies [49, 50]. Legumin, an 11S globulin, is a hexameric protein formed by subunits with MW ~ 60 kDa, which consist of an acidic (~ 40 kDa) and a basic (~ 20 kDa) subunit linked by disulfide bonding [14, 24]. Under reducing conditions, similar profiles were observed, although bands at 37 kDa and 25 kDa were slightly more intense, with the disappearance of some high MW bands at ~ 50 kDa. This can be correlated with the dissociation of legumin into its acidic (MW ~ 40 kDa) and basic (~ 20 kDa) subunits by the dissociation of the disulphide bond when a reducing agent (DTT) is applied.

Representative sodium dodecyl sulphate–polyacrylamide gel electrophoresis (SDS-PAGE) pattern of lentil protein isolates obtained by ultrafiltration (LPI–UF) and isoelectric precipitation (LPI–IEP) under non-reducing (NR) and reducing (R) conditions. The first lane of the gel contains the molecular weight marker

Secondary structure

Furthermore, far-UV CD spectroscopic measurements were performed to gain information about the secondary structure of LPIs. Amide groups are optically active and absorb circular polarized far-UV light. Depending on their conformation, i.e., their secondary structure, characteristic CD spectra are obtained [51]. As shown in Fig. 3, both LPIs exhibited a positive peak at 185 nm, and a broad negative peak with a minimum at 208 nm, indicating a defined secondary structure of α-helix [51]. Only slight differences can be observed in the spectra. Similar spectra for lentil flour and isolated proteins using IEP were found by Aryee and Boye [52], indicating that secondary structure conformational changes were limited during the extraction of the proteins.

Scanning electron microscopy

Representative micrographs of the LPI powders are given in Fig. 4. In general, a heterogeneous mixture of rounded particles with smooth, shrivelled, hollow and wrinkled surfaces was observed in both LPIs. These features are typical for spray-dried powders and have been attributed to rapid evaporation of water during the spray-drying process [53,54,55]. Joshi et al. [24] also observed similar folded and wrinkled surfaces in LPI powders obtained by spray drying. The sizes of the powder particles, as seen from the scale bars, were generally between 10 and 50 µm. LPI–IEP and LPI–UF showed similar powder characteristics, although the LPI–IEP primary particles are in a closer arrangement than the LPI–UF particles where the powder particles seem more dispersed.

Particle size distribution

The particle size observations obtained by SEM can be correlated with the particle size distribution (PSD) determined using laser diffraction (Fig. 5). Both LPIs showed a monomodal size distribution with a size range of 10–100 µm. The volume-weighted mean particle diameter (D4,3) values of LPI–UF and LPI–IEP were 32.8 µm and 29.4 µm, respectively. The LPI–IEP also had significantly lower values for surface-weighted mean particle diameter (D3,2), D (50) and D (90) (Table 2). Similar profiles were observed by Crowley et al. [56]) in high-protein (90%) milk protein concentrates after 24 h of rehydration, with particle sizes ranging from 10 to 100 µm, classifying them as large and poorly dispersible particles.

Surface hydrophobicity

Hydrophobic groups exposed to the surface of the proteins enable hydrophobic interactions, and adsorption to interfaces; hence having an influence on many properties, such as emulsification and foaming [57]. These values are shown in Table 2. The LPI–IEP had a significantly higher surface hydrophobicity with a value of 2688 in comparison to LPI–UF with a value of 2411. However, the differences were not major, but significantly different, indicating that the extraction method had no major impact on the surface hydrophobicity of the proteins. Comparable studies found a value of 2200 for legumin-like proteins isolated from lentils [14], while Joshi et al. [58] found a considerably higher value of 568 determined for mg/mL, which translates to 5680 using the same protein concentration units as in this study.

