Abstract

Optimization with Unified Particle Swarm Optimization (UPSO) method is performed for the enhancement of buckling load capacity of composite plates having damage under hygrothermal environment which has received little or no attention in the literature. Numerical results are presented for effect of damage in buckling behavior of laminated composite plates using an anisotropic damage model. Optimized critical buckling temperature of laminated plates with internal flaw is computed with the fiber orientation as the design variable by employing a UPSO algorithm and results are compared with undamaged case for various aspect ratios, ply orientations, and boundary conditions. FEM formulation and programming in the MATLAB environment have been performed. The results of this work will assist designers to address some key issues concerning composite structures. It is observed that the degradation of buckling strength of a structural element in hygrothermal environment as a result of internal flaws can be avoided to a large extent if we use these optimized ply orientations at design phase of the composite structure. This specific application proves the contribution of present work to be of realistic nature.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

The nature of distinct problems met in structural analysis needs better understanding of the structural behavior. So, the need of a detailed study on Finite Element Analysis of buckling behavior of laminated composite structures considering optimization aspects has raised the interest among researchers. Increased use of composite laminated plates in primary structures necessitates the development of accurate theoretical models in predicting their response. Various investigators (Carrera 2002; Reddy 2004; Mantari et al. 2012; Grover et al. 2013) have developed laminated plate theories based on equivalent single layer approach. Many researchers analysed buckling of plates due to inplane mechanical loads (Zienkiewicz 1971; Pagano and Hatfield 1972; Kapania and Raciti 1989) and the thermal loads (Singha et al. 2001; Kundu et al. 2007) using finite element analysis. The reliable operation of a structure is affected by the occurrence of damage. Therefore to ensure safety, it is vital to study the effect of damage on the response behavior of the structure. Damage or flaws in structures due to projectile impact, fatigue and corrosion, or inclusions due to faulty manufacturing or fabrication procedures often cause a reduction of stiffness and must be solved by implementing the damage into the model. Researchers (Prabhakara and Datta 1993; Rahul and Datta 2013) have examined the vibration and parametric instability characteristics in damaged plate in beam structures, where the formulation considers the in-plane membrane effect of the plate in the beam problem. They used a parametric model of damage which was proposed by Valliappan et al. (1990). Pidaparti (1997) computed the free vibration characteristics of a composite plate and established that the formulation by Valliappan et al. (1990) has more influence than some other formulations. Zhang et al. (2001) also appreciated this method and concluded that a parametric model is convenient in framing problems related to structural health monitoring.

Pratihar (2008) defines optimization as the process of finding the best one, out of all feasible solutions. Optimization analysis make design more efficient and cost effective, and thereby to gain practical importance to a product. Shin et al. (1989) optimized the relative ply-thicknesses of symmetric laminated plates for maximum buckling load. Optimality equations were solved by homotopy method, which permits tracing the optima as a function of total thickness. Spallino and Thierauf (2000) investigated thermal buckling optimization of composite plates using evolution strategies. Walker et al. (1997) maximized buckling temperatures. Singha et al. (2000) also maximized buckling temperatures of graphite/epoxy laminated composite plates using the finite element method with four node shear deformable plate element. The genetic algorithm was employed for five layered plates. The particle swarm optimization (PSO) algorithm was first proposed by Kennedy and Eberhart (1995). Many advantages compared to other algorithms make PSO a perfect method to be employed in optimization problems. PSO provides faster results compared with many other optimization methods like the genetic algorithm (Pratihar 2008; Mohan et al. 2014). The algorithm is quite easy to implement, robust, and well suited to handle non-linear, non-convex design spaces with discontinuities. It can handle continuous, discrete and integer variable types with ease. This easiness of execution, quick convergence and excellent local search capability makes it a more attractive method. Hu et al. (2003) presented the efficiency of PSO when matched to other methods, requiring less number of function calculations, while leading to better or the same quality of results. Further, it does not require specific area knowledge information, internal transformation of variables or other manipulations to handle constraints. PSO can be well parallelized to decrease the overall computational time as it is a population-based process. In the last decade, PSO has been demonstrated useful on miscellaneous applications such as structural shape optimization (Fourie and Groenwold 2002), power systems design (Zheng et al. 2003), control system (Montazeri et al. 2008), and swarm of mobile robots (Tang and Eberhard 2011). Mohan et al. (2014) conducted a comparative study on crack identification of structures from the changes in natural frequencies using genetic algorithm and PSO. They observed that PSO is able to detect crack accurately for different combinations, complexities and quantities in three different structures. Many researchers (Le Riche and Haftka 1993; Huang and Haftka 2005; Sukru and Omer 2009; Chang et al. 2010; Wang et al. 2010) have conducted structural analysis employing various algorithms for ply stacking sequence optimization. Unified Particle Swarm Optimization (UPSO) is a recently proposed PSO scheme that combines the local and global searches, balances exploration and exploitation that appears to be a major advantage.

