Abstract

Free-living planktonic single bacterial strain can decolorize Congo red (CR) but often produces the carcinogenic, mutagenic and genotoxic aromatic amines. Planktonic single and bacterial consortia are more susceptible to toxic pollutants than their biofilm counterparts. In the present study, four biofilm consortia (C1 = Vitreoscilla sp. ENSG301, Acinetobacter lwoffii ENSG302, Klebsiella pneumoniae ENSG303 and Pseudomonas fluorescens ENSG304, C2 = Escherichia coli ENSD101, Enterobacter asburiae ENSD102 and E. ludwigii ENSH201, C3 = E. asburiae ENSD102, Vitreoscilla sp. ENSG301 and Bacillus thuringiensis ENSW401, and C4 = E. coli ENSD101, E. ludwigii ENSH201 and B. thuringiensis ENSW401) were prepared and assessed for bioremediation of CR. All these biofilm consortia remarkably decolorized (96.9 to 99.5%) the CR (100 mg/L) in static condition within 72 h incubation at 28 °C. These consortia also synthesized significantly more intracellular azoreductase and laccase enzyme than extracellular of these enzymes. UV–Vis spectral analysis revealed that the major peak at 478 nm wavelength of CR was completely disappeared. FTIR analysis showed several major peaks along with azo bonds are completely or partly disappeared, deformed or widened. Chemical oxygen demand was reduced by 86.4, 85.5, 87.0 and 86.2% by C1, C2, C3 and C4, respectively. Accordingly, biodegraded metabolites of CR by different biofilm consortia did not inhibit the germination of wheat seeds and bacterial growth. Thus, these biofilm consortia can be applied in bioremediation of wastewater containing CR for safe disposal into the environment. To our knowledge, this is the first report on degradation and detoxification of aqueous solution containing CR by bacterial biofilm consortia.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Congo red (CR) is a diazo dye, extensively used in textile, printing, food and biomedical industries worldwide. In microbiology, it is used in revealing of curli fimbriae (Haque et al. 2012, 2017). The wastewater containing CR is highly colored. Excessive release of such raw wastewater into aquatic ecosystems, such as rivers, ponds and cannels, remarkably decreases the photosynthetic ability of the aquatic plants by lowering the light penetration. The wastewater containing CR also deteriorates the water quality by depletion of dissolved oxygen, changing the pH, lowering the gas solubility, and increasing the biological oxygen demand, chemical oxygen demand and total organic carbon values (Forgacs et al. 2004; Chengalroyen and Dabbs 2013). CR-mixed wastewater is evident to diminish the seed germination, biomass production and soil fertility (Ghodake et al. 2009; Saratale et al. 2011; Sarim et al. 2019). Therefore, it is essential to treat the CR-containing wastewater before its final discharge into the environment.

The physicochemical methods, such as adsorption, coagulation–flocculation, filtration, ozonation, electrochemical oxidation, Fenton oxidation, sonochemical oxidation, advanced oxidation, ion exchange, reverse osmosis, and electrolysis, are used for the removal of CR from wastewater in many countries worldwide (Robinson et al. 2001; Huang et al. 2014; Ahmad et al. 2015; Ayati et al. 2016; Sathishkumar et al. 2019). However, most of these methods are expensive (Anjaneyulu et al. 2005; Vikrant et al. 2018), require high energy (Saratale et al. 2011), and produce a huge amount of sludge along with hazardous by-products (Robinson et al. 2001; Chengalroyen and Dabbs 2013; Kumar et al. 2019). Bioremediation is a microbial-based method, uses naturally occurring microorganisms to breakdown toxic substances into less toxic or non-toxic substances (Saratale et al. 2011). Compared with the physicochemical methods, bioremediation is less expensive, eco-friendly, requires less energy, produces less amount non-toxic sludge and mineralizes the dye completely (He et al. 2017). Hence, this method has been recommended to degrade and detoxify the azo dyes including CR from wastewaters (Rai et al. 2005; Pandey et al. 2007; Saratale et al. 2011).

A large number of fungi (Bhattacharya et al. 2011; Chakraborty et al. 2013; Wang et al. 2017; Asses et al. 2018), yeasts (Jadav et al. 2007; Jafaria et al. 2014), actinomycetes (Eun-Hee et al. 2005; Sathish and Joshua 2015) and bacteria (Gopinath et al. 2009; Saratale et al. 2011; Prasad and Aikat 2014; Abo-state et al. 2017; Kuppusamy et al. 2017) are effective to decolorize CR from aqueous solutions. Among them, bacterial decolorization is faster than other microorganisms (Saratale et al. 2011). Generally, single bacterial strain cannot achieve satisfactory removal of CR from wastewater due to the low substrate spectrum, adaptability and low enzyme activity (Gopinath et al. 2009). Furthermore, biodegraded metabolites of CR by free-living planktonic single bacterial strain were often found to be carcinogenic, mutagenic and genotoxic in nature due to the presence of aromatic amines (Joshi et al. 2008; Gopinath et al. 2009). Conversely, biodegraded metabolites of CR by planktonic bacterial consortia are almost non-toxic than the parent dye (Joshi et al. 2008; Asad et al. 2007; Lade et al. 2015a). In a bacterial consortium, the individual bacterial strain was shown to attack the dye molecule at different positions or utilized metabolites produced by the co-existing strain for further decomposition (Forgacs et al. 2004; Saratale et al. 2011). Thus, the degradation rate of a bacterial consortium is usually higher than that of a single bacterial strain. However, information regarding the uses of bacterial consortia to degrade and detoxify the CR is very limited in the literature (Asad et al. 2007; Joshi et al. 2008; Saratale et al. 2011; Abo-State et al. 2017). Free-living planktonic bacterial consortia are reportedly susceptible to toxic environments due to decreased protection and low metabolic activity combined with low bioavailability of the pollutants (McDougald et al. 2012; Koechler et al. 2015). Thus, more studies are required to find out bacterial consortia capable of degrading CR into less toxic metabolites even under toxic environments.

