Abstract

A fast capillary zone electrophoresis method for the simultaneous analysis of glibenclamide and its impurities (IA and IB) in pharmaceutical dosage forms was fully developed within a quality by design framework. Critical quality attributes were represented by IA peak efficiency, critical resolution between glibenclamide and IB, and analysis time. Experimental design was efficiently used for rapid and systematic method optimization. A 35//16 symmetric screening matrix was chosen for investigation of the five selected critical process parameters throughout the knowledge space, and the results obtained were the basis for the planning of the subsequent response surface study. A Box–Behnken design for three factors allowed the contour plots to be drawn and the design space to be identified by introduction of the concept of probability. The design space corresponded to the multidimensional region where all the critical quality attributes reached the desired values with a degree of probability π ≥ 90%. Under the selected working conditions, the full separation of the analytes was obtained in less than 2 min. A full factorial design simultaneously allowed the design space to be validated and method robustness to be tested. A control strategy was finally implemented by means of a system suitability test. The method was fully validated and was applied to real samples of glibenclamide tablets.

Identification of sequence variants in IgG Fc mixtures

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

The quality by design (QbD) concept is increasingly applied in the pharmaceutical industry to improve the quality of products, as recently recommended by International Conference on Harmonisation of Technical Requirements for Registration of Pharmaceuticals for Human Use (ICH) guideline Q8(R2) [1]. The fundamental tenet of QbD is a science- and risk-based approach to pharmaceutical development, whereby quality is built into the product and not merely established by testing the end product. Even if ICH guideline Q8(R2) does not take into account analytical method development, the advantageous application of QbD in pharmaceutical analysis has been recently described by the definition of a systematic approach for the setting up of analytical methods [2, 3]. Analytical QbD emphasizes the need to thoroughly understand the analytical system by an in-depth study of critical process parameters (CPPs) based on risk assessment and multivariate tools. The design space (DS) is determined as the multidimensional region of successful operating ranges for the CPPs, which lead to desired values for the critical quality attributes (CQAs). Recent examples of analytical QbD concern mainly chromatography [4–9] and to a much lower extent capillary electrophoresis (CE) [10–13].

A fundamental aspect for the quality of the pharmaceutical product is the control of impurities, which often represents a critical analytical issue, owing to the similarity of the drug and the related substances in terms of chemical structure and behavior. Fast and validated methods should be available for the routine quality control of pharmaceutical dosage forms, which should allow the impurities to be determined at least at 0.1% w/w with respect to the main compound. For routine purity assessment, CE has been positioned as a complementary tool with respect to more commonly used high-performance liquid chromatography, owing to its several well-known benefits [14]. This technique has unique features, such as high efficiency and resolving power, low sample consumption, and wide possibility of finely tuning the separation conditions and selectivity.

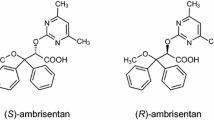

Glibenclamide (GLI; CAS no. 10238-21-8), also known as glyburide, is a potent antidiabetic drug belonging to the second-generation sulfonylurea class, and is administered by mouth in the treatment of type 2 diabetes mellitus [15]. Sulfonylureas appear to have several modes of action, apparently mediated by inhibition of ATP-sensitive potassium channels, from the initial increase of secretion of insulin from the β cells of the pancreas to the persistence of the hypoglycemic effect possibly due to inhibition of hepatic glucose production and to increased sensitivity to insulin [15]. In the European Pharmacopeia, GLI specified impurities are reported as A (IA) and B (IB) [16], and their structural formulas are shown in Fig. 1. The official chromatographic procedure described in the European Pharmacopeia for the analysis of GLI and its impurities has an analysis time of about 5 min. Only a few other publications have focused on impurity profiling of GLI in raw materials or pharmaceutical formulations, concerning chromatographic methods [17–21], thin-layer chromatography [22, 23], and spectrophotometric methods [24]. As far as we know, no CE method has been reported for the analysis of the impurities in GLI formulations. CE has been used for the analysis of mixtures of antidiabetic drugs, including GLI, in biological fluids [25–30], in traditional Chinese medicines [31, 32], and in antidiabetic herbal medicines [33] as adulterants.

