Abstract

A fast, simple, economical, and environmentally friendly magnetic solid-phase extraction (MSPE) procedure has been developed to preconcentrate 2,4,6-trinitrotoluene (TNT) from water samples prior to determination by liquid chromatography-UV-Vis employing graphene oxide/Fe3O4 nanocomposite as sorbent. The nanocomposite synthesis was investigated, and the MSPE was optimized by a multivariate approach. The optimum MSPE conditions were 40 mg of nanocomposite, 10 min of vortex extraction, 1 mL of acetonitrile as eluent, and 6 min of desorption in an ultrasonic bath. Under the optimized experimental conditions, the method was evaluated to obtain a preconcentration factor of 153. The linearity of the method was studied from 1 to 100 μg L−1 (N = 5), obtaining a correlation coefficient of 0.994. The relative standard deviation and limit of detection were found to be 12% (n = 6, 10 μg L−1) and 0.3 μg L−1, respectively. The applicability of the method was investigated, analyzing three types of water samples (i.e., reservoir and drinking water and effluent wastewater) and recovery values ranged between 87 and 120% (50 μg L−1 spiking level), showing that the matrix had a negligible effect upon extraction. Finally, the semiquantitative Eco-Scale metrics confirmed the greenness of the developed method.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

The existence of graphene was reported in 2004 and classified as an advanced carbonaceous two-dimensional material of unique properties that has been the object of various investigations [1–3]. Among these properties, graphene has a high theoretical surface area (2630 m2 g−1), resulting in a high adsorption capacity. In addition, its electron delocalization system can form π–π bonds with benzene rings. Thanks to these particular properties, graphene can be used for adsorbing aromatic compounds [4–8]. The chemical synthesis of graphene commonly follows the Hummers method [9], consisting of the oxidation of graphite to form graphene oxide (GO) followed by the chemical reduction of GO to graphene using a reducing agent such as hydrazine. Hummers oxidation method [9] is considered the most efficient for the production of graphene on a large scale and is also highly economical.

Graphene has been used as an adsorbent for solid-phase extraction (SPE) to increase the adsorptive capacity [4]. The SPE separation technique turns out to be simple, fast, economical, offers a low consumption of reagents, and has the ability to combine with different detection techniques in off-line and as well as in on-line modes [10]. Recent studies using graphene as adsorbent presented excellent extraction efficiency for pesticides [11], polycyclic aromatic hydrocarbons [12], drugs [13], and phthalate esters [14]. An increased selectivity of the SPE can be achieved when using functionalized graphene with oxidized groups [4]. Hydrophilic functional groups, such as hydroxyl and carbonyl, increase the affinity of graphene with polar compounds [4]. Miniaturization of the SPE technique includes the solid-phase microextraction (SPME) technique which also used graphene as adsorbent coating of the fibers [5–8, 15]. However, the use of fiber as adsorbent has disadvantages such as its fragility, the reduced amount of adsorbent phase, its high cost, and possible memory effects [16].

On the other hand, GO as a derivative of the graphene synthesis presents numerous oxygen groups on the surface such as epoxy, carboxyl, and hydroxyl radical groups [17], providing greater hydrophilicity than graphene [18]. The functional groups of GO are capable of forming hydrogen bonds or electrostatic interactions with aromatics and polar compounds or metal ions [18–20]. GO has proved to be an ideal sorbent for SPE [21] and SPME [22].

Another recent sample separation technique is the magnetic solid-phase extraction (MSPE). The adsorbents used in the MSPE technique possess a magnetic phase mainly composed of an iron mineral or iron oxides such as magnetite (Fe3O4) or maghemite (γ-Fe2O3) and a sorbent, including organic and inorganics polymers [23] and metal oxides [24]. Modified silica (C18, C8, and phenyl groups) [25], molecularly imprinted polymers [26], and recently carbon nanotubes [27], graphene [28], and GO [29] have been employed. The use of sorbents decorated with magnetic solids is an excellent alternative for preconcentrating and isolating different chemical species because it synergically combines the excellent sorbent capacity with easy sorbent handling by means of an external magnetic field. Other advantages are the reduced processing time, amount of sorbent, solvent consumption, and reusability of sorbent [18]. This sample preparation technique has been employed in the analysis of phenolic compounds [23], perfluorinated compounds [25], bisphenol A [27], anti-inflammatory drugs [30], and pesticides [28, 31]. Recently, GO hybrid materials have gained interest in analytical sample preparation. The GO/Fe3O4 magnetic nanocomposite has been synthesized and used in MSPE for adsorption of polycyclic aromatic hydrocarbons (PAHs) [29], drugs [32], and PCBs [33], among others, but the number of applications is still scarce.

