Abstract

A method to improve wood durability using natural extracts was evaluated. Wood deterioration is a condition caused by several abiotic and biotic factors including fungal contamination. To date, approaches aiming at the reduction of these contaminants mainly involve the use of chemicals agents. Natural products could represent an alternative strategy. Aqueous extracts of Punica granatum L. (pomegranate) peel and Melia azedarach L. barks were evaluated as antifungal agents to improve natural durability of beech wood and maritime pine. To evaluate the effect of treatments under simulated accelerated ageing of wood by natural conditions, impregnation and leaching tests were performed. Results demonstrated that samples impregnated with pomegranate or M. azedarach solutions notably increased the biological resistance of wood in a dose-dependent manner. These results were confirmed by the reduction in weight losses in treated samples even after 6 weeks of fungal exposure. Moreover, after leaching tests, 20 and 7% (w/v) of pomegranate and M. azedarach extract solutions were demonstrated as the better concentrations to enhance wood durability. Total phenol content and characterization of the phenolic compounds in both, natural extracts and wood samples were analyzed by Folin–Ciocalteu assay and HPLC-DAD. In conclusion, it was demonstrated that the present method can be considered as an effective treatment to increase wood durability while it proposes the valorization of natural extractives in wood industry.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

1 Introduction

Wood is an eco-material and an attractive option because of its wide availability, low price and favorable mechanical properties (Rowell 2006). Nevertheless, wood presents a major weakness concerning its low resistance to environmental damage posing a serious problem for the construction industry and forest managers. Indeed, wood decay can be caused by mechanical and chemical deterioration as well as biological agents such as insects and fungi (Gonzalez-Laredo et al. 2015; Monrroy et al. 2011). Concerning wood fungal deterioration, one of the most occurring contaminants correspond to the white-rot fungi Coriolus versicolor (Quél, 1886) and the brown-rot fungi Coniophora puteana (P. Karst., 1868) (Witomski et al. 2016; Singh and Singh 2014). To counter this problem, the use of synthetic fungicides is nowadays the most common remedy. However, these products contain toxic residues leading to environmental pollution which justifies the need to develop ecological technologies in order to improve wood resistance (Künniger et al. 2014; Zabalza et al. 2011; Brimner and Boland 2003). In the last years, numerous studies have been conducted to identify natural inhibitors of wood-rot fungi (Brocco et al. 2017; Hedenstrom et al. 2016; Zhang et al. 2016; Hu et al. 2015; Mansour and Salem 2015). It has been demonstrated that several plants and food commodities present important biological activities as it is the case of Melia azedarach L. and Punica granatum L. (Linnaeus, 1753) (Tascioglu et al. 2013; Fischer et al. 2011; Al-Zoreky 2009; Sultana et al. 2007; Yamaguchi and Okuda 1998). M. azedarach, belonging to the Meliaceae family, is a tree easily growing in areas like the northern region of Africa, Argentina, India, China and Australia (Taverna and Corrado 2017). Leaves and bark extracts of this tree have demonstrated biological activities as antifungal, insecticidal, nematicidal, antibacterial, antiviral and antimicrobial (Zahoor et al. 2015; Ntalli et al. 2010; Rachokarn et al. 2008; Akhtar et al. 2007; Zhang et al. 2007; Carpinella et al. 2005; Andrei et al. 1986).

Concerning pomegranate tree, this species principally grows in semi-arid, tropical and subtropical regions (Gullon et al. 2016). Numerous studies have demonstrated that peel, mesocarp, aril and juices of pomegranate exhibit high antioxidant activities due to the presence of phenolic acids, flavonoids and hydrolysable tannin compounds such as gallotannins (type I-tannins) and ellagitannins (type II-tannins) (Fischer et al. 2011; Mena et al. 2012; Saad et al. 2012). Linked to this antioxidant activity, pomegranate extracts also presented beneficial properties as antifungal, antibacterial, anti-mutagenic, anti-inflammatory and antioxidant agents (Lucci et al. 2015; Tehranifar et al. 2011; Endo et al. 2010; Guo et al. 2009).

In Tunisia, environmental conditions greatly allow the wide distribution of M. azedarach and pomegranate trees. In fact, M. azedarach grows like a widespread ornamental and shade tree while pomegranate is cultivated in more than 11,000 ha with an estimated production of 71,597 tons by year (Akacha et al. 2017; Ayed 2011). Therefore, it will be of interest to take advantage of their beneficial biological properties for wood industry purposes and more specifically, to improve wood durability against fungal contamination. Indeed, a natural fungicide produced from M. azedarach barks and pomegranate peel extracts could represent a financial income to native population due to the valorization of tree wastes, while it offers an alternative and durable strategy to synthetic fungicides.

Thus, the aim of the present study was to evaluate the effect of M. azedarach bark and pomegranate peel aqueous extracts against C. versicolor and C. puteana fungal strains in order to increase the natural durability of two of the most important European wood species: beech and maritime pine.

