Abstract

Cutting parameters and tool wear both have significant influence on energy consumption in the processing. In a multi-feature parts batch processing, tool wear values are continuously increasing with the proceeding of processing, leading to a higher energy consumption. To reduce the wear speed, cutting parameters should be continuously adjusted according to different states of tool wear during batch processing. However, current cutting parameter optimization studies only focus on one specific workpiece and the tool wear is seldom considered in the batch processing. To fill this research gap, a cutting parameter energy-saving optimization method considering tool wear for multi-feature parts batch processing was proposed in this paper. First, the synergistic effect mechanism of cutting parameters and tool wear on energy consumption in the batch processing was analyzed. On this basis, a multi-objective cutting parameter optimization model for multi-feature parts batch processing was established. Then, the multi-objective cuckoo search (MOCS) algorithm was used to solve the optimization model. Finally, an experimental case was carried out to verify the effectiveness and practicability of the proposed method. Results show that energy consumption and machining time can be, respectively, decreased by 22.9% and 4.1%. Meanwhile, a conflict relationship exists between the energy consumption and machining time in the processing and the trade-off of them is analyzed in this paper.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

Due to the increasing demand of production and productivity in the modern society, mass fossil fuels are burned to generate electricity in manufacturing industries, which causes huge amounts of energy consumption [1]. According to a report from U.S. Energy Information Administration, more than 33% of global energy is consumed by industrial manufacturing sectors, and demands for industrial energy consumption will increase by 50% in 2050 compared with 2018, predictably [2]. As the main carrier of machining activities, computer numerical control (CNC) machine tools consume about 60% of machinery tool sections energy [3, 4], which have become dominant energy consumers [5]. However, the energy efficiency of CNC machine tools is below 15% during machining activities according to the work presented by Gutowski et al. [6]. Therefore, numerous attempts should be implemented to improve energy efficiency of machine tools and relieve the impact of energy consumption [7].

Proper cutting parameters selection affects energy consumption significantly in a processing process [8, 9]. According to the study by Li et al. [10], the reduction in energy consumption can reach a maximum of 40% by selecting proper cutting parameters. Thus, many scholars have conducted research on relationships between cutting parameters and energy consumption, where studies can be divided into two groups. The first group of studies investigated contributions of cutting parameters affecting energy consumption through experimental methods. For instance, Bhushan [11] designed a CNC turning experiment to analyze effects of cutting parameters on energy consumption. The response surface methodology (RSM) results showed that cutting speed was the most significant parameter, followed by cutting depth and feed rate, as well as the energy consumption could be reduced by 13.55% by selecting optimum cutting parameters. Cui ang Guo [12] explored most optimal cutting parameters on energy saving in intermittent turning by an orthogonal experiment. Experimental results showed that lowest energy consumption could be achieved when feed rate was within 0.2–0.25 mm/r and cutting speed was within 110–125 m/min. The second group of studies conducted cutting parameter energy-saving optimization by modeling. For example, Chen et al. [13] established a cutting parameter optimization model to reduce energy footprint in face milling process. They found that energy footprint could be decreased by 10.97% through the proposed model. Similar work can be found in Moreira et al. [14] where a multi-objective cutting parameter optimization model was established and solved. The optimal solution achieved a 19.28% machining energy consumption reduction. The above two groups of studies point out several important cutting parameters which affect energy consumption and indicate that the energy-saving potential of cutting parameter optimization on CNC machining is tremendous.

Tool wear is inevitable in CNC machining and can affect energy consumption significantly [15]. Several studies proved that cutting energy consumption would increase continuously along the aggravation of tool wear [16], with a maximal rise of 44% approximately [17]. Hereby, optimizations should be adopted to reduce the impact of tool wear on energy consumption, especially in the cutting parameter optimization since cutting parameter selections are affected by tool wear [18]. Along with the deepening of research on this area, taking tool wear into consideration in cutting parameter optimization models has become a research focus in recent years. For example, Bagaber and Yusoff [19] took tool wear as an optimization parameter in the multi-objective optimization model. Results showed that energy consumption could be reduced by 14.94% under the optimized cutting parameters considering tool wear compared with initial cutting parameters. Xie et al. [20] studied turning parameter cooperative optimization for minimal energy consumption under different tool wear conditions. The cutting energy consumption could finally be decreased by 13.58% through the proposed model compared with the empirical setting parameters without tool wear values. Zhang et al. [21] integrated random tool wear processes into the proposed cutting parameter optimization energy-saving model, and results implied that the energy consumption could be reduced by 7.89% considering tool wear compared with results not considering tool wear in machining. In summary, it can be known by the perusal of literature that integrating tool wear into the cutting parameter optimization model can make a huge improvement on energy consumption and thus needs to be comprehensively considered.

In a batch processing, there are mass workpieces to be processed continuously and the tool wear of cutting tools will increase with the progress of processing [22]. A study by Shi et al. [23] showed that different tool wear states in processing would lead to a full difference in final energy consumption. Accordingly, the energy consumption of a batch processing process is much higher because of increasing tool wear values. As mentioned earlier, cutting parameters are significant in machining and there is also a close mixing relationship between cutting parameters and the tool wear [24]. Generally, the setting of cutting parameters will affect the process of tool wear and current tool wear state will also affect the selection of cutting parameters [25]. In actual production, cutting parameters are set in advance and constant during machining. However, with tool wear values increasing in a batch processing process, current cutting parameters are not guaranteed to be the most optimal for energy saving. Consequently, it is necessary to continuously adjust cutting parameters to adapt ever-changed tool wear state during batch processing [26]. Meanwhile, the optimal combination of cutting parameters and tool wear can contribute more for energy saving [27]. Therefore, comprehensively considering cutting parameter adjustment and tool wear state in the energy optimization during batch processing is meaningful. However, existed research focused more on cutting parameter optimization for one specific workpiece, which cannot be applied to the batch processing for energy saving. What’s more, there are few studies utilizing the strategy of continuous cutting parameters adjustment according to tool wear states to reduce energy consumption.

Motivated by above remarks, this paper takes the CNC milling batch processing as an example to study the cutting parameter optimization for energy saving under different tool wear states. The gap can be filled in this research on following two areas:

-

1.