Military activities, mining, and building demolition leave explosive residues in the environment that can easily contaminate soils, surface water, and groundwater. Many explosives or explosive mixtures have toxic effects on the environment, animals, and humans [34]. 2,4,6-Trinitrotoluene (TNT) is classified as a high secondary explosive that pollutes the soil and water during the production process, purification, and use [35]. Small amounts of TNT are also used in the colorant industry and as photographic components [36]. However, the direct determination of TNT in the environment at trace levels is limited due to its low concentration and matrix interferences. To this end, bulky and expensive instrumentation as gas chromatrography-mass spectrometry (GC-MS) has been usually employed [37–40]. Thus, the demand for innovative, simple, fast, economical, and sensitive analytical techniques capable of detecting nitroaromatic explosives (i.e., TNT) at trace level concentrations is mandatory.

Therefore, the objective of this work was to develop a new, fast, and sensitive analytical method for TNT determination in water samples employing the GO/Fe3O4 nanocomposite as sorbent prior to liquid chromatography-UV-Vis detection (LC-UV-Vis). The method was optimized by experimental design, validated, and applied to real samples. Finally, the Eco-Scale metrics was carried out in order to assess the greenness of the developed method.

Materials and methods

Chemical reagents and real-world water samples

Iron oxide II, III (Fe3O4) (50–100 nm) and graphene oxide (GO) were purchased from Sigma-Aldrich (St. Louis, MO, USA).

TNT solution of 1000 mg L−1 in acetonitrile was obtained from LGC Standards (Barcelona, Spain). This standard solution was stored in the dark at 4 °C. Working solutions were prepared daily by diluting the stock solution with deionized water.

Acetonitrile and methanol HPLC-grade from Sigma-Aldrich and milli-Q water (resistivity of 18 mΩ cm) from Millipore (Billerica, MA, USA) were used for elution and mobile phase.

HNO3 65% from Merck (Darmstadt, Germany) and NaOH pellets from Scharlau (Barcelona, Spain) were used for the synthesis of nanocomposite.

Reservoir water and drinking water from Seville (Spain) and effluent wastewater from a sewage treatment plant in Vitoria (Spain) were used in the study as real-world water samples. All samples were stored in the dark at 4 °C. The previous analysis of the real-world water samples confirmed the absence of TNT.

Instrumentation

Transmission electron microscope JEM 2010 (JEOL, Japan), X-ray photoelectron spectrometer Thermo K-Alpha-Scientific (Waltham, MA, USA), D8 Advance X-ray diffractometer (Bruker, Germany), and SQUID magnetometer MPMS-XL-5 (Quantum Design, CA, USA) were used for nanocomposite characterization (i.e., GO/Fe3O4).

In the MSPE procedure, a Ni-coated neodymium magnet, N45 grade, dimensions 45 × 30 mm from Supermagnete (Gottmadingen, Germany) was used as magnetic external field.

The chromatographic analyses were performed by Shimadzu LC-20AT liquid chromatograph (Kyoto, Japan) coupled to a Shimadzu SPD-10A UV-Vis detector (operated at 254 nm), equipped with a Phenomenex C18 column (3 μm particle diameter, 4.6 mm i.d. × 15 cm) (Torrance, CA, USA). Isocratic water/methanol mixture (50:50, v/v) was employed as mobile phase at a flow rate of 1 mL min−1. The injection volume was 20 μL.

