Abstract

Smart manufacturing systems combine sensor systems and manufacturing processes, and they have been widely adopted in the industry to solve real production problems, help manufacturing enterprises achieve rapid decision-making, and improve manufacturing value. However, manufacturing enterprises still face huge challenges with the coexistence of continuously changing dynamic demands, collaborative scheduling of dynamic resources, precise matching of manufacturing resources, and multiple resource constraints. To address this challenge, this research combines digital twin (DT) technology to propose a smart site-selection system with dynamic resource-accurate matching characteristics based on the attributes and associations of both resource sides, supply and demand sides, and site-selection sides, which can integrate and optimize resources according to the requirements of manufacturing tasks. In addition, by establishing the discovery mechanism of bottleneck processes and resource allocation methods, generating configuration priorities, and thus reducing the solution space for resource allocation, the precise allocation of limited resources is achieved more quickly and easily, and the scheduling chaos in the parallel scheduling of multiple resources is solved and the multi-objective robust optimization model is solved by combining smart optimization algorithms. Combined with the example analysis, the results show that the smart site-selection system and multi-resource cyclic allocation mechanism proposed in this paper can collaboratively match a large amount of dynamic resources, and the utilization rate of idle manufacturing resources can be increased by 60%. This research effectively realizes the optimal allocation of multiple manufacturing resources in a resource-constrained environment and helps manufacturing enterprises create more manufacturing value.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

1 Introduction

With the development of digital network and the wide application of sensors in industry, the manufacturing industry has entered the digital era. Meanwhile, the manufacturing industry is facing challenges from the complex market environment and the rational allocation and utilization of resources in the manufacturing process. In this context, more and more manufacturing strategies are proposed by scholars, such as Industry 4.0 and IoT technologies. These strategies have the common aim of achieving smart manufacturing [1]. Smart manufacturing (SM) integrates the next generation of information manufacturing technologies and integrates them throughout the product lifecycle. Active manufacturing technologies can respond in real time to complex and diverse situations in manufacturing. Germany, the USA, and other advanced manufacturing countries have been developing technologies to achieve smart manufacturing in various fields in the past few years. A key application of smart manufacturing is to help enterprises achieve prediction and modeling, a process that requires effective visualization of products for analysis and the sharing of various data across the product lifecycle [2]. The digital network combines effective data computation output with the physical implementation of the data [3]. Computational tools can be used to predict future states and failures, thus generating better service and control solutions. Smart manufacturing can start with digital twin technology. Digital twin refers to the organic whole of physical assets and their digital representation communicating, facilitating, and co-evolving with each other through two-way interaction. DT digitizes entities and relationships in the physical world as a whole through various digital technologies, together with sensor data collection, big data analytics, and machine learning. DT can be used for monitoring, diagnosis, prediction, and optimization. Essentially, DT involves creating virtual models of physical entities in digital form to simulate entity behavior, monitor ongoing states, identify internal and external complexity, detect anomalous models, react to system performance, and predict future trends [4]. Essentially, DT involves creating virtual models of physical entities in digital form, monitoring ongoing states, and detecting anomalous models, ultimately reacting to system performance and predicting future trends. With the rising market demand, the development of DT shows new trends. For example, the application of DT has been gradually expanded from the initial military and aerospace fields to the civil field in recent years [5]. The international mainstream digital twin vendors and solutions are shown in Table 1.

The rational allocation of manufacturing resources mainly lies in the realization of cross-organizational coordination among enterprises, which will have certain requirements in terms of timely data sharing and response speed in the face of an unexpected market environment. There are still some challenges in the manufacturing resource allocation problem, and most of the previous manufacturing resource allocation is limited to the integration of resources within enterprises. However, with the development of digital networks, enterprises are more frequently connected, and interoperability of manufacturing resources in a cooperative manner already exists among some enterprises to enhance the overall manufacturing value among enterprises. Wang et al. modeled the corresponding services based on the digital twin to achieve resource allocation [6]. Wu et al. established a better resource allocation scheme for the resource allocation planning problem combined with a Bayesian approach [7]. Lee et al. proposed a smart data management resource allocation system designed to provide efficient and timely decisions for resource allocation; the complex system consists of product materials, people, information, control, and support functions to ensure production efficiency [8]. Chu et al. combined fuzzy integrated evaluation method to achieve optimal allocation of manufacturing resources including process planners, cutting tools, and manufacturing processes for aircraft construction [9]. Luo et al. combined a data-driven modeling and simulation approach to ultimately achieve dynamic manufacturing resource allocation [10]. Lee et al. proposed a resource allocation system, which combines fuzzy logic concepts to achieve better resource allocation [11].

In the manufacturing process, according to the demand of manufacturing tasks, a large number of manufacturing services with similar functional characteristics will be generated. The complexity and diversity of manufacturing resources also increase the difficulty of resource allocation in manufacturing enterprises. Cao et al. proposed a method for selection of resource services based on the degree of dominance of intuitionistic fuzzy values, and discussed the performance and advantages of the method [12]. Wang et al. developed a smart resource allocation model using genetic algorithms to reduce the late delivery rate of orders, communicating the allocation of resources to each order through a fuzzy inference module [13]. Guo et al. used fuzzy averaging algorithm to determine the priority of multiple objectives for the optimization problem of manufacturing resource combination in group production [14]. Lee et al. proposed a smart data management-induced resource allocation system consisting of product material, people, information, control, and support functions to ensure productivity [8]. Chen et al. designed a fuzzy Markov model to evaluate the reliability of manufacturing systems, in response to the problem that the performance of manufacturing systems in enterprises can hardly meet the manufacturing needs of enterprises [15]. Xu et al. proposed a fuzzy two-level planning model to better achieve a rational allocation of manufacturing resources after considering customer uncertainty and supplier’s interest and analyzing the manufacturing resource allocation process [16].

Based on the previous research on the application of digital twin technology in enterprise co-production and the existing research on co-production, we found that there are still some shortcomings. First, the current digital factory research faces problems such as independent data and information, difficulty in establishing complex resource scheduling models between enterprises, and applications that cannot be managed autonomously [17]. In addition, in terms of digital twin applications, the existing digital twin technology mainly focuses on the development and exploration of the corresponding concepts, but there is a lack of research on the in-depth integration of digital twin and collaborative manufacturing process, and there is not enough research on the production site selection process of manufacturing enterprises. In terms of collaborative manufacturing, it is difficult for manufacturing enterprises to develop and utilize big data with the help of digital twin technology, and there is a lack of research on the reasonable use of shared resources and the design of transfer schemes in the site selection process. In addition, there is usually a problem of reasonable allocation of multiple manufacturing resources (e.g., labor, equipment, raw materials, information systems) in the site selection process, and it is difficult for manufacturing enterprises to reasonably allocate limited manufacturing resources to new production sites. Based on the analysis of the above problems, we propose a smart collaborative manufacturing system based on digital twin to help manufacturing enterprises realize the rational scheduling of multiple resources present in the site selection process and generate the corresponding production plans. The main contributions made in the article are as follows:

-

This paper proposes a smart collaborative manufacturing system based on digital twin technology to help manufacturing enterprises to analyze big data accurately and make reasonable site selection, resource allocation, and production planning plans with the help of sensors.

-

This paper establishes a funnel model for analyzing the resource constraint environment by analyzing the attributes of both resource sides, supply and demand sides, and site selection sides and their correlation with each other, and integrates and optimizes the existing manufacturing resources by allocating the order tasks.

-

By establishing the manufacturing resources needed for the bottleneck process, the optimal matching of resources is precisely realized, reducing the solution space and achieving the precise allocation quickly and easily.

-

Different from the traditional resource allocation, facing the problem of difficult to quantify indicators in the process of collaborative scheduling of multiple manufacturing resources (the proficiency of workers’ operation, the depreciation of equipment, the adaptation matching of information system, etc.), this paper realizes the parallel scheduling decision of multiple resources based on the arithmetical intuitionistic fuzzy generalized \(\lambda -\) Shapley Choquet (\(AIFGS{C}_{g\lambda }\)) operator, which solves the chaotic problem of parallel scheduling of resources in the scheduling process; for the quantifiable capacity enhancement problem, a multi-objective robust optimization model is established and solved using a population intelligence algorithm.

The structure of the article is as follows: Section 2 is an introduction to the collaborative siting model based on dynamic resource scheduling, which includes as follows: the application of digital twin technology in smart collaborative manufacturing in combination, the manufacturing environment under multiple resource constraints, the funnel model based on digital twin technology, and the introduction to the cyclic allocation system of manufacturing resources. Section 3 is an introduction to the multi-resource scheduling model based on \(AIFGS{C}_{g\lambda }\) operator, which includes an introduction to the relevant fuzzy theory and its application in a multi-resource constrained environment. Section 4 is an introduction to the construction of a multi-objective collaborative optimization model for the site selection process of manufacturing enterprises. Section 5 is an example analysis. Section 6 draws conclusions of the article and proposes future research directions.