Sulfhydryl groups

Results of sulfhydryl groups measured as free and total are shown in Table 2. The concentration of free and total sulfhydryl groups was found to be higher for LPI–IEP, with 6.04 µmol/g and 23.9 µmol/g protein, respectively, compared to 5.88 µmol/g and 22.5 µmol/g protein, respectively, for LPI–UF. Literature considering the sulfhydryl groups of lentil proteins is scarce and diverse; Li and Lee [59] reported disulphide contents of 0.31 µmol/g, and free sulfhydryl groups of 0.032 µmol/g, being considerably lower than the values found in this study. On the other hand, Ladjal-Ettoumi et al. [49] found comparable values; they reported 16.1 µmol/g and 31.0 µmol/g for free and total sulfhydryl groups, respectively. In both cases, the relatively low amount of free sulfhydryl groups indicated the formation of aggregates, being characteristic for globular proteins, and can be linked also to the relatively large particle size. In general, both LPIs showed similar values for hydrophobicity and also sulfhydryl groups. However, LPI–IEP showed a trend with significant difference (p < 0.05) to higher values, indicating a slightly more open structure with higher surface-active groups.

Functional properties

Solubility and zeta potential

Both isolates showed similar solubility and zeta potential values across the pH range, as shown in Fig. 6, achieving the highest solubility at acidic and alkaline pH values. Similarly, at the extreme low and high pH ranges, the lentil protein particles showed the highest positive and negative charge, respectively. LPI–IEP showed lower solubility values across the pH range compared with LPI–UF. This may be explained by the removal of soluble proteins in the supernatant during the extraction process and, therefore, more insoluble protein fraction is present in LPI–IEP (Fig. 1). High-solubility values and positive charge (+ 30 mV) were observed at pH 3, followed by minimum solubility and a net charge of 0 mV for both isolates at pH 4.5, indicating that the isoelectric point was reached. Solubility was higher again at pH 6 and pH 6.5 for LPI–UF and LPI–IEP, reaching a value of 43% for both isolates at pH 7 and the surface charge decreased, reaching values between -20 and -30 mV. Karaca et al. [16], found similar values for surface charge (-22.6 mV) for LPI–IEP at pH 7. The highest solubility was obtained for the LPI–UF at pH 9, at 54.7%, while LPI–IEP reached 50.18%. LPI–UF showed also a higher solubility at acidic conditions with a value of 39.4% at pH 3.5. The LPI–IEP had lower solubility at lower pH, having a value of 11.9% at pH 3.5. The general profiles of the observed solubility and zeta potential curves are characteristic for lentil proteins, as previously reported by Boye et al. [13], who studied the solubility of different plant-based protein isolates finding high solubilities for lentil and pea proteins in comparison with chickpea. Lee et al. [60] analysed the protein solubility of commercial soya products including flours, concentrates and isolates and found generally lower solubility at low pH. Solubility is one of the most important properties of proteins, influencing for example the ability to form and stabilise foams, emulsions and gels. Although insoluble proteins can be used in meat preparations, highly soluble proteins provide the most versatility for substitution and extension of animal proteins [61].

Foaming properties

Foaming is, in many product applications, a desired property of proteins, providing structure and stability. The foaming properties of LPIs, as a function of protein concentration, are shown in Table 3. The foaming capacity was low for both isolates at 0.1% (w/v) at 9.42 and 6.52% for LPI–UF and LPI–IEP, respectively. With increasing concentration, the foaming capacity increased, reaching 69.5 and 57.2% for 3.3% (w/v) LPI–UF and LPI–IEP, respectively. Likewise, the foam stability increased from 0% for both LPIs to 44.9% and 39.1% for LPI–UF and LPI–IEP, respectively. The LPI–UF showed significantly better foaming properties at the high protein concentrations compared to the LPI–IEP. In addition, other studies found that protein isolates of various sources prepared by UF were superior to those obtained by precipitation, especially in terms of protein solubility and foaming characteristics [13, 62]. The results obtained show a high ability of lentil proteins to create foam with high stability, indicating its potential for application in food processing. Compared to other commercial proteins from potato (36.9%), pea (10.6%), carob (17.2%), lupin (13.9%) and soya (36.4%) analysed by Horstmann et al. [63] for their application in bread, both LPIs showed better foam capacities; even potato protein, known to have good foaming ability, showed lower values. These results underline the great prospect of LPIs being used in bakery products, ice cream or other dairy formulations, where foaming properties are desired.