Synthesis of GO/Fe3O4 nanocomposite

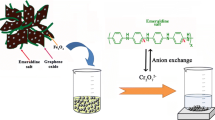

The synthesis of GO/Fe3O4 nanocomposite is based on a previous work conducted by Han et al [29]. Fe3O4 nanoparticles were dispersed in 1 M HNO3 solution through sonication for 30 min, generating a solution containing 150 mg mL−1 of Fe3O4 with positively charged surface. A dispersion of GO in deionized water (1 mg mL−1) was prepared using ultrasound energy for 1 h, wherein the GO surface was negatively charged. The dispersions of Fe3O4 and GO were mixed, the pH of the mixture was adjusted to 2, and the mixture (GO/Fe3O4 ratio 1:5 (w/w)) was subjected to vigorous magnetic stirring for 5 h. Later, GO/Fe3O4 nanocomposite was separated from the liquid phase applying an external magnetic field (neodymium magnet). Finally, the nanocomposite was dried in an oven under vacuum of 70 cm/Hg at 60 °C for 24 h. Fig. S1 (see Electronic Supplementary Material, ESM) shows the magnetization hysteresis loops of (A) Fe3O4 and (B) GO/Fe3O4 and a photograph showing the magnetic attraction between the synthesized composite and the magnet. The magnetization hysteresis loops of Fe3O4 and GO/Fe3O4 were S-like curves indicating that both were superparamagnetic materials. The specific magnetization saturation (Ms) was 87.1 and 77.6 emu g−1 for Fe3O4 and GO/Fe3O4 nanocomposite, respectively. Ms decreases when Fe3O4 nanoparticles were decorating GO sheets, which could be attributed to the surface spin effect on Fe3O4 caused by modification [41].

Magnetic solid-phase extraction procedure

The procedure of MSPE is illustrated in Fig. 1. For each MSPE experiment, 40 mg GO/Fe3O4 nanocomposite was introduced into a 22-mL vial. Then, 20 mL of standard solution or water sample was added. The mixture was vortex stirred during 10 min, and once the extraction was complete, the nanocomposite was separated from the liquid phase with a neodymium magnet placed at the bottom of the vial. The liquid was discarded, and 1 mL of acetonitrile was added to the nanocomposite to elute the analyte. The vial was left in an ultrasonic bath for 6 min. Then, using the magnet, the eluate obtained was transferred to another vial. The solvent was completely evaporated by N2 gas at 800 mbar pressure for 20 min and reconstituted with 50 μL of acetonitrile. Finally, 20 μL of the eluate was injected into the LC-UV-Vis system. Figure 2 shows a typical chromatogram of a drinking water sample non-spiked and spiked at 50 μg L−1 level with the target analyte subjected to the optimized MSPE-LC-UV-Vis method. In order to ensure that no residual TNT remained adsorbed on composite, two more elutions were carried out with 1 mL of acetonitrile and 6 min in ultrasonic bath.

Data processing

Plackett-Burman design was carried out to determine the optimum conditions for MSPE procedure. The statistical software NEMRODW® version 2007/2010 (“New Efficient Methodology for Research using Optimal Design”) from LPRAI (Marseille, France) was used to build the experimental design matrices and evaluate the results. The peak area of TNT was used as the response function.

Results and discussion

Study of the synthesis of GO/Fe3O4 nanocomposite

Firstly, the optimal conditions for the synthesis were investigated. Factors such as the type of stirring, pH, and GO/Fe3O4 ratio were studied. The optimal conditions for the synthesis of GO/Fe3O4 nanocomposite were determined according to the highest chromatographic peak area of TNT after MSPE.

Different stirring systems were studied (i.e., magnetic stir plate, oscillating table, and vortex) obtaining better results for magnetic stir plate (ESM Fig. S2).

The study of the GO/Fe3O4 ratio (w/w) was made for 1:5 and 1:1 in accordance with the best results obtained in the work conducted by Han et al [29]. The results were similar for the TNT extraction with a ratio of 1:5 and 1:1. However, in the present study, we decided to work with the ratio 1:5 for practical and economical reasons. The MSPE procedure with a GO/Fe3O4 ratio 1:1 generates an eluate containing dispersed nanoparticles that can cause obstruction problems in the chromatographic column. In addition, GO is more expensive than Fe3O4.