2 Materials and methods

Aqueous extractives of plants were prepared in order to evaluate their protective effect on wood durability. For that, impregnation, leaching and durability tests were performed. An immersion technique was followed for impregnation while leaching tests were realized according to the specifications of the European standard EN 84 (1997). Durability tests of the impregnated and leached wood samples were evaluated against fungal resistance. Finally, phenolic characterization of natural extractives and wood samples was performed by Folin–Ciocalteu and High Performance Liquid Chromatography (HPLC) analyses.

2.1 Plant material and wood species

Peel of the pomegranate variety “Chelfi” and barks of M. azedarach L. were used in this study. Barks of M. azedarach and peels of pomegranate were collected in Tunis town (Tunisia) during the periods of December 2012 and March 2013, respectively. A total of 1 kg of fresh material was collected from 55 and 40 years-old pomegranate and M. azedarach L. trees respectively. To avoid phenolic degradation, material samples were stocked in vacuum plastic bags at − 20 °C until their use. Commercial wood types Fagus sylvatica L. (European beech wood) and Pinus pinaster A. (maritime pine sapwood) were kindly provided by the local sawmill “Montoise des bois” of Mont de Marsan, France. The wood choice was based on their vulnerability to degradation factors presenting low natural durability against fungi (class 5 according to the EN 350-2 standard). Both species have highly treatable properties justifying their choice in this study. Experimental tests were performed with wood blocks of 25 × 25 × 2 mm3 RTL (Radial–Tangential–Longitudinal).

2.2 Fungal strains

Fungal strains were selected in accordance with the European standard directive CEN/TS 15083-1 (2005). C. versicolor (CTB 863-A) and C. puteana (BAM Ebw. 15) were supplied by the Laboratory of Biology FCBA Technological Institute (Bordeaux, France). Stock and experimental cultures were performed in 20 ml of malt agar medium (40 g/l malt extract, 20 g/l agar) (Thermo-Fisher Scientific, Illkirch, France).

2.3 Phenolic standards and solvents

Commercial standards of gallic acid (98%) and ellagic acid (97%) were provided by Acros Organics (Geel, Belgium); vanillin aldehyde by Merck (Darmstadt, Germany), (+) -catechin hydrate (98%) and punicalagin by Sigma-Aldrich (Saint-Quentin-Fallavier, France). Analytical grade solvents of methanol (80%) and ortho-phosphoric acid (85%) were provided by Thermo-Fisher Scientific (Illkirch, France).

2.4 Preparation of natural treatment solutions

Aiming to propose a realistic alternative to industrial fungicides, the preparation of the natural solutions had to be easily transposed to industrial levels while being the most eco-friendly as possible. For this purpose, an aqueous extraction to obtain the phenolic compounds was preferred without the use of organic solvents. Extraction conditions were adapted from Sotillo et al. (1994) with several modifications. Briefly, 100 g of plant materials were suspended in 600 ml of distilled water and homogenized during 4 min using a Ultra-Turrax blender®. The obtained solutions were then magnetically stirred during 3 h in a hotplate in order to reach water temperature of 70 °C. After cooling at room temperature, samples were filtered through a Whatman filter no.1 (GE Healthcare, Life Sciences, Vélizy-Villacoublay, France). Once the filtrate was recovered, different concentrations of the natural treatment solutions were obtained by diluting the filtrate at different weight percentages with distilled water. Solutions of pomegranate peel were adjusted at three different concentrations: 5, 10 and 20% (w/v of water) and M. azedarach solutions were prepared at two concentrations: 5 and 7% (w/v of water). The choice of the solution treatment concentrations was based on phenolic extracts yields (30 and 8% for pomegranate and M. azedarach bark extracts respectively).

2.5 Impregnation, leaching and durability test conditions

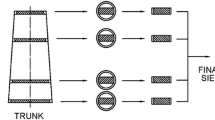

2.5.1 Impregnation test conditions

Impregnation tests were conducted with five wood replicates. Wood samples were taken from the sapwood with sectional dimensions of 25 × 25 × 2 mm3 (RTL). Specimens were first dried at 105 ± 2 °C until anhydrous weight (Wanhyd). Wood treatment immersion was performed according to Salem et al. (2016) because of its simple implementation in industry. The process was performed by immersing each wood sample into the different pomegranate or M. azedarach treatment solutions during 8 and 1 h, respectively. To avoid the modification of certain substances in treated woods, samples were oven dried at 50 °C until constant weight and the weight of impregnated specimens was recorded (Wimp). Impregnation yield (IY) was calculated using Eq. 1 representing the percent weight ratio between the uptake liquid and impregnated weight (Wimp).