Although an extensive study has been performed on static and dynamic behavior of structural elements, most investigations have ignored the effects of damage in buckling of laminated composite plates. A review of the existing literature has shown the need for the development of a finite element computer program that could optimize the thermal buckling loads using Particle Swarm Optimization (PSO) method, which has a good exploration and exploitation capability. In the present investigation, optimization of the critical buckling temperature of laminated plates with internal flaw considering the fiber orientation as the design variable and employing a UPSO algorithm is carried out. Degradation of buckling strength of a structural element in hygrothermal environment as a result of internal flaws can be avoided to a large extent if we use optimized ply orientations at design phase of the composite structure. This specific application proves the novel research contribution of present work to be of realistic nature. In broad sense, this study on new structural materials such as composite materials can be applied where enhanced performance and reliability of structural system are required. The results and observations from this work will assist addressing some important issues concerning structures where strength/weight is a key design factor as in aerospace applications. Strength/weight ratio, an important factor in structural design, is improved by optimized orientation of plies. Especially in structures prone to thermal buckling, this type of optimized composites offer more strength/weight compared to simple composite plates. This work can also be applied in spacecraft structures or in very high speed flights where the structures are subjected to large scale varying environmental (hygrothermal) conditions. These can also be applied to aircraft wing panels, etc. where a chance of compression buckling is present on both sides of the wing.

2 Mathematical modeling

2.1 Buckling problem

The current study starts with the buckling analysis of a laminated composite plate. The formulation takes into account the effects of hygrothermal environment and is done using the Finite Element Method. The chosen displacement field for structural analysis is as per inverse hyperbolic shear deformation theory (IHSDT) (Grover et al. 2013) as shown in (1).

In present analysis we have taken a composite plate comprising of n orthotropic layers. Also, θ k is the angle between the principle material co-ordinates (x k1 , x k2 , x k3 ) of the k th lamina and the laminate co-ordinate, x. The thickness, length, and width of plate are h, a, and b respectively. The transverse shear stress parameter, r, is set as 3 per the inverse method in post processing step given by Grover et al. (2013). Considering the first order derivatives of the transverse displacement that appears in the in-plane displacement terms as separate independent degrees of freedom as shown below, the continuity requirement is decreased from C1 to C0 continuity.

As demonstrated in recent literature (Grover et al. 2013), the overall percentage error in results of various structural analysis problems is less with the new IHSDT when compared to other existing shear deformation theories. Involvement of inverse hyperbolic shear functions makes this theory to efficiently predict structure response at a similar computational cost as that of first order or higher order theories. The prebuckling equilibrium equation is presented below.

where [K] is linear stiffness matrix and {F} is thermal load vector.

In the next step, geometric stiffness matrix [K G ] is calculated as by Zienkiewicz (1971). The critical buckling temperature is found by solving the linear eigenvalue problem,

The lowest eigenvalue is the critical buckling temperature. Authors had explained the detailed formulation for buckling of composite structures earlier (Sreehari and Maiti 2015).