The pH was also studied from 0.6 to 6, and the results are shown in Fig. S3 (see ESM). The better extraction was obtained with the nanocomposite synthesized at pH 2. The GO/Fe3O4 nanocomposite can be formed through electrostatic self-assembly. Hence, the effect of pH on the nanocomposite synthesis can be a compromise between the negative charge of GO when dispersed in aqueous solution, as a result of the ionization of the carboxylic acid and phenolic hydroxyl groups on the GO particles, and the positively charged surface of Fe3O4. At a low pH (i.e., 0.6), Fe3O4 particles possess a high positive surface charge and they are strongly attracted by GO sheets, decreasing the available surface area of the GO for adsorption of analytes. On the other hand, at a pH higher than 2, the carboxyl groups of the GO sheets are deprotonated [42], also increasing the attraction by the Fe3O4 particles and decreasing the available surface area of GO. However, at 2 pH, a maximum value is observed (ESM Fig. S3) due to maximum GO area available (ESM Fig. S4b).

In summary, the optimal conditions for the GO/Fe3O4 nanocomposite synthesis were: stirring on magnetic stir plate, pH 2, and GO/Fe3O4 ratio (w/w) 1:5. Additionally, batch-to-batch repeatability was studied for three different batches using each and every batch to MPSE of an aqueous solution spiked at 0.5 mg L−1 in triplicate. The relative standard deviation (RSD) obtained was of 15%, confirming the good repeatability of the synthesis process.

Finally, it is important to point out that extractions using Fe3O4 as extractant phase (without GO) were carried out and TNT was not detected in the eluates, showing that Fe3O4 did not possess a sorption capacity for target analyte.

Characterization of the GO/Fe3O4 nanocomposite

Transmission electron microscopy

The morphology of the GO, Fe3O4, and prepared nanocomposite were characterized by transmission electron microscopy (TEM) (Fig. 3). As shown in Fig. 3a, the TEM image of the GO sheet revealed an irregular shape and contained some wrinkles providing a large surface area. The Fe3O4 nanoparticles (Fig. 3b) were cubic in shape with a mean size of approximately 100 nm, and they aggregated by dipole–dipole interaction. Figure 3c presents a representative TEM image of the obtained GO/Fe3O4 nanocomposite. It can be observed that the Fe3O4 nanoparticles were anchored as clusters onto the surface of the GO sheets. This observation was attributed to electrostatic self-assembly between the positively charged surface of the Fe3O4 and the negatively charged GO in aqueous solution.

X-ray photoelectron spectroscopy

X-ray photoelectron spectroscopy (XPS) determined the chemical composition of the GO/Fe3O4 nanocomposite, confirming the exclusive presence of carbon (C), iron (Fe), and oxygen (O) and the absence of impurities (Fig. 4).

The scan XPS spectra of the GO/Fe3O4 nanocomposite appeared at binding energies of approximately 290, 520, and 710 eV attributed to the C1s, O1s, and Fe 2p, respectively (Fig. 4a). There were two peaks for Fe 2p, corresponding to Fe 2p1/2 and Fe 2p3/2, which indicated the presence of Fe3O4 in the nanocomposite (Fig. 4a). Figure 4b corresponds to the spectrum in the Fe 2p region. Comparing the spectrum obtained with database spectra [43], it confirmed that the iron oxide of the nanocomposite was magnetite (i.e., Fe3O4). Three peaks were present in the O1s spectra of nanocomposite (Fig. 4c), which corresponded to C(O)OH at 530 eV, C═O at 531.5 eV, and C–OH at 533 eV. C1s spectra was represented in the Fig. 4d with binding energies of 284.8 eV for C═C, 286.9 to 289 eV for epoxyl and alcoxyl carbon (C–O), and the carboxylate carbon (O–C═O), respectively.

X-ray diffraction

The X-ray diffraction (XRD) measurement was performed to obtain crystalline structural information of the GO/Fe3O4 nanocomposite. Fig. S5 (see ESM) shows the XRD pattern of the GO/Fe3O4 where intense peaks can be observed at 2θ values of 30.2°, 35.5°, 43.2°, 53.4°, 57°, and 62.5° indexed to (220), (311), (400), (422), (511), and (440) reflections, respectively. These results are consistent with the standard XRD data for the cubic phase Fe3O4 (blue lines assigned in the Fig. S5, see ESM) and confirm the magnetite as the iron oxide in the synthesized GO/Fe3O4 nanocomposite.

Optimization of the MSPE procedure

Fractional factorial designs are commonly used in optimization studies for screening to identify the important variables (i.e., factors) [44]. Plackett-Burman is a two-level fractional factorial design for studying up to K = N − 1 variables in N runs, where N is a multiple of 4. This sort of design assumes that interactions between factors can be ignored, so the main effects can be calculated with a reduced number of experiments [44]. A Plackett-Burman design was chosen to construct the matrix of experiments including five factors (Table 1).

