Abstract

The aim of this work was to provide a thorough evaluation of quality characteristics of French fries prepared from frozen potatoes using different home-cooking systems. French fries were prepared using deep-fat fryer, air-frying appliances, convection oven, and microwave oven. Two commercial frozen potato sticks, specifically intended for deep-fat frying and for oven cooking, respectively, were used for the cooking tests. The obtained French fries were analyzed for compositional parameters and for sensory properties by instrumental analyses (texture, color, and aroma) and descriptive analysis. Significant differences in physico-chemical and nutritional characteristics of the final products were observed, depending on both the raw material and the cooking system; analytical data were in good agreement with the sensory results. French fries obtained by oven cooking of apposite frozen potato sticks had sensory characteristics similar to those of deep-fat fried potatoes, with low acrylamide (about 50 µg/kg) and lower fat content (7.4–11.1 g/100 g compared to 14.5–17.1 g/100 g in deep-fat fried potatoes); on the other hand, oven cooking was the most expensive system in terms of energy consumption. Quality characteristics of French fries obtained by air-frying and microwave cooking were poorer, and these products had higher acrylamide content (up to 410 µg/kg in microwave cooked samples).

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Fried foods, and French fries in particular, are widely consumed in Europe and all over the world because of their unique and typical sensory properties. The health risks correlated with a diet rich in fats are well known [1], and consumers are increasingly aware that fried foods contain high level of fats, which have been subjected to thermal damage and have, therefore, lost part of their positive nutritional properties. Fried potato products are also known to be particularly rich in acrylamide [2, 3], an early product of the Maillard reaction that is typically formed during severe heat treatment of food matrices containing reducing sugars and asparagine, such as potatoes [4–6]. Acrylamide exerts carcinogenic effect on humans [7, 8], and the mechanisms of its formation as well as its occurrence in potato and in various baked and fried products have been investigated in recent years [9, 10]. Another negative aspect of fried food is that traditional preparation, i.e., deep-fat frying, requires the supply of high amounts of frying medium (generally vegetable oils) and consequent final disposal of the exhausted oils. In addition, frying generates unpleasant and very persistent off odors.

Despite these constraints, fried products are very popular in Europe and are highly consumed both at home and outdoor [11], representing typical dishes in fast-food and street-food services. In this context, a number of alternative appliances have been proposed by various companies, with the aim of replacing deep-fat frying with cooking systems able to achieve similar sensorial properties combined with better nutritional quality and ease of use. To prepare French fries at household level, the following cooking systems can be used: oven cooking (baking), air frying, and microwave cooking. Due to the popularity of French fries, food producers have developed ready-to-use frozen potato sticks that can be directly used for both traditional frying and alternative cooking systems. Some studies evaluated the effects of different cooking systems on the quality characteristics [12–14] and the acrylamide content [2, 15] of French fries, but none of them considered at one time the various cooking systems available for consumers and the sensory and nutritional attributes of the resulting products. The aim of this work was to provide a thorough evaluation of quality characteristics of French fries prepared using the major cooking appliances available on the Italian market, i.e., traditional deep-fat fryer, air-frying appliances, convection oven, and microwave oven, applying the conditions typical of home cooking. Various aspects were considered: the cooking performance, evaluated by weight loss, moisture, color, and texture of the final product; the nutritional quality, by determination of fat and acrylamide content; the sensory properties, evaluated by descriptive analysis; the aromatic profile, evaluated by the application of the electronic nose; and the cooking costs, taking into account time and energy required for each cooking system. The e-nose has already been applied to evaluate flavor changes during the frying process and during shelf life of fried potatoes, but it has never been applied for the characterization and comparison of products obtained by different cooking systems [16, 17].

Materials and methods

Potatoes

All cooking trials were carried out using two commercial frozen potato sticks, provided by Pizzoli SpA (Budrio, Italy), the Italian market leader for this product: Viva le Patatine (VLP), a product specifically intended for deep-fat frying, and PataSnella (PS), a product specifically intended for oven cooking.

Both products consist of potato sticks 75 × 35 × 35 mm, and are subjected to a light pre-frying step in sunflower oil before freezing. The only ingredients of these products are potatoes and sunflower oil and their nutritional composition, as reported in the labels, is shown in Table 1. Frozen potatoes were fried using “Friol” (Deoleo, Rivas Vaciamadrid, Spain), an oil specific for frying, principally composed of sunflower oil and vegetable fractionated oils.