2.2 Incorporation of damage in composite plates

Anisotropic damage is parametrically incorporated into the finite element formulation by considering a parameter. This factor fundamentally depicts the lessening in effective area and is given by

Where A i * is the effective area (with unit normal) after damage and i indicates the 3 orthogonal directions. Valliappan et al. (1990) had conducted studies using this effective area concept and readers may consult for more details. For a thin plate, only Γ 1 and Γ 2 need to be considered. Γ 1 denotes the damage in the fibre direction whereas Γ 2 refers to orthogonal damage (in same plane). The effects of a damaged region are introduced by means of an idealized model having a decrease in the elastic property in the damaged region. This method which parametrically models damage in any anisotropic material was proposed by Valliappan et al. (1990) and the following relationship between the damaged stress tensor [σ * ij ] and the undamaged stress tensor [σ ij ] was established assuming that the internal forces acting on any damaged section are same as the ones before damage (Valliappan et al. 1990),

where {Ψ} is a transformation matrix. This matrix relate a damaged stress–strain matrix with an undamaged one, [D*]− 1 = [Ψ]T[D]− 1[Ψ]. The stress–strain relation can be given as {σ*} = [D*]{ε} for a zone of damage, i.e., it retains its basic form as that of undamaged region and (except incorporation of these parameters) the computations can be proceeded as in the undamaged formulation (As the formulation for damaged case is similar to that of undamaged case except the incorporation of damage parameters, no detailed formulation is giving here). This method which parametrically models the damage in any anisotropic material was used recently (Sreehari et al. 2016) for finding the effects of damage in a smart plate. Damage model considered here have a broader scope of application because of the elegance and simplicity of constitutive relations, i.e., stress–strain relation for a damaged region retains its basic form.

2.3 Optimized design of damaged composite plate

Maximization of critical buckling temperature of the laminated plate configuration having an internal flaw by changing the ply orientations in stacking sequence is performed in the optimization problem. Computation of the maximum thermal buckling load is performed through a Unified Particle Swarm Optimization method. The optimal design problem can be stated as follows:

find : θ

Where θ l = ply angle of the l th layer.

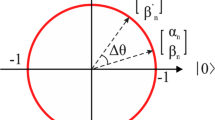

The PSO which is a population-based computation method employs the idea of bird flocking in evolving each solution and is referred to as a particle. Mathematically, the positions of i th particle (x i ) in a swarm of S particles is a D-dimensional search space, provides a candidate solution for the problem. The velocity and position of the particles at t th iteration can be represented by v i (t) = (v i1, v i2, v i3…….., v iD ) and x i (t) = (x i1, x i2, x i3, ……….., x iD ); where i ∈ S.

Movement of each particle to new positions throughout the search process is based on the previous best position of itself (pbest), and the best position so far found by any individual of the population (gbest- in global best neighbourhood approach) or the best position so far found by any of its neighbour (lbest- in local best neighbourhood approach).

Here the population and its individuals are referred respectively as swarm and particles. The swarm is updated by velocity and position update. The velocity is updated by,

G id (t + 1) and L id (t + 1) are the velocity update of the i th particle (x i ), global best and local best variants of PSO for (t + 1)th iteration. Random numbers (usually, equally scattered between 0 and 1) are represented by rand. R, C 1 , C 2 denotes the constriction factor, cognitive parameter, and social parameter of the optimization algorithm. The three terms of (12) and (13) represents the different influencing elements that lead to the final solution and it can be represented as in Fig. 1. The unification factor, u, in (11) can be varying or a constant. In this paper, an exponentially varying unification factor is considered, as given below

The updated position is attained from

We will obtain the solution after much iteration. The simple representation of the convergence in swarm optimization is shown in Fig. 2 and a schematic representation of the PSO algorithm is presented in Fig. 3. The optimization problem is concluded when the change amongst the present value of the objective function and the best design until now is less than a stated tolerance. Also it is important to note that here we are not considering any functional constraints to avoid computational complexities and there is plenty to occupy us in unconstrained problems. Furthermore, the methods for solving unconstrained problems are the basis for constrained optimization algorithms and most of problems we met in real life can be solved by unconstrained optimization methods (Dennis Jr and Schnabel 1996; Rao 2009). A constrained problem must be treated as such, only if the existence of the constraints is likely to affect the solution. Several algorithms to solve constrained problems in fact will boil down to solving a related in unconstrained problem whose solution is very close the solution of constrained one. However, thus many problems with simple constraints, such as bounds on the variables, can be solved by unconstrained algorithms.