Emulsification properties

Proteins can act as emulsifiers by forming a film/skin around oil droplets dispersed in an aqueous medium, thereby stabilizing emulsions and preventing structural changes such as coalescence, creaming, flocculation or sedimentation [13]. The emulsifying activity (EAI) and emulsifying stability index (ESI) of LPI–UF and LPI–IEP are shown in Table 4. EAI and ESI are two indices often used to evaluate the emulsifying properties of proteins. ESI values were found to be higher for LPI–UF (63.8 min), compared to LPI–IEP (51.0 min). The EAI values were quite similar for both LPIs; however, higher values were found for LPI–IEP (16.5 m2/g) in comparison with LPI–UF (14.3 m2/g). These higher values for LPI–IEP can be related to the higher surface hydrophobicity compared to LPI–UF. The EAI values were lower in comparison to other studies where different protein-to-fat ratios or high-pressure homogenization were applied [13, 64]. For example, Joshi et al. [58] found that the EAI increased threefold when the concentration of protein increased from 10 to 30 mg/mL, whereas in this study the protein concentration was maintained at 10 mg/mL. In addition, high-pressure homogenization, as applied to cow’s milk, can help to unfold globulins (which are known for having high MW and compact structures) and enable them to migrate to the interface to form a stable emulsion [16]. These factors can be taken into consideration for further studies to enhance the emulsification properties.

Water-holding and fat-holding capacity

Water-holding and fat-holding capacity (WHC and FHC) of proteins are important functionalities, since they influence structure, mouth feel and flavour retention of food formulations. The ability of protein to retain oil or water can be important in food applications, such as ground meat formulations, doughnuts and bakery products. Values are shown in Table 2. Significant differences were found for the WHC between the two different LPIs, showing a higher value of 3.96 g/g for the LPI–UF, compared to 2.60 g/g for LPI–IEP. Compared to other studies, both isolates showed a relatively high WHC; Boye et al. [13] reported values of 0.6 g/g and 2.7 g/g for protein concentrates isolated from several legumes. However, the authors found no considerable effect of the preparation method, possibly due to the comparatively low protein contents of their samples. Horstmann et al. [63], found values ranging from 0.0 g/g for a potato and soya, and up to 2.66 g/g for a pea protein ingredient. They associated the protein content to be negatively correlated with the WHC, i.e., other constituents affect the values to a substantial degree. In contrast, in this study it was found that a higher protein content correlated with a higher WHC. Results for FHC also showed significantly higher values for LPI–UF (2.24 g oil/g protein) in comparison to LPI–IEP (2.09 g oil/g protein). The value obtained for LPI–UF is comparable to that obtained by Boye et al. [13] for red lentil protein with a FAC of 2.26 g oil/g protein. In addition, this author found the highest FAC value for LPI in comparison with yellow pea and kabuli chickpeas proteins.

Gelation characteristics

Heat-induced gelation occurs when proteins aggregate to form a three-dimensional network. The ability to do so depends on the state and surface conformation of the proteins, e.g., free sulfhydryl groups, hydrophobicity, charge and correspondingly the electrostatic interaction between proteins, and their ability to associate to form a continuous network throughout the matrix [65]. LGC was measured as an indicator of the gelation capacity. The LPI–UF formed a gel, resisting flow when inverted, at a concentration of 11% (w/v), whereas for the LPI–IEP 16% was needed (Table 4). The lower concentration needed for a firm gel to be formed by the LPI–UF may be associated with the higher protein solubility, which is known to be an important factor in gel formation [24]. Likewise, Boye et al. [25] found that various legume proteins isolated by UF have lower LGC in comparison to IEP methods. They found comparable values, with 10% for LPI prepared by UF and 12% for isolates prepared by IEP. The LPI–UF also formed a much stronger gel, which is evident in the values obtained from the TPA test: the hardness for LPI–UF was three-fold higher than that of LPI–IEP. Likewise, gumminess and chewiness were also significantly higher for LPI–UF than for LPI–IEP gels. On the other hand, other parameters, such as adhesiveness, springiness, resilience and cohesiveness were not significantly different. The higher gelling properties of LPI–UF may be linked to the higher calcium levels, which have been shown to enhance hydrophobic coagulation of heat-treated milk and soya proteins [46]. The ability to form strong gels upon heating is a desirable property in bakery products: when heat is applied to the dough, its viscosity increases and results in a higher gas retention during baking and a higher desirable specific volume of the product is reached [66]. Furthermore, in non-traditional ways, meat, yoghurt and cheese alternatives may be produced from heat-set gels, providing to the product a gel-like matrix.