Appliances

The following appliances, all available on the Italian market and produced by premium brands, were used:

-

deep-fat fryer (AKT 326/IX, Whirlpool, Benton Harbor, USA) with a 2.5 L capacity stainless steel basin, heated by a 1600 W electric resistance;

-

air fryer ActiFry (ActiFry Snacking, Tefal Italia, Milano), consisting of a covered pan of 1 kg capacity, heated by a 1440 W electric resistance and provided with a stirrer that moves the product during cooking. An air-convection system forces air throughout the pan from holes located at the top of the vessel;

-

air fryer AirFryer (Viva Collection AirFryer HD 9220/20, Philips Italia, Milano), a closed vessel of 800 g capacity, heated by a 1425 W resistance located on the top. A fan forces the hot air from the top to the bottom of the vessel, and the shape of the bottom allows air to go up again. The product is put in a perforated basket suspended between the top and the bottom of the vessel;

-

traditional oven (AKZM6551IXL, Whirlpool, Benton Harbor, USA), 3000 W power, capacity 73 L, with static, forced convection and grill functions;

-

microwave oven (Family Chef, Whirlpool, Benton Harbor, USA), 1000 W power, capacity 27 L, with specific function and specific plate (CRISP) for French fries.

Cooking protocols

All cooking trials were carried out following the instructions given by the devices’ producers to obtain French fries with optimal and similar cooking degree.

Deep-fat frying was carried out in 2.5 L oil (Friol), heated at 180 °C; 300 g of frozen chips (PS and VLP) were put in the basket and fried for 5 min. French fries were then drained and put on paper to remove excess oil.

Cooking with ActiFry was performed placing 300 g frozen chips (PS and VLP) in the pan and the cooking time was 20 min. This device does not allow to control the temperature, which ranges from 130 to 220 °C. The product is continuously mixed by the rotating stirrer.

In the case of AirFryer, the device was preheated for 4 min at 200 °C, then 300 g frozen chips (PS and VLP) were put in the basket and cooked at 200 °C for 12 min.

For oven cooking, the oven was preheated at 225 °C in static function, then 300 g frozen chips (PS and VLP) were spread on the enameled steel plate covered with a sheet of greaseproof paper, avoiding contact between sticks. The plate was positioned at level 2 in the oven and chips were cooked at 225 °C in static function for 15 min (PS) and 22 min (VLP).

Microwave cooking was performed with the Family Chef microwave oven, using the function of the control panel specifically intended for French fries. 300 g frozen sticks (PS and VLP) were placed on the CRISP plate that can be heated by microwaves up to 220 °C and, therefore, heats the product by conduction. Cooking time was 12 min; after about 7 min, the oven was opened and potato sticks were rapidly turned over with a plastic scoop, then cooking was completed.

All cooking trials were carried out in duplicate for each device with the two products (PS and VLP).

Temperature and power profiles

Temperature and power profiles were monitored for each cooking appliance. A temperature control system (WT210, Yokogawa Italia, Novate Milanese, Italy) equipped with K thermocouples (Tersid, Milano, Italy) was used. Thermocouples (3–5) were positioned in different points of each cooking appliance and temperature monitoring was carried out in the same conditions used for French fries cooking; the monitoring was performed for almost 1 h and the initial equilibration period was discarded for data elaboration. In the case of MW oven, thermocouples could not be installed because of the rotating plate.

Power profiles were recorded (Power Meter WT 310 E, Yokogawa Italia, Novate Milanese, Italy) during cooking trials with each cooking device.

Analytical methods

Analytical determinations on cooked samples were carried out after a 5 min rest on greaseproof paper, to obtain cooling and stabilization of the products.

Weight loss was determined gravimetrically for each cooking trial. Data are expressed as percentage variation.

Moisture content of cooked products was determined by drying the homogenized samples to constant weight at 105 °C [18]. This determination was carried out in triplicate for each sample.

Fat content was determined by Soxhlet extraction using petroleum ether as solvent, as described by Del Rocio Teruel et al. [13], in triplicate.

Acrylamide content was determined by LC-MS as described by Palazoglu et al. [15], in triplicate.

Color was evaluated as RGB and L*a*b* indexes. For each cooking trial, 16 potato sticks were placed on a black cardboard and images were acquired with a digital camera (Canon PowerShto S3 IS) at maximum resolution (1600 × 1200 pixels) in jpeg format. The camera was placed perpendicularly to the sample under controlled lighting conditions. The lighting system consisted of four cool daylight lamps (23 W/865, Philips MASTER PL-Electronic) placed above the sample at a 45° angle to avoid irregular reflection on the sample surface. The white balance of the camera was set using the ColorChecker White Balance Card (X-Rite Europe GmbH, Regensdorf, Switzerland), and the color balancing was performed by the Digital ColorChecker SG (X-Rite Europe GmbH, Regensdorf, Switzerland). Images were processed with the CameraWindow—Canon PowerShot software and elaborated by the Image ProPlus 6.2 (Media Cybernetics, Inc. Bethesda, MD, USA) software to obtain the R (red), B (blue), and G (green) color indexes and the intensity mean values (average of R, G, and B values).