3 Numerical results and discussion

3.1 Setup

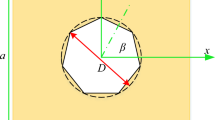

A FEM formulation has been done for optimization analysis of a damaged composite plate. Governing equations based on IHSDT has been derived and programming in MATLAB environment has been performed. The numerical results were obtained and compared with previous investigations. A C0-continuous isoparametric biquadratic-quadrilateral serendipity element (as in Fig. 4) with 56 degrees of freedom (each node has 2 degrees of freedom due to artificial constraints (as explained in Section 2.1), 3 translational degrees of freedom, and 2 rotational degrees of freedom) has been employed for discretization of the laminated plate. Numerical results are shown in figures and tables. The non-dimensionality used for transverse deflection and critical buckling load is given respectively as,

The basic concept of finite element formulation being an assemblage of building blocks like elements interconnected at nodal points was utilized. The element that was chosen for the present analysis is an 8-noded iso-parametric element as in Fig. 4. Benefit of isoparametric element is that element geometry and displacements are represented by same set of shape functions. Advantage of 8 noded element is that all the nodes are located on element sides and hence there are no internal nodes and shape functions have quadratic variation in x and y direction. The various Material Models are (taken from literatures from which, comparison studies are done),

Material Model 1 (MM1): E1/E2 = 25, G12 = G13 = 0.5 E2, G23 = 0.2 E2, v12= 0.25, α2/α1 = 10.

Material Model 2 (MM2): E1/E2 = 25, G12 = G13 = 0.5 E2, G23 = 0.2 E2, v12 = 0.25.

Material Model 3 (MM3): E1 = 181 GPa, E2 = 10.3 GPa, G12 = G13 = 7.17 GPa, G23 = 2.39 GPa, ν12 = 0.28, α1 = 0.02 × 10−6 °C−1, α2 = 22.5 × 10−6 °C−1.

3.2 Validation studies in buckling

Current finite element formulation using IHSDT and Matlab programming is validated in Table 1. Non dimensional central deflections are computed for different span-to-thickness ratio’s and for simply supported square laminated (0/90/90/0) plate under transverse sinusoidal loading (MM1 property). When compared with exact solutions percentage variation of other higher order theory (Reddy 2004) is larger, whereas variation is less with IHSDT. Analysis is done with side to thickness ratio varying from 10 to 100 using FSDT and IHSDT for validation of results as shown in Fig. 5. For this study, we have taken a (0/90)s laminated composite plate with simply supported at all ends subjected to uniaxial inplane loads. The results by applying biaxial inplane loads are shown in Fig. 6. It is found that nondimensional critical loads are higher for uniaxial loading. And as thickness decreases, the nondimensional buckling load increases. The variation is very less above a/h = 40 for both cases. Analysis is done with side to thickness ratio varying from 10 to 100 using FSDT and IHSDT for validation of results by considering square antisymmetric cross ply plates (two layered and eight layered) as shown in Figs. 7 and 8. Here, uniaxial loading and simply support conditions on all edges is considered. As number of layers is high, buckling loads also are high. So, it is observed from these comparison results that present finite element model predicts the bending and buckling behavior quite accurately.

Similar investigation can be extended for coefficient of moisture concentration instead of thermal expansion coefficient for finding the buckling moisture concentration. Strains are set up in laminas of composite due to change in temperature and moisture. These in turn give rise to stresses which are called as hygrothermal stresses. On the loading, if material is unconstrained, no stresses are developed. Stress develops only when the material is constrained. The stresses developed in the body are proportional to the constraint imposed.