2 DT-assisted collaborative site selection model based on dynamic resource scheduling

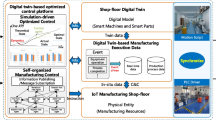

In the limited resource environment, collaborative manufacturing enterprises are faced with capacity constraints of bottleneck processes, and some manufacturing enterprises need to add new sites to face the increasing market demand, while in this process, manufacturing enterprises also face the problem of insufficient manufacturing capacity to regulate manufacturing resources. This study combines a funnel model to analyze the resource requirements of critical processes and solves the problem of collaborative scheduling of multiple manufacturing resources by constructing a multi-objective siting model for collaborative manufacturing enterprises in a manufacturing environment with multiple resource constraints. In this process, compared with the traditional equipment scheduling problem, we combine digital twin technology to realize resource information sharing among collaborative manufacturing enterprises, and establish the optimal resource scheduling solution, site selection solution, and corresponding production solution by simulating the scheduling results of multiple resource scheduling solutions by computer. The principle of the smart collaborative manufacturing system based on the collaborative manufacturing enterprise site selection process species is shown in Fig. 1.

Firstly, the manufacturing resource provider combines sensors and other monitoring devices to store and upload various types of manufacturing resource information (such as the wear and tear level and working status of equipment resources, the proficiency level of talent resources, and the data analysis function of information systems) to the shared platform. In addition, the data at the end of the market will also be collected and stored in real time through computers and other market terminal devices, and then uploaded to the shared platform after sorting. The main role of the digital twin system lies in two aspects. On the one hand, the digital twin system combines data information to classify various manufacturing resources and establishes bottleneck processes according to the funnel model to clarify various manufacturing resource information required in this production cycle. On the other hand, the digital twin system can simulate the scheduling process of various manufacturing resources in the manufacturing network and construct a complex manufacturing resource analysis model and a multi-objective robust optimization function. Combined with the swarm intelligence algorithm, the digital twin system establishes the optimal benefits under different scheduling conditions and uploads the results to the sharing platform. Finally, the manufacturing resource demand side makes decisions on various scheduling situations and results based on its own needs. The manufacturing enterprise realizes the scheduling of various manufacturing resources according to the final scheduling decision scheme and produces according to the production plan. In the production process of manufacturing enterprises, it is necessary to combine all kinds of monitoring equipment to make real-time statistics, store all kinds of data information, and upload them to the sharing platform for other manufacturing enterprises to realize manufacturing resource scheduling decision in the next cycle. In the process of site selection, manufacturing enterprises often face the problem of insufficient capacity at the new site, which mainly involves the following aspects:

-

New site locations tend to create bottleneck processes that limit further capacity increases.

-

Manufacturing enterprises themselves contain a limited number of manufacturing resources that make it difficult to provide better production services to new manufacturing sites.

-

The variety and sources of manufacturing resources within the platform make it difficult to achieve optimal decision-making.

-

After the scheduling of multiple manufacturing resources is realized, the value of resources is still difficult to best match the actual required manufacturing value, which easily causes the problem of wasting manufacturing resources.

-

Different locations face different manufacturing costs, and it is difficult to calculate the best production planning plan and scheduling plan of manufacturing resources.

2.1 Multi-resource constrained manufacturing environment

In the manufacturing process, manufacturing enterprises often face difficulties in increasing production capacity, which is partly caused by some bottleneck processes resulting in limited capacity. In addition to bottleneck process limitations, manufacturing enterprises are faced with a variety of manufacturing resources limited manufacturing environment. The common manufacturing resources are mainly raw material resources, human resources, and equipment resources. In the environment of big data analytics, enterprises need to use suitable data analytics systems to assist production. As a result, manufacturing enterprises face the manufacturing situation of collaborative scheduling of multiple manufacturing resources. The specific multiple manufacturing resource-constrained environment and its scheduling process are shown in the following figure (Fig. 2):

The corresponding model with basic parameters is constructed as follows: Assume that a distributed manufacturing network contains a total of \(J\) wholesalers. There are \(I\) subsidiaries in the manufacturing enterprise \({M}_{t}\), and the number of scheduling available equipment is \(A\). The following definitions are made: the nodes are represented by \(T, I, K, J, P\), where \(\{\mathrm{1,2},...,T\}\in T\), \(\{\mathrm{1,2},...,I\}\in I\), \(\{\mathrm{1,2},...,K\}\in K\), \(\{\mathrm{1,2},...,J\}\in J\), and \(\{\mathrm{1,2},...,P\}\in P\) are the set of \({M}_{t}\), \({C}_{i}\), \({W}_{k}\), \({D}_{J}\), and \({R}_{P}\) nodes of the manufacturing enterprise, subsidiary enterprise, repository, wholesaler, and retailer. \(\{\mathrm{1,2},...,M\}\in M\) is the set of products. \({C}_{ij}^{tm\alpha }, {C}_{ij}^{tm\beta }, \mathrm{and }\;{C}_{ij}^{tm\lambda }\) represent the labor cost, material cost, and other cost, respectively. \({V}_{ij}^{tm}\) is the sales price. \({C}_{ijd}^{tm}\) represents the unit product transportation price of the unit product. \(D\) represents the set of transportation modes, \(d\in D\). The arrival of goods received is \({Q}_{ijn}^{tm}={Q}_{ij}^{tm}*(1-{e}_{ijd}^{tm})\). The wholesaler’s order quantity is \({Q}_{ji}^{tm}\). \({Q}_{pj}^{tm}\) represents the predicted demand. \({Q}_{kmax}^{tm}\) represents the maximum storage capacity. \({Q}_{kn}^{tm}\) denotes the existing warehouse reserves, and \({Q}_{kn}^{tm}\in [0,{Q}_{kmax}^{tm}]\). \({Q}_{jkn}^{tm}\) represents the actual cargo arrival, and \({Q}_{jkn}^{tm}={Q}_{jk}^{tm}(1-{e}_{jkd}^{tm})\), where \({Q}_{jk}^{tm}\) and \({e}_{jkd}^{tm}\) represent the cargo volume and path wear rate respectively. \({Q}_{ki}^{tm}\) represents the amount of goods that the warehouse \({W}_{k}\) returns the remaining goods of product \(m\) to the subsidiary \({C}_{i}\) of the manufacturing enterprise \({M}_{t}\) for reprocessing. \({Q}_{ijr}^{tm}\) and \({Q}_{ijf}^{tm}\) represent the reprocessing cargo volume of the subsidiary \({C}_{i}\) of the manufacturing enterprise \({M}_{t}\) and the cargo volume processed by the production line. \({T}_{ijr}^{tm}\) and \({T}_{ijf}^{tm}\) respectively represent the time required for the unit product reprocessing of product \(m\) and the time required for the production line processing. \({T}_{ai{i}{\prime}}^{tm}\) represents the sum of transportation and equipment adjustment time required for equipment to be transported from subsidiary \({C}_{i}\) to subsidiary \({C}_{{i}{\prime}}\). \({T}_{ijd}^{tm}\) denotes the unit product transportation time.

In this resource-constrained environment, manufacturing enterprises usually find it difficult to cope with the complex market environment and their own capacity load. Therefore, when faced with the problem of increasing market demand and building new sites, most manufacturing enterprises choose to increase their production capacity by scheduling their own equipment or purchasing new equipment, but at the same time, this will mean increasing the production cost of manufacturing enterprises, so the process of scheduling manufacturing resources among collaborative manufacturing enterprises means increasing the value of manufacturing resources. Conventional manufacturing resource scheduling mainly contains equipment resources, human resources, etc. The matching of information system will also enhance the manufacturing capability of manufacturing enterprises to a certain extent. The process of scheduling equipment resources usually implies the improvement of production capacity to better match the market demand. Compared with equipment resources, the proper allocation of human resources and information system will mean the improvement of equipment monitoring capability, fault prediction capability and the reduction of product defect rate in manufacturing process. For equipment resources, the inter-enterprise equipment scheduling process can be reasonably calculated through a formula to increase capacity, but at the same time, equipment depreciation, wear and tear, and model issues should also be taken into account. After idle equipment scheduling between manufacturing companies, the current manufacturing capacity of manufacturing enterprise \({M}_{t}\) for product \(m\) is:

where: \(C{O}_{i}^{tm}\) denotes the manufacturing capacity of subsidiary \({C}_{i}\). \({Q}_{ki}^{tm}\) denotes the existing storage capacity of warehouse \({W}_{k}\) corresponding to subsidiary \({C}_{i}\). When the manufacturing enterprise faces the problem of insufficient capacity in the process of site selection, it needs to achieve capacity growth through the scheduling of equipment resources. After scheduling, the capacity of subsidiary \({C}_{i}\) is:

where \(C{{O}{\prime}}_{i}^{tm}\) denotes the manufacturing capacity of subsidiary \({C}_{i}\) after equipment resource scheduling. \({x}_{a{i}{\prime}i}^{{t}{\prime}m}\) denotes the decision variable that determines whether equipment \(a\) of subsidiary \({C}_{{i}{\prime}}\) within manufacturing company \({M}_{{t}{\prime}}\) needs to be scheduled, and if scheduling is performed \({x}_{a{i}{\prime}i}^{{t}{\prime}m}\)=1, then the device needs to be scheduled. When \({x}_{a{i}{\prime}i}^{{t}{\prime}m}=0\), the equipment does not need to be dispatched. \(\Delta C{O}_{a{i}{\prime}i}^{{t}{\prime}m}\) indicates the calculated amount of capacity improvement regarding product \(m\) after dispatching equipment \(a\) of subsidiary \({C}_{{i}{\prime}}\) within manufacturing company \({M}_{{t}{\prime}}\) to subsidiary \({C}_{i}\) within manufacturing company \({M}_{{t}{\prime}}\). Correspondingly, the new manufacturing capacity of manufacturing enterprise \({M}_{{t}{\prime}}\) with respect to product \(m\) after the equipment resources are dispatched is:

After the scheduling of equipment resources, the common costs are mainly divided into: scheduling costs of equipment resources, production costs, transportation costs, and site selection costs. Correspondingly, the profit of manufacturing enterprise \({M}_{t}\) is:

where \({C}_{{i}^{{\prime}{\prime}}}^{tm}\) is denoted as the plant construction cost of the additional plant site \({C}_{{i}^{{\prime}{\prime}}}\) for manufacturing company \({M}_{t}\).

