Abstract

In the manufacturing industry, cutting tool failure is a serious event which causes damage to the cutting tool and reduces the quality of the product, which increases the cost of production. A reliable, intelligent, tool wear monitoring system is required in the metal cutting manufacturing process to mitigate these negative effects. This study presents a model-based approach for tool wear monitoring based on an adaptive neuro-fuzzy inference system (ANFIS) for a cold-finished steel bar 1215 turning process. A three-input cutting force (Fx, Fy and Fz) and single-output (tool flank wear) model was designed and implemented using the ANFIS approach. The forces were measured using a piezoelectric dynamometer and data acquisition system. Flank wear was also monitored using a tool maker’s microscope. The model prediction results show that it is accurate enough to perform online monitoring of the turning process and can detect wear while operating.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

1 Introduction

The main goal of industrial companies is to manufacture high-quality parts at a minimum price in the minimum time. Monitoring machining operations contribute significantly to the automation of the manufacturing process and minimise human factor costs [1]. In the past, predicting tool failure and tool changing strategy were based on operator experience and played an important role during the machining process [2]. However, these days, a tool condition monitoring (TCM) system is essential in the manufacturing process. The degree of tool wear may be determined from signals related to cutting force, acoustics, vibration of both the workpiece and the tool, spindle motor current and temperature [3].

Fu et al. [4] studied the optimisation problem of the cutting parameters in milling NAK80 mild steel and found that the depth of cut was the most influential factor for cutting force in the milling process. Shi et al. [5] investigated using the cutting sound signal for tool breakage detection in the machining process and determined that the proposed method was capable of separating cutting sound signals from other source components related to a normal insert and a broken one.

Seemuang et al. [6] monitored tool wear in the turning process using spindle noise. It was found that machining parameters such as cutting speed, feed rate and depth of cut had a substantial effect on the amplitude of the spindle noise, making it possible to use spindle noise to identify tool flank wear in the machining process. It was also found that using simple and inexpensive instrumentation could produce data for condition monitoring of the process. García-Ordás et al. [7] proposed a new online, low-cost and fast approach based on computer vision. They claimed that the decision about whether a cutting edge is serviceable or disposable is based on the number of sub-regions classified as worn.

Lu et al. [8] studied high-frequency sound signals for tool wear monitoring in milling and found that there was a significant variation between sharp and worn tools. The maximum amplitude of the sound signal was related to worn tools. Zhang et al. [9] proposed a tool wear model based on a least squares support vector machine (LS-SVM) analysis procedure combined with machining parameters to predict tool wear of different positions at the tool cutting edge for a milling operation.

It has been reported that cutting force has a direct effect on machinability such as surface roughness, vibration and tool flank wear during the machining of alloys and composites [10,11,12,13]. Shankar et al. [5] reported that cutting force is the most accurate measurement for the online TCM. Boud et al. [14] investigated the application of multi-sensor signals for monitoring tool wear and reported that tool wear was identified by the cutting force, pressure and table displacement signals. They developed techniques in tool wear monitoring using a combination of sensors. In addition, they saved costs for industry by introducing high levels of automation along with improving the quality of final products.

In recent years, artificial intelligence (AI) techniques have been utilised in TCM [15, 16]. The network based on an adaptive neuro-fuzzy inference system (ANFIS) comprising both fuzzy and artificial neural networks (ANN) has been verified as a robust system recognition tool with the capacity to forecast accurately [17]. Shankar et al. [18] investigated the applicability of predicting cutting tool wear using AI techniques. The flank wear of the tool was found to be assessed precisely with the ANN model. Saglam [19] proposed a three-level ANN based on the cutting force for intelligent TCM in the milling process. A close match was found between the model output and directly measured wear of the flank. The ANN model was suitable even for research with insufficient data.

Mohtaram et al. [20] studied how to detect tool breakage using a combination of neural decision and an ANFIS tool wear predictor. They found that their proposed model enables monitoring of the cutting process with high reliability. It was also found that an ANFIS model can estimate tool flank wear progress quickly and accurately. Therefore, in this research, ANFIS is used to predict flank wear of a tool in the turning process for machining a steel alloy. The cutting forces are used as the indicator of the tool flank wear variation.

The paper is organised as follows: After the introduction, Section 2 introduces the methodology used for monitoring of tool flank wear. Section 2.1 describes turning experiments. This section provides a description of the material, tool and experimental setup. Section 2.2 provides a description of the ANFIS model. Section 2.3 presents ANFIS structure and membership function selection. Section 2.4 describes the TCM structure in detail. The result and discussion are presented in Section 3. The tool wear measurement results are explained in Section 3.1. Section 3.2 presents feature extraction and correlation with tool condition states. Sections 3.3 and 3.4 describe ANFIS training and ANFIS prediction results, respectively. Finally, the conclusion is listed in Section 4.