According to the type of design, eight different experiments were randomly conducted with 20 mL standard solution of 0.5 mg L−1 of TNT. The data obtained were evaluated by ANOVA, and the results were visualized with the Pareto chart shown in Fig. 5. The length of each bar was proportional to the influence of the corresponding factor, while the effects that exceed reference vertical lines can be considered significant with 95% of probability. In addition, negative and positive signs reveal whether the system response decreases or increases, respectively, when passing from the lowest to the highest level of the corresponding factor.

As shown in Fig. 5, the amount of nanocomposite was the only significant factor exhibiting a positive effect. Thus, the other factors were selected considering the sign of effect. Extraction time and desorption time were non-significant with positive effect as longer times increase the extraction and elution, and they were fixed at maximum level (i.e., 10 and 6 min, respectively). Type and volume of eluent were non-significant with negative effect because best elution with acetonitrile at a lower volume increases the concentration of analyte in the eluate. Therefore, these factors were fixed at minimum level (i.e., acetonitrile and 1 mL, respectively).

According to the result of the experimental design, the amount of nanocomposite was thoroughly studied varying the amount of sorbent from 10 to 50 mg, with the other factors at the corresponding fixed level. A TNT solution of 0.5 mg L−1 was used in the extractions. Figure 6 presents the results of MSPE with different amounts of nanocomposite (i.e., 10–50 mg).

The peak area increased by increasing the amount of nanocomposite from 10 up to 40 mg. Below 40 mg of nanocomposite, the analyte was not quantitatively adsorbed due to saturation of the adsorption sites; as a result, the sensitivity decreased. On the other hand, at over 40 mg, and considering the experimental error, the peak area exhibited a small decrease. Hence, 40 mg of nanocomposite was used in all the experiments.

Optimal MSPE conditions for extracting TNT were: 40 mg of nanocomposite, 10 min of vortex extraction, acetonitrile as eluent, 6 min of ultrasonic desorption, and 1 mL of eluent.

Reuse of GO/Fe3O4 nanocomposite

The possibility of reusing the nanocomposite was studied in twelve consecutive MSPE experiments using a TNT solution of 0.5 mg L−1.

The peak area obtained remains without significant changes up to the sixth MSPE. XPS study of fresh and six times used nanocomposite was carried out. Results provided that the fresh nanocomposite was made of 43% of C and 8% of Fe. However, the six times used material contained around 34% of C and 10% of Fe. Although these results confirmed the detachment of the GO, the extraction capacity and the magnetic property were maintained up to the sixth extraction. After the sixth extraction, the sorbent was still extracting TNT but in a less effective way, decreasing around 40% the signal intensity. Therefore, the same nanocomposite could be used up to six times without losing adsorptive capacity. Reuse of the nanocomposite allows reducing the cost of the method and generates less waste.

Analytical parameters

The analytical figures of merit were determined under optimized extraction conditions. Quantitative parameters regarding the working range, correlation coefficient, limit of detection (LOD), and limit of quantification (LOQ) were examined to validate the proposed MSPE-LC-UV-Vis method. The methodological working range and correlation coefficient (r) of the calibration curve were from 1 to 100 μg L−1 and 0.994 (N = 5), respectively. In the repeatability study, extractions of an aqueous solution of 10 μg L−1 of TNT were made, obtaining a RSD of 12% for the intra-day repeatability and of 17% for the inter-day repeatability. The intra-day RSD values were obtained by repeating the extraction six times within a day, and the inter-day RSD values were obtained by repeating the extraction in triplicate in three different days. Methodological LOD was empirically determined, progressively measuring more diluted concentrations of the analyte. LOD was found to be 0.3 μg L−1, and LOQ was calculated as 3.3 times LOD, being 1 μg L−1 (i.e., lowest concentration of the working range). Additionally, LOD was evaluated using 3sb criterion, being sb the standard deviation of a diluted concentration solution obtaining a value of 0.5 μg L−1, which confirmed the results obtained in the empirical approach.

