Abstract

Twenty-five compounds, among which flavonoids and secoiridoids, were separated and quantified after extraction from Olea europaea leaves. Differences were found in total polyphenols content and in oleuropein depending on cultivar, production area, sampling time (pruning or harvest time), and state of leaves (fresh, refrigerated, dried, frozen, or lyophilized). Polyphenols content in fresh leaves ranged from 34.21 to 7.87 mg/g, while oleuropein content changes from 21.03 to 2.79 mg/g in fresh leaves of different cultivars and decreases after the drying process. The differences are discussed in order to exploit these by-products for food supplements. In addition, five commercial food supplements from olive leaves were analyzed, and their total polyphenol, secoiridoids, and flavonoid contents were detected by HPLC/DAD analysis. In order to provide stable contents of bioactive molecules, all the above-mentioned variabilities should be taken into account.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Olea europaea L. leaves, a typical herbal drug of the Mediterranean region, have been widely used like traditional remedy as extract, infusion, herbal tea, and powder in countries such as Greece, Spain, Italy, France, Turkey, Israel, Morocco, Albania, and Tunisia. Olive leaves are the source of many bioactive compounds, the main of which is oleuropein, a secoiridoid, which can constitute up to 6–9 % of leaf dry matter. Oleuropein and its derivatives exhibit specific biological activities as antioxidant, antihypertensive, antiatherogenic, anti-inflammatory, hypoglycemic, hypocholesterolemic, antiproliferative, and antifungal [1–10]. The composition of leaves extract has been studied, and active compounds were identified such as secoiridoids, flavonoids, and triterpenes [7, 11–13]. Olive leaves may be regarded as a by-product in the cultivation of olives both for olive oil and table olives during pruning operations and/or during olive harvest; leaves extract is used to prepare commercial affordable dietary supplements [14]. Extraction process in order to obtain commercial supplements needs quite constant starting material while it has been pointed out that leaf polyphenols content depends on cultivar [7], geographic production zone, and time of olive leaf harvesting [15].

From the quantitative determination of flavonoids and secoiridoid derivatives of leaves, subjected to different treatments, the final product, i.e., dietary supplements and/or dry leaves, or extracts used for pharmaceutical purposes, can be achieved with a quite constant content of bioactive compounds. We set up a method, which was tested to characterize and quantify secondary metabolites (oleuropein and its derivatives, flavonoids, hydroxycinnamic acids, hydroxytyrosol, and elenolic acid derivatives) in Olea europaea leaves extracts. The aim of this study is the characterization of fresh, refrigerated, frozen, dried, and lyophilized Olea leaves of different cultivars under various extraction conditions. The identification of the best operating conditions, which may help in obtaining a high and almost constant bioactive products yield when Olea leaves are used in the achievement of commercial food supplements, is the further goal of the study.

Materials and methods

Plant material

Olive leaves were collected in Tuscany (Siena district), Latium (Rieti district), and Apulia (Foggia district) during the year 2014 and were immediately processed.

Extraction

Fresh cut leaves were extracted with water at 70 °C for 30 and/or 60 min. The same conditions were applied to leaves stored in refrigerator (4 °C) and in freezer (−18 °C). Fresh leaves were extracted overnight with ethanol/water (30:70) under stirring. Fresh leaves were dried at room temperature for 15 days, or in ventilated stove at 40 °C for 3 days or lyophilized. Extracts were obtained at different of Olea leaves percentages (g leaves/100 g solvent). Five liquid commercial Olea leaves food supplements were analyzed after 1:3 water dilution.

HPLC/DAD analyses

Analyses of polyphenols were carried out using a HP 1200 liquid chromatograph equipped with a DAD detector and managed by an Agilent HPLC Chemstation (Agilent Technologies, Palo Alto, CA, USA). Compounds were separated using a 250 × 4.6 mm i.d, 5-μm Lichrosorb RP18 column. UV/Vis spectra were recorded in the 190–600 nm range and the chromatograms acquired at 250, 280, 330, and 350 nm. The samples were analyzed by gradient elution at a flow rate of 0.8 mL/min. The mobile phase is a multi-steps linear solvent gradient system, starting from 100 % H2O (adjusted to pH 3.2 by HCOOH) up to 100 % acetonitrile in 82 min. The elution method is reported in Table 1.

Identification and quantification of individual compounds

The identity of polyphenols was ascertained using data from HPLC/DAD analyses, by comparison with bibliographic data [16] and combination of retention times and UV/Vis spectra with those of authentic standards. Hydroxytyrosol, verbascoside, vitexin diglucoside, rutin, luteolin-7-O-glucoside, quercetin-3-O-glucoside, apigenin-7-O-glucoside, apigenin-7-O-rutinoside, luteolin-4′-O-glucoside, luteolin, chrysoeriol-7-O-glucoside, and oleuropein were purchased from Extrasynthese (Lyon, France). The following compounds were isolated by preparative HPLC: hydroxytyrosol glycol, hydroxytyrosol glucoside, elenolic acid glucoside, dimethyl oleuropein, 10-hydroxy-oleuropein glucoside, and ligustaloside B. Quantification of individual polyphenolic compounds was performed by HPLC/DAD using a five-point regression curve (r 2 = 0.998) in the range of 0–30 µg on the basis of authentic standards. In all cases, concentrations of the derivatives were calculated after applying corrections for differences in molecular weight. Each sample was analyzed in triplicate, to express the analytical results as an average with its standard deviation.