On the same 16 potato sticks used for image analysis, color was determined as L*, a*, and b* coordinates (CIE L*a*b* color space) with a portable UV–VIS spectrophotometer (CM-600d, Konica Minolta). Measurements were taken at two opposite sides of every stick, obtaining 32 measurements for each trial. Mean values were calculated for L*, a*, and b* indexes.

Texture of French fries was evaluated using TA.HDplus Texture Analyser (TXT, Stable Micro System), supported by Exponent software (v. 6, 1, 5, 0). A cutting test with Warner Blatzer blade was developed. Fifteen potato sticks were analyzed for each cooking trial, and each stick was placed at the basis of the texture analyzer to be transversally cut in the middle by the Warner Blatzer blade. The operating conditions were as follows: load cell 30 kg; test speed 2 mm/s; displacement 40 mm; and the force–displacement curve was recorded, obtaining curves with a peak-like shape. The following parameters were elaborated from the curve: peak force (N), corresponding to the maximum force reached to first penetrate the potato stick, index of the crust resistance; energy (N*mm), corresponding to the area under the force–displacement curve from initial compression to complete cut of the stick, and index of the overall consistency of the product.

Electronic nose analysis

The aromatic profile of French Fries was evaluated by the portable PEN2 e-nose from Win Muster Airsense (WMA) Analytics Inc. (Schwerin, Germany). It consists of a sampling apparatus, a detector unit containing the sensor array, and a pattern recognition software (Win Muster v.1.6) for data recording and elaboration. The sensor array is composed of 10 Metal Oxide Semiconductor (MOS) sensors: W1C (aromatic), W5S (broadrange), W3C (aromatic), W6S (hydrogen), W5C (arom-aliph), W1S (broad-methane), W1W (sulphur-organic), W2S (broad-alcohol), W2W (sulph-chlor), W3S (methane-aliph). The sensor response is expressed as resistivity (Ohm).

After 60 min cooling at room temperature, 50 g of potato sticks were placed in 500 mL airtight glass jars fitted with a pierceable Silicon/Teflon disk in the cap. After 30 min equilibration at 40 ± 1 °C, the measurement started and the sample headspace was pumped over the sensor surfaces for 60 s (injection time) at a flow rate of 300 mL/min; during this time, the sensor signals were recorded. After sample analysis, the system was purged for 180 s with filtered air prior to the next sample injection to allow reestablishment of the instrument base line. The sensor drift was evaluated using a standard solution of 1% ethanol included in each measurement cycle. Electronic nose analysis was carried out in duplicate for each sample, and the average of the sensor responses was used for subsequent statistical analysis.

Sensory evaluation

Nine assessors (5 males and 4 women, age 26–55 years) recruited among the staff of the Whirlpool company (Cassinetta di Biandronno, Varese, Italy) voluntarily participated in the descriptive analysis at the company site. The assessors had no history of disorders in oral perception. Some of them had previous experience in participating in descriptive analysis. The panellists participated in three 90-min training sessions, in which ten samples (five VLP and five PS) were presented to expose the panellists to the entire variability range of the products. During the first training session, the panellists spontaneously elicited attributes to describe the products. In subsequent sessions, the panellists were provided by the panel leader with some standards and refined the list of words selecting the 15 descriptors that were most suitable for describing the sensory differences among the samples (Table 2). From the second training session, a score sheet was given to quantify the perceived intensity of the descriptors on a discrete nine-point scale (1 = extremely weak, 9 = extremely intense). After the training phase, the panellists evaluated in triplicate the intensity of the selected attributes for the VLP and PS French fries in separate sessions (three sessions for the VLP and three sessions for the PS samples). The samples were presented in a balanced and randomized order within each replicate. The panellists rinsed their mouths with still water and rested for a 5 min between samples. Each session was conducted under white light and lasted approximately 40–50 min.

Statistical analysis

Analytical data were statistically evaluated by one-way ANOVA and multiple range test (LSD method) to put in evidence significant differences between the cooking systems, considering separately VLP and PS (Statgraphics Plus v. 5.1 package).

Electronic nose data were statistically elaborated by principal component analysis (PCA) with confidence ellipses.

The intensity data from the trained panel were analyzed by PCA (Tucker-1 Principal Component Analysis) and by p-MSE (p value vs mean squared error) plot (Panel Check software, v. 1.4.0, Nofima, Norway) to assess the panel calibration and assessor performance, respectively [19]. All of the assessors were considered to be reliable; thus, none of the subjects were excluded from further data analysis. Descriptive data were submitted to a two-way ANOVA mixed model (fixed factors: appliance, potato stick type) to assess the effect of the cooking systems and of the potato stick type (VLP, PS). Two-way ANOVA models (fixed factor: sample; random factor: judge) and multiple range test (LSD method) were also separately conducted for VLP and PS samples. PCA with confidence ellipses was computed on the panel data of significant attributes.