Biofilms are highly organized surface-associated microbial cells, encased in self-produced extracellular polymeric substances (EPS). EPS comprises curli fimbriae, cellulose-rich polysaccharides and lipids (McDougald et al. 2012; Haque et al. 2017; Mosharaf et al., 2018). It was reported that bacteria associated with biofilms are resistant to environmental stressors, including high concentration of toxic chemicals (including heavy metals and dyes), pH, temperature and salinity as compared to their planktonic counterparts (Haque et al. 2012, 2017; McDougald et al. 2012; Koechler et al. 2015). Despite these advantages, the significance of enabling bacterial biofilms to enhance detoxification has just recently been appreciated and applied (Edwards and Kjellerup 2013). Recently, we isolated metal-adapted biofilm-producing bacteria, such as Escherichia coli ENSD101, Enterobacter asburiae ENSD102, E. ludwigii ENSH201, Vitreoscilla sp. ENSG301, Acinetobacter lwoffii ENSG302, Klebsiella pneumoniae ENSG303, Pseudomonas fluorescens ENSG304 and Bacillus thuringiensis ENSW401 from different wastewaters of Bangladesh (Mosharaf et al. 2018). In this study, we developed four biofilm consortia using these bacterial strains. The assumption is that these consortia might degrade and detoxify the CR completely. The variation of operational and physicochemical parameters, such as carbon and nitrogen sources, temperature, pH, dye concentration, agitation and incubation period, plays a vital role in the decolorization of azo dyes in bioremediation processes (Gopinath et al. 2009; Saratale et al. 2011; Prasad and Aikat 2014). Therefore, we studied the effect of these important physicochemical operational parameters on decolorization of CR in bioremediation processes. Various oxidoreductive enzymes have been shown to synthesize by different bacteria to degrade azo dyes (Saratale et al. 2011; Telke et al. 2015; Sarkar et al. 2017; Bhatia et al. 2017). Among them, azoreductase and laccase are the principal enzymes in degradation of CR (Imran et al. 2014; Lade et al. 2015a, b). Hence, we also quantified the production of azoreductase and laccase by different biofilm consortia. The biodegraded metabolites of CR were analyzed by UV–Vis spectrophotometer and Fourier-transform infrared (FTIR) spectroscopy. This study will contribute toward understanding the mechanism of decolorization of CR by bacterial biofilm consortia. To our knowledge, this is the first report, so far, on degradation and detoxification of CR by bacterial biofilm consortia under various nutritional and environmental conditions.

Materials and methods

Dyes and chemicals

Congo red (CR), Methyl red, 2, 2′-azono-bis (3-ethylbenzothiazoline-6-sulfonic acid) (ABTS), nicotinamide adenine dinucleotide (NADH) were obtained from Sigma-Aldrich (St. Louis, MO, USA). All other chemicals used were of an analytical grade and were purchased from Wako Pure Chemical Industries, LTD (Japan), Bio Basic Canada Inc. (Canada) and HiMedia (Mumbai, India).

Bacterial strains and growth conditions

Escherichia coli ENSD101, Enterobacter asburiae ENSD102, E. ludwigii ENSH201, Vitreoscilla sp. ENSG301, Acinetobacter lwoffii ENSG302, Klebsiella pneumoniae ENSG303, Pseudomonas fluorescens ENSG304 and Bacillus thuringiensis ENSW401 used in this study were collected from our laboratory stock. All these bacterial strains were reported to produce biofilms in the SOBG broth at 28 °C in static condition (Mosharaf et al. 2018). These strains were routinely grown in yeast extract peptone (YP) medium at 28 °C. The optical density (OD at 660 nm) of the culture was measured by an absorption spectrophotometer (Intertech, Inc. Tokyo, Japan).

Compatibility tests

Compatibility tests were carried out as described in Furuya et al. (1997) with a few modifications. In brief, a single colony of each producer bacterium was spotted onto YP agar plate then incubated at 28 °C in static condition for 36 h. To kill the producer bacterium, a sheet of sterilized Whatman™ filter paper containing 0.5 mL chloroform was placed in Petri dish lid, then incubated at room temperature (25 ± 2 °C). After 2 h incubation, producer bacteria were covered with 5 mL melted water agar (1.5% at 50 °C) containing a suspension of indicator bacterium [ca. 108 cfu (colony forming unit)/mL] and incubated at 28 °C for 48 h. If no inhibition zone was observed around producer bacteria, then these bacteria were considered as compatible.

Preparation of consortia

Initially, a single colony of each compatible bacterium was inoculated in 50 mL Erlenmeyer flask containing 10 mL YP broth and incubated at 28 °C in shaking (160 rpm) condition until optical density (OD660) reached at 1.0. Then, each culture was centrifuged at 10,000 rpm for 10 min. After discarding the supernatant, the cell pellet was re-suspended in 10 mL salt-optimized broth [(SOB) per liter, 20 g of tryptone, 5 g of yeast extract, 0.5 g of NaCl, 2.4 g of MgSO4, 0.186 g of KCl plus 2% glycerol (SOBG)]. Each consortium (10 mL, ca. 108 CFU/mL) was prepared using equal volume of compatible bacterial suspension (ca. 108 CFU/mL). Based on compatibility tests, four consortia were prepared as follows: C1 composed of Vitreoscilla sp. ENSG301, A. lwoffii ENSG302, K. pneumoniae ENSG303 and P. fluorescens ENSG304, C2 consisted of E. coli ENSD101, E. asburiae ENSD102 and E. ludwigii ENSH201, C3 contained E. asburiae ENSD102, Vitreoscilla sp. ENSG301 and B. thuringiensis ENSW401, and C4 comprised E. coli ENSD101, E. ludwigii ENSH201 and B. thuringiensis ENSW401. All these consortia were used for the decolorization of CR.

Decolorization and process optimization studies

For decolorization experiment, 10 mL culture (ca. 108 CFU/mL) of each consortium was inoculated in 250 mL Erlenmeyer flasks containing 90 mL broth with 100 mg/L CR. The flasks were then kept at 28 °C in stationary condition. Within 72 h, 3 mL suspension was collected and centrifuged at 14,000 rpm for 15 min. The resultant supernatant was carefully collected in fresh test tubes. Decolorization was checked by measuring the change in absorbance of cultured supernatants at the maximum absorption wavelength (λmax) of 478 nm in UV–Vis spectrophotometer (Ultrospec-3000, Pharmacia Biotech, Cambridge, England). Abiotic control was also included. The decolorization efficiency was calculated as described (Prasad and Aikat 2014).

CR decolorization in different nutritional conditions [nutritional strength (e.g., full strength SOB plus 2% glycerol, ½ strength SOB plus 2% glycerol and ¼ strength SOB plus 2% glycerol), carbon sources (glycerol and glucose) and nitrogen sources (tryptone and yeast extract)], incubation conditions (shaking and static), CR concentrations (50, 100, 150 and 200 mg/L), temperatures (20, 28, 37 and 42ºC), pH (5, 6, 7, 8 and 9), and incubation periods (24, 48, 72, 96, 120, 144 and 168 h) were also studied.