3.3 Validation of incorporation of damage

After incorporating the effects of damage, some results for simple plate were compared with the results obtained by Prabhakara and Datta (1993). A plate with centre damage is considered and the plate is having a damage area of 4 % of the total plate area, i.e., we have introduced the damage parameters in the centre 4 elements for a plate with 10 × 10 mesh size as in Fig. 9. The buckling coefficients for a plate for 3 different aspect ratios (AR) are found and compared with those of reference as shown in Table 2, and it clearly indicates that, present damage formulation using IHSDT possess excellent accuracy. Thus, authors validated the present finite element formulation incorporating damage and the methodology.

A laminated composite plate (MM2 property) with simply supported boundary conditions on all sides is analysed for uniaxial loads. The variation of nondimensional buckling load for a 4 layered (0/90/90/0) plate with damage in two middle layers and for centrally located damage patches having damage intensities of Γ 1 /Γ 2 = 3 and Γ 1 /Γ 2 = 7 is presented in Table 3. The damage ratio Γ 1 /Γ 2 takes values between 0.0 and 9.0. A mild damage may be represented with a damage ratio 0.0 ≤ Γ 1 /Γ 2 ≤ 3.0 while a heavy damage may be denoted by the range of values, 7.0 ≤ Γ 1 /Γ 2 ≤ 9.0. As damage intensity increases the buckling load decreases with the decrement being higher in case of larger damage areas. Critical buckling temperature is found and plotted for a square laminated composite plate having (0/+45/-45/90)s lamination, with and without damage in Fig. 10. This real world lamination sequence increases the practical side and applicability of the results. The plate considered is under simply supported boundary conditions and uniform temperature distribution. The damage considered here is a mild damage with damage intensity of Γ 1/Γ 2 = 3. As E 1/E 2 increases from 10 to 40, the critical buckling temperature decreases. The decrement is higher for damaged plates, as observed from the steeper curve of damaged case.

3.4 Optimization of thermal buckling load using UPSO

In this investigation, a 4 layered laminated plate subjected to uniform temperature load is considered. The material properties taken are that of MM3. Each of the laminate is assumed to be of the same thickness. The UPSO Algorithm related parameters used here are: Swarm size, S = 20, Maximum number of iterations = 100, Cognitive parameter, C 1 = 2.05, Social parameter, C 2 = 2.05, and Constriction factor, R = 0.7298. Clerc (2002) had described the constriction factor R, that increases PSO’s capability to constrain and control velocities and described its calculation. Recent literatures (Premalatha and Natarajan 2009; Sumathi and Surekha 2010) explained that if C = C 1 + C 2 = 4.1, then R = 0.7298 and as C increases above 4.0, R gets smaller and the damping effect is even more prominent and suggested that it would be better to choose C 1 = C 2 = 2.05 which shown an overall better performance of PSO. The parameters C 1 and C 2 are not much critical for the convergence of algorithm, but quicker convergence and alleviation of local optimum solutions can be achieved through the fine-tuning of these parameters. Here, the tolerance value is considered as 0.001 for the objective function. Initially we had conducted optimization process with values 0.1, 0.01, 0.001, etc. and with 0.001 there is not differentiable change occurring in results. So we fixed the tolerance value as 0.001 for this work.

Optimum ply-angle (in degree) of a four layered (θ/-θ/θ/-θ) composite plate for maximum critical buckling temperature using UPSO is computed. The optimum fiber orientations obtained from the present analysis (using UPSO) and from Walker et al. (1997) and Singha et al. (2000) (using genetic algorithm) are shown in Table 4 for simply supported and clamped boundary conditions. These numerical results clearly demonstrate the effectiveness of UPSO algorithm on the thermal buckling optimization for laminates.