Manufacturing enterprises often face a variety of uncertain factors in the manufacturing process, such as changes in market demand [18], uncertainty in enterprise output [19], and unstable performance of manufacturing resources after scheduling. Under the influence of various uncertain factors, it is difficult for manufacturing enterprises to achieve the best production plan for production. Therefore, in order to alleviate the negative impact of uncertainties, we establish the corresponding robust optimization formula according to [20]. The corresponding robust optimization formulation is established as follows:

where \({Q}_{ki}^{\alpha tm*}\) represents the optimal output of the manufacturing system. \(g\left({Q}_{ki}^{\alpha tm*},\Delta C{O}_{a{i}^{\mathrm{^{\prime}}}i}^{\alpha {t}^{\mathrm{^{\prime}}}m}\right)\le 0\) represents the relevant equality and inequality constraints in actual production.

Therefore, there is the basic multi-objective robust site selection optimization model as:

2.2 DT-based funnel model

The digital twin system achieves dynamic simulation of the production process by constructing the entire production scenario and modeling it in the production process. Taking Tencent’s “Transparent Factory” project as an example, the digital twin technology can realize automatic collection and integration of production, process, monitoring, quality, cost and other data, and then complete 3D dynamic modeling to realize data visualization [21]. There are many uncertain factors in modern manufacturing processes, which will lead to frequent transfer of bottleneck processes. Manufacturing enterprises make production planning and control decisions based on dynamic bottleneck processes to cope with the occurrence of uncertain factors [22]. The common response methods for bottleneck processes are usually to maintain the normal operation of the bottleneck process. In order to prevent equipment failures in other processes, a certain reserve is usually set in advance to ensure the continuous operation of the bottleneck process [23]. However, this approach still limits the output of manufacturing enterprises. Based on the funnel model proposed by Ma et al. based on the critical process identification process [24], we made corresponding improvements to identify the corresponding bottlenecks in the process as shown in Fig. 3.

The bottleneck process is identified by identifying the input and output volumes of the critical process, and the existing manufacturing resources are combined to increase the throughput of the bottleneck process until it becomes a non-bottleneck process, and then the next bottleneck process is found. After the next bottleneck is identified, the process of mobilizing existing manufacturing resources is repeated to help increase the overall throughput of the manufacturing system until the remaining manufacturing resources cannot be allocated to any of the processes. The corresponding manufacturing resource cycle allocation process is shown in Fig. 4.

The circular allocation of manufacturing resources designed for bottleneck processes can allocate the maximum amount of available idle resources to the required processes. The inflow of each process during the process flow is equal to the output of the previous process, so there is:

where \({Q}_{{\text{Output}}}^{timrl}\) and \({Q}_{{\text{Input}}}^{timr(l+1)}\) denote the output and inflow of the parallel processes in step \(l\) and \((l+1)\) of the process of producing product \(m\) by subsidiary \({C}_{i}\) in manufacturing company \({M}_{t}\), respectively. The actual processing volume of the process in the production process is limited by the output volume of the previous process, and since the processing volume of some processes does not reach the maximum processing volume of the process, so there is:

where \({Q}_{{\text{Actual}}}^{timrl}\) and \({Q}_{{\text{Process}}}^{timrl}\) indicate that the actual processing volume of the process at step \(l\) in the process of producing product \(m\) in subsidiary \({C}_{i}\) within manufacturing enterprise \({M}_{t}\) should be no more than the theoretical processing volume, respectively. It is the limitation of the upstream bottleneck process that causes the processing volume of the downstream process not to reach the theoretical processing volume, so there is:

where \({\Delta }_{{\text{Actual}}}^{timrl}\) denotes the processing volume difference of the process at step \(l\) in the process of producing product \(m\) by subsidiary \({C}_{i}\) within manufacturing enterprise \({M}_{t}\). In a process, flow process is usually accompanied by the emergence of multiple poorly processed processes; the most critical bottleneck processes should be identified and resourced in a timely manner to achieve an increase in capacity, so there are:

If \({\Delta }_{{\text{Actual}}}^{timrl}=0\), the process is saturated and in good processing condition. \({\Delta }_{{\text{Actual}}}^{timrl}>0\) indicates that the process is not saturated and its processing capacity can be enhanced by means of resource allocation. Thus, we propose \(\underset{r}{{\text{argmin}}}\left\{{\Delta }_{{\text{Actual}}}^{timrl}\right\}\) to establish the critical bottleneck process among the poorly processed processes to achieve a collaborative scheduling process of multiple manufacturing resources. After the implementation of manufacturing resource allocation, the digital twin system will continue to combine real-time data information feedback from the manufacturing process. Among them, the cyclic configuration system will achieve further bottleneck process inspection. The digital twin system, combined with bottleneck processes, continues to simulate the manufacturing resource scheduling process until manufacturing resources within the manufacturing network cannot continue to improve the processing capacity of bottleneck processes.

3 Multi-resource scheduling model based on \({\varvec{A}}{\varvec{I}}{\varvec{F}}{\varvec{G}}{\varvec{S}}{{\varvec{C}}}_{{\varvec{g}}{\varvec{\lambda}}}\) operator

In a multi-resource scheduling model, it is difficult to measure the manufacturing value of different resources in the form of data, e.g., it is difficult to directly visualize the productivity gains from human resources for decision-makers. Faced with the bottleneck process problem in a resource-constrained environment, it is necessary to combine the most effective types of resources to get rid of the dilemma of difficult production capacity increase. In order to facilitate the decision-making process of multi-resource scheduling for decision-makers, this paper combines digital twin technology to realize the interoperability of resource information; through the transfer of information data and the combination of \(AIFGS{C}_{g\lambda }\) operator to help decision-makers realize the decision-making of multi-resource scheduling in the existing distributed network, and then select several better strategies to build a multi-objective model to finally obtain the most accurate multi-resource scheduling solution and production solution. In this paper, we use Shapley method to solve a related problem, which is used to measure the average of individual elements’ contributions to all alliances in a coalition. Shapley value is a mathematical method to solve a multi-person cooperative response problem. It mainly focuses on the application of the distribution of cooperative benefits among the cooperating parties. The Shapley value achieves the magnitude of each cooperative member’s contribution to that cooperative alliance, highlighting the importance of each member in the cooperation. The greatest advantage of the Shapley value method is that its principles and results are easily perceived as fair by each cooperating party and the results are easily accepted by all parties. In addition, the Shapley function is one of the most important indicators in cooperative games, which satisfies the well-known axioms of validity, symmetry, and additivity. Because of these three axioms, many scholars believe that it is the most powerful tool for solving things with interconnected indicators [25]. With the above advantages of \(AIFGS{C}_{g\lambda }\) operator, the collaborative scheduling model of multiple resources in the process of collaborative manufacturing enterprise site selection is constructed to solve the problem of confusion in the scheduling process of multiple manufacturing resources and to realize the scheduling decision process of multiple manufacturing resources more quickly and easily. This paper mainly introduces and defines Choquet integral, \(AIFGS{C}_{g\lambda }\) operator and multi-attribute group decision-making method based on λ-Shapley Choquet integral.

3.1 Relevant definitions of Choquet integral

Definition 1

[26]: Let \(X\) be a non-empty set, \(A=\left\{\left.\langle x,{t}_{A}\left(x\right),{f}_{A}\left(x\right)\rangle \right|x\in X\right\}\) is called an intuitionistic fuzzy set (IFSs), where \({t}_{A}\left(x\right),{f}_{A}\left(x\right)\in \left[\mathrm{0,1}\right]\), \({t}_{A}\left(x\right)\), and \({f}_{A}\left(x\right)\) are the membership and non-membership degree of the element \(x\) in \(X\) belonging to \(X\), and satisfy the condition \({t}_{A}\left(x\right)+{f}_{A}\left(x\right)\le 1\). In addition, \({\pi }_{A}\left(x\right)=1-{t}_{A}\left(x\right)-{f}_{A}\left(x\right)\) is defined to represent the hesitation degree of the element \(x\) in the intuitionistic fuzzy set \(X\) belonging to \(X\). In particular, when \({\pi }_{A}\left(x\right)=0\), the intuitionistic fuzzy set \(X\) degenerates into the traditional fuzzy set [27].