A novel energy consumption model comprehensively considering cutting tools adjustment, cutting parameters adjustment and tool wear for multi-feature parts batch processing is established. This model indicates the synergistic effect between cutting parameters and tool wear on energy consumption.

-

2.

A multi-objective cutting parameter optimization model considering tool wear is proposed and instantly solved through MOCS algorithm, where cutting parameters are continuously adjusted based on wear values. The validity of this model is proved via a case study and the trade-off between energy consumption and machining time is analyzed.

The rest of the paper is organized as follows: Sect. 2 gives the problem description for the multi-feature parts batch processing with definitions and assumptions. Section 3 analyzes the energy characteristics of multi-feature parts batch processing and establishes the energy consumption model. Section 4 presents the multi-objective optimization model and adopts the MOCS algorithm to solve the model. Section 5 gives the case study together with main results and discussions, while in Sect. 6, we present the conclusion of our work and point out a future research issue.

2 Problem description

In a batch processing, workpieces to be processed are generally multi-feature and each workpiece needs to be processed in accordance with the machining sequence of features. To ensure machining sequences of each feature for one workpiece, the corresponding cutting tools and cutting parameters for each feature should be selected in advance according to process flows, machining requirements and experience. There are following machining characteristics for the multi-feature parts batch processing:

-

1.

The one-to-one correspondence between feature and cutting tool is not fixed. Due to the universal applicability of cutting tools, one specific feature can be processed by different cutting tools in a batch processing;

-

2.

Before each feature processing, one cutting tool can be selected from the available tool set for this feature and corresponding cutting parameters will vary with different selected cutting tools;

-

3.

During the batch processing, tool wear values are increasingly intensified. Even if using the same cutting tool to process the same feature, cutting parameters should be adjusted according to different tool wear states to reduce wear speed.

To sum up, the setting of cutting parameters is affected by cutting tools and tool wear states, as well as cutting tool and cutting parameter adjustments can be applied in the batch processing. The detailed flow diagram of this multi-feature parts batch processing problem is shown specifically in Fig. 1. To simplify this problem, several specific definitions related to this multi-feature parts batch processing process are given in Table 1.

Among them, batch processing task T is composed of N workpiece processing task Tj and each workpiece task Tj is composed of w feature processing task Tji. In addition, when cutting tool IUil reaches cutting tool adjustment standard \(VB_{max}^{il}\), this cutting tool should be changed. And when cutting tool IUil reaches cutting parameter adjustment standard [ΔVB/Δt]il, this set of cutting parameters should be adjusted.

Meanwhile, the following assumptions in the problem are given:

-

1.

One batch is continuously processed until the end on the same machine tool, and cutting tools do not process other types of workpieces;

-

2.

Ignore size errors and manufacturing errors between each workpiece;

-

3.

Ignore errors caused by manufacturing technologies, processing environment, workers' operations and others on the machining process and tool wear law;

-

4.

After finishing the previous task, it does not affect the tool wear law if the same cutting tool Uu is used for processing again after a short time;

-

5.

All cutting tools are new when starting a batch machining task in the cutting tool set U;

-

6.

The cutting tool adjustment standard and cutting parameter adjustment standard of the cutting tool IUil are only related to the type of the cutting tool itself;

-

7.

Features of workpiece Jj in the workpieces set J are processed sequentially from I1 to Iw;

-

8.

There is at least one optional cutting tool for each feature Ii to be processed.

3 Energy consumption of multi-feature parts batch processing

The energy consumption model of the multi-feature parts batch processing is established in this section. According to the problem description, there are altogether N Tj in T. Besides, workpiece \(J_{(\,j-1)}\)needs to be removed and workpiece Jj needs to be set before Tj. Thus, energy consumption Etotal of task T includes energy consumption of each workpiece processing task Ej and workpiece setting and removal Ewsr:

Between each Tj, the machine tool is standby to change workpieces, so workpiece setting and removal energy consumption is related to standby power Pst and corresponding workpiece setting and removal time twsr:

In each Tj, there are altogether w Tji. Take one feature cutting of one workpiece in the CNC milling as an example, and Fig. 2 shows real-time power of one feature cutting process.

As shown in Fig. 2, there are five parts in one feature cutting process: startup, standby, spindle acceleration, air cutting and cutting. Among them, standby state, air cutting state and cutting state are the most significant with more energy consumption produced. In the standby state, the machine tool is standby and only some basic systems operate such as CNC system, lubricating system and lighting system. Before cutting, an air cutting distance is set to avoid violent collisions between cutting tools and workpieces. During this air cutting state, the spindle system, feed system and auxiliary system (cooling pump, etc.) are operating. In the cutting state, features are processed where cutting tools touch workpieces to remove extra material and all systems are operating to consume energy. During the multi-feature parts batch processing, the startup and spindle acceleration energy consumption can be ignored since the time is short. Moreover, the cutting tool and cutting parameters need to be adjusted because of tool wear according to Sect. 2, which also produce energy consumption. Therefore, energy consumption of one Tj can be calculated by:

where \(E^{st}_{ji}\), \(E^{air}_{ji}\), \(E^{c}_{ji}\), \(E_{adtool}\), and \(E_{adpar}\) are energy consumption in each Tji of standby, air cutting, cutting, cutting tool adjustment and cutting parameter adjustment, respectively.

-

1.

Standby energy consumption

Standby energy consumption of each Tji is related to standby power \({P}_{ji}^{st}\) that drives basic systems and corresponding standby time \({t}_{ji}^{st}\).

$${E}_{ji}^{st}={P}_{ji}^{st}\bullet {t}_{ji}^{st}$$(4) -

2.

Air cutting energy consumption

Air cutting energy consumption is related to air cutting power \({P}_{ji}^{air}\) and corresponding air cutting time \({t}_{ji}^{air}\). And \(P_{ji}^{air}\) is composed of standby power \({P}_{ji}^{st}\), unload power \({P}_{ji}^{u}\) which drives the spindle and feed system and auxiliary power \({P}_{ji}^{aux}\) which drives auxiliary systems. Air cutting time is related to cutting tool diameter D, air cutting distance \({l}_{ji}^{air}\), cutting speed \({v}_{c}^{ji}\) and feed rate \(f^{ji}\).

$${E}_{ji}^{air}={P}_{ji}^{air}\bullet {t}_{ji}^{air}=\left({P}_{ji}^{st}+{P}_{ji}^{u}+{P}_{ji}^{aux}\right)\bullet {t}_{ji}^{air}$$(5)$${t}_{ji}^{air}=\frac{60\pi D{l}_{ji}^{air}}{{v}_{c}^{ji}{f}^{ji}\times {10}^{3}}$$(6) -

3.