The preconcentration factor of the proposed procedure, defined as the ratio Ce/Co, wherein Ce is the concentration of TNT in the eluate after the extraction and Co is the initial concentration of TNT in aqueous phase, was 153. For comparison, the analytical figures of merit of different chromatographic methods for TNT determination are given in Table 2.

The MSPE method used in this work presents an extraction time similar to most of the other analytical methods, but the most striking feature is the low LOD value that is of the same order as those supplied by more expensive and sensitive instrumentation (i.e., gas chromatography-mass spectrometry) employing just 40 mg of sorbent.

MSPE-LC-UV-Vis applied to real-world water samples analysis

The developed method was applied for TNT determination in samples of reservoir water, drinking water, and effluent wastewater in order to assess the method applicability and matrix effects. Preliminary analysis of these samples confirmed the absence of TNT. Therefore, three analyses were conducted for each sample at 50 μg L−1 spiking level, and the relative recoveries and RSD for each sample were calculated. The relative recovery values obtained were 101, 120, and 87%, and the RSD values 13, 13, and 10% for reservoir water, drinking water, and effluent wastewater, respectively. These results indicate that the matrix effects were negligible for the determination of TNT in the water samples studied.

Eco-Scale metrics to assess the greenness of the analytical method

A. Gałuszka et al. [45] have recently introduced a method for semiquantitatively evaluating the greenness of analytical methodologies. It is based on assigning penalty points to parameters of an analytical process that are not in agreement with the ideal green analysis.

The Eco-Scale metrics was applied to assess the developed method and the results are given in Table 3.

The penalty points were calculated taking into account the synthesis of GO/Fe3O4 nanocomposite for one MSPE and MSPE-LC-UV-Vis method applied to a sample of 0.5 mg L−1 of TNT and 2 cleaning stages between samples.

In accordance with Eco-Scale metrics, the result of this work is ˃50 and ˂75, representing an acceptable green analysis.

Conclusion

A sensitive and environmentally friendly method has been developed for the analysis of TNT in water samples based of magnetic solid-phase extraction (MSPE) coupled to LC-UV-Vis. GO/Fe3O4 nanocomposite has been used as sorbent that synergistically combines the excellent extraction capabilities of GO with the easy handling of Fe3O4. In addition, the nanocomposite can be reused up to six times without losing extraction capacity, reducing cost and wastes. Optimization of MSPE has been done by experimental design. MSPE-LC-UV-Vis methodology is simple, fast, economical, and sensitive, reaching LOD values obtained with more expensive and sensitive instrumentation (GC-MS). Therefore, the suggested method represents an attractive alternative very affordable to any laboratory.

The promising analytical eco-scale concept has been used to assess the greenness of the suggested analytical method. Although the suggested Eco-scale concept still has limitations, this simple and fast-to-use green analytical metrics can be an excellent semiquantitative tool that should be applied to any known and new analytical methodologies.

References

Stoller MD, Park S, Zhu Y, An J, Ruoff RS. Graphene-based ultracapacitors. Nano Lett. 2008;8:3498–502.

Lee C, Wei X, Kysar JW, Hone J. Measurement of the elastic properties and intrinsic strength of monolayer graphene. Science. 2008;321:385–88.

Bolotin KI, Sikes KJ, Jiang Z, Klima M, Fudenberg G, Hone J, et al. Ultrahigh electron mobility in suspended graphene. Solid State Commun. 2008;146:351–55.

Liu Q, Shi J, Zeng L, Wang T, Cai Y, Jiang G. Evaluation of graphene as an advantageous adsorbent for solid-phase extraction with chlorophenols as model analytes. J Chromatogr A. 2011;1218:197–204.

Chen J, Zou J, Zeng J, Song X, Ji J, Wang Y, et al. Preparation and evaluation of graphene-coated solid-phase microextraction fiber. Anal Chim Acta. 2010;678:44–9.

Zhang H, Lee HK. Plunger-in-needle solid-phase microextraction with graphene-based sol–gel coating as sorbent for determination of polybrominated diphenyl ethers. J Chromatogr A. 2011;1218:4509–16.

Zhang S, Du Z, Li G. Layer-by-layer fabrication of chemical-bonded graphene coating for solid-phase microextraction. Anal Chem. 2011;83:7531–41.

Ponnusamy VK, Jen JF. A novel graphene nanosheets coated stainless steel fiber for microwave assisted headspace solid phase microextraction of organochlorine pesticides in aqueous samples followed by gas chromatography with electron capture detection. J Chromatogr A. 2011;1218:6861–68.