Investigation of the effect of thermal expansion ratio, α 2 /α 1 on the optimum design of a four layered square plate with a 4 % central damage in a layer (in middle two layers) is performed. The optimum fiber orientations obtained are plotted against the corresponding α 2 /α 1 ratios for 3 different E 1/E 2 ratios in Fig. 11. It is observed that the optimum fiber orientation angle decrease with increase in α 2 /α 1 ratio. It is further observed that the optimum fiber orientation angle decrease with increase in E 1/E 2 ratio. The optimized critical temperatures for various a/b ratios are computed for both damaged and undamaged cases. The analysis results for symmetric and anti-symmetric ply orientations with simply supported boundary condition at all ends are plotted in Fig. 12. The analysis is also performed for a composite plate with all edges clamped and results are plotted in Fig. 13.

It is noted that the optimum critical temperature comes down as a/b ratio increases, and it is due to the higher stiffness of square plates in thermal loading analysis. Under clamped conditions the critical temperatures are always higher than those for corresponding simply supported conditions. The optimum critical temperature is higher for symmetric lamination scheme than anti-symmetric lamination scheme. As a/b increases, the variation between optimum critical temperature obtained for symmetric and anti-symmetric cases decreases. The same is true in damaged as well as in undamaged composite plate. The critical temperatures for a composite plate with damage seem to be lesser than the corresponding values for undamaged cases. The variation between optimum critical temperature obtained for damaged and undamaged composite plates increases as a/b increases, for both symmetric and anti-symmetric conditions.

In the next example, optimization analysis of a damaged composite plate is performed employing continuous ply angle laminate configuration keeping all other properties same as that of previous examples. Optimized critical buckling temperatures for variable ply angle lay up are presented and are compared with fixed angle lay up in Fig. 14. The analysis is done for all edges simply supported and all edges clamped boundary conditions. For square plates, the maximum critical temperature was obtaining at 45.04/-45.04/45.04/-45.04 lamination sequence for plates with simply supported boundary condition whereas at 0/90/90/0 for plates with clamped boundary condition. The thermal buckling load obtained now is 1.68 % higher than that for corresponding fixed angle antisymmetric lay up in clamped boundary case. But at a/b = 1.5 maximum critical buckling temperature was obtaining at 69.42/-51.64/62.09/-70.3 (the angle values are approximated to the nearest integer values, resulting in stack 69/-52/62/-70, for practical composite design) ply lay up for simply supported boundary conditions and at 67.8/-34/28.41/-68.37 ply lay up for clamped boundary conditions. The thermal buckling load obtained now for a/b = 1.5 is 13.59 % higher than that for corresponding fixed angle lay up in simply supported case and 4.11 % higher in clamped case. Similarly for a/b = 2 the maximum critical buckling temperature was obtaining at 68.55/-53.01/56.39/-66.66 and at 77.25/-28.81/15.04/-80.91 respectively for simply supported and clamped plates. The thermal buckling load obtained now for a/b = 2 is 16 % higher than that for corresponding fixed angle lay up in simply supported case and 9.78 % higher in clamped case. Thus the reduced buckling load capacity of a composite plate due to an internal flaw can be regained almost if we use this type of laminate configuration at design phase and therefore this can be used in real applications.

4 Conclusion

A finite element computer program is developed and implemented in the present work that could optimize the thermal buckling loads of laminated plates with internal flaw considering the fiber orientation as the design variable and employing a UPSO algorithm. Buckling analysis for a laminated composite plate subject to mechanical and uniform in-plane thermally induced loadings using IHSDT are presented. A plate having centre damage (damage area of 4 % of the total plate area) is considered for validating the finite element damage formulation and the methodology. The theoretical formulation has been verified, and programming in the MATLAB environment for analysis has been performed. The codes provide satisfactory results when compared with references. The excellent agreement of the results obtained in the present method with those from references shows that the technique is effective and precise. The contributions of present work are summarized in the following points,

-

Optimized critical buckling temperature of damaged composite plate is computed with the fiber orientation as design variable employing a UPSO algorithm.

-

Effect of the ratio of thermal expansion coefficients on the optimum fiber orientations is presented and it is observed that the optimum fiber orientations decrease with increase in α 2 /α 1 ratio.