2 Methodology

2.1 Turning experiments

Turning experiments were conducted on a Mazak CNC (Nexus 100-II M) which has a maximum spindle speed of 8000 rpm. A three-component piezoelectric dynamometer (Kistler, Type 9255C) was used to record the cutting forces during the turning operations. The dynamometer was connected to charge amplifiers (type 5010) that measured the cutting forces along the x, y and z axes, recorded as Fx, Fy and Fz. LabView (Cut Pro 8.0) software was used to record and monitor all signals independently. All cutting force signals were exported to Matlab software for further analysis.

A cold-worked steel bar (1215) having a diameter of 100 mm and an overall length of 300 mm was used as a workpiece during the turning process. The cutting tool used for this research work was a CVD/TiCN-coated carbide tool having a 7° relief angle and a nose radius of 0.7 mm. Figure 1 shows the experimental setup. The experimental conditions are summarised in Table 1. The turning tool cuts the workpiece 36 times with the same machining conditions. Therefore, a total of 36 profiles of the turning force signals were gathered.

2.2 Adaptive neuro-fuzzy inference system

An adaptive neuro-fuzzy interface system (ANFIS) is an artificial neural network–based Takagi Sugeno fuzzy interface system which integrates both artificial neural networks (ANN) and fuzzy logic principals in a single frame [21]. The goal of ANFIS is to find a model to correlate the inputs and output correctly. ANFIS is an essential and intelligent tool for building efficient models for complex processes and datasets with uncertainty [22]. It has been found that ANFIS is useful for establishing a model with a complex data distribution under uncertainty [23].

2.3 ANFIS structure and membership function selection

The ANFIS architecture has five layers, as shown in Fig. 2. Every individual layer has a specific function to modify the incoming signals from the previous layer. The Matlab environment was employed to build up the ANFIS model using 36 pairs of data (27 were used for training and 9 were used for testing). As can be seen in Fig. 2, three different inputs, which are Fx, Fy and Fz with two membership functions (MFs) were considered in the proposed ANFIS model. In addition, 23 rules were considered for the structure of the recommended model.

Table 2 describes the function of each layer. The cutting forces as the inputs of the model are acquired to predict tool flank wear as output. The model splits the inputs Fx, Fy and Fz into various spaces using two MFs in the first layer.

Four different MF types, Sigmoidal, Triangular, Gaussian and Bell-shaped, were implemented to determine the most accurate model. Table 3 shows the function of these applied MFs. An AND rule is applied in the second layer to execute the multiplication of the outgoing signals from the first layer and then the relative weights of every rule are obtained in the third layer using the equation described in Table 2. A linear function of the inputs Fx, Fy and Fz is involved in the fourth layer of the model as defined in Table 3. Finally, in the fifth layer, the outgoing signals of the fourth layer are aggregated to obtain the predicted tool flank wear.

2.4 TCM structure

The purpose of TCM is to adopt corresponding sensor signal processing techniques to monitor and predict the cutter state during the machining process. A powerful TCM system can improve productivity and guarantee product quality, which has a considerable influence on machining efficiency. Hence, TCM is considerably important in the manufacturing industry [24]. In the current study, two main steps were considered for the proposed approach. First, a set of data obtained during an actual machining test on the turning machine was used to develop an ANFIS model of tool wear. Then, the trained ANFIS model for the tool wear was used for estimating specific tool wear condition as either initial, workplace or dull.

The force sensor was used to collect the signals during the turning process through a data acquisition module. The machining signals were analysed using a signal processing module for extracting features sensitive to tool wear. The data set was created by the features to be used as input to the decision system and estimator in order to map the input features to the current state of the tool. The data were divided into a training set and a testing set with a random pattern classifier module. The training set was used for learning, while the testing set was used to test the performance of the decision system [25]. A machining test was carried out with three different tools: a new tool, a working tool and a dull tool. To expedite the development of tool wear during the turning experiments, a set of machining conditions was applied according to the suggestion of a toolmaker company for steel alloys.