Life cycle assessment

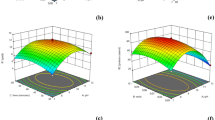

Environmental performance of LPI obtained by IEP and UF was examined by means of life cycle assessment (Table 5). Indicators such as aquatic eutrophication, photochemical oxidant formation, stratospheric ozone depletion, phosphorus use and land use showed lower potential environmental impacts for LPI–UF in comparison to LPI–IEP. For the remaining indicators studied, the ranking was switched. Especially the contribution of the lentil cultivation stage affects the outcome of these indicators. An overview on main contributors is exemplarily given in Fig. 7 for four indicators—the remaining indicators followed one out of those four illustrated result contribution patterns. The higher the contribution of the lentil cultivation stage, the more important is the protein yield advantage from LPI–UF, as less lentil seeds were required per kg protein isolated. On the other hand, lower process energy was required for processing of LPI–IEP, which leads to lower potential environmental impacts for the remaining indicators including climate change. The net nitrogen benefit due to air nitrogen fixation by lentil plants (as they are legumes) in the growth phase is up to 20% of the total environmental impact depending on the indicator for both LPIs.

Further, LPIs showed promising carbon footprints within the portfolio of soya-based and cow’s milk-based protein isolate food ingredients: The production of both LPIs potentially releases a quarter of carbon dioxide equivalents (3.5–4.2 kg CO2-e/kg) than caseinate or whey protein production (19 kg CO2-e/kg and 20 kg CO2-e/kg, respectively) as examined in an attributional LCA by Thrane et al. [67]. Compared to soya protein isolate, depending on the literature source chosen, LPIs showed similar [67] or up to fourfold lower values [68] for their potential release of carbon dioxide equivalents.

The environmental impact profiles of LPIs were also compared with traditional cow’s milk protein as illustrated in Fig. 8. Two different scenarios for the production of cow’s milk protein were taken into consideration: the environmental impact, high or low, of the milk protein was set up depending on the theoretical amount of protein that is fed to the cow, i.e. cow feed per kg milk and share of concentrate versus silage feed components within the feed mix were the parameters set to low and high for those ranges. Indicator results of LPIs are lower (and thus favourable) or equal for all of the examined indicators except the land-use indicator. The latter is related to comparatively high agricultural yields of feed crops in comparison with relatively low yields for lentils. It should be noted that feed crops have undergone long-time optimisation of agricultural practices to reach relatively high yields. Lentils on the other hand have not been cultivated in comparable amounts on global scale than animal feed crops. Therefore, related optimization might take place along with increased interest in lentils in the future.

Overall, the environmental impact of both LPIs was lower, contributing, e.g. to a reduction of greenhouse gases compared to cow’s milk protein.

Conclusion

Various physical and functional properties of two LPI isolated by IEP and UF were investigated, indicating that they could contribute different desirable attributes to a wide range of food products. The results suggest that, in general, UF resulted in a product with better functional properties, such as higher protein solubility, WHC, greater gelling and foaming properties and emulsion stability. Differences in functional properties between the isolates under investigation were attributed to differences in the extraction methods, resulting in different compositions. Both isolates contained high levels of protein; however, LPI prepared by UF contained significantly higher values of protein, calcium and magnesium, whereas LPI prepared by IEP had higher levels of other minor constituents such as fibre, sodium and phosphorous. The life cycle assessment showed that the two main drivers for the environmental impact of LPIs were the cultivation stage and the protein isolation process. Overall, both LPIs exhibited promising environmental performance, especially if compared to traditional cow’s milk proteins. These favourable functional, nutritional and environmental properties of LPIs could be exploited in the preparation and development of diverse food products and may also be suitable for the substitution of soya- or animal-derived proteins. Further studies are required to investigate protein functionality and applicability of these in food systems as well as life cycle assessments of the food products thereof.