Definition 2

Let \({\widetilde{\alpha }}_{i}=\left({t}_{{\widetilde{\alpha }}_{i}},{f}_{{\widetilde{\alpha }}_{i}},{\pi }_{{\widetilde{\alpha }}_{i}}\right)\left(i=\mathrm{1,2}\right)\) be two sets of intuitionistic fuzzy numbers, \(\lambda >0\), have:

Definition 3

Let \(S\) be a finite set. \(P\left(S\right)\) denotes the power set of \(S\). If \(\mu :P(S)\to [\mathrm{0,1}]\) satisfies the following conditions, then \(\mu\) is called a fuzzy measure defined on \(\left(S,P(S)\right)\).

-

(1)

\(\mu \left(\varnothing \right)=0,\mu \left(S\right)=1\);

-

(2)

\(A,B\in P(S),A\subseteq B\Rightarrow \mu \left(A\right)\le \mu \left(B\right)\).

For the convenience of calculation, suppose that \({g}_{\lambda }(C\cup D)={g}_{\lambda }(C)+{g}_{\lambda }(D)+\lambda {g}_{\lambda }(C){g}_{\lambda }(D)\), where \(\lambda \in (-1,+\infty )\), for any \(C,D\in P(S),C\cap D=\varnothing\), then \(g\) is called the fuzzy measure of \(\lambda\), denoted by \({g}_{\lambda }\). For a finite set \(S\), \({g}_{\lambda }\) satisfies the following conditions:

Since \(\mu \left(S\right)= \text{1}\), there is:

Therefore, when each \({g}_{\lambda }(i)\) is given, the value \(\lambda\) can be calculated by this equation.

Definition 4

If \(f\) is a nonnegative real function defined on \(S\) and \(\mu\) is a fuzzy measure defined on \(S\), then the discrete Choquet integral is:

At the same time, some scholars defined the intuitionistic fuzzy correlation averaging operator [28]:

where \({\widetilde{\gamma }}_{\left(i\right)}=\left({t}_{{\widetilde{\gamma }}_{\left(i\right)}},{f}_{{\widetilde{\gamma }}_{\left(i\right)}},{\pi }_{{\widetilde{\gamma }}_{\left(i\right)}}\right)\left(i=\mathrm{1,2},...,n\right)\) is a set of intuitionistic fuzzy numbers, \(\left(i\right)\) denotes a permutation of \({\gamma }_{i}\) such that \({\widetilde{\gamma }}_{\left(1\right)}\le {\widetilde{\gamma }}_{\left(2\right)}\le ...\le {\widetilde{\gamma }}_{\left(n\right)},{A}_{\left(i\right)}=\left\{\mathrm{1,2},...,n\right\},{A}_{\left(n+1\right)}=\varnothing\).

For decision-making problems, the fuzzy measure of experts and the fuzzy measure of attribute values are subjectively determined by experts, which will also produce corresponding contingency. The Shapley function can solve related problems. Marichal proposed the generalized Shapley value [29]. Meng et al. applied it to the decision environment [26], and the related expressions are as follows:

In Eq. 21, \(\mu\) is a fuzzy measure on \(S\). In order to consider the fuzzy measure of the set of experts and attributes as a whole, Meng et al. proposed a generalized Shapley Choquet integral fuzzy measure[27], which is expressed as follows:

Equation 22 reflects not only each expert, a single attribute value and between experts, but also the overall average fuzzy measure between attribute values. Therefore, when Shapley value is used to deal with fuzzy measure, it can make the fuzzy measure closer to the actual situation.

3.2 Intuitionistic fuzzy\({\varvec{A}}{\varvec{I}}{\varvec{F}}{\varvec{G}}{\varvec{S}}{{\varvec{C}}}_{{\varvec{g}}{\varvec{\lambda}}}\)operator

Definition 5

[26]: Let the intuitionistic fuzzy set \({\widetilde{\alpha }}_{i}=\left({t}_{{\widetilde{\alpha }}_{i}},{f}_{{\widetilde{\alpha }}_{i}},{\pi }_{{\widetilde{\alpha }}_{i}}\right)\left(i=\mathrm{1,2},...,n\right)\) be a set of intuitionistic fuzzy numbers, \({g}_{\lambda }\) be a fuzzy measure on \(S\), let \(AIFGS{C}_{g\lambda }:{\Omega }^{n}\to \Omega\), if:

where \(\left(i\right)\) denotes a permutation of \({\alpha }_{i}\) such that \({\widetilde{\alpha }}_{\left(1\right)}\le {\widetilde{\alpha }}_{\left(2\right)}\le ...\le {\widetilde{\alpha }}_{\left(n\right)},{A}_{\left(i\right)}=\left\{\mathrm{1,2},...,n\right\},{A}_{\left(n+1\right)}=\varnothing\). Then the function \(AIFGS{C}_{g\lambda }\) is called the generalized \(\lambda\)-Shapley Choquet integral operator of \(n\)-dimensional intuitionistic fuzzy arithmetic.

Theorem 1

[26]: Let the intuitionistic fuzzy set \({\widetilde{\alpha }}_{i}=\left({t}_{{\widetilde{\alpha }}_{i}},{f}_{{\widetilde{\alpha }}_{i}},{\pi }_{{\widetilde{\alpha }}_{i}}\right)i=\mathrm{1,2},...,n\) be a set of intuitionistic fuzzy numbers, and \({g}_{\lambda }\) be a fuzzy measure on \(S\), then:

3.3 λ-Shapley Choquet integral TOPSIS multi-attribute group decision-making method

Definition 6

Let \({\widetilde{\alpha }}_{i}=\left({t}_{{\widetilde{\alpha }}_{i}},{f}_{{\widetilde{\alpha }}_{i}},{\pi }_{{\widetilde{\alpha }}_{i}}\right),{\widetilde{\alpha }}_{i}^{\prime}=\left({t}_{{\widetilde{\delta }}_{i}^{\prime}},{f}_{{\widetilde{\delta }}_{i}^{\prime}},{\pi }_{{\widetilde{\delta }}_{i}{\prime}}\right)\left(i=\mathrm{1,2},...,n\right)\) be any two intuitionistic fuzzy numbers, \({g}_{\lambda }\) is a fuzzy measure on \(S\), then the Hamming distance between them is defined as:

In Eq. 25, \(d\left(\widetilde{\alpha },{\widetilde{\alpha }}_{1}^{\prime}\right)=\left|{t}_{{\widetilde{\alpha }}_{i}}-{t}_{{\widetilde{\delta }}_{i}}^{\prime}\right|+\left|{f}_{{\widetilde{\alpha }}_{i}}-{f}_{{\widetilde{\delta }}_{i}}^{\prime}\right|+\left|{\pi }_{{\widetilde{\alpha }}_{i}}-{\pi }_{{\widetilde{\delta }}_{i}}^{\prime}\right|\), \(\left(i\right)\) denotes a permutation of \(d\left(\widetilde{\alpha },{\widetilde{\alpha }}_{1}^{\prime}\right)\) such that \({d}_{\left(1\right)}\left(\widetilde{\alpha },{\widetilde{\alpha }}^{\prime}\right)\le {d}_{\left(2\right)}\left(\widetilde{\alpha },{\widetilde{\alpha }}^{\prime}\right)\le ...\le {d}_{\left(n\right)}\left(\widetilde{\alpha },{\widetilde{\alpha }}^{\prime}\right),{A}_{\left(i\right)}=\left\{\mathrm{1,2},...,n\right\},{A}_{\left(n+1\right)}=\varnothing\).

According to [30], the Hamming distance between two decision matrices \({\widetilde{A}}^{\left(k\right)}\) and \({\widetilde{A}}^{\left(h\right)}\) is:

The intuitionistic fuzzy \({\widetilde{A}}^{k}\) Hamming distance is:

The \(\lambda\)-fuzzy measure of expert \({e}_{k}\) is defined as:

For the determination of attribute fuzzy measure, according to [30], let \(\widetilde{A}={\left({\widetilde{\alpha }}_{ij}\right)}_{m*n}\) be an integrated intuitionistic fuzzy matrix, let \({\varsigma }_{j}\) and \({\eta }_{j}\) be the membership and non-membership degree of the attribute value \({c}_{j}\in C\), respectively. The \({c}_{j}\) evaluation value of the scheme \({a}_{i}\) attribute can be expressed by the intuitionistic fuzzy number, denoted by \({\widetilde{\theta }}_{{c}_{j}}=\left({\varsigma }_{j},{\eta }_{j}\right)\), then the \({g}_{\lambda }^{E}\left({c}_{j}\right)\) of the attribute value \({c}_{j}\) is located in the closed interval \([{g}_{\lambda }^{lj},{g}_{\lambda }^{uj}]\), where \({g}_{\lambda }^{lj}={\varsigma }_{j},{g}_{\lambda }^{uj}={\eta }_{j}\). Let the decision-maker choose a scheme \({a}_{i}\left(i=\mathrm{1,2},...,m\right)\) from the attributes \(\left\{{c}_{r1},{c}_{r2},...{c}_{rn}\right\}\left(\left\{{r}_{1},{r}_{2},...,{r}_{v}\right\}\subseteq \left\{\mathrm{1,2},...,n\right\}\right)\). The decision-maker gives the fuzzy measure \({g}_{\lambda }^{C}\left({c}_{r1}\right),{g}_{\lambda }^{C}\left({c}_{r2}\right),...,{g}_{\lambda }^{C}\left({c}_{rn}\right)\) of the attribute values \({c}_{r1},{c}_{r2},...{c}_{rn}\), where \({g}_{\lambda }^{l{r}_{p}}\le {g}_{\lambda }^{C}\left({c}_{rp}\right)\le {g}_{\lambda }^{u{r}_{p}},p=\mathrm{1,2},...,v\).