3 Results and discussion

3.1 Tool wear measurement results

For tool wear measurement, nine turning passes, including the 4th, 8th, 12th, 16th, 20th, 24th, 28th, 32nd and 36th passes, were selected from among the total of 36 passes. When measuring the tool wear, the turning process was paused after finishing each selected pass, and the tool was detached for measurement. Thus, an actual tool condition after each turning pass could be identified. A microscope with image analyser software was used to take images after cutting each pass. The flank wear is a result of abrasion and adhesion wear on a tool’s clearance face contacting with workpiece surface [26]. Figure 3 shows the optical images of the turning tool and measured flank wear values after machining the 8th, 20th and 36th passes. As can be seen in Fig. 3, flank wear values increased as the number of turning passes increased. For instance, after machining the 8th pass, the flank wear value was 0.06 mm, and it increased to 0.11 mm after machining the 20th pass. The flank wear also increased to 0.18 mm after machining the last pass (36th) for the steel alloy.

3.2 Feature extraction and correlation with tool condition states

In this study, the data collected from the cutting forces was processed and classified to extract the main feature of machining operations from all data. One of the important steps of a TCM system is the application of signal processing which has been considered beside the data acquisition system [27]. The signal from the machining process is generally classified either in the time domain or in the frequency domain [28]. Some procedures such as signal conditioning, filtering and root mean square (RMS) computation are commonly used in time domain signal processing. The difference between normal and irregular behaviour of the machine is often obtained by frequency domain signal processing.

In this research work, the air-cut signals were extracted from the raw signals as they could be differentiated by their magnitude. Then, the features from the signals were extracted from the entry cut and the exit cut of the raw signals. It has been found that noise is the main obstacle to obtaining signals through sensor data acquisition [28]. Therefore, wavelet transformation was used for denoising the original cutting force signals for Fx, Fy and Fz as it is the most popular and most important method for signal analysis in the time-frequency domain [23]. Figure 4 shows cutting force signals and denoised signals. As can be seen in Fig. 4, tangential force (Fx) and radial force (Fy) are always smaller than the main cutting force (Fz).

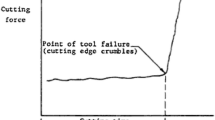

In addition, the mean values of the cutting force were calculated for Fx, Fy and Fz. Figure 5 illustrates the mean value of cutting force for all axes. As can be seen in Fig. 5, cutting forces increased with increasing number of machining pass. This means that cutting force signals increased with increasing machining time [27]. The measured turning signals were divided into 36 sections, one for each cutting pass of the tool. Observing the magnitudes of the measured turning force in different sections showed a sudden increase from the 24th pass and it fluctuated up and down between the 24th and 36th passes. In addition, the turning forces, Fx and Fy, increased significantly in this span. Since the measured tool flank wear also increased in this span, it was concluded that the turning process was not stable, and the tool was in a ‘dull’ condition.

A dull tool requires more power to cut the material due to the large contact area as well as friction between that tool and the workpiece which increases the magnitude of the main cutting force, Fz. Therefore, it was believed that measuring cutting force signals could be used to represent tool wear conditions in the turning process. As can be seen in Fig. 5, in the first section, from the 1st machining pass to the 8th pass, the measured turning cutting forces gradually increased, and it is observed that a new turning tool had become stabilised by turning the first six machining passes (Fig. 5a). Meanwhile, from the 8th pass to the 24th, the measured turning force signals had nearly constant magnitude, and measured tool wear values gradually increased (Fig. 5b). Therefore, in these sections, the turning process could be considered stable for machining the workpiece (workable). Finally, the dull state includes those from the 24th to the 36th passes. In this section, the measured turning force signals fluctuated sharply (Fig. 5c).

Figure 6 shows tool wear and turning forces in three directions, Fx, Fy and Fz. As can be seen in Fig. 6, the tool flank wear is about 0.2 mm at the end of the 36th machining pass. The tool flank wear conditions were defined along with the turning process: the initial state, workplace state and dull state. The turning forces increased with the increasing of flank wear values. The main cutting force (Fz) illustrates the highest turning force is about 450 N compared with the other forces. The tangential (Fx) and radial (Fy) forces were also consistent with the change in tool wear. The results illustrate that the influence of the tool’s wear state on Fy is greater than its effect on Fx, which is related to the sever adhesion caused by tool wear deterioration, especially at the tool chip interface [29]. According to the classification of cutting tool conditions, the tool flank wear value below 0.06 mm was classified as the initial state, those between 0.06 and 0.13 mm were classified as the workplace state, and those larger than 0.13 mm were classified as the dull state.

3.3 ANFIS training results

After construction of the ANFIS model, the values of the model coefficients were defined by using training data. In fact, every prediction model needs to initially learn the phenomenon. The data used in the learning (training) process must be different from the data which will be used to evaluate the predictive ability of the model. Therefore, 75% of the whole data was used to train the ANFIS model. In this step, the ANFIS model can learn the process with adequate accuracy if the model complexity is at a similar level with the process complexity. In this study, the ANFIS model was designed using 36 pairs of data (27 were used for training and 9 were used for testing). Various error analysis tools were used to determine the quality of the learning process in which regression analysis was selected as an appropriate and reliable method in this study.