Quantification of oxidoreductive enzyme produced by different biofilm consortia

Each biofilm consortium (10 mL) was inoculated in ¼ strength SOB containing 2% glycerol and 100 mg/L CR then incubated at 28 °C in static condition. Within 72 h incubation, each biofilm culture was collected, then centrifuged at 14,000 rpm for 15 min at 4 °C. For extracellular enzyme production, the supernatant was carefully collected and assessed. For intracellular enzyme production, the cell pellet was re-suspended in sterile deionized water, then broken down the cells using ultrasonic cell disrupter (Ultrasonic Disrupter UD-200, Tommy, Tokyo, Japan). After sonication, the suspension was centrifuged at 14,000 rpm for 5 min at 4 °C and supernatant was collected. Production of extracellular and intracellular laccase (an oxidative enzyme) and azoreductase (a reductive enzyme) by different biofilm consortia were measured using UV–Vis spectrophotometer (Ultrospec-3000, Pharmacia Biotech, Cambridge, England). Laccase specific activity was measured as described in Welfenden et al. (1982) by monitoring the increase in optical density at 420 nm. On the other hand, azoreductase specific activity was determined by monitoring the reduction in concentration of Methyl Red at 430 nm (Chen et al. 2005). Lowry method (Lowry et al. 1951) was used to determine protein with bovine serum albumin as standard.

Analysis of biodegraded metabolite by UV–Vis spectrophotometer

Biodegraded metabolite from each biofilm consortium was prepared as follows: each biofilm consortium was inoculated in ¼ strength SOB containing 2% glycerol and 100 mg/L CR, then incubated at 28 °C in static condition. Within 72 h incubation, 1.5 mL broth of each consortium was collected, then centrifuged at 13,000 rpm for 20 min. The pellets were discarded. The supernatant was carefully collected and again filtered through Einmalfilter [CHROMAFIL® Xtra PTFE-45/25, 0.45 µM (Macherey–Nagel, GmbH and Co. KG, Germany)]. Each biodegraded metabolite was analyzed using UV–Vis spectrophotometer (Ultrospec-3000, Pharmacia Biotech, Cambridge, England) within 350 to 700 nm wavelength. For control, ¼ strength SOB containing 2% glycerol and 100 mg/L CR was used.

Fourier-transform infrared (FTIR) spectroscopy

The biodegraded metabolite was prepared as described earlier section. Perkin Elmer FTIR (Spectrum-2) instrument operated by CPU32M software was used to acquire the IR spectra. Triglycine sulphate (TGS) detector was applied for FTIR scanning within 450 to 4000 cm−1 (16 scans at 4 cm−1 at 0.2 cm/sec scanning speed). The ¼ strength SOBG without CR was also scanned. Perkin Elmer’s proprietary software (Version 10.05.03) was used to analyze the baseline subtracted spectra.

Toxicity tests

Removal of COD

For COD removal studies, biodegraded metabolite by each biofilm consortium was prepared as mentioned in earlier section. The COD removal by each biofilm consortium was determined by the dichromate closed reflux titrimetric method (APHA 2012) using the following equation:

Seed germination tests

For phytotoxicity tests, wheat (Triticum aestivum L.) seeds were collected from Bangladesh Wheat and Maize Research Institute, Bangladesh. Seeds were surface-sterilized with 1% sodium hypochlorite for 3 min, then rinsed 3–4 times with sterile distilled water. Three sterilized Whatman™ filter papers were soaked in cell-free biodegraded metabolite and placed in Petri plates. Then 20 seeds were placed in each plate. A total of 200 seeds were tested in each case. The seeded plates were kept at 20 °C and checked regularly. To maintain moisture content, adequate amount of biodegraded metabolites or 1/4 strength SOBG containing 100 mg/L CR was added every alternate day. At day 8, germinated seeds were counted and compared.

Bacterial growth inhibition tests

Two plant-growth-promoting rhizobacterial strains, including Pseudomonas chlororaphis ESR15 and Bacillus aryabhattai ESB6 used in this study were collected from our laboratory stock. For growth, a single colony of each bacterial strain was inoculated in glass test tubes containing 5 mL cell-free biodegraded metabolite containing 2% glycerol then incubated at 28 °C in shaking (160 rpm) condition. For control experiment, each strain was inoculated in 5 mL SOBG broth. Bacterial growth (OD660) was measured by spectrophotometer after 24 h incubation.

Statistical analysis

All the experiments were laid out in a complete randomized design with three replications and repeated at least twice. The “agricolae” of R software version 3.3.3 was used to calculate analysis of variance and comparison of means. The means were compared using Fisher’s least significance difference (LSD) test.

Results and discussion

Nutritional conditions on CR decolorization

All the bacterial strains used in the preparation of consortia were reported to produce biofilms on SOBG broth after 72 h incubation at 28ºC in static condition (Mosharaf et al. 2018). In this study, all these biofilm consortia i.e., C1, C2, C3 and C4 were also formed the air–liquid (AL) biofilms on full strength SOB (data not shown), ½ strength SOB (data not shown) and ¼ strength SOB containing 2% glycerol plus 100 mg/L CR (Fig. 1a) during biodegradation process. The clear biodegraded solutions were found after discarding the bacterial cells from the broths (Fig. 1b). In static condition, the rate of decolorization within 72 h incubation varied from 98.06 to 99.48%, 98.02 to 98.41% and 96.91 to 97.71% in full strength SOB, ½ strength SOB and ¼ strength SOB containing 2% glycerol, respectively (Fig. 2a). Decolorization percentage was found to be only slightly lessened in ¼ strength SOB containing 2% glycerol than the full strength SOB supplemented with 2% glycerol in static condition (Fig. 2a). Compared to static condition, CR removal by these consortia was decreased by 21.95–34.08%, 25.96–38.33% and 25.66–44.99% in full strength SOB, ½ strength SOB and ¼ strength SOB containing 2% glycerol, respectively, in agitated condition (Fig. 2a). Lade et al. (2015a) observed that only 14% CR was removed by the microbial consortia composed of eight bacterial strains in aerobic (120 rpm) condition, while 99% CR removal was achieved in microaerophilic condition. Removal of Reactive blue 160 (a diazo dye) was also sturdily inhibited by oxygen-rich conditions (remove only 24% after 4 h) than under microaerophilic (remove 90% after 4 h) conditions (Balapure et al. 2014). Furthermore, Babu et al. (2015) reported a vividly increased decolorization (93.10%) of CR by Dietzia sp. DTS26 in static condition compared to the shaking condition (28.56%) within 30 h. Availability of molecular oxygen strongly hindered azo dye removal (Chang et al. 2001), due to competition of NADH with oxygen or azo groups as the electron receptor leading to shrink dye removal (Chung et al. 1992).