Cutting energy consumption

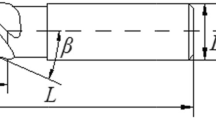

Cutting energy consumption of each Tji is related to cutting power \({P}_{ji}^{c}\) and corresponding cutting time \({t}_{ji}^{c}\). During cutting, \({P}_{ji}^{c}\) can be divided into five parts: standby power \({P}_{ji}^{st}\), unload power \({P}_{ji}^{u}\), auxiliary power \({P}_{ji}^{aux}\), material removal power \({P}_{ji}^{mr}\) which removes workpiece material and additional load power \({P}_{ji}^{a}\) which is generated accompanied with cutting loads. Cutting time is the function of cutting distance L, teeth number z, feed per tooth \(f_{z}^{ji}\) and spindle rotational speed nji.

$${E}_{ji}^{c}={P}_{ji}^{c}\bullet {t}_{ji}^{c}=\left({P}_{ji}^{st}+{P}_{ji}^{u}+{P}_{ji}^{aux}+{P}_{ji}^{mr}+{P}_{ji}^{a}\right)\bullet {t}_{ji}^{c}$$(7)$${t}_{ji}^{c}=\frac{60L}{z{f}_{z}^{ji}{n}_{ji}}$$(8)According to Sect. 2, cutting tool IUil is selected to process feature Ii in each Tji and cutting parameter set Xji is selected based on cutting tools and tool wear state. Thus, \(P_{ji}^{mr}\) in this problem is the function of cutting parameters, cutting tools and wear values, as shown in Eq. (9):

$${P}_{ji}^{mr}=F\left({X}_{ji}\right)=F\left({v}_{c}^{ji},{f}^{ji},{a}_{p}^{ji},{a}_{e}^{ji}\left|I{U}_{il}\Theta V{B}_{il}^{ji}\right.\right)$$(9)where \(a_{p}^{ji}\) and \(a_{e}^{ji}\) are, respectively, the cutting depth and cutting width.

-

4.

Cutting tool adjustment energy consumption

In a batch processing, cutting tool adjustment should be executed when cutting tool IUil reaches cutting tool adjustment standard \(VB_{max}^{il}\), which is accompanied with energy consumption. According to machining experience, cutting tool adjustment includes automatic adjustment and manual adjustment. Therefore, cutting tool adjustment energy consumption can be described as:

$${E}_{adtool}={E}_{adtool}^{aut}+{E}_{adtool}^{man}$$(10)where \({E}_{adtool}^{aut}\) and \({E}_{adtool}^{man}\) are energy consumption of automatic adjustment and manual adjustment, respectively.

Automatic adjustment refers that there is another cutting tool on the machine tool can be used when the last one is broken, and the specified cutting tool will be automatically adjusted by machine tool according to the program setting. At this state, machine tool is operating and \({E}_{adtool}^{aut}\) is related to automatic adjustment power \({P}_{adtool}^{aut}\) and corresponding time \({t}_{adtool}^{aut}\):

$${E}_{adtool}^{aut}={P}_{adtool}^{aut}\bullet {t}_{adtool}^{aut}{k}_{il}\text{, where }{k}_{il}\text{=}\left\{\begin{array}{l}{1} \, \, {\text{Automatic}} \, {\text{adjustment}}\\ {0} \, \, {\text{No}} \, {\text{automatic}} \, {\text{adjustment}}\end{array}\right.$$(11)Manual adjustment refers that when all cutting tools on machine tool need to be changed, the specified cutting tool should be manually adjusted by workers. At this state, the machine tool is standby and the reference point should be set again after changing new cutting tools. \(E_{adtool}^{man}\) is related to standby power and corresponding time \(t_{adtool}^{man}\):

$${E}_{adtool}^{man}={P}_{st}\bullet {t}_{adtool}^{man}{r}_{il}\text{, where }{r}_{il}=\left\{\begin{array}{l}{1} \, \, {\text{Manual}} \, {\text{adjustment}}\\ {0} \, \, {\text{No}} \, {\text{manual}} \, {\text{adjustment}}\end{array}\right.$$(12) -

5.

Cutting parameter adjustment energy consumption

Cutting parameter adjustment refers that when cutting parameters cannot meet processing requirement, this set of cutting parameters needs to be adjusted along cutting parameter adjustment time tadpar by workers before processing feature Ii. Cutting parameter adjustment energy consumption Eadpar is shown in Eq. (13):

$${E}_{adpar}={P}_{st}\bullet {t}_{adpar}{u}_{il}\text{, where }{u}_{il}=\left\{\begin{array}{l}{1} \, \, {\text{Parameter}} \, {\text{adjustment}}\\ {0} \, \, {\text{No}} \, {\text{parameter}} \, {\text{adjustment}}\end{array}\right.$$(13)

4 Multi-objective optimization model of multi-feature parts batch processing

4.1 Variables

In this problem of the multi-feature parts batch processing, there is a close crossing influence between cutting tools and cutting parameters. Cutting tools selection and cutting parameters setting both can determine total energy consumption and machining time in the batch processing [28]. Based on this, cutting tools and cutting parameters under different tool wear are taken as the optimization variables in this integrated optimization model, which are shown as:

4.2 Objectives

To achieve high efficiency and energy conservation in the processing process, the energy consumption and machining time are chosen as optimization objectives in this optimization model. According to the analysis in Sect. 3, the energy consumption and machining time can be described as:

4.3 Optimization model

Based on the above analysis, the cutting parameter optimization model considering tool wear for multi-feature parts batch processing is as follows:

To ensure the rationality and accuracy of the established multi-feature parts batch processing optimization model, constraints should be made on cutting parameters, feature cutting, machine tool characteristics and other aspects. Constraints (18)-(21) ensure \({v}_{c}^{Uu}\), \({f}_{z}^{Uu}\), \({a}_{p}^{Uu}\), \({a}_{e}^{Uu}\) and rotational speed n are within the feasible range, where \({v}_{c-\mathrm{min}}^{Uu}/{v}_{c-\mathrm{max}}^{Uu}\), \({f}_{z-\mathrm{min}}^{Uu}/{f}_{z-\mathrm{max}}^{Uu}\), \({a}_{p-\mathrm{min}}^{Uu}/{a}_{p-\mathrm{max}}^{Uu}\) and nmin/nmax are maximum and minimum cutting speed, feed, cutting depth and rotation speed, k is the tool path spacing coefficient and dUu is the cutting tool diameter. Constraints (22)–(24) ensure Pc, cutting force and roughness should not, respectively, exceed the permitted maximum power Pmax, maximum cutting force Fc-max and roughness requirement, where η is the effective coefficient, Ka, Ca, Xa, Ya, Ua, Qa, Za are the corresponding influence indexes of the cutting forces [29], La and Ta are the front angle and the back angle of the milling cutter. Constraints (25) and (26) indicate that cutting tools and cutting parameters should be adjusted when reaching the adjustment standard. Constraint (27) ensures that all IUil used are within U in the batch processing. Constraint (28) ensures that all features are processed sequentially.

4.4 Multi-objective cuckoo search algorithm

Cuckoo search (CS) algorithm is a bionic swarm intelligent optimization algorithm proposed by simulating cuckoo nesting behavior, which is mainly based on the natural law of cuckoo breeding by means of other birds’ nests and Levy Flight [30]. CS algorithm is widely used in the engineering practice due to fewer parameters, unique optimization mechanism and strong convergence [31].

In this paper, cutting tools, cutting parameters and tool wear are taken as variables and there exists mutual restricting and influencing relationships between them. Therefore, the cutting parameter optimization considering tool wear of multi-feature parts batch processing is a typical nonlinear, multi-constrained and high-dimensional problem. To this end, the MOCS algorithm is used to solve the optimization problem. The specific flow chart is shown in Fig. 3.

According to actual requirements of this problem, algorithm mechanism is adjusted to improve search efficiency as follows:

-

1.

Initial solution generation

Initialize Archive = 0, Archive length as Amax, the maximum number of iterations as Iter, and the current number of iterations as r = 0. When r < Rmax, cutting tools and cutting parameters are randomly selected according to cutting tool and cutting parameter set K, as shown in Eq. (29). Calculate the fitness function value corresponding to the generated solution, then save the solution and delete the dominated solution in Archive in real time. Then, let r = r + 1. When r = Rmax, K should be output corresponding to each Pareto solution in Archive.

$$K=\sum_{j=1}^{N}\sum_{i=1}^{w}{X}_{ji}\left(I{U}_{il},{v}_{c}^{ji},{f}^{ji},{a}_{p}^{ji},{a}_{e}^{ji}\left|V{B}_{il}^{ji}\right.\right)$$(29) -

2.

Neighborhood solutions generation

According to the analysis of the multi-feature parts batch processing in this paper, two methods are used to generate neighborhood solutions. Cutting tool diameter and cutting parameter a are updated by crossover and mutation operations, where a is the cutting parameter that affect wear speed most. Cutting parameters b, c and d are updated with Levy Flight.

-

(a)

Crossover & mutation operation

Figure 4 shows the flow chart of crossover and mutation operations. Known that crossover happens between current solution Kcurrent and Pareto solution K’ to generate a new cutting tool IU and new a. Then, a new cutting tool in IUi is randomly selected again and a is updated according to the new cutting tool through the mutation.

-

(b)

Levy flight

On the premise of the generated a and cutting tool IU, b, c and d are generated by Levy Flight [32] in Eq. (30) within the range of feasible cutting parameters. The search step size σ and the random step size obeying Levy distribution are shown in Eqs. (31) and (32), respectively.

$${K}_{i}\left(r+1\right)={K}_{i}\left(r\right)+\sigma \oplus Levy\left(\delta \right)$$(30)where Ki(r + 1) is the i-th optimal solution in generation r + 1. Ki(r) is i-th optimal solution in generation r. \(\oplus\) is the point to point multiplication.

$$\sigma \text{=}{\sigma }_{0}\left[{K}_{j}\left(r\right)-{K}_{i}\left(r\right)\right]$$(31)$$Levy\sim \xi ={t}^{-1-\delta }$$(32)where σ0 is the control value of the search step size. δ is constant. Kj(r) and Ki(r) are the optimal randomly selected solutions in generation r.

-

(a)

-

3.

Cutting tool and parameter adjustment strategy

Cutting tool and parameter adjustments are not always happening in every Tji. Several steps should be performed to judge whether there is a cutting tool adjustment or a cutting parameters adjustment before each Tji. Figure 5 shows the strategy:

-

(a)

If cutting tool IUil is not the cutting tool of feature Ii of workpiece J(j-1), a set of cutting parameters can be directly selected within standard [ΔVB/Δt]il and there is no cutting parameter adjustment;

-

(b)

If cutting tool IUil is the cutting tool of feature Ii of workpiece J(j-1) and reaches standard [ΔVB/Δt]il, cutting parameter adjustment should be performed;

-

(c)

If all cutting tools IUil in cutting tool set IUi reach standard \(VB_{max}^{il}\), manual cutting tool adjustment should be performed;

-

(d)

If there exists cutting tool IUil in cutting tool set IUi not reaching standard \(VB_{max}^{il}\), and IUil is not the cutting tool of the feature I(j-1), automatic cutting tool adjustment should be performed. Otherwise, there is no cutting tool adjustment.

-

(a)

5 Case study

5.1 Experimental setup

To verify the effectiveness and practicability of the proposed model, the batch processing experiment is carried out by conducting CNC milling at an industrial enterprise in Chongqing. The multi-feature z-axis cutter block is selected as the workpiece. There are three kinds of features on this workpiece which is one hole with the diameter of 80 mm, eight M10 threaded holes and two 100 mm × 20 mm × 15 mm slots, shown in Fig. 6. There is one machine tool and two kinds of cutting tools used in the experiment with 50 workpieces to be processed.