Results and discussion

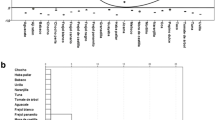

In Fig. 1, the chromatograms of the aqueous extract of Frantoio leaves are reported at four different wavelengths. A number marks all the identified compounds. Secoiridoid derivatives are the most abundant compounds in the extract. In Table 2, the quantitative data of Frantoio leaves are compared to those of Leccino, Moraiolo, and Carboncella. These four Italian cultivars are much widely used for olive oil production: Leccino and Frantoio are peculiar Tuscany cultivars, Moraiolo is typical of central Italy regions, and Carboncella is a Latium cultivar from the Sabina area. Frantoio is by far the richest matrix in oleuropein and in flavonoids with regard to Leccino and Moraiolo, while Carboncella exhibited the highest amount of hydroxytyrosol and hydroxytyrosol derivatives and comparable amount of oleuropein. The contents of biofunctional compounds are higher than those reported for Tunisian cultivars [7, 10], while lower than those relative to unknown provenance olive leaves [11]. Oleuropein content is lower than that extracted with methanol/water mixture from Tunisian Chemlali leaves, and hydroxytyrosol content was higher than that reported for the same leaves [12]. With the ethanol/water extraction method, polyphenols amount was much lower in the case of Frantoio and Carboncella (22 and 27 %, respectively) and lower in the case of Moraiolo (52 %) and Leccino (70 %). Other than cultivar, even extraction solvent conditions affect the profile of the starting material so as the production area. In Table 3, biomolecules content of Ogliarola cultivar leaves is reported; for four out of five provenances, oleuropein and polyphenols contents are very close each other; only in the case of Gargano, a lesser amount was found. Leaves from Bicchieri are the richest in hydroxytyrosol and hydroxytyrosol derivatives, while for flavons and hydroxyl-cinnamic acids no important variation was pointed out. Sampling time, on the contrary, has a much larger importance on secondary metabolites content. For Carboncella cultivar, the content changes from 33.9 mg/g fresh weight at pruning time to 19.8 mg/g fresh weight at olive harvest time, with oleuropein content changing from 51 to 59 %. This occurrence has already been pointed out [15] when leaves are used for the extraction of biocomponents. It has already been demonstrated that thawing of frozen leaves involves a loss in oleuropein content, while drying at room temperature preserves oleuropein [17]. Our data partly confirm these findings. In the case of Frantoio (see Table 4), there are minor differences depending on the starting material status, while in the case of Carboncella the best results were achieved when fresh leaves are extracted and even the drying process causes a loss in oleuropein content. Along with the increase in extraction time, an increase in extracted biomolecules is generally observed (from 23 to 32 %); this increase, however, involving a longer extraction period, may not justify the production of high extraction volumes in the light of the raw material low cost. When lyophilized material is used, as reported in Table 5, minor differences owing to the extraction time were found. For Carboncella, the polyphenols content decrease, with dry lyophilized leaves respect to fresh ones, is about 80 %, while in the case of Frantoio under the same conditions the decrease is about 33 %. These differences may be ascribed to the different dying condition of the two cultivars (see experimental section). Also dried leaves in many cases are commercialized for industrial production of phytotherapic compounds. We deemed it interesting, therefore, to analyze commercial dried leaves from three different provenances, Morocco, Albania, and Italy. Table 6 lists oleuropein and secoiridoids derivatives contents: Moroccan leaves are the richest in polyphenols. We may assume that the differences are bound not only to raw materials characteristics but also to the different drying conditions, which affect the final product (see Table 3) and to the period in which the leaves were harvested. From oleuropein content, we may assume that Moroccan and Albanian leaves were harvested at the pruning time different from Italian leaves, which were collected at olive technological harvest time. Table 7 lists the quantitative data of commercial food supplements from olive leaves (almost 90 % of the commercial product). Different contents were pointed out; in one case, however, the two lots exhibited comparable values, showing that commercial products with a standardized composition can be achieved.

Chromatograms of the aqueous extract of Frantoio leaves recorded at 240, 280, 330, and 350 nm. 1. Hydroxytyrosol glicol; 2. hydroxytyrosol; 3. hydroxytyrosol glucoside; 4. oleoside; 5. elenolic acid diglucoside; 6. elenolic acid glucoside; 7. elenolic acid glucoside derivative; 8. dimethyl oleuropein; 9. oleuropein 10. ligustaloside B.; 11. caffeic acid derivatives; 12. p-coumaric acid derivatives; 13. rutin; 14. luteolin-7-O-glucoside; 15. quercetin-3-O-glucoside; 16. apigenin-7-O-glucoside; 17. luteolin-4′-O-glucoside + Chrysoeriol; 18. verbascoside; Asterisk cinnamic acid derivative

Conclusions

The commercial products analyzed are used as antioxidants and/or as arterial blood pressure modulators. Oleuropein content and stability has been demonstrated as related to both the drying process and the extraction temperature; this occurrence has never been pointed out before. The bioactive compounds content variability, which was demonstrated, does not allow a proven efficacy and biological efficiency. However, from the knowledge of raw material composition, harvest time, drying conditions and extraction procedures, commercial products with a constant and standardized content of active ingredients could be obtained.