Decolorization of CR by different biofilm consortia within 72 h incubation at 28 °C in static condition. a All these consortia formed the air–liquid biofilms on the flasks containing 100 mL 1/4 strength SOB plus 2% glycerol along with 100 mg/L CR as shown by arrows. b Decolorized biodegraded metabolites of CR by different biofilm consortia along with non-biodegraded sample (red color) (color figure online)

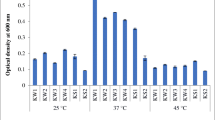

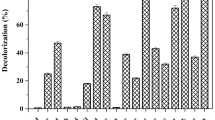

Nutritional and environmental conditions on decolorization of CR by different biofilm consortia: a nutritional strength, b carbon sources (2% glycerol/glucose), c nitrogen sources (tryptone/yeast extract), d concentrations of CR (50 to 200 mg/L), e temperature, and f pH. The 1/4 strength SOB plus 2% glycerol was used for all the experiments and incubated in static conditions (except nutritional strength) at 28 °C (except for the effect of temperatures). The 1/4 strength SOB plus 2% glycerol was supplemented with 100 mg/L CR (except for the concentrations studies). The pH of the broth was always adjusted to 7.0 (except for the effect of pH). Data represent averages from triplicate assays and error bars showing standard deviation

To examine the role of carbon source on CR removal in static condition, 2% glycerol was replaced by 2% glucose. The similar results were found within 72 h incubation period (Fig. 2b). However, when 2% glycerol was excluded from the 1/4 strength SOB containing 2% glycerol, decolorization percentage in C1, C2, C3 and C4 was reduced by 63.6, 63.9, 56.2 and 59.5% as compared to 1/4 strength SOB containing 2% glycerol (Fig. 2b). The similar results were also observed when 2% glucose was discarded from 1/4 strength SOB containing 2% glucose (Fig. 2b). Thus, a carbon source is required for the enhancement of the rate of the decolorization of CR. It was stated that reducing equivalents from various carbon sources are transferred to the dye during decolorization of azo dyes via reduction of azo bonds (Saratale et al. 2011). Conversely, Saratale et al. (2009a) remarked that carbon sources only stimulated the microbial growth but not decolorize the azo dyes. In this study, we found that 2% glycerol stimulated the microbial growth (Fig. 1a), thus, enhanced the rate of decolorization of CR (Fig. 2a).

To evaluate the effect of nitrogen sources on CR decolorization, we excluded tryptone and/or yeast extract or both from 1/4 SOB plus 2% glycerol. Bacterial growth (data not shown) and decolorization rate were harshly abridged by exclusion of tryptone and/or yeast extract or both (Fig. 2c). It was reported that peptone, tryptone, beef extract and yeast extract played a pivotal role in generation of NADH, which has been shown to act as an electron donor for the reduction of azo dyes by microorganisms (Chang et al. 2000).

Effect of concentrations of CR on decolorization

To order to quantify the impact of different concentrations of CR (50–200 mg/L) on decolorization, a time-course experiment was carried out (Fig. 2d). The decolorization increased significantly as the time increased and reached maximum within 72 h incubation in static condition responding to the concentrations of CR. Conversely, CR removal was notably decreased as the concentrations increased. The C4 consortium displayed the highest decolorization (98.91%) which was identical with C1 (98.75%), C2 (97.95%) and C3 (98.23%) responding to 50 mg/L CR. Interestingly, CR removal efficiencies by these biofilm consortia were found to be alike in the concentrations of 50 and 100 mg/L CR. On the other hand, CR removal was reduced only 16% and 26% in response to 150 and 200 mg/L, respectively, as compared to 100 mg/L of CR within 72 h incubation period (Fig. 2d). However, bacterial growth rate was indistinguishable in these concentrations (50–200 mg/L) of CR (data not shown). Generally, textile wastewater contains 10–200 mg/L of structurally different dyes (Pandey et al. 2007). It was reported that increasing the dye concentration gradually decreased the decolorization rate due to inadequate cell biomass, ratio of cell biomass and dye, toxic effect of the dyes and obstruction of active sites of azoreductase by dye molecules with different structures (Jadhav et al. 2008; Saratale et al. 2009b). However, this toxic effect was reported to be compromised using bacterial co-culture than pure culture (Lade et al. 2015a; Bhatia et al. 2017; Saratale et al. 2009a).

Temperature on CR decolorization

Figure 2e depicts that different biofilm consortia are able to remove the CR (100 mg/L) over a wide range of temperatures (20–40 °C). However, the growth rate of different biofilm consortia was considerably reduced at 40 °C but not at temperature tested (data not shown). At 28 °C, a maximum of 97.23% color removal was recorded followed by 93.83% (37 °C), 91.76% (20 °C) and 74.6% (40 °C) within 72 h incubation. Similarly, decolorization rates were reported to be only marginally affected when incubated at lower and higher temperatures than the optimum (Lade et al. 2015b). However, several researchers stated that incubation at high temperatures markedly reduced both microbial growth and enzymatic activities leading to poorer dye decolorization (Saratale et al. 2011; Phugare et al. 2011; Selvakumar et al. 2013).

pH on CR decolorization

The effect of different pHs on decolorization of CR dye (100 mg/L) is shown in Fig. 2f. At pH 8, the maximum CR removal (97.45%) was achieved followed by pH 7 (97.23%), pH 6 (96.89%), pH 9 (94.89%) and pH 5 (90.91%) within 72 h incubation at 28 °C in static conditions. The results suggested that all these biofilm consortia are able to decolorize CR in acidic to alkaline conditions. The maximum decolorization (90.81%) of CR by Dietzia sp. DTS26 was reported at pH 8 within 30 h (Chang et al. 2001). Maximum color removal was stated to accomplish at pH 6–10 (Chen et al. 2003; Kilic et al. 2007). The pH was shown to play an important role in transportation of dye molecules across the cell membrane (Kodam et al. 2005) and biological reduction of azo bonds (Willmott 1997). Dye removal rate was reported to increase 2.5-fold when pH raised to 7 from 5, however, increment of pH from 7 to 9 seemed to be less effective (Chung et al. 1992). According to another report, a microbial consortium composed of 15 different bacteria was proficient in decolorization of Trypan blue, a diazo dye, at pH 7.0, while a slight decrease was reported at pH 6.0, however, the increase of pH 8.5 did not have significant on dye removal (Lade et al. 2015b). Textile effluents generally possess the alkaline pH (Kuhad et al. 2004). Thus, all these biofilm consortia used in this study might be applied to treat the dye-containing wastewater with variable pH ranges.