PCA with confidence ellipses (both for e-nose and sensory data) was performed using the R software (v. 3.1.2, The R Foundation for Statistical Computing).

Results and discussion

Quality characteristics of VLP and PS obtained with the various appliances

Table 3 shows the percentage weight loss, the final moisture, and the texture parameters of French fries obtained from VLP and PS. Results are reported as the mean value ± standard deviation of the replicated trials. Samples differed significantly for all the parameters (p < 0.001) and results of the multiple range test show statistically significant differences between the cooking systems.

Considering VLP, conventional deep-fat frying determined a final moisture content of approximately 41.5%; for this cooking system, weight loss was the lowest (34.4%), because final weight is influenced by fat absorption. Considering the texture parameters, deep-fat fried VLP showed the lowest peak force and energy values (7.3 N and 49 N*mm, respectively), meaning that these products have a thinner crust and are softer inside: these characteristics correspond to the desirable texture of French fries. Air-frying systems (ActiFry and AirFryer) and traditional oven cooking produced French fries with similar weight loss and final moisture content; moisture content of these fries was the highest (52–54%), and these products appeared as less cooked than the others. MW-cooked VLP had the lowest final moisture content, corresponding to the highest weight loss (46.7%); despite this cooking method is the faster one, water loss is the highest. The significantly lower moisture content of microwaved chips is due to rapid inner heating and to difficulty in the formation of the crust that would represent a barrier to water evaporation. With regard to texture, air-frying and oven cooking resulted in products harder than the conventionally fried ones, both in terms of crust and inner flesh. In particular, traditional oven and MW cooking produced French fries with the hardest crust and flesh, with Force values ranging from 12 to 14 N and energy values ranging from 78 to 82 N mm.

Cooking results obtained using PS were quite different: PS is specifically designed for oven cooking and this cooking system produced chips with the highest final moisture content (approx. 49%), similar to the moisture content of deep-fat fried VLP. Again, MW cooking resulted in high weight loss and too low final moisture content (about 38 g/100 g). No significant differences in moisture content were observed between PS cooked with ActiFry, AirFryer, and deep-fat frying; all these products appeared too much dehydrated, as well as MW-cooked PS.

Despite the high variability of the texture data, differences between cooking systems can be evidenced. In the case of PS, peak force and energy values were the lowest in oven cooked chips, i.e., these products were softer and more similar, concerning texture characteristics, to deep-fat fried VLP, which correspond to optimal crust and inner portion textural properties. Air-frying systems resulted in harder overall texture and crust, and chips obtained by microwave cooking showed the highest values for both texture parameters.

Color is an important characteristic for the evaluation and appreciation of the cooking performance. Color of French fries was determined by colorimetric analysis in the CIELab space and is expressed in terms of L*, a*, and b* color coordinates; R, G, and B values were obtained by image analysis and were elaborated into Intensity mean index, which corresponds to overall color intensity. Color data are reported in Table 4.

There was great variability between individual potato sticks within the same cooking trial, and considering different areas of the same stick, therefore, instrumental color analysis cannot provide accurate information about color appearance. Images in Fig. 1 allow to compare visual characteristics of French fries obtained from VLP.

Deep-fat fried VLP represent the sample with the best appearance, corresponding to a homogeneous golden-yellow color. L* values are an index of luminosity, and for French fries, lower L* values represent more browned products. Considering VLP, ActiFry and traditional oven produced the darkest (L* = 60.5) and the lightest (high L* = 65.4) French fries, respectively. In effect, oven cooked potatoes had a light yellow color in the central area but were burnished at the ends, and this feature was not appreciated by instrumental L*a*b* color analysis. AirFryer produced chips with uneven color, characterized by dark areas and pale ones. RGB and intensity mean values determined on French fries by image analysis confirm data obtained in the CIELab space: MW-cooked chips were less colored compared to the other samples (lower R, G, and B and intensity mean values), whereas ActiFry and oven cooked chips showed the highest values of all color parameters, appearing as the most browned samples. Comparing VLP with PS samples, the latter showed a more intense color (higher R, G, and B values).

Nutritional characteristics of the products: fat and acrylamide content

The fat content and acrylamide concentration of the various samples are reported in Table 5.

As expected, deep-fat fried chips have a final fat content higher than chips obtained by the other cooking appliances, where no fat is added and the final fat content only depends on the initial one. VLP have an initial lipid concentration lower than PS (4.4 g/100 g and 6.0 g/100 g, respectively) and consequently a lower final fat content (14.5 vs 17.1 g/100 g). The difference between deep-fat fried and otherwise cooked chips is approximately 6–7 g/100 g, both for VLP and PS. Comparing oven cooked PS and deep-fat fried VLP, i.e., the products prepared according to their expected cooking method, fat intake can be reduced by approximately 3.5 g per 100 g final product.