Hummers WS, Offeman RE. Preparation of graphitic oxide. J Am Chem Soc. 1958;80:1339–39.

Fritz JS. Analytical solid-phase extraction. New York: Wiley; 1999.

Han Q, Wang Z, Xia J, Xia L, Chen S, Zhang XQ, et al. Graphene as an efficient sorbent for the SPE of organochlorine pesticides in water samples coupled with GC-MS. J Sep Sci. 2013;36:3586–91.

Wang Z, Han Q, Xia J, Xia L, Ding M, Tang J. Graphene-based solid-phase extraction disk for fast separation and preconcentration of trace polycyclic aromatic hydrocarbons from environmental water samples. J Sep Sci. 2013;36:1834–42.

Wu J, Chen L, Mao P, Lu Y, Wang HZ. Determination of chloramphenicol in aquatic products by graphene-based SPE coupled with HPLC-MS/MS. J Sep Sci. 2012;35:3586–92.

Luo X, Zhang FF, Ji S, Yang B, Liang X. Graphene nanoplatelets as a highly efficient solid-phase extraction sorbent for determination of phthalate esters in aqueous solution. Talanta. 2014;120:71–5.

Wang SL, Hu S, Xu H. Analysis of aldehydes in human exhaled breath condensates by in-tube SPME-HPLC. Anal Chim Acta. 2015;900:67–75.

Pawliszyn J. Solid Phase Microextraction. Theory and Practice. New York: Wiley; 1997.

He H, Klinowski J, Forster M, Lerf A. A new structural model for graphite oxide. Chem Phys Lett. 1998;287:53–6.

Sitko R, Zawisza B, Malicka E. Graphene as a new sorbent in analytical chemistry. Trends Anal Chem. 2013;51:33–43.

Yang X, Li J, Wen T, Ren X, Huang Y, Wang X. Adsorption of naphthalene and its derivatives on magnetic graphene composites and the mechanism investigation. Colloid Surface A. 2013;422:118–25.

Sitko R, Turek E, Zawisza B, Malicka E, Talik E, Heimann J, et al. Adsorption of divalent metal ions from aqueous solutions using graphene oxide. Dalton Trans. 2013;42:5682–89.

Liu Q, Shi J, Sun J, Wang T, Zeng L, Jiang G. Graphene and graphene oxide sheets supported on silica as versatile and high-performance adsorbents for solid-phase extraction. Angew Chem Int Ed. 2011;50:5913–17.

Xu L, Feng J, Li J, Liu X, Jiang S. Graphene oxide bonded fused-silica fiber for solid-phase microextraction-gas chromatography of polycyclic aromatic hydrocarbons in water. J Sep Sci. 2012;35:93–100.

Meng J, Shi C, Wei B, Yu W, Deng C, Zhang X. Preparation of Fe3O4@C@PANI magnetic microspheres for the extraction and analysis of phenolic compounds in water samples by gas chromatography-mass spectrometry. J Chromatogr A. 2011;1218:2841–47.

Sasaki T, Tanaka S. Adsorption behavior of some aromatic compounds on hydrophobic magnetite for magnetic separation. J Hazard Mater. 2011;196:327–34.

Zhang X, Niu H, Pan Y, Shi Y, Cai Y. Modifying the surface of Fe3O4/SiO2 magnetic nanoparticles with C18/NH2 mixed group to get an efficient sorbent for anionic organic pollutants. J Colloid Interface Sci. 2011;362:107–12.

Tang H, Zhu L, Yu C, Shen X. Selective photocatalysis mediated by magnetic molecularly imprinted polymers. Sep Purif Technol. 2012;95:165–71.

Li S, Gong Y, Yang Y, He C, Hu L, Zhu L, et al. Recyclable CNTs/Fe3O4 magnetic nanocomposites as adsorbents to remove bisphenol A from water and their regeneration. Chem Eng J. 2015;260:231–39.

Sun T, Yang J, Li L, Wang X, Li X, Jin Y. Preparation of graphene sheets with covalently bonded Fe3O4 for magnetic solid-phase extraction applied to organochlorine pesticides in orange juice. Chromatographia. 2016;79:345–53.