Hence, the aim of this work was to develop a fast and simple CE method for the simultaneous analysis of GLI and its related substances for the quality control of GLI tablets. The development followed a risk-based multifactorial strategy based on QbD principles, which allowed a high level of understanding of the analytical system to be accomplished. A key role in method development was played by DS computation with response surface methodology [34] and Monte Carlo simulation [35]. In this way, the DS was defined by consideration of the probability for the selected CQAs to fulfill their acceptance requirements, thus introducing a concept of assurance of quality. After the definition of a control strategy based on robustness and system suitability criteria, the CE method was finally validated and applied to real samples of GLI tablets.

Materials and methods

Chemicals and reagents

The reference standard of GLI was kindly supplied by A. Menarini Industrie Farmaceutiche Riunite (Florence, Italy). Reference standards of GLI impurities IA and IB, and metformin hydrochloride (MET; CAS no. 1115-70-4) used as an internal standard were from Sigma-Aldrich (St Louis, MO, USA). Methanol, borax, boric acid, phosphoric acid, Euglucon® excipients (maize starch, pregelatinized maize starch, lactose monohydrate, magnesium stearate, anhydrous colloidal silica, talc) were purchased form Sigma-Aldrich. Euglucon® tablets (Roche, Milan, Italy), containing 5 mg GLI, were purchased in local pharmacies. Ultrapure water used for the preparation of solutions and running buffers was provided by a Simplicity 185 system (Millipore, Billerica, MA, USA) after electrodeionization treatment with an Elix system (Millipore).

Solutions and sample preparation

Standard stock solutions of GLI (5 mg mL-1), GLI impurities (1 mg mL-1), and MET (1 mg mL-1) were prepared in methanol and were stored at 4 °C for 1 week. Working standard solutions were prepared each day by dilution of the proper amount in a 500-μL vial with ultrapure water. We prepared borate and borate/phosphate buffers by mixing a proper volume of 0.5 M H3BO3 or a solution of 0.5 M mixed H3BO4/H3PO4 with 1 M NaOH to the desired pH and then with ultrapure water to the desired volume. In the case of borax buffer, 1 M NaOH or 1 M HCl was added to obtain the desired pH.

For sample preparation, 30 tablets were weighed, crushed, and powdered. The equivalent of about 50 mg GLI was accurately weighed and transferred to a 25-mL beaker. Then, 10 mL methanol was added to the powder, and the resulting mixture was stirred for 5 min, sonicated for 10 min, and stirred again for 5 min. One milliliter of the mixture was centrifuged, and 300 μL of the supernatant was diluted in a vial up to 500 μL by addition of 50 μL of MET stock solution and 150 μL of ultrapure water. The final test concentration of GLI was about 3 mg mL-1, and the resulting concentration of MET was 0.1 mg mL-1.

Electrophoresis procedure

All CE separations were performed with a 3DCE system (Agilent Technologies, Waldbronn, Germany) equipped with a UV–visible diode-array detector for absorbance measurements at 200 nm. 3DCE ChemStation (revision A.09.01) was used for data acquisition.

Uncoated fused-silica capillaries purchased from Unifibre (Settimo Milanese, Italy) were used. The dimensions of the capillary were 33.0 cm × 50-μm inner diameter with an effective length of 24.5 cm. A new capillary was conditioned with 1 M NaOH and with ultrapure water for 5 min each. At the beginning of each working day, the capillary was rinsed with 0.1 M NaOH and with ultrapure water, each for 2 min. Before each injection, the capillary was washed successively with methanol, 1 M NaOH, 0.1 M NaOH, and ultrapure water for 1 min each, and was then equilibrated with the background electrolyte (BGE) for 4 min.

Injection of samples was done by application of a pressure of 50 mbar for 6 s, followed by a BGE plug at 50 mbar for 6 s. The working conditions (with the interval corresponding to the DS) were as follows: temperature, 20 °C; voltage, 20 kV (19–21 kV); BGE, 30 mM (26–24 mM) borax buffer pH 10.20 (10.05–10.35).

Calculations and software

The efficiency of the IA peak was calculated according to the formula N=5.54(t m/w 1/2)2, where N is the number of theoretical plates, t m is the migration time, and w 1/2 is the peak width at half height.