As shown in Fig. 7, VGC1500 vertical machining center is adopted to process workpieces and the efficiency monitoring system is used to monitor and collect power and time data in real time. Besides, tool wear states and values are measured using a super-depth three-dimensional microscope system. Details of machine tool, cutting tools, workpieces and relevant parameters are shown in Table 2.

5.2 Optimization model parameter configuration

The proposed optimization model involves several parameters such as power coefficients and tool wear values which are hard to obtain directly. In this paper, the experiment method is operated utilizing equipment in Sect. 5.1 to quantify the energy model. Firstly, the spindle idle experiment is conducted to fit unload power Pu. Then, the material removal power Pmr ji and the additional load power Pa ji are fitted since the relationship between them is complex and it is difficult to extract data separately. Finally, tool wear values VB are measured under different conditions.

-

1.

Modeling Pu

When the machine tool is idling, basic systems, spindle system and feed system are operating. As a result, idle power Pidle includes standby power Pst and unload power Pu. Also, Pu is the quadratic function of the spindle speed nji, as shown in Eq. (33). To obtain Pu, Pidle under different spindle speed nji need to be obtained through the idle experiment with nji (r/min) increasing from 2500 to 4500. Results are shown in Table 3 and the unload power expression can be obtained by fitting, as shown in Eq. (34). The variance analysis of the obtained unload power function model is carried out and results are shown in Table 4. It can be seen from the table that R-Sq = 98.91%, and R-Sq(adj) = 98.62%, indicating that the model is reliable.

$${P}_{idle}-{P}_{st}={P}_{u}={a}_{0}+{a}_{1}{n}_{ji}+{a}_{2}{\left({n}_{ji}\right)}^{2}$$(33)$${P}_{ji}^{u}\left({n}_{ji}\right)=647.46-0.39{n}_{ji}+9.01\times {10}^{-5}{n}_{ji}^{2}$$(34)where a0, a1 and a2 are relevant coefficients of unload power.

-

2.

Modeling \({P}_{ji}^{mr}\) and \({P}_{ji}^{a}\)

There is a quadratic relationship between \({P}_{ji}^{a}\) and \({P}_{ji}^{mr}\). According to formulas (5) and (7), the sum of \({P}_{ji}^{mr}\) and \({P}_{ji}^{a}\) is the difference of \({P}_{ji}^{c}\) and \({P}_{ji}^{air}\), as shown in Eq. (35). Meanwhile, \({P}_{ji}^{mr}\) considering tool wear can be expressed in Eq. (36) from the literature [18]. To obtain the sum of \({P}_{ji}^{mr}\) and \({P}_{ji}^{a}\), the orthogonal experiment with three levels of cutting parameters and tool wear values shown in Table 5 is carried out. Experimental results are shown in Table 6 and the final expression of the sum of \({P}_{ji}^{mr}\) and \({P}_{ji}^{a}\) is shown in Eq. (37). The variance analysis of the obtained \({P}_{ji}^{mr}-{P}_{ji}^{a}\) model is carried out and results are shown in Table 7, where R-Sq = 96.16%, R-Sq(adj) = 95.01%, indicating that the model is reliable.

$${P}_{ji}^{mr}+{P}_{ji}^{a}=\left({c}_{0}+1\right){P}_{ji}^{mr}+{c}_{1}{\left({P}_{ji}^{mr}\right)}^{2}\text{=}{P}_{ji}^{c}-{P}_{ji}^{air}$$(35)$${P}_{ji}^{mr}=k{\left(1+V{B}_{il}\right)}^{w}{v}_{c}^{a}{f}_{z}^{b}{a}_{p}^{c}{a}_{e}^{d}$$(36)$${P}_{ji}^{mr}+{P}_{ji}^{a}=56.4\times {\left(1+V{B}_{il}\right)}^{1.28}{v}_{c}^{0.97}{f}_{z}^{0.83}{a}_{p}^{0.46}{a}_{e}^{0.29}-0.79\times {\left(1+V{B}_{il}\right)}^{2.56}{v}_{c}^{1.94}{f}_{z}^{1.66}{a}_{p}^{0.92}{a}_{e}^{0.58}$$(37)where k, c0, c1 and c2 are relevant coefficients of material removal power and additional load power.

At last, the energy consumption model in Eq. (15) can be finally translated in Eq. (38) according to Eqs. (34) and (37):

$${E}_{total}=\sum\limits_{j=1}^{N}\left(\sum\limits_{i=1}^{w}\left(\begin{array}{l}{P}_{ji}^{st}\cdot {t}_{ji}^{st}+\left({P}_{ji}^{st}+647.46-0.39{n}_{ji}+9.01\times {10}^{-5}{n}_{ji}^{2}+{P}_{ji}^{aux}\right)\cdot \frac{60\pi D{l}_{ji}^{air}}{{v}_{c}^{ji}{f}^{ji}\times {10}^{3}}\\ +\left(\begin{array}{c}{P}_{ji}^{st}+647.46-0.39{n}_{ji}+9.01\times {10}^{-5}{n}_{ji}^{2}+{P}_{ji}^{aux}\\ +56.4\times {\left(1+V{B}_{il}\right)}^{1.28}{v}_{c}^{0.97}{f}_{z}^{0.83}{a}_{p}^{0.46}{a}_{e}^{0.29}\\ -0.79\times {\left(1+V{B}_{il}\right)}^{2.56}{v}_{c}^{1.94}{f}_{z}^{1.66}{a}_{p}^{0.92}{a}_{e}^{0.58}\end{array}\right)\bullet \frac{60L}{z{f}_{z}^{ji}{n}_{ji}}+{P}_{adtool}^{aut}\bullet {t}_{adtool}^{aut}{k}_{il}\\ +{P}_{st}\bullet {t}_{adtool}^{man}{r}_{il}+{P}_{st}\bullet {t}_{adpar}{u}_{il}\end{array}\right)+{P}_{st}\bullet {t}_{wsr}\right)$$(38) -

3.