References

Covas MI, Ruiz-Gutierrez V, de la Torre R, Kafatos A, Lamuela-Raventos RM, Osada J (2006) Minor component of olive oil: evidence to date of health benefits in humans. Nutr Rev 64:S20–S30

Perrinjaquet-Moccetti T, Busjahn A, Schmidlin C, Schmidt A, Bradl B, Aydogan C (2008) Food supplementation with an olive (Olea europaea L.) leaf extract reduces blood pressure in borderline hypertensive monozygotic twins. Phytother Res 22:1239–1242

Deiana M, Rosa A, Corona G, Atzeri A, Incani A, Visioli F, Melis MP, Dessi MA (2007) Protective effect of olive oil minor polar components against oxidative damage in rats treated with ferric-nitrilotriacetate. Food Chem Toxicol 45:2434–2440

Andreadou I, Iliodromitis EK, Mikros E, Constantinou M, Agalias A, Magiatis P, Skaltsounis AL, Kamber E, Tsantili-Kakoulidou A, Kremastinos DTh (2006) The olive constituent oleuropein exhibits anti-ischemic, antioxidative, and hypolipidemic effects in anesthetized rabbits. J Nutr 136:2213–2219

Fares R, Bazzi S, Baydoun SE, Abdel-Massih RM (2011) The antioxidant and anti-proliferative activity of the lebanese Olea europaea extract. Plant Foods Hum Nutr 66:58–63

Korukluoglu M, Sahan Y, Yigit A (2008) Antifungal properties of olive leaf extracts and their phenolic compounds. J Food Saf 28:76–87

Taamalli A, Arráez-Román D, Zarrouk M, Valverde J, Segura-Carretero A, Fernández-Gutiérrez A (2012) The occurrence and bioactivity of polyphenols in Tunisian olive products and by-products: a review. J Food Sci 77:R83–R92

Schroder H (2007) Protective mechanisms of the Mediterranean diet in obesity and type 2 diabetes. J Nutrit Biochem 18:149–160

Soler-Rivas C, Espin JC, Wichers HJ (2000) Oleuropein and related compounds. J Sci Food Agric 80:1013–1023

Abaza L, Talorete TPN, Yamada P, Kurita Y, Zarrouk M, Isoda H (2007) Induction of growth inhibition and differentiation of human leukemia HL-60 cells by a Tunisian Gerboui olive leaf extract. Biosci Biotechnol Biochem 71:1306–1312

Japón-Luján R, Luque de Castro MD (2006) Superheated liquid extraction of oleuropein and related biophenols from olive leaves. J Chromatogr A 1136:185–191

Bouaziz M, Sayadi S (2005) Isolation and evaluation of antioxidants from leaves of a Tunisian cultivar olive tree. Eur J Lipid Sci Technol 107:497–504

Tóth G, Alberti Á, Sólyomváry A, Barabás C, Boldizsárc I, Noszalá B (2015) Phenolic profiling of various olive bark-types and leaves: HPLC–ESI/MS study. Ind Crops Prod 67:432–438

Ahmad-Qasem MH, Cánovas J, Barrajón-Catalán E, Carreres JE, Micol V, García-Pérez JV (2014) Influence of olive leaf processing on the bioaccessibility of bioactive polyphenols. J Agric Food Chem 62:6190–6198

Brahmi F, Mechri B, Dhibi M, Hammami M (2013) Variations in phenolic compounds and antiradical scavenging activity of Olea europaea leaves and fruits extracts collected in two different seasons. Ind Crops Prod 49:256–264

Pinelli P, Galardi C, Mulinacci N, Vincieri FF, Tattini M, Romani A (2000) Quali-quantitative analysis and antioxidant activity of different polyphenolic extracts from Olea europaea L. Leaves. J Commod Sci 39:71–83

Malik NSA, Bradford JM (2008) Recovery and stability of oleuropein and other phenolic compounds during extraction and processing of olive (Olea europaea L.) leaves. J Food Agric Environ 6:8–13

Acknowledgments

Part of the work presented was funded by the Regione Toscana with the Tuscany Projects—NATURBEN (PRAF 2012–2015) and VOLATOSCA.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

None.

Compliance with ethics requirements

This article does not contain any studies with human or animal subjects.

Rights and permissions

About this article

Cite this article

Romani, A., Mulas, S. & Heimler, D. Polyphenols and secoiridoids in raw material (Olea europaea L. leaves) and commercial food supplements. Eur Food Res Technol 243, 429–435 (2017). https://doi.org/10.1007/s00217-016-2756-3

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00217-016-2756-3