The elaboration of the screening symmetric matrix was performed by NEMRODW [36], and the elaboration of the Box–Behnken design and full factorial design was performed by MODDE [37]. The experiments described in the experimental plans were run by analyzing a sample containing GLI at 3 mg mL-1 and GLI impurities at 0.0300 mg mL-1 (1% with respect to the main compound).

Results and discussion

Method scouting and critical quality attributes

The analytical target profile of the method was represented by a CE method that baseline separates GLI and its impurities, allowing an accurate and precise determination of the analytes. The method should respect general validation requirements [10, 38], with a limit of quantitation for IA and IB equal to or lower than 0.1% with respect to the main compound. The analytes are weak acids (GLI, pK a=5.3), thus leading to running preliminary experiments involving a simple capillary zone electrophoresis system based on borax buffer. The use of this separation system gave good results in terms of separation pattern, whereas the use of borate or borate/phosphate buffer did not result in any improvement, and thus borax buffer was selected as the starting point for further method optimization. In these initial conditions, the migration order of the compounds was IA, GLI, and IB (with Rs1 and Rs2 indicating resolution values between the pairs IA/GLI and GLI/IB, respectively). These scouting experiments also led to identification of the main analytical issues of the method—namely, IA peak efficiency and critical separation between GLI and IB (Rs2). The internal standard was selected as MET, a basic compound which migrated first in the electropherogram without any separation problems with respect to the analytes. Thus, the CQAs describing the global quality of the electropherogram were defined as IA efficiency N, critical resolution Rs2, and analysis time t. CQA requirements were set as log N ≥ 4.50, Rs2 ≥ 0.40, and t ≤ 2 min. The target value for Rs2 was selected as the value describing a baseline resolution between GLI and IB peaks, which were very different for width characteristics [13]. The duration of the analysis was required to be equal to or less than 2 min, because in general the development of fast methods is deemed important to improve productivity in pharmaceutical analysis.

Risk assessment, critical process parameters, and knowledge space

An Ishikawa fishbone diagram [10, 39] (not shown) was used to point out the risk factors associated with the characteristics of the capillary zone electrophoresis analysis and thus to highlight the CPPs which could affect the selected CQAs. As a result of scouting data and risk assessment, the five CPPs selected were voltage, temperature, buffer concentration, buffer pH, and injection time. The inclusion of injection time among the CPPs can lead to practical advantages in tuning sample loading and thus in finding a good compromise between method selectivity and sensitivity, as previously shown [12]. In this sense, the potential of experimental design in optimization was fully exploited, considering not only BGE and separation parameters, but also a parameter related to sample injection. The total length of the capillary was fixed at 33.0 cm on the basis of the results of scouting experiments.

The CPPs were screened to investigate their effects on the selected CQAs by means of a 35//16 symmetric screening matrix [34], where each CPP was studied at three levels covering the knowledge space: voltage, 16, 19, and 22 kV; temperature, 18, 20, and 22 °C; buffer concentration, 10, 20, and 30 mM; buffer pH, 9.20, 9.70, and 10.20; injection time, 6, 8, and 10 s. The highest voltage tested was set at 22 kV to avoid a high developed current. The shortest injection time was fixed at 6 s to obtain adequate sensitivity, whereas values greater than 10 s were not considered in order to maintain good selectivity.

The experimental plan and the measured responses are reported in Table S1. ANOVA showed that for all the CQAs considered, the models were significant, and graphical analysis of effects was performed to obtain information on the factor levels which could lead to good results [34]. In the first type of plot (Fig. 2a–c) it is possible to identify the variations between the CPP levels considered which have a significant effect on the CQAs. The bar length is proportional to the amplitude of the difference of the relative effects between two levels. The confidence intervals were calculated from the estimate of the experimental variance; the selected threshold of significance was set as 95% and is indicated by the dotted lines. In the second type of plot (Fig. 2d–f) the levels corresponding to the best results can be readily indentified, as the longer bars correspond to levels which lead to higher values of the response. The highest level of each variable is represented by a red bar, of the same arbitrary length for all the factors. The indication of the presence of a statistically significant effect when passing from one level to another can be found in the first type of graph. From Fig. 2a and d, the change of the level of the voltage, buffer concentration, and buffer pH had a significant effect on IA efficiency. The maximization of log N was obtained with low voltages and medium–high buffer concentrations, and the higher increase of this CQA was undoubtedly noticed when switching from the lowest to the medium and to the highest level of buffer pH. As concerns Rs2 (Fig. 2b, e), as expected a high buffer concentration and a short injection time were preferred for maximization of this response. Finally, the most important effects on t were exerted by the change of voltage, temperature, and buffer concentration (Fig. 2c, f).