Fat content of French fries can vary widely, depending on the frying conditions and the size and characteristics of potato sticks [20–22]; literature data report fat content between 6.2 and 20.8 g/100 g in French fries purchased from restaurants and take away and from 12 to 20 g/100 g in French fries homely processed from frozen chips [23].

Acrylamide content was determined in the differently cooked French fries (Table 5). The acrylamide content of French fries detected in our study is in the range reported in the literature; EFSA recent review on acrylamide in food [24] indicates 300–350 μg/kg of acrylamide in potato fried products (except potato crisps), both purchased as ready-to-eat or as precooked. These values were obtained by a high number of samples (n = 1694) and can, therefore, be considered as representative and reliable. Higher values are reported for potato crisps and other potato fried products (606 and 389 μg/kg as average level, respectively).

When excluding MW cooking, the acrylamide concentrations found in VLP and PS cooked with the various appliances were in the range of 48–237 μg/kg; French fries prepared by ActiFry showed the highest acrylamide concentration (182 and 237 μg/kg in VLP and PS, respectively), which is in any case lower than the average concentration in potato fried products reported by EFSA [24], and similar to values reported by Ye et al. [25]. AirFryer determined an acrylamide content similar to deep-fat frying and the lowest acrylamide content was detected in French fries cooked in static oven. From our data, it is not possible to ascertain differences between VLP and PS in terms of final acrylamide content. Instead, data clearly show a higher acrylamide formation in French fries prepared by MW oven. This result was quite unexpected, since MW cooking time is one of the shortest (12 min) and the inner temperature of the product cannot exceed 100 °C. Our results can be discussed considering some literature data. Erdogu et al. [2] investigated the effects of MW precooking time (10, 20 and 30 s) and frying oil temperature (from 150 to 190 °C) on the acrylamide content of French fries. The study demonstrated that increasing oil temperature corresponded to higher acrylamide concentration and that MW precooking reduced in all cases the acrylamide content of French fries. Nevertheless, increasing MW precooking time produced higher acrylamide content in the core region of French fries and authors attributed this effect to faster drying of the inner region of the MW-treated samples, which promotes the Maillard reaction. A similar effect had already been observed in baked cut potato products, previously subjected to MW pre-heating [26]. Ye et al. [25] also observed increased acrylamide concentrations in potato chips prepared by MW cooking when compared to conventional frying. Results suggested that both the microwave heating mechanism and the correlated faster decrease in moisture content can favor acrylamide formation in potato products.

Sensory characteristics

The results of the ANOVA fixed model applied to assess the effect of the potato stick type and appliance on the sensory properties of French fries revealed a significant effect for both variables. In comparison with PS samples, VLP samples resulted significantly (p ≤ 0.001) more intense for the color uniformity (VLP = 6.4 ± 0.2; PS = 4.5 ± 0.2), texture uniformity (VLP = 5.8 ± 0.2; PS = 4.8 ± 0.2), and flesh softness (VLP = 6.8 ± 0.2; PS = 5.3 ± 0.2), and less intense in terms of visual defects (VLP = 3.8 ± 0.2; PS = 5.3 ± 0.2) and crust crunchiness (VLP = 4.7 ± 0.2; PS = 5.7 ± 0.2). Regarding the appliance effect, the conventional deep-fat frying produced French fries significantly higher in color uniformity (p = 0.007) and oil flavor (p < 0.0001), and lower in visual defects (p < 0.0001) than all the other four cooking systems. The samples obtained using both the Fryer and the traditional oven resulted significantly higher in terms of oiliness (p < 0.0001) and potato odor (p = 0.047) and flavor (p = 0.041) than those cooked with the air-frying systems (ActyFry and AirFryer) and the microwave oven.

The results of the mixed ANOVA model and LSD Fisher’s test separately applied to the sensory data obtained for the VLP and PS French fries are reported in Table 6. A sample effect was found for 10 and 11 out of 15 attributes for VLP and PS samples, respectively. Nine significant attributes were in common for VLP and PS samples. The potato flavor resulted significant only for the PS samples, while the odor and flavor defects resulted significant only for the VLP samples. The saltiness and the persistency of the flavor and of the flavor defects were not significant, for both VLP and PS. Non-significant attributes were excluded from further data analyses.