Tool wear acquisition

According to the analysis in Sect. 2, tool wear values VB vary with respect to cutting parameters. To find out how cutting parameters (vc, fz, ap, ae) affect tool wear values, the sensitivity analysis is carried out. Two cutting parameters are set fixed successively, and the influence of the remaining two cutting parameters on tool wear is analyzed. Figure 8 shows the sensitivity analysis results. Figure 8a shows that at the condition of fz = 0.12 mm/r, ap = 1.0 mm, VB increases with the increasing of vc and ae. The steepness in the direction ae-axis is lower than of vc-axis, so the effect of vc is higher than ae. Figure 8b shows that at the condition of fz = 0.12 mm/r, ae = 10 mm, with the rise of vc and ap, VB continuously increases. The rate of vc-VB curve is higher than ap-VB, which means that vc influences wear value VB more than ap. In Fig. 8c, VB also increases with the growing of vc and fz. And vc has more effects than fz observing that vc rises faster than fz. Therefore, cutting speed has the greatest impact on tool wear values among these four cutting parameters. In this paper, tool wear values are measured under seven sets of cutting speeds (vc = 70, 80, 90, 100, 110, 120, 130, unit m/min). Time and tool wear values corresponding to reference points at each set of vc are shown in Table 8.

5.3 Optimization results and discussions

-

1.

Optimization results

To prove the effectiveness of the optimization model and algorithm, three optimization schemes are set: 1) Scheme 1: Separate optimization of Etotal; 2) Scheme 2: Separate optimization of ttotal; 3) Scheme 3: Comprehensive optimization of Etotal&ttotal. Main parameters of the MOCS algorithm are set as Table 9. Based on this, programming is conducted and optimization results of the above schemes are obtained in Tables 10, 11, and 12, where cutting tools, cutting parameters, tool wear values and their adjustments are given. According to tables, cutting parameters are continuously adjusted according to different cutting tool to reduce the wear speed and obtain optimal objectives.

Tables 10 and 11 show detailed optimization results of scheme 1 and 2. In scheme 1, cutting speeds are set at a higher level with five times of cutting tool automatic adjustment, three times of cutting tool manual adjustment and three times of cutting parameters adjustment. In scheme 2, cutting speeds are set at a lower level with three times of cutting tool automatic adjustment, four times of cutting parameters adjustment and no cutting tool manual adjustment. Compared with scheme 2, Etotal of scheme 1 decreases by 3.8%, but ttotal increases by 20%, as well as cutting tool and parameter adjustments of scheme 1 are more frequent.

Figure 9 shows the Pareto front of scheme 3, where there is an obvious conflict relationship between Etotal and ttotal. Thus, the separate optimization of Etotal and ttotal is inapplicable in the actual production and a trade-off between the reduction in Etotal and ttotal should be conducted to obtain the comprehensive optimization result [33, 34].

Table 12 shows optimization results of scheme 3, which is one set of Pareto solutions. There is one time of cutting tool manual adjustment, four times of cutting tool automatic adjustment and four times of cutting parameters adjustment. Compared with scheme 3, Etotal of scheme 1 decreases by 16.3%, but ttotal increases by 9.6%, and ttotal of scheme 2 decreases by 8.7%, but Etotal increases by 35.5%. Frequency of cutting tool and parameter adjustments in scheme 3 is compromise. Through the comparative result, although the multi-objective optimization cannot both reduce Etotal and ttotal, it can make a good trade-off between the conflict of Etotal and ttotal and realize the win–win between energy saving and production efficiency. This result can provide guidance for engineering practice with different production objectives, which verifies the effectiveness of proposed optimization model and algorithm.

-

2.

Results verification

To verify the proposed optimization model, a set of fixed empirical cutting parameters is selected according to actual engineering experience to process workpieces under the same processing condition. Comparative results between scheme 3 and empirical scheme are shown in Table 13. Compared with empirical scheme, cutting tools number is less in scheme 3, and Etotal decreases by 22.9% and ttotal decreases by 4.1%. Main reason lies that 1) empirical scheme has no cutting parameters adjustment so that tool wear values increases rapidly, causing more cutting tools used in the processing and high Ec. Although no cutting parameter adjustment can reduce standby energy consumption, Etotal increases at last. 2) In empirical scheme, more cutting tool adjustments result in high \({t}_{adtool}^{man}\). At the same time, due to the interference factors such as the inconsistency of workers’ operation, time such as tool adjustment and workpiece clamping has certain deviation, eventually leading to an increase in ttotal.

Based on comparative results and analysis, continuously adjusting cutting parameters based on tool wear states is an effective way to reduce wear speeds, and considering tool wear in cutting parameter optimization can reduce energy consumption and machining time significantly. The validation of proposed optimization model is verified.

-

3.

Decomposition analysis

To further explain optimization results and summarize energy-saving rules that can be used to guide engineering practice, the energy consumption and machining time composition diagrams of different schemes are drawn, shown in Fig. 10. Figure 10a shows the energy consumption composition, where the greatest difference between three schemes is Ec, followed by \({E}_{adtool}^{man}\) and \({E}_{adtool}^{aut}\). Est, Eair, Eadpar and Ewsr are at the same level. Figure 10b shows he machining time composition, where tst, tair, tc and twsr are at the same level. Differences between \({t}_{adtool}^{man}\), \({t}_{adtool}^{aut}\) and tadpar will mainly affect ttotal in different schemes.

The analysis is as follows: 1) In scheme 1, there are three cutting tool 1 and two cutting tool 2 used to complete the batch processing task and parameters are adjusted frequently during processing. As a result, tadpar and tman adtool become longer, thus increasing ttotal. On the other hand, the processing of scheme 1 starts at a high cutting speed, and the cutting parameters are constantly adjusted frequently to make the cutting tools act on the low tool wear state for a long time, ultimately resulting in a lower Etotal. 2) In scheme 2, there is only one cutting tool 1 and one cutting tool 2 used to complete the batch processing task. The number of tools used is small, and there is no manual cutting tool adjustment. As a result, there is no \({t}_{adtool}^{man}\) and tadpar is also short, finally making ttotal become shorter. On the other hand, the same cutting tool without cutting parameters adjustment is used for a long time so that the tool wear state is intensified, resulting in a higher Etotal.

-

4.

Influence of cutting parameters and tool wear on cutting power

As aforementioned study, cutting parameters and tool wear have synergistic effect on energy consumption, and cutting state consumes dominate energy known from the decomposition analysis. Thus, this section comprehensively analyzes the influence of cutting parameters and tool wear on cutting power to explore the detailed relationship and influence mechanism between them and prove the existence of the synergistic effect. Tool wear VB, cutting speed vc, feed fz and cutting depth ap are selected as variables. Figure 11 shows different cutting powers Pc under different cutting parameters and wear values. From Fig. 11a to Fig. 11d, VB, vc, fz and ap vary sequentially with other three parameters staying constant.