Investigation of knowledge space by graphical analysis of effects. The length of the bars is related to the difference of effects between the two considered levels (a–c) or to the weight of each considered level (d–f). The dotted lines define the 95% confidence interval. Responses: a, d IA efficiency (log N); b, e resolution GLI/IB (Rs2); c, f analysis time (t). V voltage, T temperature, CONC buffer concentration, pH buffer pH, INJ injection time

These results induced us to directly set the temperature at its medium value (20 °C) and to adjust the experimental domain of the other CPPs, which needed further investigation. For the voltage, the effect on t was prevalent and the experimental domain was moved toward higher levels (19–21 kV). Higher voltages were excluded from the study, as the screening runs evidenced a too high generated current when 22 kV was applied. Buffer concentration was shifted toward higher values (25–35 mM), mainly taking into account the effects exerted on log N and Rs2. Buffer pH was moved toward higher values, considering the important effect of the change of this CPP on efficiency. For the injection time, even if the lower value (6 s) definitely led to the best results especially in terms of Rs2, we decided to continue studying this CPP in the range from 6 to 8 s in order to find a limit of quantitation as low as possible—namely, to identify the highest applicable injection time compatible with the desired CQA requirements.

Response surface methodology and design space

Response surface methodology [34] was applied to conduct an in-depth investigation of the effects of the four CPPs on the CQAs throughout the new experimental domain. The following quadratic model was postulated to relate the CPPs with the CQAs:

where y represents the experimental response, x i the independent evaluated factors, β 0 the intercept, β i the true coefficients, and ε the experimental error.

The new experimental domain which was selected for the voltage and the injection time could not be fractionated into more than three levels for instrumental reasons. Thus, a Box–Behnken design, which requires three levels for each factor, was selected to calculate the coefficients of the model. Other classical designs suited for response surface study, such as a Doehlert design or a central composite design, could not be practically applied. Moreover, Box–Behnken designs are designs where the k variables are varied two at a time by 22 designs, while maintaining the remaining k-2 variables fixed at their middle level, and are usually very efficient in terms of the required runs [34]. Twenty-seven experiments, including three center points for estimating the experimental variance, were required, according to the experimental plan reported in Table 1. Following the indications from the Box–Cox plot, the analysis time t was inversely transformed, t -1, and all three models, calculated by multiple linear regression, were significant in terms of ANOVA. Effectively, the selected calibration procedure was able to give very good results for the three models in terms of both goodness of fit R 2 (0.952–0.981) and goodness of prediction Q 2 (0.725–0.900).

Four-dimensional contour plots were drawn reporting the calculated isoresponse curves in order to obtain detailed information on the behavior of the CQAs throughout the experimental domain, and are reported in Fig. 3 for log N, Rs2, and t, with the voltage maintained at its middle value. The investigation of these plots, together with the analysis of the coefficients (not shown), enable us to obtain an accurate description of the performances of the CQAs. For log N, the maximization of this response was obtained at low buffer concentrations and high levels of buffer pH, which were also shown to be the only significant factors. Buffer concentration was also demonstrated to have a positive quadratic effect on this CQA. For Rs2, the most important effect was obviously exerted by the injection time; however, buffer concentration and buffer pH also had a significant effect. A strong positive interaction between buffer concentration and buffer pH was found, and the zone leading to the best results corresponded to high values of both these CPPs. Analysis time t was mainly influenced by voltage, but buffer concentration showed both linear and quadratic significant effects.