Mechanism of biodegradation

Production of oxidoreductive enzymes by different biofilm consortia

We measured the specific activity of azoreductase and laccase enzyme produced by different biofilm consortia (Table 1). There were no significant variations found amongst the extracellular and intracellular specific activities of azoreductase and laccase enzymes synthesized by these biofilm consortia (Table 1). However, as presented in Table 1, both the enzymes showed significantly higher intracellular specific activities than those of extracellular ones (Table 1). As reported in the literatures, azoreductase enzyme plays an active role in the reductive cleavage of azo bonds (Lade et al. 2015a; Olukanni et al. 2013), while laccase enzyme was reported to oxidize the secondary metabolites formed after decolorization (Imran et al. 2014; Olukanni et al. 2013; Telke et al. 2009). Thus, combined action of azoreductase and laccase enzyme might be the responsible for the decolorization and degradation of CR.

UV–Vis spectral analysis

The extent of decolorization of CR by different biofilm consortia was measured by the UV–Vis spectrophotometer (350–700 nm) and the observations are presented in Fig. 3. The untreated CR erected the major peak was found in 478 nm wavelength. However, this peak was completely disappeared when the dye solutions were treated by different biofilm consortia within 72 h incubation at 28 °C. The disappearance of peak suggests the success of CR decolorization using the studied microbial consortia (Chen et al. 2003).

FTIR analysis

FTIR analysis was carried out to explain the possible changes of functional groups during decolorization of CR. The shifting or alteration of the structural bonds indicated in the FTIR analyses confirmed the ability of the bacterial biofilm consortia to degrade CR (Fig. 4). The standard CR diluted in 1/4 strength SOB containing 2% glycerol produced several characteristic peaks near to 925.83 cm−1, 995.05 cm−1, 1042.82 cm−1, 1112 cm−1, 1226 cm−1, 1368 cm−1, 1406.95 cm−1, 1575 cm−1, 1630 cm−1, 1673.43 cm−1, 1706.43 cm−1, 2845.32 cm−1, and 2945.52 cm−1 (Fig. 4a) which are the documented IR peak regions for CR (Olukanni et al. 2013; Prasad and Aikat 2014; Lade et al. 2015a). The peak at 1042.82 cm−1 of the CR represents stretching vibration of S = O, 1226 cm−1 for C–N stretching vibrations, 1368 cm−1 for C–N bending vibrations, 1575 cm−1 for N = N stretching vibrations, while the peak at 2945.52 cm−1 is produced from the symmetric stretching (C–H). In this study, we observed that the principal characteristic peaks are completely or partly disappeared, deformed or widened. However, degradation of CR by different bacterial biofilm consortia might vary. The cleavage of azo bond was confirmed by the absence of peak at 1575 cm−1 for N = N stretching vibrations in the FTIR spectra (Fig. 4a–d) of biodegraded CR samples. Telke et al. (2010) reported that the absence of peak at 1578 cm−1 corresponds to N = N stretching vibrations in the FTIR spectrum for degraded metabolites of CR. Absence of N = N indicates the cleavage of azo bond by the different biofilm consortia. Our UV–Vis and FTIR results suggested that secondary metabolites are generated after degradation of CR by different biofilm-producing consortia. Gas chromatography-mass spectrometry (GC–MS) and High-performance liquid chromatography (HPLC) are also used for the determination of secondary metabolites of azo dyes formed after bacterial treatment. Based on GC–MS and HPLC, 4-amino-3-diazenylnaphthalene-1-sulfonate and phenylbenzene were identified as the secondary metabolites of CR degraded by B. thuringiensis (Olukanni et al., 2013). On the other hand, Lade et al. (2015b) have found biphenyl-1,4´-diamine, biphenyl and naphthalene are the secondary metabolites of CR degraded by a microbial consortium. Thus, secondary metabolites of CR might vary in response to different bacterial strains or consortia. Thus, future studies should focus on identifying the secondary metabolites of CR degraded by bacterial biofilm consortia.

Detoxification studies

COD removal

To confirm mineralization, we compared COD removal before and after treatment (72 h incubation at 28 °C in static conditions) by different biofilm consortia (Table 2). The decolorized CR solutions by C1, C2, C3 and C4 consortia showed 86.4, 85.5, 87.0 and 86.2% reduction of COD, respectively. The enhanced reduction of COD indicates the efficient biodegradation of the CR dye. Dietzia sp. was found to reduce COD by 86.4% within 30 h at 100 mg/L of CR dye (Babu et al. 2015).

Biodegraded metabolites are non-toxic

Germination percentage varied from 87.5 to 93.8% when biodegraded metabolites used as irrigation water, while 73.6% germination was noted in control (i.e., ¼ SOBG containing 2% glycerol plus 100 mg/L CR used as irrigation water) (Table 3). Toxicity tests were also done using plant-growth-promoting rhizobacteria because of their agricultural importance. In this study, growth rate of P. chlororaphis ESR15 and B. aryabhattai ESB6 were indistinguishable in biodegraded metabolites and SOBG broth after 24 h incubation in shaking condition (Table 3). After that, bacterial treatment of extract of degraded metabolites was also reported to less toxic than the parental compound (Saratele et al. 2011; Babu et al. 2015). These results indicated that biodegraded metabolites are non-toxic. Thus, all these biofilm consortia can be used to degrade and detoxify the CR from wastewater.

Conclusion

In this study, we developed four novel bacterial biofilm consortia. All these biofilm consortia remarkably decolorized the CR (100 mg/L) in static condition within 72 h incubation at 28 °C. These consortia synthesized significantly more intracellular azoreductase and laccase enzyme than those of extracellular of these enzymes. UV–Vis spectral analysis revealed that the major peak at 478 nm wavelength of CR was completely disappeared. FTIR analysis showed several major peaks are completely or partly disappeared, deformed or widened. Toxicity tests revealed that biodegraded metabolites of CR are non-toxic. Thus, these biofilm consortia can be applied in bioremediation of CR from wastewater for safe disposal into environment.