Some scholars established the fuzzy measure of attribute set by constructing a linear goal programming model and solving it with Lingo11 software. The corresponding linear goal programming model is:

The positive ideal solution and the negative ideal solution can be identified as:

where \({J}_{1}\) and \({J}_{2}\) are revenue attribute set and cost attribute set respectively.

The weighted positive separation measure and negative separation measure of scheme \({a}_{i}\) are defined as:

The relative closeness coefficient of scheme \({a}_{i}\) is:

The schemes can be sorted according to the relative progress coefficient equation.

4 Construction and solution of multi-objective site selection model

Section 4 mainly introduces the construction and solution process of the multi-objective location model and the operation flow chart of the system. In Section 4.1, we construct a multi-objective robust optimization model based on the analysis of practical engineering problems and Section 2. In the Section 4.2, the non-dominated sorting genetic algorithms-II-multiple objective particle swarm optimization (NSGA-II-MOPSO) algorithm is used to solve the multi-objective robust optimization model. The quality of the solution is improved by the algorithm fusion to avoid the result falling into the local optimal solution. The multi-objective location model based on digital twin technology integrates various methods and concepts, so we have provided a detailed introduction and explanation of the operating principle and flowchart of the smart collaborative manufacturing system in Section 4.3.

4.1 Construction of multi-objective site selection model

After the scheduling of manufacturing resources, the digital twin system will simulate the capacity increase of each resource agent and collect real-time data. Maximizing manufacturing profits is one of the important directions for manufacturing enterprises’ production [31]. Fluctuating market demand often brings greater production risks to manufacturing enterprises [32]. Robust optimization methods can effectively alleviate the negative impact of uncertain factors when manufacturing enterprises face changing market demands and production capacity changes caused by manufacturing resource scheduling [33]. Combined with practical analysis, we establish the maximization of supply and demand matching ability of manufacturing enterprises and the maximization of manufacturing Profit maximization as the objective function. Based on the analysis of manufacturing resource constraint environment in Section 2, this paper establishes a specific multi-objective robust optimization function. The specific objective function is shown below:

s.t.

Equation 35 shows that the goods received by wholesaler \({D}_{j}\) are equal to the number of shipments minus the number of shipping losses. Equation 36 shows that the sum of processing time and goods transportation time of subsidiaries is not more than the goods delivery time. Equation 37 indicates that the total amount of production from the manufacturing enterprise \({M}_{t}\) within the subsidiary \({C}_{i}\) about product \(m\) is equal to the sum of the amount processed by the production line and the amount of product stored by re-processing. Equation 38 indicates that each wholesaler \({D}_{j}\) returned to the warehouse \({W}_{k}\) the number of goods and warehouse \({W}_{k}\) the sum of existing goods storage should not be greater than the warehouse \({W}_{k}\) on the maximum storage capacity. Equation 39 indicates that the sum of the quantity of goods shipped from subsidiary \({C}_{i}\) to each wholesaler \({D}_{j}\) within manufacturing enterprise \({M}_{t}\) should be no more than the existing capacity.

4.2 Solution of multi-objective site selection model

Assuming an \(N\)-dimensional space, the solution composition of the problem can be represented by a \(n\)-dimensional vector. At each iteration of the algorithm, the current best position determined by particle \(q\) is \(pop(i).Best.Position\). In addition, combined with the roulette operator, the algorithm can choose a non-dominated solution as the global optimal solution \(leader.Position\). The algorithm uses the vectors \(pop(i).Position\) and \(pop(i).Velocity\) to represent the position and velocity of particle \(q\), respectively. The update equations for the particle velocity and position vectors are shown as follows:

where \(\omega\) is the inertia coefficient. \(c1\) and \(c2\) are the acceleration factors. \(rand(VarSize)\) is a uniformly distributed independent random number between [0,1].

4.2.1 Particle coding

-

1.

Set the algorithm parameters. \(npop\), \(nrep\) represent the number of populations and the number of non-dominated solution populations, respectively. \(MaxIt\) represents the number of iterations. \(nGrid\) represents the size of the extended network of the solution set domain.

-

2.

Initialize the particle population. This includes initializing the position and velocity information of the particle population and then constructing a particle population with a structure.

-

3.

Calculate the objective function values of the particles within the algorithm, determine the individual optimal positions of the individual particles \(pop(i).Position\) and calculate the optimal fitness value \(pop(i).Best.Cost\).

-

4.

The NSGA-II-MOPSO algorithm generates non-dominated solution sets and iterates them.

-

5.

Update \(pop(i).\; Position\) and \(pop(i).\; Velocity\) in the particle swarm.

-

6.

When the particle satisfies the constraints in this paper, then skip to step 7. If the particle does not satisfy the constraints, then skip to step 8.

-

7.

Calculate the evaluation index of each particle and update the individual optimal particle. Skip to step 11.

-

8.

The particle enters the while loop and transform the particle swarm particle \(pop(i)\) into the genetic particle \(chromo(i)\)). Generate parent population \(chromo\_parent\) with the help of multi-objective genetic algorithm principle.

-

9.

The algorithm adopts selection, crossover, and mutation strategies for the genetic particle \(chromo(i)\) and thus obtains the child population \(chromo\_off\).

-

10.

Combine the parent population \(chromo\_parent\) with the child population \(chromo\_off\) and compute the values of non-dominated ordering, crowding, etc. Keep the non-dominated genetic particles to generate non-dominated solution set. Until the genetic particle satisfies the constraints end the while loop. And convert genetic particle \(chromo(i)\) to swarm particle \(pop(i)\). Skip to step 11.

-

11.

The algorithm updates the set of nondominated solutions. The final algorithm retains \(nrep\) optimal solutions.

-

12.

Determine whether the corresponding number of iterations has been reached. If it is less than the maximum number of iterations. Skip to step (3). If the maximum number of iterations is reached, end the iteration and plot the particles within the non-dominated solution set to generate the \(pareto\) surfaces. The algorithm outputs the corresponding non-dominated solution set.

In addition, after generating \(i*j\) particles in each production range, the corresponding supply and demand matching capacity and profit are calculated where \({Q}_{ij}\) denotes the transportation volume of the path. At the same time, in order to facilitate the comparison of algorithms, this paper takes the opposite of the manufacturing company’s profit as the result of the objective function II, where if the particle generated by the \((i+1)\) th iteration is smaller than the value of the multi-objective function corresponding to the particle generated by the \(i\) th iteration, the value \({Q}_{ij}\) representing the transportation volume of the path is recorded; otherwise, it is not recorded.

4.2.2 Particle decoding

Statistical information on various types of manufacturing resources within each manufacturing company such as idle equipment models, quantities, workers’ operational proficiency, and convenience of information systems. The digital twin simulates the scheduling process for each type of manufacturing resource and calculates the \(\Delta C{O}_{a{i}^{\mathrm{^{\prime}}}i}^{{t}^{\mathrm{^{\prime}}}m}\) for each manufacturing resource to be scheduled to each manufacturing company. In addition, the manufacturing resource demand enterprise forecasting method establishes the market demand and uploads the demand results to the manufacturing resource platform. The system constructs a multi-objective robust optimization model based on different manufacturing enterprise information and supply information such as maximum storage capacity and path wear rate. Finally, we combine the NSGA-II-MOPSO algorithm to generate the corresponding scheduling plan and execute the corresponding production plan.