References

Henchion M, Hayes M, Mullen AM, Fenelon M, Tiwari B (2017) Future protein supply and demand: strategies and factors influencing a sustainable equilibrium. Foods 6:53. https://doi.org/10.3390/foods6070053

United Nations (2015) Revision of world population prospects. In: United Nations. https://population.un.org/wpp/Graphs/Probabilistic/POP/TOT/. Accessed 1 Dec 2018

Day L (2013) Proteins from land plants—potential resources for human nutrition and food security. Trends Food Sci Technol 32:25–42. https://doi.org/10.1016/j.tifs.2013.05.005

Don C (2017) Future proteins: functionality, processing, and sourcing. AACC Int 62:144–148

Poore J, Nemecek T (2018) Reducing food’s environmental impacts through producers and consumers. Science 360(80):987–992. https://doi.org/10.1126/science.aaq0216

Shepon A, Eshel G, Noor E, Milo R (2016) Energy and protein feed-to-food conversion efficiencies in the US and potential food security gains from dietary changes. Environ Res Lett 11:105002. https://doi.org/10.1088/1748-9326/11/10/105002

Aiking H (2011) Future protein supply. Trends Food Sci Technol 22:112–120. https://doi.org/10.1016/j.tifs.2010.04.005

Coda R, Varis J, Verni M, Rizzello CG, Katina K (2017) Improvement of the protein quality of wheat bread through faba bean sourdough addition. LWT Food Sci Technol 82:296–302. https://doi.org/10.1016/J.LWT.2017.04.062

Jiménez-Martínez C, Hernández-Sánchez H, Dávila-Ortiz G (2003) Production of a yogurt-like product from Lupinus campestris seeds. J Sci Food Agric 83:515–522. https://doi.org/10.1002/jsfa.1385

Lin S, Huff HE, Hsieh F (2002) Extrusion process parameters, sensory characteristics, and structural properties of a high moisture Soy protein meat analog. J Food Sci 67:1066–1072. https://doi.org/10.1111/j.1365-2621.2002.tb09454.x

Riaz MN (2011) Texturized vegetable proteins. In: Phillips GO, Williams PA (eds) Handbook of food proteins, 1st edn. Woodhead Publishing Limited, Cambridge, pp 395–418

Duranti M (2006) Grain legume proteins and nutraceutical properties. Fitoterapia 77:67–82. https://doi.org/10.1016/j.fitote.2005.11.008

Boye JI, Aksay S, Roufik S, Ribéreau S, Mondor M, Farnworth E, Rajamohamed SH (2010) Comparison of the functional properties of pea, chickpea and lentil protein concentrates processed using ultrafiltration and isoelectric precipitation techniques. Food Res Int 43:537–546. https://doi.org/10.1016/j.foodres.2009.07.021

Jarpa-Parra M, Bamdad F, Tian Z, Zeng H, Temelli F, Chen L (2015) Impact of pH on molecular structure and surface properties of lentil legumin-like protein and its application as foam stabilizer. Colloids Surf B Biointerfaces 132:45–53. https://doi.org/10.1016/J.COLSURFB.2015.04.065

FAOSTAT Database (2016) Food and agriculture organization. http://www.fao.org/faostat/en/#data/QC. Accessed 15 Nov 2018

Karaca AC, Low N, Nickerson M (2011) Emulsifying properties of chickpea, faba bean, lentil and pea proteins produced by isoelectric precipitation and salt extraction. Food Res Int 44:2742–2750. https://doi.org/10.1016/j.foodres.2011.06.012

Arntfield SD, Maskus HD (2011) Peas and other legume proteins. In: Phillips GO, Williams PA (eds) Handbook of food proteins, 1st edn. Woodhead Publishing, Cambridge, pp 233–266

Dijkstra D, Linnemann A, Van Boekel T (2003) Towards sustainable production of protein-rich foods: appraisal of eight crops for western europe. part ii: analysis of the technological aspects of the production chain. Crit Rev Food Sci Nutr 43:481–506. https://doi.org/10.1080/10408690390246332