References

Abo-State MAM, Saleh YE, Hazaa HA (2017) Decolorization of Congo red dye by bacterial isolates. J Eco Heal Env 5(2):41–48. https://doi.org/10.12785/jehe/050201

Ahmad A, Mohd-Setapar SH, Chuong CS, Khatoon A, Wani WA, Kumar R, Rafatullah M (2015) Recent advances in new generation dye removal technologies: novel search for approaches to reprocess wastewater. RSC Adv 5(39):30801–30818. https://doi.org/10.1039/c4ra16959j

Anjaneyulu Y, Chary NS, Raj SSD (2005) Decolorization of industrial effluents-available methods and emerging technologies-a review. Rev Environ Sci Biotech 4(4):245–273. https://doi.org/10.1007/s11157-005-1246-z

APHA (2012) Standard methods for the examination of water and wastewater, 20th edn. American public Health Association, Washington, DC, USA

Asad S, Amoozegar MA, Pourbabaee AA, Sarbolouki MN, Dastgheib SM (2007) Decolorization of textile dyes by newly isolated halophilic and halotolerant bacteria. Bioresour Technol 98(11):2082–2088. https://doi.org/10.1016/j.biortech.2006.08.020

Asses N, Ayed L, Hkiri N, Hamdi M (2018) Congo red decolorization and detoxification by Aspergillus niger: removal mechanisms and dye degradation pathway. BioMed Res Int. https://doi.org/10.1155/2018/3049686

Ayati A, Shahrak MN, Tanhaei B, Sillanpaa M (2016) Emerging adsorptive removal of azo dye by metal-organic frameworks. Chemosphere 160:30–44. https://doi.org/10.1016/j.chemosphere.2016.06.065

Babu SS, Mohandass C, Vijayaraj AS, Dhale MA (2015) Detoxification and color removal of Congo red by a novel Dietzia sp. (DTS26) - A microcosm approach. Ecotoxicol Environ Safety 114:52–60. https://doi.org/10.1016/j.ecoenv.2015.01.002

Balapure K, Bhatt N, Madamwar D (2014) Mineralization of reactive azo dyes present in stimulated textile wastewater using down flow microaerophilic fixed film bioreactor. Bioresour Technol 175:1–7. https://doi.org/10.1016/j.biortech.2014.10.040

Bhatia D, Sharma NR, Singh J, Kanwar RS (2017) Biological methods for textile dye removal wastewater: a review. Crit Rev Environ Sci Technol 47(19):1836–1876. https://doi.org/10.1080/10643389.2017.1393263

Bhattacharya S, Das A, Mangai G, Vignesh K, Sangeetha J (2011) Mycoremediation of Congo red by filamentous fungi. Brazilian J Microbiol 42(4):1526–1536. https://doi.org/10.1590/S1517-83822011000400040

Chakraborty S, Basak B, Dutta S, Bhunia B, Dey A (2013) Decolorization and biodegradation of Congo red dye by a novel white rot fungus Alternaria alternata CMERI F6. Bioresour Technol 147:662–666. https://doi.org/10.1016/j.biortech.2013.08.117

Chang JS, Chou C, Lin Y, Ho J, Hu TL (2001) Kinetic characteristics of bacterial azo dye decolorization by Pseudomonas lutola. Water Res 35(12):2041–2050. https://doi.org/10.1016/S0043-1354(00)00581-9

Chang JS, Kuo TS, Chao YP, Ho JY, Lin PJ (2000) Azo dye decolorization with a mutant Escherichia coli strain. Biotechnol Lett 22:807–812. https://doi.org/10.1023/A:1005624707777

Chen H, Hopper SL, Cerniglia CE (2005) Biochemical and molecular characterization of an azoreductase from Staphylococcus aereus, a tetrameric NADPH-dependent flavoprotein. Microbiol 151(5):1433–1441. https://doi.org/10.1099/mic.0.27805-0

Chen KC, Wu JY, Liou DJ, Hwang SCJ (2003) Decolorization of the textile dyes by newly isolated bacterial strains. J Biotechnol 101(1):57–68. https://doi.org/10.1016/S0168-1656(02)00303-6

Chengalroyen MD, Dabbs ER (2013) The microbial degradation of azo dyes: minireview. World J Microbiol Biotechnol 29(3):389–399. https://doi.org/10.1007/s11274-012-1198-8

Chung KT, Stevens SEJ, Cerniglia CE (1992) The reduction of azo dyes by the intestinal microflora. Crit Rev Microbiol 18(3):175–197. https://doi.org/10.3109/10408419209114557

Edwards SJ, Kjellerup BK (2013) Application of biofilms in bioremediation and biotransformation of persistent organic pollutants, pharmaceuticals/personal care products, and heavy metals. Appl Microbiol Biotechnol 97:9909–9921. https://doi.org/10.1007/s00253-013-5216-z

Forgacs E, Cserhati T, Oros G (2004) Removal of synthetic dyes from wastewater: a review. Environ Intl 30(7):953–971. https://doi.org/10.1016/j.envint.2004.02.001

Furuya N, Yamasaki S, Nishioka M, Shirasshi I, Ityama K, Matsuyama N (1997) Antibacterial activities of pseudomonads against plantpathogenic organisms and efficacy of Pseudomonas aeruginosa ATCC7700 against bacterial wilt of tomato. Ann Phytopathol Soc Jpn 63(6):417–424. https://doi.org/10.3186/jjphytopath.63.417

Ghodake G, Jadhav S, Dawkar V, Govindar SP (2009) Biodegrdation of diazo dye direct brown MR by Acinetobacter calcoaceticus NCIM 2890. Int Biodeter Biodegr 63(4):433–439. https://doi.org/10.1016/j.ibiod.2008.12.002

Gopinath KP, Murugenesan S, Abraham J, Muthukumar K (2009) Bacillus sp. mutant for improved biodegradation of Congo red: random mutagenesis approach. Bioresour Technol 100(24):6295–6300. https://doi.org/10.1016/j.biortech.2009.07.043

Haque MM, Oliver MMH, Nahar K, Alam MZ, Hirata H, Tsuyumu S (2017) CytR homolog of Pectobacterium carotovorum subsp. carotovorum controls air-liquid biofilm formation by regulating multiple genes involved in cellulose production, c-di-GMP signaling, motility, and type III secretion system in response to nutritional and environmental signals. Front Microbiol 8:972. https://doi.org/10.3389/fmicb.2017.00972