4.2.3 Experimental parameter setting

In order to verify the applicability and effectiveness of NSGA-II-MOPSO, this paper applies the algorithm to practical problems of different scales. The basic background of the practical problem is the multi-objective problem of multi-manufacturing resource scheduling among multi-manufacturing enterprises. The parameters of the simulation are designed as follows: the maximum demand \({Q}_{j{\text{max}}}\) corresponding to each demand point is 90, 110, 30, 100, and 80. The demand quantity \({Q}_{j}\) of products at each demand point is randomly generated within [0,\({Q}_{j{\text{max}}}\)]. The maximum storage capacity \({Q}_{k{\text{max}}}^{tm}\) of product \(m\) in warehouse \({W}_{k}\) is 15, 10, 13, 10, and 15. The warehouse \({W}_{k}\) corresponding to the subsidiary \({C}_{i}\) in the manufacturing enterprise \({M}_{t}\) is randomly generated in [0,\({Q}_{k{\text{max}}}^{tm}\)] for the existing reserves \({Q}_{ki}^{tm}\) of the product \(m\). The total number of idle equipment \(A\) is 20. The output \({\sum }_{i=1}^{I}C{O}_{i}^{tm}\) of the subsidiary company \({C}_{i}\) in the manufacturing enterprise \({M}_{t}\) before scheduling is randomly generated in [100,150]. The labor cost, material cost, and other cost corresponding to the production unit product \(m\) in the production process of the subsidiary company \({C}_{i}\) in \({M}_{t}\) manufacturing enterprise: \({C}_{ij}^{tm\alpha }, {C}_{ij}^{tm\beta },\;\mathrm{ and }\;{C}_{ij}^{tm\lambda }\) are randomly generated in [80,120], [1000,1300], and [40,70]. The transportation unit price and equipment installation unit price of equipment resource \(a\) transported to subsidiary \({C}_{i}\): \({C}_{ai{i}^{\mathrm{^{\prime}}}}^{tm}\) and \({C}_{a{i}^{\mathrm{^{\prime}}}}^{tm}\) are randomly generated in [1200,1400] and [500,900] respectively. The NSGA-II-MOPSO algorithm uses the following parameter settings: the individual and population learning coefficients \(c1\) and \(c2\) are 1 and 2, respectively, the initial weight \(\omega\)=0.5, the crossover probability \({P}_{c}=0.5\), and the genetic probability \({P}_{m}=1/x\_{\text{num}}\), where \(x\_{\text{num}}\) represents the number of populations. The maximum number of iterations \({\text{max}}\;It\) =100, the maximum speed \({V}_{{\text{max}}}\) is 1. The algorithm is implemented by MATLAB programming, the running environment is a PC, and the CPU is Pentium IV 2.50 GHz. For the convenience of comparison, the objective function 2 is negative and the unit is one hundred thousand dollars.

4.2.4 Algorithm testing

In order to verify the complexity of the NSGA-II-MOPSO algorithm, this paper selects multiple indicators. The performance evaluation index of the multi-objective evolutionary algorithm solution set is mainly divided into three aspects: convergence metric, spacing metric, and diversity metric [34]. The specific calculation method and principle of the index are as follows:

-

Convergence metric: Generational distance (GD) [35] denotes the average minimum distance from each point in the solution set P to the reference set \({P}^{*}\). The smaller the GD value, the better the convergence. \(GD\left(P,{P}^{*}\right)=\frac{\sqrt{{\sum }_{y\in P}{{\text{min}}}_{{\text{x}}\in {{\text{P}}}^{*}}{\text{dis}}{\left(x,y\right)}^{2}}}{\left|P\right|}\) where \(P\) is the solution set obtained by the algorithm. \({P}^{*}\) is the solution set of the optimal Pareto surface. \(dis\left(x,y\right)\) denotes the Euclidean distance between the solution \(y\) in the solution set \(P\) and the solution x in the solution set \({P}^{*}\).

-

Spacing metric [36]: \({\text{Spacing}}(P)=\sqrt{\frac{1}{(N-1)}{\sum }_{j=1}^{N}{\left|{d}_{{\text{mean}}}-{d}_{j}\right|}^{2}}\) where \({d}_{j}\) denotes the minimum distance from the \(j\) th solution to the other solutions in the non-dominated solution set, and \({d}_{{\text{mean}}}\) denotes the mean value of all \({d}_{j}\). \({\text{Spacing}}(P)\) is used to calculate the standard deviation of the minimum distance from each solution to other solutions in the non-dominated solution set. The smaller the S \({\text{Spacing}}(P)\) value is, the more uniform the solution set is.

-

Diversity metric [37]: \(DM=\sqrt{{\left({\text{max}}{f}_{1i}-{{\text{min}}}_{1i}{f}_{1i}\right)}^{2}+{\left({\text{max}}{f}_{2i}-{{\text{min}}}_{2i}{f}_{1i}\right)}^{2}}\). This metric determines the diversity of non-dominated solutions which are achieved by each algorithm. In this metric, the algorithm with a higher value has a better capability.

In order to analyze the performance of the algorithm combined with this problem, this paper compares MOPSO, NSGA-II, and NSGA-II-MOPSO algorithm. The size of the solution is set as follows: \(a*(b*c)\), where \(a\) represents the actual demand, and \((b*c)\) represents the number of product categories and manufacturing enterprises that can be located. Multiple tests are performed on the scale of the solution. The test results are shown in Fig. 5a–h.

In order to analyze the performance of the algorithm in more detail, this paper introduces hypervolume (HV) to verify the comprehensive performance of the algorithm. The comprehensive performance of the algorithm is illustrated by the calculated non-dominated solution set and the volume of the region in the target space of the reference point siege. The larger the HV value, the better the comprehensive performance of the algorithm.

where \(\delta\) denotes the Lebesgue measure, which is used to measure the volume. \(\left|S\right|\) denotes the number of non-dominated solutions. \({\nu }_{i}\) denotes the hypervolume of the reference point and the \(i\) th solution in the solution set. According to the calculation, the comprehensive performance of NSGA-II-MOPSO algorithm is better than that of MOPSO algorithm and NSGA-II algorithm under each operation scale. The calculation results of each index are shown in Table 2 and the following conclusions are drawn: Firstly, MOPSO, NSGA-II, and NSGA-II-MOPSO algorithms have obtained the non-dominated solution set of the location problem under resource constraints. In terms of solution speed, the NSGA-II-MOPSO algorithm solves better than the MOPSO algorithm. Also, NSGA-II-MOPSO outperforms NSGA-II in terms of uniformity of non-dominated solutions, which are uniformly distributed. In terms of diversity metrics, NSGA-II-MOPSO significantly outperforms NSGA-II and MOPSO algorithms in terms of wider search of non-dominated solutions. In addition, it is more obvious that NSGA-II-MOPSO is significantly better than NSGA-II and MOPSO algorithms in terms of the convergence of pareto surfaces. The MOPSO algorithm lacks the escape mechanism of local optimum and is prone to fall into the local optimum solution but the quality of the solution is higher. NSGA II can effectively improve the global search capability of the algorithm under the perturbation strategies such as mutation and crossover operator but the quality of the solution is lower. NSGA-II-MOPSO combines the advantages of the two algorithms, and has significant performance in the indexes of solution speed, solution quality, solution range, and uniformity of the non-dominated solution. Combined with the data analysis, the NSGA-II-MOPSO algorithm can effectively solve the problem under the resource limitation proposed in this paper, and the algorithm has good solution performance.

4.3 Flow chart of smart collaborative manufacturing system

In summary, with the help of digital twins, manufacturing enterprises can efficiently and conveniently identify bottleneck processes and achieve the scheduling of various manufacturing resources. Smart collaborative manufacturing systems can effectively assist manufacturing resource demand enterprises in achieving the decision-making process of manufacturing resources. The system consists of multiple mathematical models related to it, so this article constructs corresponding flowchart explanations. The specific smart collaborative manufacturing system process is shown in Fig. 6.

Due to the extensive use of models, algorithms, and data, the system of smart collaborative manufacturing systems is relatively complex. For the convenience of explanation, we divide the smart collaborative manufacturing system into four parts based on the different functions of each part and label them in different colors in Fig. 6. Firstly, manufacturing resource demand enterprises and manufacturing resource providers upload their own needs and enterprise data. Secondly, the resource platform classifies manufacturing resources and stores corresponding data information. The location selection system based on digital twins simulates the scheduling process of various manufacturing resources and incorporates various models in this process: manufacturing resource ranking combined with Choquet integral, multi-objective robust optimization model combined with resource scheduling, and identification model of bottleneck processes. The final scheduling decision plan is generated through a large amount of data simulation for decision-makers to make decisions. The specific process of a smart collaborative manufacturing system is as follows:

-

Step 1: Manufacturing resource providers establish their own idle manufacturing resources and upload various information of corresponding resources to the manufacturing resource platform for other manufacturing enterprises to schedule manufacturing resources.

-

Step 2: The manufacturing resource platform classifies manufacturing resources based on their characteristics to facilitate the selection of resource demanding enterprises.

-

Step 3: The demand enterprise determines the order demand to clarify the production capacity difference and establish the production capacity target of the factory site, as well as to establish alternative factory site locations.

-

Step 4: By establishing bottleneck processes through the manufacturing resource cycle configuration system, manufacturing enterprises can clarify various manufacturing resource requirements, and upload the results of various manufacturing requirements to the manufacturing resource platform.

-

Step 5: After receiving resource information from both supply and demand sides, the manufacturing resource platform uniformly classifies resources into talent resources, equipment resources, and information system resources.

-

Step 6: The digital twin system organizes historical data from sensors and other observational data. In addition, the system, combined with \(AIFGS{C}_{g\lambda }\) operator, helps manufacturing enterprises achieve preliminary sorting of manufacturing resources to complete the preliminary screening process of various resources.

-

Step 7: The digital twin system simulates the scheduling process of various manufacturing resources and establishes a multi-objective robust optimization model based on location selection problems. The digital twin system is solved by combining the NSGA-II-MOPSO algorithm, and ultimately the manufacturing resource demand enterprise establishes a scheduling plan for equipment resources.

-

Step 8: Repeat steps 4 ~ 7 until the manufacturing resources are difficult to improve the processing capacity of the bottleneck process in the manufacturing resource demand enterprise.

-

Step 9: Generate the final location plan, scheduling plan of various manufacturing resources, and production plan. At the same time, the system combines sensors to realize real-time recording of data in the production process to prepare for the next production cycle.