Nishinari K, Fang Y, Guo S, Phillips GO (2014) Soy proteins: a review on composition, aggregation and emulsification. Food Hydrocoll 39:301–318. https://doi.org/10.1016/j.foodhyd.2014.01.013

Fox PF, Uniacke T, McSweeney PLH, O’Mahony JA (2015) Dairy chemistry and biochemistry, 2nd edn. Springer International Publishing, New York

Papalamprou EM, Doxastakis GI, Biliaderis CG, Kiosseoglou V (2009) Influence of preparation methods on physicochemical and gelation properties of chickpea protein isolates. Food Hydrocoll 23:337–343. https://doi.org/10.1016/j.foodhyd.2008.03.006

Peng W, Kong X, Chen Y, Zhang C, Yang Y, Hua Y (2016) Effects of heat treatment on the emulsifying properties of pea proteins. Food Hydrocoll 52:301–310. https://doi.org/10.1016/j.foodhyd.2015.06.025

Sánchez-Vioque R, Clemente A, Vioque J, Bautista J, Millán F (1999) Protein isolates from chickpea (Cicer arietinum L.): chemical composition, functional properties and protein characterization. Food Chem 64:237–243. https://doi.org/10.1016/S0308-8146(98)00133-2

Joshi M, Adhikari B, Aldred P, Panozzo JF, Kasapis S (2011) Physicochemical and functional properties of lentil protein isolates prepared by different drying methods. Food Chem 129:1513–1522. https://doi.org/10.1016/j.foodchem.2011.05.131

Boye J, Zare F, Pletch A (2010) Pulse proteins: processing, characterization, functional properties and applications in food and feed. Food Res Int 43:414–431. https://doi.org/10.1016/j.foodres.2009.09.003

Jarpa-Parra M (2018) Lentil protein: a review of functional properties and food application. An overview of lentil protein functionality. Int J Food Sci Technol 53:892–903. https://doi.org/10.1111/ijfs.13685

Johnston SP, Nickerson MT, Low NH (2015) The physicochemical properties of legume protein isolates and their ability to stabilize oil-in-water emulsions with and without genipin. J Food Sci Technol 52:4135–4145. https://doi.org/10.1007/s13197-014-1523-3

Jacob F (ed) (2011) MEBAK–Wort, beer and beer-based beverages, collection of brewing analysis methods of the Mitteleuropäische Brautechnische Analysenkommission, Selfpublished by MEBAK, Freising-Weihenstephan

AACC International (2011) Approved methods of analysis, 11th edn. Method 30-25.01-Crude fat in wheat, corn, soy flour and feed mixes. AACC International, St. Paul, MN

AOAC, Official Methods of Analysis of AOAC International, AOAC Method 923.03—Ash of Flour (2005) Official methods of analysis, 18th edn. AOAC International Publisher, Gaithersburg

AOAC, Official Methods of Analysis of AOAC International, AOAC Method 925.10, Solids (Total) and Moisture in Flour (2005) Official methods of analysis, 18th edn. AOAC International Publisher, Gaithersburg

AOAC, Official Methods of Analysis of AOAC International, AOAC Method 996.11—Total Starch in Cereal Products (2005) Official methods of analysis, 18th edn. AOAC International Publisher, Gaithersburg

AACC International (2001) Approved methods of analysis, 11th edn. Method 76-13.01-Total starch assay procedure. AACC International, St. Paul, MN

US EPA (1994) Method 6020 metals by ICP/MS, inductively coupled plasma/mass spectrometry. Boston, MA

AOAC, Official Methods of Analysis of AOAC International, AOAC Method 991.43—Total, Soluble and Insoluble Dietary Fibre in Foods (2005) Official methods of analysis, 18th edn. AOAC International Publisher, Gaithersburg

Alonso-Miravalles L, O’Mahony JA (2018) Composition, protein profile and rheological properties of pseudocereal-based protein-rich ingredients. Foods 7:1–18. https://doi.org/10.3390/foods7050073