In Fig. 11, with the other three parameters fixed, Pc increases along another parameter. The analysis shows that 1) the friction between tool and workpiece increases with the increase in tool wear, causing the workpiece subjected to a greater cutting force, which is transmitted to the motor and increases the output power of the motor. 2) With cutting parameters increasing, more materials are removed in unit time, and the cutting force on the workpiece increases, leading to the increase in motor output power. 3) According to the actual processing experience, increasing vc and fz can improve the processing efficiency. Under the requirement of large cutting thickness, increasing ap can reduce cutting steps to save time. Through the above analysis, cutting parameters and tool wear have significant indigenous effects on energy consumption and machining time. Therefore, in the actual processing, cutting parameters should be selected according to the comprehensive consideration of the propensity of enterprises to energy consumption and machining time.

On this basis, the sensitivity analysis of above four parameters (VB, vc, fz and ap) on cutting power is conducted. Two of them are set fixed successively, and the influence of the remaining two is analyzed. Figure 12 shows the analysis result. In Fig. 12a, b, the steepness of vc-axis is higher than fz-axis and ap-axis, and fz-axis rises faster than ap-axis in Fig. 12c, showing that vc is the most influential parameter on cutting power among three cutting parameters under fixed wear value, followed by fz and ap. Figure 12d reveals that under fixed fz and ap, effects of vc on cutting power is a little higher than that of VB, since the rate of vc curve is higher than VB curve. In addition, it can be obtained that the energy consumption is different under different cutting parameters and tool wear values. Even under the same cutting parameters, the energy consumption is still different if tool wear values are different, which proves that there is a synergistic effect between cutting parameters and tool wear on the energy consumption.

6 Conclusion

In the cutting parameter optimization of the multi-feature parts batch processing problem, the comprehensive influence of cutting parameters, cutting tools and too wear states on the energy consumption and machining time are less included in previous researches. A cutting parameter optimization model considering tool wear for multi-feature parts batch processing is proposed for energy and machining time saving in this paper. Firstly, the energy consumption analysis for the multi-feature parts batch processing considering tool wear and adjustment of cutting tools and cutting parameters is conducted. Secondly, a multi-objective optimization model is proposed. In this model, the influence of the synergistic effect between the tool wear and cutting parameters is comprehensively considered. Finally, the MOCS algorithm is combined in this problem to solve the model and a case study is carried out to verify the effectiveness and practicability of the proposed model. The optimization results show that the trade-off between energy consumption and machining time is achieved. The verification results show that the continuous adjustment of cutting parameters can further reduce tool wear speeds, thus reducing energy consumption and machining time.

In the actual production, to complete a batch processing tasks may require multiple machine tools and multiple processing technologies cooperating to complete the task. Therefore, under the premise of considering the tool wear state, comprehensively considering the influence of the coordination of multiple machine tools and multiple processing technologies on the whole batch processing will be the research focus of the next step.

Availability of data and material

The data needed to evaluate the conclusions in the study are included in this article.

Code availability

Not applicable.

References

Spiering T, Kohlitz S, Sundmaeker H, Herrmann C (2015) Energy efficiency benchmarking for injection moulding processes. Rob Comput Integr Manuf 36:45–59. https://doi.org/10.1016/j.rcim.2014.12.010

International Energy Agency (IEA) (2019) International energy outlook 2019. Retrieved 15 Mar 2021 from https://www.eia.gov/outlooks/ieo/pdf/ieo2019.pdf

Park CW, Kwon KS, Kim WB, Min BK, Park SJ, Sung IH, Yoon YS, Lee KS, Lee JH, Seok J (2009) Energy consumption reduction technology in manufacturing—a selective review of policies, standards, and research. Int J Precis Eng Manuf 10:151–173. https://doi.org/10.1007/s12541-009-0107-z

Xiao Q, Li C, Tang Y, Li L (2019) Meta-reinforcement learning of machining parameters for energy-efficient process control of flexible turning operations. IEEE Trans Autom Sci Eng 99:1–4. https://doi.org/10.1109/TASE.2019.2924444

Xie J, Cai W, Du Y, Tang Y, Tuo J (2021) Modelling approach for energy efficiency of machining system based on torque model and angular velocity. J Clean Prod 293:126249. https://doi.org/10.1016/j.jclepro.2021.126249

Gutowski T, Dahmus J, Thiriez A (2006) Electrical energy requirements for manufacturing processes. Proc CIRP Int Conf Life Cycle Eng 5–11

Zhao X, Li C, Chen X, Cui J, Cao B (2021) Data-driven cutting parameters optimization method in multiple configurations machining process for energy consumption and production time saving. Int J Precis Eng Manuf Green Technol 1–20. https://doi.org/10.1007/s40684-021-00373-0

Newman ST, Nassehi A, Imani-Asrai R, Dhokia V (2012) Energy efficient process planning for CNC machining. CIRP J Manuf Sci Technol 5:127–136. https://doi.org/10.1016/j.cirpj.2012.03.007

Hu L, Tang R, Cai W, Feng Y, Ma X (2019) Optimisation of cutting parameters for improving energy efficiency in machining process. Robot Comput Integr Manuf 59:406–416. https://doi.org/10.1016/j.rcim.2019.04.015

Li C, Xiao Q, Tang Y, Li L (2016) A method integrating Taguchi, RSM and MOPSO to CNC machining parameters optimization for energy saving. J Clean Prod 135:263–275. https://doi.org/10.1016/j.jclepro.2016.06.097

Bhushan RK (2013) Optimization of cutting parameters for minimizing power consumption and maximizing tool life during machining of Al alloy SiC particle composites. J Clean Prod 39:242–254. https://doi.org/10.1016/j.jclepro.2012.08.008

Cui X, Guo J (2018) Identification of the optimum cutting parameters in intermittent hard turning with specific cutting energy, damage equivalent stress, and surface roughness considered. Int J Adv Manuf Technol 96:4281–4293. https://doi.org/10.1007/s00170-018-1885-1