The impact of possible errors in the input parameter on predicted model responses can be explored and quantified by sensitivity analysis procedures. Most approaches examine the effects of changes in a single parameter input variable, assuming no changes in all the other inputs [40]. In this case, a schematic presentation of sensitivity analysis was reported in the form of a dynamic profile obtained by MODDE [41], shown in Fig. S1. The dynamic profile shows the effect of each factor over the range investigated, displaying the predicted values of the selected response when each factor varies from its lowest to its highest level, with all other factors held constant at their medium value.

We took the predicted and the accepted values for the CQAs into consideration when drawing the sweet spot plots, which are shown in Fig. S2. In these graphs, the region where the requirements for all three CQAs were fulfilled is depicted in dark blue, whereas the areas where one or two CQAs were fulfilled are depicted in pale blue and brilliant blue, respectively. From examination of these plots, it is possible to note that when the injection time is increased from 6 to 8 s (Fig. S2), the area corresponding to the desired values for all the CQAs strongly decreases and disappears when the injection time is 8 s, clearly due to the predicted values of Rs2.

After modeling the responses, we calculated the DS as the combinations of CPP conditions that are likely to provide satisfactory values for all the CQAs. Monte Carlo simulations were performed by MODDE to take into account the model-parameter uncertainty—namely, propagating uncertainty from parameters to responses [3, 4, 35]. The selected level of probability for the CQAs to reach the desired values was set at π ≥ 90% and the original set point was calculated as follows: 20 kV, 6 s, 30 mM, pH 10.20. Because the injection time cannot be fractionated, the value for this CPP was locked at 6 s and the DS was recalculated, resulting in the probability surface shown in Fig. 4. In this graph, the zone corresponding to the DS can be easily identified as the zone where the risk of error is 10% or less, and corresponds to the following ranges for the CQAs: voltage, 19-21 kV; buffer concentration, 26-34 mM; buffer pH, 10.05-10.35. The original set point was selected as the working point, and the related electropherogram is shown in Fig. 5, where all the compounds were baseline separated within 2 min with a generated current equal to 110 μA. The migration order of the peaks is due to the different electrophoretic effective mobility of the compounds in the sample: first the internal standard MET, which possesses a positive effective mobility, then methanol, which migrates with electroosmotic flow, and finally the three analytes, all possessing a negative effective mobility.

Electropherogram obtained with the working point conditions. Sample: GLI at 3 mg mL-1, GLI impurities at 0.03 mg mL-1, metformin hydrochloride (MET; internal standard) at 0.1 mg mL-1 Experimental conditions: injection time, 6 s; temperature, 20°C; voltage, 20 kV; background electrolyte, 30 mM borax buffer pH 10.20. Methanol was used as an electroosmotic flow (EOF) marker

Robustness and control strategy

In general, the DS needs to be validated by experiments performed at the extremes of the CPP ranges in order to verify that the CQAs fulfill the requirements also near the edges of failure [10]. In this study, the DS zone was quite limited and could be almost comparable to small changes in the CQAs as those generally examined by robustness studies [38]. Consequently, in this case the same matrix was selected for simultaneously validating the DS and verifying method robustness, and consisted of a 23 full factorial design [34], reported in Table S2. The injection time was excluded from the study as little variations of this factor are not possible for instrumental reasons. The related analysis of effects is shown in Fig. S3. The precision of the regression coefficients was calculated as the 95% confidence interval, which was superimposed as an error bar on each bar. The size of the confidence interval depends on three factors: the quality of the experimental design (condition number), the goodness of the regression model (residual standard deviation), and the number of degrees of freedom [41]. Analysis of effects revealed that the buffer concentration was the only factor which had a significant effect on log N and Rs2, whereas only the voltage had a significant effect on t. The CQA values were within the desired limits in all the experiments, as the extreme measured values were as follows: log N, 4.53-5.12; Rs2, 0.40-0.54; t, 1.56-1.95 min.

Finally, a control strategy for the method was accomplished [1] on the basis of the data collected during method development. By means of a proper control strategy, the method performances can be monitored to ensure that the method remains in compliance with the defined analytical target profile. In this study, the extreme values of the CQAs measured during system repeatability studies were selected as limits for the system suitability intervals [42]: log N, 4.69-5.03; Rs2, 0.44-0.51; t, 1.77-1.92 min. Moreover, from the robustness results it was deemed necessary to make a precautionary statement about carefully controlling the BGE concentration.