Hayakawa SS, Nakai S (1985) Relationships of hydrophobicity and net charge to the solubility of milk and Soy proteins. J Food Eng 50:486–491. https://doi.org/10.1111/j.1365-2621.1985.tb13433.x

Van Der Plancken I, Van Loey A, Hendrickx MEG (2005) Changes in sulfhydryl content of egg white proteins due to heat and pressure treatment. https://doi.org/10.1021/jf050289+

AACC International (2001) Approved methods of analysis, 11th edn. Method 56-30.01-Water hydration capacity of protein materials. AACC International, St. Paul, MN

Pearce KN, Kinsella JE (1978) Emulsifying properties of proteins: evaluation of a turbidimetric technique. J Agric Food Chem 26:716–723. https://doi.org/10.1021/jf60217a041

Sathe SK, Deshpande SS, Salunkhe DK (1982) Functional properties of Lupin Seed (Lupinus mutabilis) proteins and protein concentrates. J Food Sci 47:491–497. https://doi.org/10.1111/j.1365-2621.1982.tb10110.x

Bourne MC (2002) Food texture and viscosity—concept and measurements. In: Food texture and viscosity. Food science and technology, 2nd edn. Elsevier, Amsterdam

Detzel A, Kauertz B, Grahl B, Heinisch J (2016) Prüfung und Aktualisierung der Ökobilanzen für Getränkeverpackungen. Umweltforschungsplan des Bundesministeriums für Umwelt, Naturschutz, Bau und Reaktorsicherheit, Berlin

Foegeding EA, Davis JP (2011) Food protein functionality: a comprehensive approach. Food Hydrocoll 25:1853–1864. https://doi.org/10.1016/j.foodhyd.2011.05.008

Farrell HM, Bleck GT, Brown EM, Butler JE, Creamer LK, Hicks CL, Hollar CM, Swaisgood HE (2004) Nomenclature of the Proteins of Cows’ Milk—Sixth Revision. J Dairy Sci 87:1641–1674

Pathomrungsiyounggul P, Lewis MJ, Grandison AS (2010) Effects of calcium-chelating agents and pasteurisation on certain properties of calcium-fortified soy milk. Food Chem 118:808–814. https://doi.org/10.1016/j.foodchem.2009.05.067

Joshi M, Timilsena Y, Adhikari B (2017) Global production, processing and utilization of lentil: a review. J Integr Agric 16:2898–2913. https://doi.org/10.1016/S2095-3119(17)61793-3

Dagorn-Scaviner C, Gueguen J, Lefebvre J (1987) Emulsifying properties of pea globulins as related to their adsorptions behaviours. J Food Sci 52:335–341

Ladjal-Ettoumi Y, Boudries H, Chibane M, Romero A (2016) Pea, chickpea and lentil protein isolates: physicochemical characterization and emulsifying properties. Food Biophys 11:43–51. https://doi.org/10.1007/s11483-015-9411-6

Barbana C, Boye JI (2011) Angiotensin I-converting enzyme inhibitory properties of lentil protein hydrolysates: determination of the kinetics of inhibition. Food Chem 127:94–101. https://doi.org/10.1016/j.foodchem.2010.12.093

Greenfield N (2007) Using circular dichroism spectra to estimate protein secondary structure. Nat Protoc 1:2876–2890. https://doi.org/10.1038/nprot.2006.202.Using

Aryee AN, Boye JI (2015) Comparative study of the effects of processing on the nutritional, physochochemical and functional properties of lentil. J Food Process Preserv 41:1–13. https://doi.org/10.1111/jfpp.12824

Kim EHJ, Chen XD, Pearce D (2009) Surface composition of industrial spray-dried milk powders. Effects of spray drying conditions on the surface composition. J Food Eng 94:169–181. https://doi.org/10.1016/j.jfoodeng.2008.10.020

Kelly GM, O’Mahony JA, Kelly AL, Huppertz T, Kennedy D, O’Callaghan DJ (2015) Influence of protein concentration on surface composition and physico-chemical properties of spray-dried milk protein concentrate powders. Int Dairy J 51:34–40. https://doi.org/10.1016/j.idairyj.2015.07.001