The perceptive maps obtained for VLP and PS samples from PCA applied to the mean intensity data of significant attributes are shown in Fig. 2. The total variance explained for the sensory attributes of the VLP samples based on the first two significant dimensions was 84%, with PC1 and PC2 accounting for 53 and 31%, respectively. The overlapping of the 95% confidence ellipses of the samples cooked with the ActiFry and microwave oven shows that these two appliances produced VLP French fries with similar sensory properties. On the contrary, the other three appliances produced samples with significant sensory differences. Samples were distributed along PC1 mainly as a function of the presence of visual defects, which were very low in VLP cooked with the deep-fat fryer, medium in the samples obtained with the AirFryer and the traditional oven, and very high in the samples cooked using the ActiFry and microwave oven appliances. The sample cooked in the fryer is the most correlated to PC1 and it resulted the most intense in terms of oiliness, crust crunchiness, oil flavor, and fried odor. PC2 contrasted the sample obtained with the AirFryer to the other products showing that the AirFryer produced French fries generally less intense in terms of oiliness and crust crunchiness and more intense for the potato flavor and flesh softness. The sample cooked with the traditional oven has an intermediate position on the map, indicating a medium level of intensity for most of the significant attributes.

The total variance explained for the sensory attributes of the PS samples based on the first two significant dimensions was 78%, with PC1 and PC2 accounting for 53 and 25%, respectively. The overlapping of the 95% confidence ellipses of the samples shows that (as already noticed above for VLP) the ActiFry and microwave oven produced PS French fries with similar sensory properties. The same observation is also valid for the samples cooked with the traditional oven and the Fryer. On the contrary, the use of the AirFryer produced French fries with sensory properties different from those obtained with the others appliances. Samples were distributed along PC1 according to the decreasing intensity of the visual, odor, and flavor defects and the increasing intensity of all positive attributes related to appearance, odor, flavor, and texture. In particular, PS cooked with the AirFryer is the most intense for all defects considered and the least uniform sample in terms of color and texture. On the contrary, the French fries cooked in the Fryer were low intense in defects and higher for potato and fried odor, oil flavor, flesh softness, and texture uniformity. PC2 contrasted the samples cooked in the traditional oven and AirFryer, which were higher in oiliness and oil flavor, to the sample obtained using the ActiFry, which was more intense in terms of crust crunchiness.

Comparing the sensory results with the analytical data, good agreement was observed. In particular, the sensory evaluation of the French fries’ appearance confirmed the results of the colorimetric analysis: the higher color uniformity and the lower visual defects observed in VLP than in PS were in agreement with the higher L* and lower intensity mean values generally observed for VLP in comparison with PS. Similarly, the worst values obtained for the appearance attributes in PS cooked using the AirFryer correspond to the more intense darkness noticed in this sample considering the colorimetric parameters. Moreover, the sensory evaluation confirmed that, among the PS samples, the French fries cooked in the traditional oven had the softest flesh and the least crunchy crust, in agreement with the lowest peak force and energy values and the highest humidity content observed for this sample.

Aromatic profile

To obtain an exhaustive characterization of the aromatic profile of VLP ad PS French fries, cooked samples were analyzed by electronic nose and the collected data were elaborated by PCA jointly with the significant sensory attributes for odor and flavor.

Figures 3, 4 show the score plot (a) and loading plot (b) for VPL and PS samples, respectively. The total variance explained on the first two significant dimensions was 88.2% for VLP and 90.8% for PS. Considering the score plot of VLP (Fig. 3a), samples were clearly discriminated on PC1 and PC2 according to cooking appliances. French fries cooked with ActiFry and MW oven were located in the negative part of PC1, and their aromatic components were perceived in particular by WC sensors (W1C; W2C; W3C) (Fig. 3b). Samples cooked with AirFryer and with traditional oven were located close on the plot, discriminated by F-potato attribute and characterized by a similar aromatic profile perceived by WS sensors (W1S; W2S; W3S; W5S) and by WW sensors (W1W; W2W). VLP cooked in the fryer, located on the right of the plot in the positive part of PC2 (Fig. 3a), were characterized by O-potato, O-fried, and F-oil attributes and by high value of W6S sensor of broad range sensitivity (Fig. 3b).

By the score plot in Fig. 4a, representing the distribution of PS samples, it is possible to notice that ActiFry and MW oven produced French fries with similar aromatic profile, perceived by WC sensors (W1C; W2C; W3C) (Fig. 4b); AirFryer sample was discriminated on the negative part of PC2 and was characterized by odor and flavor defects; PS cooked with traditional oven and by deep-fat frying are characterized by a similar aromatic profile (perceived by WS and WW sensors) and by a greater intensity of odor and flavor attributes (Fig. 4b).