Validation and application

We validated the method by following ICH guidelines [38], and the related data are reported in the electronic supplementary material, showing adequate performances for the intended use. After method validation, the amount of GLI in the commercially available Eugucon® tablets was quantified, and the percentage of the claimed amount (5 mg) was found to be 98.4±1.4 %, with a relative standard deviation of 0.9% (n = 4, α/2 = 0.025). A typical electropherogram of the real sample is shown in Fig. S4, evidencing that no GLI impurity was detected.

Conclusions

A fast and QbD-compliant CE method was developed for the simultaneous determination of GLI and its related impurities in pharmaceutical dosage form. Implementation of QbD allowed enhanced understanding of the analytical method, which was effectively supported by experimental design. The CQAs were selected from a preliminary examination of the analytical issues of the method evidenced during the scouting phase, and were represented by a critical value of efficiency, a critical value of resolution, and analysis time. The data gathered through well-suited experimental designs, which were planned first in a screening phase and then in a response surface study, made it possible to identify the DS. This zone was defined on the basis of the calculated models for the CPPs and on the basis of Monte Carlo simulations, and consisted of a set of CPP conditions which provided satisfactory values for the CQAs with a selected degree of probability. A full factorial design was used to simultaneously validate the DS and perform a robustness study, allowing the importance of the correct value of the buffer concentration to be pointed out. In the selected working conditions, baseline separation of the analytes was obtained in less than 2 min. The method developed successfully passed the validation process, demonstrating its good suitability for the routine analysis of GLI tablets.

References

International Conference on Harmonisation of Technical Requirements for Registration of Pharmaceuticals for Human Use (2009) ICH harmonised tripartite guideline, Q8(R2), pharmaceutical development. International Conference on Harmonisation of Technical Requirements for Registration of Pharmaceuticals for Human Use, Geneva

Orlandini S, Pinzauti S, Furlanetto S (2013) Anal Bioanal Chem 405:443–450

Rozet E, Lebrun P, Debrus B, Boulanger B, Hubert P (2013) Trends Anal Chem 42:157–167

De Backer B, Debrus B, Lebrun P, Theunis L, Dubois N, Decock L, Verstraete A, Hubert P, Charlier C (2009) J Chromatogr B 877:4115–4124

Debrus B, Lebrun P, Mbinze Kindenge J, Lecomte F, Ceccato A, Caliaro G, Mavar Tayey Mbay J, Boulanger B, Marini RD, Rozet E, Hubert P (2011) J Chromatogr A 1218:5205–5215

Debrus B, Guillarme D, Rudaz S (2013) J Pharm Biomed Anal 84:215–223

Monks KE, Rieger H-J, Molnár I (2011) J Pharm Biomed Anal 56:874–879

Schmidt AH, Molnár I (2013) J Pharm Biomed Anal 78–79:65–74

Vemić A, Rakić T, Malenović A, Medenica M (2015) J Pharm Biomed Anal 102:314–320

Furlanetto S, Orlandini S, Pasquini B, Del Bubba M, Pinzauti S (2013) Anal Chim Acta 802:113–124

Orlandini S, Pasquini B, Stocchero M, Pinzauti S, Furlanetto S (2014) J Chromatogr A 1339:200–209

Orlandini S, Pasquini B, Gotti R, Giuffrida A, Paternostro F, Furlanetto S (2014) Electrophoresis 35:2538–2545

Orlandini S, Pasquini B, Del Bubba M, Pinzauti S, Furlanetto S (2015) J Chromatogr A 1380:177–185

Jouyban A, Kenndler E (2008) Electrophoresis 29:3531–3551

Sweetman SC (ed) (2005) Martindale: the complete drug reference, 34th edn. Pharmaceutical Press, London

Council of Europe (2010) European pharmacopoeia 7.0, vol 2. Council of Europe, Strasbourg