-

Optimized critical temperatures for a damaged composite plate are compared with undamaged case for various a/b ratios, ply orientations, and boundary conditions.

-

Optimization analysis is performed employing variable ply angle laminate configuration and the results for maximum thermal buckling loads are compared with the corresponding 4 layered antisymmetric lay ups. The percentage increment in maximum critical buckling temperature by the application of variable ply angle laminate configuration is computed.

-

The results of chosen optimization problem bring new insight that would indeed address design issues. Degradation of buckling strength of a structural element in hygrothermal environment as a result of internal flaws can be avoided to a large extent if we use these optimized ply orientations at design phase of the composite structure. It appears to be a major practical application.

-

This study can be applied in aircraft and spacecraft where improved performance and reliability of structural system are required.

5 Notation

The following symbols are used in this paper:

- E 1 , E 2 :

-

Young’s moduli

- G 12 , G 13 , G 23 :

-

shear moduli

- h :

-

thickness of the plate

- [K], [K G ]:

-

global linear and geometric stiffness matrices

- T:

-

temperature

- {U}:

-

global displacement field

- u 0 , v 0 , w 0 :

-

midplane displacements

- w :

-

maximum out of plane displacement

- x i (t), v i (t):

-

position and velocity of particles at t th iteration of optimization

- α 1, α 2 :

-

thermal expansion coefficients

- θ l :

-

ply angles of n layers

- θ x, θ y :

-

rotations at the midplane

- λ cr :

-

inplane magnification factor; and

- ν 12 :

-

Poisson’s ratio

References

Carrera E (2002) Theories and finite elements for multilayered, anisotropic, composite plates and shells. Arch Comput Methods Eng 9(2):87–140

Chang N, Wang W, Yang W, Wang J (2010) Ply stacking sequence optimization of composite laminate by permutation discrete particle swarm optimization. Struct Multidisc Optim 41(2):179–187

Clerc M, Kennedy J (2002) The particle swarm-explosion, stability, and convergence in a multidimensional complex space. IEEE Trans Evol Comput 6(1):58–73

Dennis Jr JE, Schnabel RB (1996) Numerical methods for unconstrained optimization and nonlinear equations. 16 SIAM, Philadelphia

Fourie P, Groenwold A (2002) The particle swarm optimization algorithm in size and shape optimization. Struct Multidisc Optim 23(4):259–267

Grover N, Singh BN, Maiti DK (2013) New nonpolynomial shear-deformation theories for structural behavior of laminated-composite and sandwich plates. AIAA J 51(8):1861–1871

Hu X, Eberhart R, Shi Y (2003) Engineering optimization with particle swarm. IEEE Swarm Intell Symp, Indianapolis, pp 53–57

Huang J, Haftka RT (2005) Optimization of fiber orientations near a hole for increased load-carrying capacity of composite laminates. Struct Multidisc Optim 30(5):335–341

Kapania RK, Raciti S (1989) Recent advances in analysis of laminated beams and plates, part i: shear effects and buckling. AIAA J 27(7):923–935

Kennedy J, Eberhart R (1995) Particle swarm optimization. In: Proc. IEEE Int Conf on Neural Networks (Perth), IEEE Service Center 4, Piscataway, NJ, 1942–1948

Kundu CK, Maiti DK, Sinha PK (2007) Nonlinear finite element analysis of laminated composite doubly curved shells in hygrothermal environment. J Reinf Plast Compos 26(14):1461–1468

Le Riche L, Haftka RT (1993) Optimization of laminate stacking sequence for buckling load maximization by genetic algorithm. AIAA J 31(5): 951–956

Mantari JL, Oktem AS, Soares CG (2012) A new higher order shear deformation theory for sandwich and composite laminated plates. Compos Part B: Eng 43(3):1489–1499

Mohan SC, Yadav A, Maiti DK, Maity D (2014) A comparative study on crack identification of structures from the changes in natural frequencies using GA and PSO. Eng Comput 31(7):1514–1531