Temperature profiles and energy costs of the various cooking systems

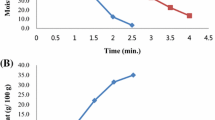

Temperature data, cooking times, and energy consumption (considering the pre-heating time, when prescribed) for each cooking system are shown in Table 7. Temperature parameters consist in: average temperature of the various thermocouples and relevant standard deviation; range, as the difference between maximum and minimum temperature recorded during the trial; and accuracy, as the difference between the target temperature (setpoint) and the actual average temperature. The traditional fryer and static oven showed good precision and accuracy, achieving an equilibrium temperature in both cases slightly lower (4–6 °C) than the setpoint (accuracy), good homogeneity for the different positions in the device (standard deviation of the average), and a range between maximum and minimum temperature of about 15 °C. AirFryer actual temperature was more distant from the setpoint (187.7 vs 200 °C), and temperature fluctuations were higher (36.2 °C). Accuracy could not be determined for ActiFry, since the setpoint is authomatic, but the measured average temperature was the lowest (162.5 °C) and very high fluctuations occurred during the monitoring (82.6 °C).

The energy consumption for one cooking varied from a minimum of 193.8 Wh (AirFryer) to a maximum of 746.6 Wh (oven cooking of VLP), indicating that energy costs can vary widely. Traditional oven cooking resulted the most expensive because of long pre-heating (10 min) and cooking times (22 and 15 min for VLP and PS, respectively) that lead to total times as long as 32 min; in addition, power requested by traditional electric oven is the highest one (3500 W). Intermediate energy consumption is referred to MW oven, according to the power requirements of this device (1000 W) despite the shortest cooking time. Traditional deep-fat frying and air-frying systems requested lower and comparable energy consumption (193.8–270.4 Wh); for these devices, maximum power absorption was 1400–1600 W and cooking times varied from 13 to 20 min. AirFryer required 193.8 Wh to prepare French fries both from VLP and PS, corresponding to 70% saving with respect to oven and 55% saving with respect to MW oven.

Conclusions

The results of this study allow to compare the performance of the main commercially available cooking appliances for home preparation of French fries, obtained by frozen potato sticks. Various aspects have been considered: French fries were evaluated in terms of nutritional value by fat and acrylamide content, and general quality characteristics were determined by analytical parameters, such as color and texture, by aromatic profile (e-nose) and sensory profile. Deep-fat fried potatoes represent the target quality profile (optimal appearance, texture, flavor, and aroma characteristics); however, their fat content is the highest (about 14.5 g/100 g in the end product). Air frying, oven, and microwave cooking allow to lower the fat content by 45–50%, but appearance, texture, flavor, and odor characteristics are significantly different from the standard. Compared to deep-fat fried potatoes, French fries obtained from VLP by air frying and by oven cooking had higher final moisture content (52.4–53.8 g/100 g compared to 49.2 g/100 g in deep-fat fried VLP) and higher texture values (oven cooked VLP in particular), showed uneven color and were assigned lower sensory scores for typical flavor, odor, color, and texture descriptors. The two air-frying devices tested in this study (AirFryer and ActiFry) produced French fries which were similar for moisture content and consistency, but differed in their sensory attributes, as revealed by the sensory and the e-nose evaluation. Microwave cooked VLP have the lowest final moisture content (46.7 g/100 g) and show sensory characteristics similar to chips obtained by ActiFry, as evidenced by multivariate analysis (PCA) of sensory and e-nose data: these products have the lowest sensory scores. Different results were obtained using PS as raw material: the use of frozen potatoes specifically designed for oven cooking that have initial higher fat content (6 g/100 g) allows to obtain oven cooked French fries with good sensory characteristics, evaluated both by instrumental (texture, color, and e-nose) and sensory analysis, with a final fat content of about 11.1 g/100 g. ActiFry and microwave cooking of PS produced again the worst results in terms of sensory profile. Particular consideration must be given to acrylamide formation, which is a critical parameter in French fries. Excluding microwave cooked samples, the acrylamide concentration detected in our samples (48–237 µg/kg) was quite low when compared to the range reported for French fries by EFSA (300–350 µg/kg) [24]; oven cooking produced the lowest acrylamide level in both VLP and PS. On the contrary, microwave cooking resulted in high acrylamide concentrations (410 and 343 µg/kg in VLP and PS, respectively); this result agrees with other literature data [2, 25, 26] and must be given careful consideration when choosing the cooking method. From our results, oven cooking of potato chips specifically intended for this cooking system allows to obtain satisfactory results in terms of both nutritional and sensory characteristics. On the other hand, oven cooking is the most expensive system in terms of energy consumption (661–425 Wh), whereas traditional fryer and air-frying systems are the cheapest ones (194–270 Wh).