Beaulieu N, Graham SJ, Lovering EG (1993) J AOAC Int 76:962–965

El Deeb S, Schepers U, Wätzig H (2006) J Sep Sci 29:1571–1577

Khalil SAH, Abu-Baker MAY, Al-Shareef A-H (1998) J Pharm Pharmacol 50:50

Navaneethan G, Karunakaran K, Elango KP (2011) Lat Am J Pharm 30:1639–1643

Schepers U, Ermer J, Preu L, Wätzig H (2004) J Chromatogr B 810:111–118

Takla PG, Joshi SR (1983) J Pharm Biomed Anal 1:189–193

El Kousy NM (1998) Mikrochim Acta 128:65–68

Bedair MM, Korany MA, Ebdel-hay MA, Gazy AA (1990) Analyst 115:449–453

Lai EPC, Feng SY (2006) J Chromatogr B 843:94–99

Maier V, Znaleziona J, Jirovský D, Skopalová J, Petr J, Ševčík J (2009) J Chromatogr A 1216:4492–4498

Paroni R, Comuzzi B, Arcelloni C, Brocco S, de Kreutzenberg S, Tiengo A, Ciucci A, Beck-Peccoz P, Genovese S (2000) Clin Chem 46:1773–1780

Núñez M, Ferguson JE, Machacek D, Jacob G, Oda RP, Lawson GM, Landers JP (1995) Anal Chem 67:3668–3675

Roche ME, Oda RP, Lawson GM, Landers JP (1997) Electrophoresis 18:1865–1874

Strausbauch MA, Xu SJ, Ferguson JE, Nunez ME, Machacek D, Lawson GM, Wettstein PJ, Landers JP (1995) J Chromatogr A 717:279–291

Ku Y-R, Chag L-Y, Ho L-K, Lin J-H (2003) J Pharm Biomed Anal 33:329–334

Han FM, Cheng ZY, Cai M, Chen Y (2000) Chin J Chromatogr 18:456–458

Viana C, Ferreira M, Romero CS, Bortoluzzi MR, Lima FO, Rolim CMB, de Carvalho LM (2013) Anal Methods 5:2126–2133

Lewis G, Mathieu D, Phan-Tan-Luu R (1999) Pharmaceutical experimental design. Dekker, New York

Herrador MA, Asuero AG, Gonzalez AG (2005) Chemom Intell Lab Syst 79:115–122

Mathieu D, Nony J, Phan-Tan-Luu R (2011) NEMRODW. LPRAI, Marseille

Umetrics (2013) MODDE 10. Umetrics, Umeå

International Conference on Harmonisation of Technical Requirements for Registration of Pharmaceuticals for Human Use (2005) ICH harmonised tripartite guideline, Q2(R1), validation of analytical procedures: text and methodology. International Conference on Harmonisation of Technical Requirements for Registration of Pharmaceuticals for Human Use, Geneva

Ishikawa K (1985) What is total quality control? The Japanese way. Prentice Hall, Englewood Cliffs

Loucks DP, van Beek E, Stediger JR, Dijkman JPM, Villars MT (2005) Water resources system planning and management: an introduction to methods, models and applications. UNESCO, Paris

Eriksson L, Johansson E, Kettaneh-Wold N, Wikström C, Wold S (2008) Design of experiments-principles and applications. Umetrics, Umeå

Ermer J, Miller J.H.McB. (Eds.) (2004) Method validation in pharmaceutical analysis-a guide to best practice, Wiley-VCH, Weinheim

Acknowledgments

The authors thank Ente Cassa di Risparmio di Firenze for financial support and A. Menarini Industrie Farmaceutiche Riunite (Florence, Italy) for the gift of glibenclamide.

Conflict of interest

The authors declare that they have no conflict of interest.

Author information

Authors and Affiliations

Corresponding authors

Electronic supplementary material

Below is the link to the electronic supplementary material.

ESM 1

(PDF 258 kb)

Rights and permissions

About this article

Cite this article

Furlanetto, S., Orlandini, S., Pasquini, B. et al. Fast analysis of glibenclamide and its impurities: quality by design framework in capillary electrophoresis method development. Anal Bioanal Chem 407, 7637–7646 (2015). https://doi.org/10.1007/s00216-015-8921-x

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00216-015-8921-x