Montazeri A, Poshtan J, Yousefi-Koma A (2008) The use of particle swarm to optimize the control system in a PZT laminated plate. Smart Mater Struct 17:1–7

Pagano NJ, Hatfield HJ (1972) Elastic behavior of multilayered bidirectional composites. AIAA J 10(7):931–933

Pidaparti RMV (1997) Free vibration and flutter of damaged composite panels. Compos Struct 38(1-4):477–481

Prabhakara DL, Datta PK (1993) Vibration and static stability characteristics of rectangular plates with a localized flaw. Comput Struct 49(5):825–836

Pratihar DK (2008) Soft computing. Narosa publishing house Pvt. Ltd., NewDelhi

Premalatha K, Natarajan AM (2009) Hybrid PSO and GA for global maximization. Int J Open Problems Comput Math 2(4):597–608

Rahul R, Datta PK (2013) Static and dynamic characteristics of thin plate like beam with internal flaw subjected to in-plane harmonic load. Int J Aeronautical Space Sci 14(1):19–29

Rao SS (2009) Engineering optimization: theory and practice. 4th edn, John Wiley & Sons, Inc

Reddy JN (2004) Mechanics of laminated composite plates and shells: theory and analysis, 2nd edn. CRC Press, New York

Shin YS, Haftka RT, Watson LT, Plaut RH (1989) Design of laminated plates for maximum buckling loads. J Compos Mater 23(4):348–369

Singha MK, Ramachandra LS, Bandyopadhyay JN (2000) Optimum design of laminated composite plates for maximum thermal buckling loads. J Compos Mater 34(23):1982–1997

Singha MK, Ramchandra LS, Bandyopadhyay JN (2001) Thermal postbuckling analysis of laminated composite plate. Compos Struct 54(4):453–458

Spallino R, Theirauf G (2000) Thermal buckling optimization of composite laminates by evolution strategies. Comput Struct 78:691–698

Sreehari VM, Maiti DK (2015) Buckling and post buckling analysis of laminated composite plates in hygrothermal environment using an inverse hyperbolic shear deformation theory. J Compos Struct 129:250–255

Sreehari VM, George LJ, Maiti DK (2016) Bending and buckling analysis of smart composite plates with and without internal flaw using an inverse hyperbolic shear deformation theory. J Compos Struct 138:64–74

Sukru K, Omer S (2009) Buckling optimization of laminated composite plates using genetic algorithm and generalized pattern search algorithm. Struct Multidisc Optim 39:477–486

Sumathi S, Surekha P (2010) Computational intelligence paradigms- theory and applications using MATLAB. CRC Press

Tang Q, Eberhard P (2011) A PSO-based algorithm designed for a swarm of mobile robots. Struct Multidisc Optim 44:483–498

Valliappan S, Murti V, Zhang W (1990) Finite element analysis of anisotropic damage mechanics problems. Eng Fract Mech 35(6):1061–1071

Walker M, Reiss T, Adali S, Verijenko VE (1997) Optimum design of symmetrically laminated plates for maximum buckling temperature. J Therm Stresses 20(1):21–33

Wang W, Guo S, Chang N, Zhao F, Yang W (2010) A modified ant colony algorithm for the stacking sequence optimization of a rectangular laminate. Struct Multidisc Optim 41(5):711–720

Zhang W, Yunmin C, Yi J (2001) Effects of symmetrisation of net-stress tensor in anisotropic damage models. Int J Fract 109(4):345–363

Zheng Y, Ma L, Zhang L, Qian J (2003) Robust PID controller design using particle swarm optimizer. IEEE Int Symp Intell Control 974–979

Zienkiewicz OC (1971) The finite element method, 3rd edn. Tata McGraw-Hill Publishing, UK

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Sreehari, V.M., Maiti, D.K. Buckling load enhancement of damaged composite plates under hygrothermal environment using unified particle swarm optimization. Struct Multidisc Optim 55, 437–447 (2017). https://doi.org/10.1007/s00158-016-1498-y

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00158-016-1498-y