5 Model application

There are three enterprises, A, B, and C. Each manufacturing enterprise contains multiple subsidiaries. Each subsidiary has independent production capacity. The subsidiaries of each steel manufacturing enterprise can produce four products: cold-rolled high-strength steel plates with phosphorus, seamless steel pipes, galvanized steel coils, and low-carbon wire rod for drawing. The choice and construction of a new site for manufacturing enterprise A due to high market demand. After government coordination and relevant policy support, there are two locations available for manufacturing enterprise A to choose from. For the convenience of representation, we will use ◎, ○, ☉, and ▽ for subsidiaries with the ability to process cold-rolled high-strength steel plates with phosphorus, seamless steel pipes, galvanized steel coils, and low-carbon wire rod for drawing, respectively. The main products manufactured by each enterprise are shown in Table 3. The original transportation path is shown in Fig. 7. The subsidiaries are named by “enterprise + subsidiary,” such as A1, A2, A3, A4, and A5 (A4 and A5 are alternate locations).

-

Step 1: Each collaborative manufacturing enterprise establishes idle manufacturing resources, taking equipment resources as an example, and the results are shown in Table 4. Meanwhile, the manufacturing enterprises upload the results to the manufacturing resource platform.

Table 4 Equipment resource statistics -

Step 2: Manufacturing platform for specific classification of manufacturing resources, according to the type of manufacturing resources will be divided into three categories of existing resources, respectively: equipment resources, human resources, information systems, the corresponding classification results are shown in Table 5 (for the convenience of labeling, the four products are distinguished by a, b, c, and d, and the human resources and information systems are marked separately to show the distinction)

Table 5 Manufacturing resource classification table -

Step 3: According to the government planning and policy support to obtain the corresponding alternative plant site locations, respectively A4 and A5, the corresponding processing task is to produce sufficient quantities of galvanized steel coils and low carbon wire rod for drawing. The floor plan of each subsidiary, warehouse, wholesaler, and demand point is shown in Fig. 8.

-

Step 4: Combine the digital twin technology to simulate the production process at A4 and A5 sites, and establish the corresponding bottleneck processes through the circular scheduling system to achieve targeted scheduling of manufacturing resources. For example, the manufacturer first establishes the bottleneck process in the production of galvanized steel coils and uploads the capacity demand to the manufacturing resource platform.

-

Steps 5–6: According to the manufacturing resource classification table and the historical data of the sensor, the preliminary resource scheduling decision is made and the manufacturing resources are sorted by \(AIFGS{C}_{g\lambda }\) operator. Taking the 2030 hot rolling mill required in the production process of cold rolled high strength steel plate with phosphorus as an example, four subsidiaries A1, A3, B2, and C3 can provide mechanical equipment with different types and wear degrees. The four subsidiaries are recorded as \(\left\{{a}_{1},{a}_{2},{a}_{3},{a}_{4}\right\}\), and the four alternatives can be evaluated by five evaluation indexes \(\left\{{c}_{1},{c}_{2},{c}_{3},{c}_{4},{c}_{5}\right\}\). The wear degree of the equipment \(\left({c}_{1}\right)\), the number of maintenance of the equipment \(\left({c}_{2}\right)\), the number of years of use of the equipment \(\left({c}_{2}\right)\), the radiation degree of the equipment \(\left({c}_{4}\right)\), and the increase of the capacity of the equipment \(\left({c}_{5}\right)\). The scoring process is converted into a benefit indicator and three experts are invited, recorded as \(\left\{{e}_{1},{e}_{2},{e}_{3}\right\}\) (\(q=3\)), to judge the four devices based on their knowledge and experience. The evaluation results are shown in Table 6, 7, and 8.

Table 6 Expert \({e}_{1}\) gives the evaluation matrix \({\widetilde{A}}^{1}\) Table 7 Expert \({e}_{2}\) gives the evaluation matrix \({\widetilde{A}}^{2}\) Table 8 Expert \({e}_{3}\) gives the evaluation matrix \({\widetilde{A}}^{3}\) On this basis, the fuzzy measure of the three experts is determined by using the Eqs. 26–28: \({g}_{\lambda }^{E}\left({e}_{1}\right)\approx 0.156\), \({g}_{\lambda }^{E}\left({e}_{2}\right)\approx 0.185\), \({g}_{\lambda }^{E}\left({e}_{3}\right)\approx 0.192\). Using Eq. 17, \({\lambda }_{1}=4.007\) is obtained. The fuzzy measures of the three groups of experts are as follows: \({g}_{\lambda }^{E}\left({e}_{1},{e}_{2}\right)=0.457\), \({g}_{\lambda }^{E}\left({e}_{1},{e}_{3}\right)=0.468\), \({g}_{\lambda }^{E}\left({e}_{2},{e}_{3}\right)=0.519\), \({g}_{\lambda }^{E}\left({e}_{1},{e}_{2},{e}_{3}\right)=1\). The fuzzy measure of \(\lambda\)-Shapley is obtained by using Eq. 22: \({\rho }_{\left\{{e}_{1}\right\}}^{sha}\left({g}_{\lambda }^{E}\right)=\) 0.251, \({\rho }_{\left\{{e}_{2}\right\}}^{sha}\left({g}_{\lambda }^{E}\right)=\) 0.283, \({\rho }_{\left\{{e}_{3}\right\}}^{sha}\left({g}_{\lambda }^{E}\right)=\) 0.289, \({\rho }_{\left\{{e}_{1},{e}_{2}\right\}}^{sha}\left({g}_{\lambda }^{E}\right)=\) 0.404, \({\rho }_{\left\{{e}_{1},{e}_{3}\right\}}^{sha}\left({g}_{\lambda }^{E}\right)=\) 0.408, \({\rho }_{\left\{{e}_{2},{e}_{3}\right\}}^{sha}\left({g}_{\lambda }^{E}\right)=\) 0.422, \({\rho }_{\left\{{e}_{1},{e}_{2},{e}_{3}\right\}}^{sha}\left({g}_{\lambda }^{E}\right)=1, {\rho }_{\left\{\varnothing \right\}}^{sha}\left({g}_{\lambda }^{E}\right)=0\).

The intuitionistic fuzzy arithmetic λ-Shapley Choquet integral operator \(AIFGS{C}_{g\lambda }\) of Eq. 24 is used to aggregate the decision matrices \({\widetilde{A}}^{1}\), \({\widetilde{A}}^{2}\), and \({\widetilde{A}}^{3}\) of the three experts to construct the aggregate intuitionistic fuzzy decision matrix \({A}_{1}\).

$$\begin{gathered} A_{1} = \left( {\begin{array}{*{20}c} {\left( {0.5449,0.2020,0.2531} \right)} \\ {\left( {0.7375,0.1545,0.1080} \right)} \\ {\left( {0.5683,0.3018,0.1299} \right)} \\ {\left( {0.5739,0.1678,0.2583} \right)} \\ \end{array} } \right.\begin{array}{*{20}c} {\left( {0.4928,0.0638,0.4434} \right)} \\ {\left( {0.5967,0.1801,0.2232} \right)} \\ {\left( {0.6028,0.1495,0.2477} \right)} \\ {\left( {0.4775,0.1900,0.3325} \right)} \\ \end{array} \\ \left. {\begin{array}{*{20}c} {\left( {0.5960,0.1654,0.2386} \right)} \\ {\left( {0.5775,0.1900,0.2325} \right)} \\ {\left( {0.5967,0.1297,0.2736} \right)} \\ {\left( {0.6036,0.1041,0.2923} \right)} \\ \end{array} \begin{array}{*{20}c} {\left( {0.5791,0.1971,0.2238} \right)} \\ {\left( {0.6448,0.2931,0.0621} \right)} \\ {\left( {0.3864,0.2768,0.3368} \right)} \\ {\left( {0.5122,0.1678,0.3200} \right)} \\ \end{array} \begin{array}{*{20}c} {\left( {0.3864,0.3090,0.3046} \right)} \\ {\left( {0.5448,0.4241,0.0311} \right)} \\ {\left( {0.6209,0.2020,0.1771} \right)} \\ {\left( {0.5451,0.1545,0.3004} \right)} \\ \end{array} } \right) \\ \end{gathered}$$Using Eq. 29, the fuzzy measures of each attribute are determined as follows: \({g}_{\lambda }^{c}\left({c}_{1}\right)=0.55\), \({g}_{\lambda }^{c}\left({c}_{2}\right)=0.45\), \({g}_{\lambda }^{c}\left({c}_{3}\right)=0.5\), \({g}_{\lambda }^{c}\left({c}_{4}\right)={g}_{\lambda }^{c}\left({c}_{5}\right)=0.55\). According to Eq. 17, the integral value of attribute \({\lambda }_{2}\) is − 0.971, and the corresponding correlation measure between attributes is as follows: \({g}_{\lambda }^{c}\left({c}_{1},{c}_{2}\right)=0.760, {g}_{\lambda }^{c}\left({c}_{1},{c}_{3}\right)=0.783\), \({g}_{\lambda }^{c}\left({c}_{1},{c}_{4}\right)=0.830\), \({g}_{\lambda }^{c}\left({c}_{1},{c}_{5}\right)=0.806\), \({g}_{\lambda }^{c}\left({c}_{2},{c}_{3}\right)=0.732\), \({g}_{\lambda }^{c}\left({c}_{2},{c}_{4}\right)=0.788\), \({g}_{\lambda }^{c}\left({c}_{2},{c}_{5}\right)=0.760\), \({g}_{\lambda }^{c}\left({c}_{3},{c}_{4}\right)=0.809\), \({g}_{\lambda }^{c}\left({c}_{3},{c}_{5}\right)=0.783\), \({g}_{\lambda }^{c}\left({c}_{4},{c}_{5}\right)=0.806\), \({g}_{\lambda }^{c}\left({c}_{1},{c}_{2},{c}_{3}\right)=0.891\), \({g}_{\lambda }^{c}\left({c}_{1},{c}_{2},{c}_{4}\right)=0.904\), \({g}_{\lambda }^{c}\left({c}_{1},{c}_{2},{c}_{5}\right)=0.904\), \({g}_{\lambda }^{c}\left({c}_{1},{c}_{3},{c}_{4}\right)=0.915\), \({g}_{\lambda }^{c}\left({c}_{1},{c}_{3},{c}_{5}\right)=0.915\), \({g}_{\lambda }^{c}\left({c}_{2},{c}_{3},{c}_{4}\right)=0.891\), \({g}_{\lambda }^{c}\left({c}_{2},{c}_{3},{c}_{5}\right)=0.891\),\({g}_{\lambda }^{c}\left({c}_{2},{c}_{4},{c}_{5}\right)=0.904\), \({g}_{\lambda }^{c}\left({c}_{3},{c}_{4},{c}_{5}\right)=0.915\),\({g}_{\lambda }^{c}\left({c}_{1},{c}_{2},{c}_{3},{c}_{4}\right)=0.9651\),\({g}_{\lambda }^{c}\left({c}_{1},{c}_{2},{c}_{4},{c}_{5}\right)=0.971\), \({g}_{\lambda }^{c}\left({c}_{1},{c}_{3},{c}_{4},{c}_{5}\right)=0.9762\), \({g}_{\lambda }^{c}\left({c}_{2},{c}_{3},{c}_{4},{c}_{5}\right)=0.9651\),\({g}_{\lambda }^{c}\left({c}_{1},{c}_{2},{c}_{3},{c}_{4},{c}_{5}\right)=1\).