Chen X, Li C, Tang Y, Li L, Du Y, Li L (2019) Integrated optimization of cutting tool and cutting parameters in face milling for minimizing energy footprint and production time. Energy 175:1021–1037. https://doi.org/10.1016/j.energy.2019.02.157

Moreira LC, Li WD, Lu X, Fitzpatrick ME (2019) Energy-Efficient machining process analysis and optimisation based on BS EN24T alloy steel as case studies. Rob Comput Integr Manuf 58:1–12. https://doi.org/10.1016/j.rcim.2019.01.011

Zhang G, Guo C (2016) Modeling flank wear progression based on cutting force and energy prediction in turning process. Procedia Manuf 5:536–545. https://doi.org/10.1016/j.promfg.2016.08.044

Yoon HS, Lee JY, Kim MS, Ahn SH (2014) Empirical power-consumption model for material removal in three-axis milling. J Clean Prod 78:54–62. https://doi.org/10.1016/j.jclepro.2014.03.061

Tian C, Zhou G, Zhang J, Zhang C (2019) Optimization of cutting parameters considering tool wear conditions in low-carbon manufacturing environment. J Clean Prod 226:706–719. https://doi.org/10.1016/j.jclepro.2019.04.113

Zhou G, Yuan S, Lu Q, Xiao X (2018) A carbon emission quantitation model and experimental evaluation for machining process considering tool wear condition. Int J Adv Manuf Technol 98:565–577. https://doi.org/10.1007/s00170-018-2281-6

Bagaber SA, Yusoff AR (2017) Multi-objective optimization of cutting parameters to minimize power consumption in dry turning of stainless steel 316. J Clean Prod 157:30–46. https://doi.org/10.1016/j.jclepro.2017.03.231

Xie N, Zhou J, Zheng B (2018) Selection of optimum turning parameters based on cooperative optimization of minimum energy consumption and high surface quality. Procedia CIRP 72:1469–1474. https://doi.org/10.1016/j.procir.2018.03.099

Zhang X, Yu T, Dai Y, Qu S, Zhao J (2020) Energy consumption considering tool wear and optimization of cutting parameters in micro milling process. Int J Mech Sci 178:105628. https://doi.org/10.1016/j.ijmecsci.2020.105628

Wan T, Chen X, Li C, Tang Y (2018) An on-line tool wear monitoring method based on cutting power. IEEE Int Conf Autom Sci Eng 205–210. https://doi.org/10.1109/COASE.2018.8560412

Shi K, Zhang D, Liu N, Wang S, Ren J (2018) A novel energy consumption model for milling process considering tool wear progression. J Clean Prod 184:152–159. https://doi.org/10.1016/j.jclepro.2018.02.239

Wang P, Gao R (2016) Stochastic tool wear prediction for sustainable manufacturing. Procedia CIRP 48:236–241. https://doi.org/10.1016/j.procir.2016.03.101

Selvaraj DP, Chandramohan P, Mohanraj M (2014) Optimization of surface roughness, cutting force and tool wear of nitrogen alloyed duplex stainless steel in a dry turning process using Taguchi method. Measurement 49:205–215. https://doi.org/10.1016/j.measurement.2013.11.037

Liu Z, Guo Y, Sealy MP, Liu Z (2016) Energy consumption and process sustainability of hard milling with tool wear progression. J Mater Process Technol 229:305–312. https://doi.org/10.1016/j.jmatprotec.2015.09.032

Zhao G, Su Y, Zheng G, Zhao Y, Li C (2020) Tool tip cutting specific energy prediction model and the influence of machining parameters and tool wear in milling. P I Mech Eng B-J Eng 234:1346–1354. https://doi.org/10.1177/0954405420911298

Priarone PC, Robiglio M, Settineri L, Tebaldo V (2016) Modelling of specific energy requirements in machining as a function of tool and lubricoolant usage. CIRP Ann 65:25–28. https://doi.org/10.1016/j.cirp.2016.04.108

Albertelli P (2017) Energy saving opportunities in direct drive machine tool spindles. J Clean Prod 165:855–873. https://doi.org/10.1016/j.jclepro.2017.07.175

Mellal MA, Williams EJ (2014) Cuckoo optimization algorithm for unit production cost in multi-pass turning operations. Int J Adv Manuf Technol 76:647–656. https://doi.org/10.1007/s00170-014-6309-2

Zamani AA, Tavakoli S, Etedali S (2017) Fractional order PID control design for semi-active control of smart base-isolated structures: a multi-objective cuckoo search approach. Isa Trans 67:222–232. https://doi.org/10.1016/j.isatra.2017.01.012

Yang XS, Deb S (2009) Cuckoo search via Levy flights. World Congr Nature Biol Inspired Comput NaBIC 210–214. https://doi.org/10.1109/NABIC.2009.5393690

Arriaza OV, Kim DW, Lee DY, Suhaimi MA (2017) Trade-off analysis between machining time and energy consumption in impeller NC machining. Rob Comput Integr Manuf 43:164–170. https://doi.org/10.1016/j.rcim.2015.09.014

Wang W, Tian G, Yuan G, Pham DT (2021) Energy-time tradeoffs for remanufacturing system scheduling using an invasive weed optimization algorithm. J Intell Manuf 1–19. https://doi.org/10.1007/s10845-021-01837-5

Funding

This work was supported in part by the National Key R&D Program of China (No.2019YFB1706103), National Natural Science Foundation of China (No.51975075) and Chongqing Technology Innovation and Application Program (No. cstc2020jscx-msxmX0221).

Author information

Authors and Affiliations

Contributions

Congbo Li and Shaoqing Wu designed the work, performed the research and analyzed the data. Congbo Li, Shaoqing Wu and Qian Yi discussed the results and wrote the manuscript. All authors contributed to conducting experiment, drafting and revising the manuscript.

Corresponding author

Ethics declarations

Ethics approval

Not applicable.

Consent to participate

Not applicable.

Consent to publish

Not applicable.

Conflict of interest

The authors declare that they have no competing interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Li, C., Wu, S., Yi, Q. et al. A cutting parameter energy-saving optimization method considering tool wear for multi-feature parts batch processing. Int J Adv Manuf Technol 121, 4941–4960 (2022). https://doi.org/10.1007/s00170-022-09557-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-022-09557-7