Haque MM, Hirata H, Tsuyumu S (2012) Role of PhoP-PhoQ two-component system in pellicle formation, virulence and survival in harsh environments of Dickeya dadantii 3937. J Gen Plant Pathol 78(3):176–189. https://doi.org/10.1007/s10327-012-0372-z

He H, Chen Y, Li X, Cheng Y, Yang C, Zeng G (2017) Influence of salinity on microorganisms in activated sludge processes: a review. Int Biodeter Biodegr 119:520–527. https://doi.org/10.1016/j.ibiod.2016.10.007

Huang X, Bo X, Zhao Y, Gao B, Wang Y, Sun S, Yue Q, Li Q (2014) Effects of compound bioflocculant on coagulation performance and floc properties for dye removal. Bioresour Technol 165:116–121. https://doi.org/10.1016/j.biortech.2014.02.125

Imran M, Crowley DE, Khalid A, Hussain S, Mumtaz MW, Arshad M (2014) Microbial biotechnology for decolorization of textile wastewaters. Rev Environ Sci Biotechnol 14(1):73–92. https://doi.org/10.1007/s11157-014-9344-4

Jadav JP, Parshetti GK, Kalme SD, Govindwar SP (2007) Decolorization of dye Methyl red by Saccharomyces cerevisiae MTCC463. Chemosphere 68(2):394–400. https://doi.org/10.1016/j.chemosphere.2006.12.087

Jadhav SU, Jadhav MU, Kagalkar AN, Govindwar SP (2008) Decolorization of Brilliant Blue G dye mediated by degradation of the microbial consortium of Galactomyces geotrichum and Bacillus sp. J Chin Inst Chem Eng 39(6):563–570. https://doi.org/10.1016/j.jcice.2008.06.003

Jafaria N, Soudib MR, Kermanshahi RK (2014) Biodegradation perspectives of azo dyes by yeasts. Microbiol 83:484–497. https://doi.org/10.1134/S0026261714050130

Joshi T, Iyengar L, Singh K, Garg S (2008) Isolation, identification and application of novel bacterial consortium TJ-1 for decolorization of structurally different azo dyes. Bioresour Technol 99(15):7115–7121. https://doi.org/10.1016/j.biortech.2007.12.074

Kilic NK, Nielsen JL, Yuce M, Donmez G (2007) Characterization of a simple bacterial consortium for effective treatment of wastewaters with reactive dyes and Cr(VI). Chemosphere 67(4):826–831. https://doi.org/10.1016/j.chemosphere.2006.08.041

Kodam KM, Soojhawon I, Lokhande PD, Gawal KR (2005) Microbial decolorization of reactive azo dyes under aerobic conditions. World J Microbial Biotechnol 21:367–370. https://doi.org/10.1007/s11274-004-5957-z

Koechler S, Farasin J, Cleiss-Arnold J, Arséne-Ploetze F (2015) Toxic metal resistance in biofilms diversity of microbial responses and their evolution. Res Microbiol 166(10):764–773. https://doi.org/10.1016/j.resmic.2015.03.008

Kuhad RC, Sood N, Tripathi KK, Singh A, Ward OP (2004) Developments in microbial methods for the treatment of dye effluents. Adv Appl Microbiol 56:185–213. https://doi.org/10.1016/S0065-2164(04)56006-9

Kuppusamy S, Sethurajan M, Kadaekarai M, Aruliah R (2017) Biodecolourization of textile dyes by novel, indigenous Pseudomonas stutzeri MN1 and Acinetrobacter baumannii MN3. J Environ Chem Engineer 5:716–724. https://doi.org/10.1016/j.jece.2016.12.021

Kumar A, Sharma SK, Sharma G, Al-Muhtaseb AAH, Naushad M, Ghfar AA, Stadler FJ (2019) Wide spectral degradation of Norfloxacin by Ag@BiPO4/BiOBr/BiFeO3 nano-assembly: elucidating the photocatalytic mechanism under different light sources. J Hazard Mat 364:429–440. https://doi.org/10.1016/j.jhazmat.2018.10.060

Lade H, Govindwar S, Paul D (2015a) Mineralization and detoxification of the carcinogenic azo dye Congo red and real textile effluent by a polyurethane foam immobilized microbial consortium in an upflow column bioreactor. Int J Environ Res Public Health 12(6):6894–6918. https://doi.org/10.3390/ijerph120606894

Lade H, Kadam A, Paul D, Govindwar SP (2015b) A low-cost wheat bran medium for biodegradation of the benzidine-based carcinogenic dye Trypan blue using a microbial consortium. Int J Environ Res Public Health 12(4):3480–3505. https://doi.org/10.3390/ijerph120403480

Lee YC, Jang MS, Cho YS, Cha IH, Choi YL, Kim CH (2005) Decolorization of a sulfonated azo dye, Congo Red, by Staphylococcus sp EY-3. J Microbiol Biotechnol 15(1):221–225

Lowry OH, Rosebrough NJ, Farr AL, Randall RJ (1951) Protein measurement with the Folin phenol reagent. J Biol Chem 193:265–275

McDougald D, Rice SA, Barraud N, Steinberg PD, Kjelleberg S (2012) Should we stay or should we go: mechanisms and ecological consequences for biofilm dispersal. Nat Rev Microbiol 10:39–50. https://doi.org/10.1038/nrmicro2695

Mosharaf MK, Tanvir MZH, Haque MM, Haque MA, Khan MAA, Molla AH, Alam MZ, Islam MS, Talukder MR (2018) Metal-adapted bacteria isolated from wastewaters produce biofilms by expressing proteinaceous curli fimbriae and cellulose nanofibers. Front Microbiol 9:1334. https://doi.org/10.3389/fmicb.2018.01334

Olukanni OD, Osuntoki AA, Awotula AO, Kalyani DC, Gbenle GO, Govindwar SP (2013) Decolorization of dyehouse effluent and biodegradation of Congo red by Bacillus thuringiensis RUN1. J Microbiol Biotechnol 23(6):843–849. https://doi.org/10.4014/jmb.1211.11077

Pandey A, Singh P, Iyengar L (2007) Bacterial decolorization and degradation of azo dyes. Int Biodeter Biodegr 59(2):73–84. https://doi.org/10.1016/j.ibiod.2006.08.006