Repeat the above steps, using Eq. 22 to obtain the fuzzy measure of λ-Shapley and using Eqs. 30–31 to identify that (1,0,0) and (0,1,0) are the largest and smallest intuitionistic fuzzy numbers. The positive ideal value \({\beta }^{+}\) and negative ideal value \({\beta }^{-}\) of the five evaluation indexes \(\left\{{c}_{1},{c}_{2},{c}_{3},{c}_{4},{c}_{5}\right\}\) are denoted as follows: \({\beta }^{+}=\left(\left(\mathrm{1,0},0\right),\left(\mathrm{1,0},0\right),\left(\mathrm{1,0},0\right),\left(\mathrm{1,0},0\right),\left(\mathrm{1,0},0\right)\right)\), \({\beta }^{-}=\left(\left(\mathrm{0,1},0\right),\left(\mathrm{0,1},0\right),\left(\mathrm{0,1},0\right),\left(\mathrm{0,1},0\right),\left(\mathrm{0,1},0\right)\right)\)

The weighted positive separation measure, the weighted negative separation measure, and the sticking progress coefficient are calculated by using Eqs. 32–34. The results are shown in Table 9.

Table 9 Separating degree and sticking progress coefficient obtained from \(AIFGS{C}_{g\lambda }\) Because \({U}_{3}^{-}>{U}_{4}^{-}>{U}_{1}^{-}>{U}_{2}^{-}\), the ranking result of the 2050 hot strip mill of the corresponding four subsidiaries is as follows: \({a}_{3}>{a}_{4}>{a}_{1}>{a}_{2}\), so the optimal supplier is B2. Repeat the above steps to obtain the primary selection of equipment resources and the scheduling execution scheme of human resources and information systems.

-

Step 7: After the initial sorting results of equipment resources, further discussion is still needed, because the purpose of resource allocation is to improve the production capacity of enterprises, and the capacity increase brought by equipment resource scheduling can be directly quantified and analyzed. Therefore, we establish an optimization model to establish the final equipment resource scheduling scheme. Combined with Eqs. 1–12 and Eqs. 35–39, the model is established and solved by the NSGA-II-MOPSO algorithm. The corresponding solutions of the four products are as follows (Fig. 9):

The digital twin system uploads various solution results to manufacturing resource demand enterprises. After comparative analysis, it can be concluded that A4 as the location for manufacturing demand enterprises will achieve greater benefits and robust performance. The final scheduling scheme and location scheme are determined, and the results are shown in Table 10.

Table 10 Final production plan schedule The corresponding transportation path diagram and manufacturing resource scheduling path diagram are shown in Fig. 10 and Fig. 11 respectively:

The corresponding site selection location is A4, and the production planning scheme and manufacturing resource scheduling scheme can also be derived from it. Through the above steps and models, a site selection model supported by digital twin technology is constructed and the problem is solved by a smart collaborative system, and a concrete implementation plan is obtained.

6 Conclusion

The application of digital twin technology in process design is not yet widespread. Using digital twin technology in manufacturing process planning to quickly mine and learn from timely collected data will reveal more advantages and disadvantages. The digital twin technology represents the progress of digitization, which is being applied in more and more fields, such as smart manufacturing [38], smart cities [39], and healthcare [40]. The future requires the development of common digital twin design development platforms and tools [6]. In the traditional manufacturing process, manufacturing enterprises face many problems from the lack of manufacturing resources to solve the manufacturing needs. In the process of site selection, some manufacturing enterprises have difficulty in choosing the most suitable site to achieve manufacturing production and the cost required for manufacturing is large according to their own manufacturing resources. The development of collaborative manufacturing concept has solved this problem by helping manufacturing enterprises to achieve capacity improvement through inter-enterprise manufacturing resource leasing, and solving the problem of insufficient capacity caused by bottleneck processes will reasonably improve the resource shortage problem of manufacturing enterprises and significantly reduce the site selection cost of enterprises. Combined with the funnel model proposed in this paper, it will help manufacturing enterprises to find out the bottleneck processes more quickly and easily and combine with the circular scheduling system of manufacturing resources to achieve the maximum capacity of enterprises. We propose to combine \(AIFGS{C}_{g\lambda }\) operator to achieve a more scientific scheduling decision for some difficult to quantify metrics to help manufacturing enterprises realize the collaborative scheduling process of multiple manufacturing resources to avoid the problem of resource mismatch after scheduling. Combined with the results of the case study, we found that the combination of digital twin technology can greatly help the collaborative manufacturing enterprises to simulate the scheduling process of manufacturing resources and make the best resource scheduling decision. We believe that future research on manufacturing resource allocation by combining digital twin technology in the collaborative manufacturing process can start from several aspects:

-

Scheduling of manufacturing resources. The management of dynamic manufacturing resources is more complex than the management of enterprise independent resources. This means that manufacturing enterprises cooperate with each other, share diverse manufacturing resources, and achieve greater manufacturing value. In this process, the selection of data and information, the use of manufacturing resources, and the changing market demand will require manufacturing systems to make faster and more responsive decisions.

-

Due to the volatility of customer demand, the scheduling of dynamic manufacturing resources is difficult to control accurately. The platform needs to adjust the scheduling process of dynamic manufacturing resources in a timely manner according to the fluctuation of manufacturing enterprises’ demand in order to maximize the revenue.

-

New data storage and processing technologies will help manufacturing enterprises to be more flexible to respond to market demands [41]. Collaborative manufacturing enterprises can make quick decision responses among themselves based on timely data information to avoid unnecessary waste of manufacturing resources.

References

Tao F, Qi Q (2019) New IT driven service-oriented smart manufacturing: framework and characteristics. IEEE Trans Syst Man, Cybern Syst 49:81–91

Kang H, Lee J, Choi S, Kim H, Park J, Son J, Kim B, Noh S (2016) Smart manufacturing: past research, present findings, and future directions. Int J Precis Eng Manuf - Green Technol 3:111–128

Fawzi H, Tabuada P, Diggavi S (2014) Secure estimation and control for cyber-physical systems under adversarial attacks. IEEE Trans Automat Contr 59:1454–1467

Qi Q, Tao F (2018) Digital twin and big data towards smart manufacturing and Industry 4.0: 360 degree comparison. IEEE Access 6:3585–3593

Qi Q, Tao F, Hu T, Anwer N, Liu A, Wei Y, Wang L, Nee A (2021) Enabling technologies and tools for digital twin. J Manuf Syst 58:3–21

Wang G, Zhang G, Guo X, Zhang Y (2021) Digital twin-driven service model and optimal allocation of manufacturing resources in shared manufacturing. J Manuf Syst 59:165–179

Wu J, Zhang W, Zhang S, Liu Y, Meng X (2013) A matrix-based Bayesian approach for manufacturing resource allocation planning in supply chain management. Int J Prod Res 51:1451–1463

Lee C, Choy K, Law K, Ho G (2014) Application of smart data management in resource allocation for effective operation of manufacturing systems. J Manuf Syst 33:412–422