Figure 7 shows the train regression plot of the prediction model with Sigmoidal MF. The regression coefficient of 0.99989 illustrates that the prediction model learns the relationship between flank wear and cutting forces efficiently.

There are two types of coefficients: premise coefficients which are the parameters of the MFs, and consequent coefficients which are the parameters of the linear function in the fourth layer (see Tables 2 and 3). The training stage can provide us with a good understanding of the process. For instance, as can be seen in Fig. 8, the behaviour of the MFs for Fx, Fy and Fz inputs during the training stage is similar. Therefore, the complexity of the process with regard to all inputs is similar and the consequent parameters have a vital role in characterising the tool flank wear. This feature is considered as an advantage of using ANFIS to predict complex phenomena.

3.4 ANFIS prediction results

The results of tool condition monitoring and diagnosis models developed by the ANFIS approach are presented in this section. These results are compared with the turning experimental results under the machining condition given in Table 1.

As has been discussed in previous sections, four different ANFIS models were constructed with Sigmoidal, Triangular, Gaussian and Bell-shaped MFs. A regression analysis of test data was used to evaluate the accuracy of prediction models. Figure 9 shows the test regression plots of all prediction models with their regression coefficient values. As can be seen in Fig. 9a, the prediction model with Sigmoidal MF and regression coefficient value of 0.96775 is the most accurate model among all prediction models. Figure 9 b, c and d illustrate the regression coefficient values for Triangular, Gaussian and Bell-shaped models which are 0.94993, 0.9363 and 0.9152, respectively.

Figure 10 shows the comparison of prediction and experimental results of the models for the whole dataset including training and test data. As can be seen in Fig. 10a, the best prediction result can be obtained by the ANFIS model with Sigmoidal MF since its prediction value in the turning process showed a monotonic increasing trend according to the tool flank wear progression.

4 Conclusion

This research work was carried out to monitor tool condition with a sensor fusion technique by measuring cutting force during turning of cold-working steel 1215. The tool flank wear had three conditions: initial state, workplace state and dull state. The flank wear increased with an increasing number of experiments, which means that the flank wear increases with increasing machining time. It was found that a dull tool requires higher power to cut the material due to the larger contact area as well as friction between the tool and the workpiece which increased the magnitude of the main cutting force, Fz. The tool condition was predicted by using an ANFIS approach. It was indicated that, when the flank wear results exceed 0.13 mm, the condition becomes dull and the tool should be replaced for further machining processes. The prediction model with the Sigmoidal membership function was the best model for predicting wear compared with the other models. The ANFIS prediction of tool wear can be applied to develop a condition monitoring interface in industrial applications where tooling cost and part quality are important factors in the production system.

References

Rizal M, Ghani JA, Nuawi MZ, Haron CHC (2013) Online tool wear prediction system in the turning process using an adaptive neuro-fuzzy inference system. Appl Soft Comput 13(4):1960–1968

Gajate A, Haber R, Del Toro R, Vega P, Bustillo A (2012) Tool wear monitoring using neuro-fuzzy techniques: a comparative study in a turning process. J Intell Manuf 23(3):869–882

Snr DED (2000) Sensor signals for tool-wear monitoring in metal cutting operations—a review of methods. Int J Mach Tools Manuf 40(8):1073–1098

Fu T, Zhao J, Liu W (2012) Multi-objective optimization of cutting parameters in high-speed milling based on grey relational analysis coupled with principal component analysis. Front Mech Eng 7(4):445–452

Shi X, Wang R, Chen Q, Shao H (2015) Cutting sound signal processing for tool breakage detection in face milling based on empirical mode decomposition and independent component analysis. J Vib Control 21(16):3348–3358

Seemuang N, McLeay T, Slatter T (2016) Using spindle noise to monitor tool wear in a turning process. Int J Adv Manuf Technol 86(9–12):2781–2790

García-Ordás MT, Alegre-Gutiérrez E, Alaiz-Rodríguez R, González-Castro V (2018) Tool wear monitoring using an online, automatic, and low-cost system based on local texture. Mech Syst Signal Process 112:98–112

Lu MC, Wan BS (2013) Study of high-frequency sound signals for tool wear monitoring in micromilling. Int J Adv Manuf Technol 66(9–12):1785–1792

Zhang C, Zhang H (2016) Modelling and prediction of tool wear using LS-SVM in milling operation. Int J Comput Integr Manuf 29(1):76–91