Han Q, Wang Z, Xia J, Chen S, Zhang X, Ding M. Facile and tunable fabrication of Fe3O4/graphene oxide nanocomposites and their application in the magnetic solid-phase extraction of polycyclic aromatic hydrocarbons from environmental water samples. Talanta. 2012;101:388–95.

Aguilar-Arteaga K, Rodriguez JA, Miranda JM, Medina J, Barrado E. Determination of non-steroidal anti-inflammatory drugs in wastewaters by magnetic matrix solid phase dispersion–HPLC. Talanta. 2010;80:1152–57.

Šafařı́k I, Šafařı́ková M. Detection of low concentrations of malachite green and crystal violet in water. Water Res. 2002;36:196-200

Taghvimi A, Hamishehkar H, Ebrahimi M. Magnetic nano graphene oxide as solid phase extraction adsorbent coupled with liquid chromatography to determine pseudoephedrine in urine samples. J Chromatogr B. 2016;1009-1010:66–72.

Zeng S, Gan N, Weideman-Mera R, Cao Y, Li T, Sang W. Enrichment of polychlorinated biphenyl 28 from aqueous solutions using Fe3O4 grafted graphene oxide. Chem Eng J. 2013;218:108–15.

Stucki H. Toxicity and degradation of explosives. Chimia. 2004;58:409–13.

Keith L, Telliard W. Priority pollutants I—a perspective view. Environ Sci Technol. 1979;13:416–23.

Talmage SS, Opresko DM, Maxwell CJ, Welsh CJE, Cretella FM, Reno PH, et al. Reviews of Environmental Contamination and Toxicology. New York: Springer; 1999.

Psillakis E, Kalogerakis N. Solid-phase microextraction versus single-drop microextraction for the analysis of nitroaromatic explosives in water samples. J Chromatogr A. 2011;938:113–20.

Psillakis E, Kalogerakis N. Application of solvent microextraction to the analysis of nitroaromatic explosives in water samples. J Chromatogr A. 2001;907:211–19.

Psillakis E, Mantzavinos D, Kalogerakis N. Development of a hollow fibre liquid phase microextraction method to monitor the sonochemical degradation of explosives in water. Anal Chim Acta. 2004;501:3–10.

Cortada C, Vidal L, Canals A. Determination of nitroaromatic explosives in water samples by direct ultrasound-assisted dispersive liquid–liquid microextraction followed by gas chromatography–mass spectrometry. Talanta. 2011;85:2546–52.

Wei Y, Han B, Hu X, Lin Y, Wang X, Deng X. Synthesis of Fe3O4 nanoparticles and their magnetic properties. Procedia Eng. 2012;27:632–7.

Shih CJ, Lin S, Sharma R, Strano MS, Blankschtein D. Understanding the pH-dependent behavior of graphene oxide aqueous solutions: a comparative experimental and molecular dynamics simulation study. J Am Chem Soc. 2012;28:235–41.

Thermo Scientific database (November, 2016), www.lasurface.com

Draper NR. Plackett and Burman designs. In: Kotz S, Johnson L, editors. Encyclopedia of Statistical Sciences. New York: John Wiley & Sons; 1985. p. 754–8.

Gałuszka A, Konieczka P, Migaszewski ZM, Namiesnik J. Analytical Eco-Scale for assessing the greenness of analytical procedures. Trends Anal Chem. 2012;37:61–72.

Acknowledgements

The authors would like to thank the Ministry of Science and Innovation of Spain (project no. CTQ2011-23968) for the financial support and L. Costa thanks the Capes Foundation within the Ministry of Education in Brazil (Process 12013/13-7).

Author information

Authors and Affiliations

Corresponding authors

Ethics declarations

Conflict of interest

The authors declare that they have no conflicts of interest.

Electronic supplementary material

Below is the link to the electronic supplementary material.

ESM 1

(PDF 260 kb)

Rights and permissions

About this article

Cite this article

Costa dos Reis, L., Vidal, L. & Canals, A. Graphene oxide/Fe3O4 as sorbent for magnetic solid-phase extraction coupled with liquid chromatography to determine 2,4,6-trinitrotoluene in water samples. Anal Bioanal Chem 409, 2665–2674 (2017). https://doi.org/10.1007/s00216-017-0211-3

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00216-017-0211-3