References

Saguy S, Dana D (2003) Integrated approach to deep fat frying: engineering, nutrition, health and consumer aspects. J Food Eng 56:143–152

Erdogu SB, Palazoglu TK, Gokmen V, Sanyuva HZ, Ekiz HI (2007) Reduction of acrylamide formation in French fries by microwave pre-cooking of potato strips. J Sci Food Agric 87:133–137

EFSA (2012) Update on acrylamide levels in food from monitoring years 2007 to 2010. EFSA J 10:2938–2976

Williams JSE (2005) Influence of variety and processing conditions on acrylamide levels in fried potato crisps. Food Chem 90:875–881

Kumar D, Singh BP, Kumar P (2004) An overview of the factors affecting sugar contents of potaotes. Ann Appl Biol 145:247–256

Haiqing Y, Yutian M, Chengcheng Z, Yuan Y (2011) Acrylamine and methylglyoxal formation in potato chips by microwaving and frying heating. Int J Food Sci Technol 46:1921–1926

Hogervorst JG, Schouten LJ, Konings EJ, Goldbohm RA, van den Brandt PA (2007) A prospective study of dietary acrylamide intake and the risk of endometrial, ovarian, and breast cancer. Cancer Epid Biol Prev 16:2304–2313

Hogervorst JG, Schouten LJ, Konings EJ, Goldbohm RA, van den Brandt PA (2008) Dietary acrylamide intake and the risk of renal cell, bladder, and prostate cancer. Am J Clin Nutr 87:1428–1438

Pedreschi F, Mariotti MS, Granby K (2014) Current issues in dietary acrylamide: formation, mitigation and risk assessment. J Sci Food Agric 94:9–20

Foot RJ, Haase NU, Grob K, Gonde P (2007) Acrylamide in fried and roasted potato products: A review on progress in mitigation. Food Addit Contam 24 (iss. sup 1):37–46

Sayon-Orea C, Bes-Rastrollo M, Basterra-Gortari FJ, Beunza JJ, Guallar-Castillon P, De la Fuente-Arrillaga C, Martinez-Gonzales MA (2013) Consumption of fried foods and weight gain in a Mediterranean cohort: the SUN project. Nutr Metab Cardiovasc Dis 23:144–150

Andres A, Arguelles A, Castello ML, Heredia A (2013) Mass transfer and volume changes in French fries during air frying. Food Bioprocess Technol 6:1917–1924

Del Rocio Teruel M, Gordon M, Linares MB, Garrido MD, Ahromrit A, Keshavan N (2015) A comparative study of the characteristics of French fries produced by deep fat frying and air frying. J Food Sci 80:E349–E358

Pedreschi F, Moyano P (2005) Oil uptake and texture development in fried potato slices. J Food Eng 70:557–563

PalazogluTK, Savran D, Gokmen V (2010) Effect of cooking method (baking comparted with frying) on acrylamide level of potato chips. J Food Sci 75:E25–E29

Chatterjee D, Bhattacharjee P, Bhattacharyya N (2014) Development of methodology for assessment of shelf-life of fried potato wedges using electronic noses: Sensor screening by fuzzy logic analysis. J Food Engin 133:23–29

Savarese M, Parisini C, De Marco E, Battiamo I, Falco S, Sacchi R (2007) Application of electronic nose to monitor the frying process. A preliminary study. Riv Ital Sostanze Gr 84:33–39

AOAC (1975) Official methods of analysis of the association of official analytical chemists, 12th edn. Washington DC

Naes T, Brockhoff B, Tomic O (2010) Statistics for sensory and consumer science. Wiley, Chichester

Gamble MH, Rice P, Selman JD (1988) Relationship between oil uptake and moisture loss during frying of potato slices from cv Record UK tubers. Int J Food Sci Technol 22:233–241

Mallikarjunan PK, Ngadi MO, Chinnan MS (2010) Breaded fried foods. CRC Press, Boca Raton

Saguy IS, Pintus EJ (1995) Oil uptake during deep-fat frying: factors and mechanism. Food Technol 49:142–145

Greenfield H, Makinson J, Wills RBH (1984) Lipids in French fries: a retail and laboratory study. J Food Technol 19:239–245

EFSA (2015) Scientific opinion on acrylamide in Food. EFSA J 13(6):4104. https://www.efsa.europa.eu/it/efsajournal/pub/4104

Ye HQ, Miao YT, Zhao CC, Yuan Y (2011) Acrylamide and methylglyoxal formation in potato chips by microwaving and frying heating. Int Food Sci Tech 46:1921–1926

EU, Information on ways to lower the levels of acrylamide formed in food. Acrylamide workshop, 20–21 October 2004 http://ec.europa.eu/food/safety/docs/cs_contaminants_catalogue_acrylamide_guidance_en.pdf

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare no conflict of interest.

Compliance with ethics requirements

This article does not contain any studies with human or living animal subjects.

Rights and permissions

About this article

Cite this article

Giovanelli, G., Torri, L., Sinelli, N. et al. Comparative study of physico-chemical and sensory characteristics of French fries prepared from frozen potatoes using different cooking systems. Eur Food Res Technol 243, 1619–1631 (2017). https://doi.org/10.1007/s00217-017-2870-x

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00217-017-2870-x