Phugare SS, Kalyani DC, Surwase SN, Jadhav JP (2011) Eco-friendly degradation, decolorization and detoxification of textile effluent by a developed bacterial consortium. Ecotoxicol Environ Safe 74(5):1288–1296. https://doi.org/10.1016/j.ecoenv.2011.03.003

Prasad SS, Aikat K (2014) Study of bio-degradation and bio-decolorization of azo dye by Enterobacter sp. SXCR Environ Technol 35(8):956–965. https://doi.org/10.1080/09593330.2013.856957

Rai H, Bhattacharya M, Singh J, Bansal TK, Vats P, Banerjee UC (2005) Removal of dyes from the effluent of textile and dyestuff manufacturing industry: A Review of emerging techniques with reference to biological treatment. Crit Rev Environ Sci Technol 35(3):219–238. https://doi.org/10.1080/10643380590917932

Robinson T, McMullan G, Marchant R, Nigam P (2001) Remediation of dyes in textile effluent: a critical review on current treatment technologies with a proposed alternative. Bioresour Technol 77(3):247–255. https://doi.org/10.1016/S0960-8524(00)00080-8

Saratale RG, Saratale GD, Chang JS, Govindwar SP (2011) Bacterial decolorization and degradation of azo dyes: a review. J Taiwan Inst Chem Engineer 42(1):138–157. https://doi.org/10.1016/j.jtice.2010.06.006

Saratale RG, Saratale GD, Chang JS, Govindwar SP (2009a) Eco-friendly decolorization and degradation of sulfonated diazo dye C.I. Reactive Green 19A using Micrococcus glutamicus NCIM-2168. Bioresour Technol 110(17):3897–3905. https://doi.org/10.1016/j.biortech.2009.03.051

Saratale RG, Saratale GD, Kalyani DC, Chang JS, Govindwar SP (2009b) Enhanced decolorization and biodegradation of textile azo dye Scarlet R by using developed microbial consortium-GR. Bioresour Technol 100(9):2493–2500. https://doi.org/10.1016/j.biortech.2008.12.013

Sarim KM, Kukreja K, Shah I, Choudhary CK (2019) Biosorption of direct textile dye Congo red by Bacillus subtilis HAU-KK01. Bioremediation J 23(3):185–195. https://doi.org/10.1080/10889868.2019.1641466

Sarkar S, Banerjee A, Halder U, Biswas R, Bandopadhyay R (2017) Degradation of synthetic azo dyes of textile industry: a sustainable approach using microbial enzymes. Water Conserv Sci Eng 2:121–131. https://doi.org/10.1007/s41101-017-0031-5

Sathish S, Joshua A (2015) Study on decolorization of dye stuff (azo dye–Congo red) by using bacterial consortia. Int J Pharm Pharm Sci 7:143–146

Sathishkumar K, Alsalhi MS, Sanganyado E, Devanesan S, Arulprakash A, Rajasekar A (2019) Sequential electrochemical oxidation and bio-treatment of the azo dye congo red and textile effluent. J Photochem Photobiol B Biol 200:111655. https://doi.org/10.1016/j.jphotobiol.2019.111655

Selvakumar S, Manivasagan R, Chinnappan K (2013) Biodegradation and decolourization of textile dye wastewater using Ganoderma lucidum. 3 Biotech. 3:71–79. https://doi.org/10.1007/s13205-012-0073-5

Telke AA, Kadam A, Govindwar SP (2015) Bacterial enzymes and their role in decolorization of azo dyes. In: Singh SN (ed.) Microbial degradation of synthetic dyes in wastewater, Environmental Science and Engineering, Springer, Cham, Switzerland, pp 149–168 https://doi.org/10.1007/978-3-319-10942-8_7

Telke AA, Joshi SM, Jadhav SU, Tamboli DP, Govindwar SP (2010) Decolorization and detoxification of Congo red and textile industry effluent by an isolated bacterium Pseudomonas sp. SU-EBT Biodegrad 21(2):283–296. https://doi.org/10.1007/s10532-009-9300-0

Telke AA, Kalyani DC, Dawkar VV, Govindwar SP (2009) Influence of organic and inorganic compounds on oxidoreductive decolorization of sulfonated azo dye C. I. Reactive orange 16. J Hazard Mater 172(1):298–309. https://doi.org/10.1016/j.jhazmat.2009.07.008

Vikrant K, Giria BS, Razab N, Roya K, Kimd KH, Raia BN, Singha RS (2018) Recent advancements in bioremediation of dye: Current status and challenges. Bioresour Technol 253:355–367. https://doi.org/10.1016/j.biortech.2018.01.029

Wang N, Chu Y, Wu F, Zhao Z, Xu X (2017) Decolorization and degradation of Congo red by a newly isolated white rot fungus, Ceriporia lacerata from decayed mulberry branches. Int Biodeter Biodegr 117:236–244. https://doi.org/10.1016/j.ibiod.2016.12.015

Willmott NJ (1997) The use of bacteria polymer composites for the removal of color from reactive dye effluents. PhD thesis, University of Leeds, UK

Wolfenden BS, Willson RL (1982) Radical-cations as reference chromogens in kinetic studies of ono-electron transfer reactions: pulse radiolysis studies of 2,2ʹ-azinobis-(3-ethylbenzthiazoline-6 sulphonate). J Chem Soc Perkin Trans 2(7):805–812. https://doi.org/10.1039/P29820000805

Acknowledgements

This research is funded by the Ministry of Education (Project ID: LS2018751) and Ministry of Science and Technology of Bangladesh. No funds received form any organizations for the publication.

Author information

Authors and Affiliations

Contributions

MMH conceived the idea, developed all the methodologies, conducted several experiments, wrote the MS and collected the research fund. MAH helped in planning the research, conducted the FTIR spectroscopy and edited the MS. MKM conducted the compatibility tests. PKM conducted the CR decolorization assays. All the authors read the MS.

Corresponding author

Ethics declarations

Conflicts of interest

The authors declare that the research was conducted in the absence of any commercial or financial relationships that could be construed as a potential conflict of interest.

Additional information

Communicated by Erko stackebrandt.

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Haque, M.M., Haque, M.A., Mosharaf, M.K. et al. Novel bacterial biofilm consortia that degrade and detoxify the carcinogenic diazo dye Congo red. Arch Microbiol 203, 643–654 (2021). https://doi.org/10.1007/s00203-020-02044-1

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00203-020-02044-1