Barzani MM, Farahany S, Songmene V (2017) Machinability characteristics, thermal and mechanical properties of Al-Mg2Si in-situ composite with bismuth. Measurement 110:263–274

Barzani MM, Sarhan AA, Farahany S, Ramesh S, Maher I (2015) Investigating the machinability of Al–Si–Cu cast alloy containing bismuth and antimony using coated carbide insert. Measurement 62:170–178

Unune DR, Barzani MM, Mohite SS, Mali HS (2018) Fuzzy logic-based model for predicting material removal rate and average surface roughness of machined Nimonic 80A using abrasive-mixed electro-discharge diamond surface grinding. Neural Comput & Applic 29(9):647–662

Barzani MM, Farahany S, Yusof NM, Ourdjini A (2013) The influence of bismuth, antimony, and strontium on microstructure, thermal, and machinability of aluminum-silicon alloy. Mater Manuf Process 28(11):1184–1190

Boud F, Gindy NN (2008) Application of multi-sensor signals for monitoring tool/workpiece condition in broaching. Int J Comput Integr Manuf 21(6):715–729

Barzani MM, Zalnezhad E, Sarhan AA, Farahany S, Ramesh S (2015) Fuzzy logic-based model for predicting surface roughness of machined Al–Si–Cu–Fe die casting alloy using different additives-turning. Measurement 61:150–161

Maher I, Sarhan AA, Marashi H, Barzani MM, Hamdi M (2016) White layer thickness prediction in wire-EDM using CuZn-coated wire electrode–ANFIS modelling. Transactions of the IMF 94(4):204–210

Marani M, Songmene V, Zeinali M, Kouam J, & Zedan Y (2019) Neuro-fuzzy predictive model for surface roughness and cutting force of machined Al–20 Mg 2 Si–2Cu metal matrix composite using additives. Neural Comput Appl, 1-12

Shankar S, Mohanraj T, Rajasekar R (2019) Prediction of cutting tool wear during milling process using artificial intelligence techniques. Int J Comput Integr Manuf 32(2):174–182

Saglam H, Unuvar A (2003) Tool condition monitoring in milling based on cutting forces by a neural network. Int J Prod Res 41(7):1519–1532

Mohtaram S, Nikbakht MA (2013) Detect tool breakage by using combination neural decision system & ANFIS tool wear predictor. Int J Mech Eng Appl 1:59–63

Kang L, Wang S, Wang S, Ma C, Yi L, Zou H (2019) Tool wear monitoring using generalized regression neural network. Adv Mech Eng 11(5):1687814019849172

Sen B, Mandal UK, Mondal SP (2017) Advancement of an intelligent system based on ANFIS for predicting machining performance parameters of Inconel 690–a perspective of metaheuristic approach. Measurement 109:9–17

Lee J, Choi HJ, Nam J, Jo SB, Kim M, Lee SW (2017) Development and analysis of an online tool condition monitoring and diagnosis system for a milling process and its real-time implementation. J Mech Sci Technol 31(12):5695–5703

Zhang C, Yao X, Zhang J, Jin H (2016) Tool condition monitoring and remaining useful life prognostic based on a wireless sensor in dry milling operations. Sensors 16(6):795

Rech J, Kermouche G, Grzesik W, Garcia-Rosales C, Khellouki A, Garcia-Navas V (2008) Characterization and modelling of the residual stresses induced by belt finishing on a AISI52100 hardened steel. J Mater Process Technol 208(1–3):187–195

Maher I, Sarhan AA, Barzani MM, Hamdi M (2015) Increasing the productivity of the wire-cut electrical discharge machine associated with sustainable production. J Clean Prod 108:247–255

Nguyen D, Yin S, Tang Q, Son PX (2019) Online monitoring of surface roughness and grinding wheel wear when grinding Ti-6Al-4V titanium alloy using ANFIS-GPR hybrid algorithm and Taguchi analysis. Precis Eng 55:275–292

Bhuiyan MSH, Choudhury IA (2014) 13.22—review of sensor applications in tool condition monitoring in machining. Compr Mater Process 13:539–569

Marani M, Songmene V, Kouam J, Zedan Y (2018) Experimental investigation on microstructure, mechanical properties and dust emission when milling Al-20Mg 2 Si-2Cu metal matrix composite with modifier elements. Int J Adv Manuf Technol 99(1–4):789–802

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Marani, M., Zeinali, M., Kouam, J. et al. Prediction of cutting tool wear during a turning process using artificial intelligence techniques. Int J Adv Manuf Technol 111, 505–515 (2020). https://doi.org/10.1007/s00170-020-06144-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-020-06144-6