Amagliani L, O’Regan J, Kelly AL, O’Mahony JA (2016) Physical and flow properties of rice protein powders. J Food Eng 190:1–9. https://doi.org/10.1016/j.jfoodeng.2016.05.022

Crowley SV, Desautel B, Gazi I, Kelly AL, Huppertz T, O’Mahony JA (2015) Rehydration characteristics of milk protein concentrate powders. J Food Eng 149:105–113. https://doi.org/10.1016/j.jfoodeng.2014.09.033

Kato A, Nakai S (1980) Hydrophobicity determined by a fluorescence probe method and its correlation with surface properties of proteins. Biochim Biophys Acta Protein Struct 624:13–20. https://doi.org/10.1016/0005-2795(80)90220-2

Joshi M, Adhikari B, Aldred P, Panozzo JF, Kasapis S, Barrow CJ (2012) Interfacial and emulsifying properties of lentil protein isolate. Food Chem 134:1343–1353. https://doi.org/10.1016/j.foodchem.2012.03.029

Li M, Lee T-C (2000) Effect of extrusion temperature on the solubility and molecular weight of lentil bean flour proteins containing low cysteine residues. J Agric Food Chem 48:880–884. https://doi.org/10.1021/jf990328f

Lee K, Ryu H, Rhee K (2003) Protein solubility characteristics of commercial soy protein products. J Am Oil Chem Soc 80:85–90. https://doi.org/10.1007/s11746-003-0656-6

Boland MJ, Rae AN, Vereijken JM, Meuwissen MPM, Fischer ARH, van Boekel MAJS, Rutherfurd SM, Gruppen H, Moughan PJ, Hendriks WH (2013) The future supply of animal-derived protein for human consumption. Trends Food Sci Technol 29:62–73. https://doi.org/10.1016/j.tifs.2012.07.002

Fuhrmeister H, Meuser F (2003) Impact of processing on functional properties of protein products from wrinkled peas. J Food Eng 56:119–129. https://doi.org/10.1016/S0260-8774(02)00241-8

Horstmann SW, Foschia M, Arendt EK (2017) Correlation analysis of protein quality characteristics with gluten-free bread properties. Food Funct 8:2465–2474. https://doi.org/10.1039/C7FO00415J

Avramenko NA, Low NH, Nickerson MT (2013) The effects of limited enzymatic hydrolysis on the physicochemical and emulsifying properties of a lentil protein isolate. Food Res Int 51:162–169. https://doi.org/10.1016/j.foodres.2012.11.020

Kinsella J (1983) Relationships between structure and functional properties of food proteins. In: Fox P, Condon S (eds) Food proteins. Applied Science, London, p 51

Zhou J, Liu J, Tang X, Tang CX (2018) Effects of whey and soy protein addition on bread rheological property of wheat flour. J Texture Stud 49:38–46. https://doi.org/10.1111/jtxs.12275

Thrane M, Paulsen PV, Orcutt MW, Krieger TM (2017) Soy Protein: Impacts, Production, and Applications. In: Nadathur SR, Wanasundra JPD, Scanlin L (eds) Sustainable protein sources, 1st edn. Academic Press, London

Berardy A, Costello C, Seager T (2015) Life cycle assessment of soy protein isolate. Proc Int Symp Sustain Syst Technol 3:13. https://doi.org/10.6084/m9.figshare.1517821

Acknowledgements

The work for this publication has been undertaken as part of the PROTEIN2FOOD project. This project has received funding from the European Union’s Horizon 2020 research and innovation programme under grant agreement No. 635727. We thank our colleagues Dave Waldron, Tom Hannon and Michael Cronin for technical assistance and expertise that greatly assisted the work.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare no conflicts of interest.

Compliance with ethics requirements

This study did not involve human participants and/or animals.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Alonso-Miravalles, L., Jeske, S., Bez, J. et al. Membrane filtration and isoelectric precipitation technological approaches for the preparation of novel, functional and sustainable protein isolate from lentils. Eur Food Res Technol 245, 1855–1869 (2019). https://doi.org/10.1007/s00217-019-03296-y

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00217-019-03296-y