The concentration of the phenolic component retention was calculated as follows:

2.5.2 Leaching test conditions

Leaching tests were used to simulate the accelerated ageing of treated wood by natural conditions according to the European standard EN 84 (1997). Experiments were repeated with five replicates of each treatment condition. For that, wood samples were leached in water (1 vol. of wood/5 vol. of water) at 20 °C by applying a vacuum pressure of 370 mbar during 1 h. According to guideline, water was regularly changed during 14 days. After this period, samples were dried at 105 °C and dry leached weight (Wleach) was recorded. Weight loss was calculated following Eq. 3:

2.5.3 Durability tests against wood-rot fungi

Impregnated and leached wood samples were tested to evaluate fungal resistance against C. versicolor (for beech specimens) and C. puteana (for maritime pine specimens). Incubation conditions were performed in a growth chamber Vötsch (Illkirch, France) at 25 °C with a relative humidity of 70%. Fungal exposure was performed during 6 weeks and for each treatment five wood samples were disposed in Petri dishes corresponding to: three treated samples, an untreated control (natural state of wood) and one sample used as a reference and treated with a commercial fungicide veraxyl solution (PPG company). Tests were repeated five times. At the end of the incubation, mycelium was peeled-out with a spatula, samples were dried at 105 °C during 24 h and the final weight was recorded (Wconf). Weight loss was calculated according to Eq. 4:

Results of wood durability after treatment were based on the average percentage of weight losses and classified according to values stipulated in the standard XP CEN/TS 15083-1 where a loss mass % of ≥ 5 corresponds to class 1 (very durable); > 5 to ≥ 10 to class 2 (durable); > 10 to ≥ 15 to class 3 (moderately durable); > 15 to ≥ 30 to class 4 (slightly durable) and > 30 to class 5 (not durable).

2.6 Phenolic characterization

2.6.1 Sample preparation

For natural solutions, preparation of samples was performed following the same conditions as described in Sect. 2.4 and solutions were acidified with 1% (v/v) of ortho-phosphoric acid (85%).

For wood analysis, sawdust of impregnated and leached wood samples was used. Indeed, this process allows getting a better appreciation of the extractible phenols contained in wood samples. For this purpose, a total of 250 mg of wood specimens were pulverized to obtain sawdust with grading size of 1 mm approximately. Then, sawdust was extracted with 30 ml of methanol (80%) at room temperature during 90 min. Extract was then filtered through Whatman paper no. 1 (GE Healthcare Life Sciences, Vélizy-Villacoublay, France) and organic phase was evaporated at 40 °C until dryness (Charrier et al. 1992). Phenol determination was performed in water phase.

2.6.2 Total phenol content determination

Quantification of total phenolic content was adapted from Scalbert et al. (1989) with mild modifications. A volume of 2.5 ml of Folin–Ciocalteu reagent was added to 1 ml of aqueous extract, diluted ten times and after 1 min of incubation, 2 ml of sodium bicarbonate (75 g/l) were added. Then, mixtures were allowed to stand 5 min in a water bath at 50 °C. After cooling, sample absorbance was compared with a blank and monitored using a Jenway 6300 spectrophotometer at 760 nm. A solution of gallic acid (100 µg/ml) was used for calibration and final results were expressed as mg of gallic acid equivalent per g of dry weight (mg GAE/g DW).

2.6.3 Phenolic characterization by High-Performance Liquid Chromatography (HPLC)

Phenolic characterization from natural treatment solutions and wood samples was performed with a Thermo-Scientific Ultimate 3000 HPLC system equipped with a Diode-Array Detector (DAD). Analyses were insured with a C18 column (4.6 × 250 mm) at 25 °C; injection volume: 5 µl; pores diameter: 120 Å; particles size: 5 µm; stable at pH values between 2 and 8. Mobile phases were prepared as follows: Elute A: H2O-H3PO4 (1000:1; v/v) and elute B: MeOH-H3PO4 (1000:1; v/v). A gradient program was used beginning with 10% of eluent B during 50 min followed by a landing of 5 min and returning to 0% of eluent B. Flow rate was maintained at 1 ml/min.

2.7 Statistical treatment

The Xlstat software 2016 (Addinsoft, Paris) was used as statistical tool. Comparison between control and treated samples was assessed with one-way ANOVA followed by Dunnett’s test. Differences were considered to be statistically significant when the p-value was lower than 0.05. Graphical values were represented by mean ± standard deviation.

3 Results and discussion

3.1 Impregnation yields

According to the standard EN 350-2 (1994), beech and maritime pine sapwood are both classified as impregnable (class 1). However, results in Table 1 demonstrate that greater impregnation yields were generally obtained with beech wood than with maritime pine sapwood. It can also be observed that yields of impregnation increased in a dose-dependent manner and this effect was observed for both natural treatment solutions and in both wood species. It has to be also noted that even if veraxyl treatment presented the better impregnation yields, comparable and encouraging percentage weight losses were observed with the highest pomegranate concentration (20%) in both wood species. In the case of pinewood samples, better impregnation yields were observed with pomegranate treatment than with M. azedarach. Nevertheless, in the case of beech wood, comparable yields between both treatments were observed. Variability in the impregnation yield percentages may be due to the different wood structure of the species. Indeed, pine wood penetration occurs longitudinally and across radial direction through tracheids and parenchyma rays. Otherwise, beech wood penetration almost occurs in longitudinal direction through large and easily accessible vessels (Tondi et al. 2013). Taking into consideration these structural differences and in order to ameliorate impregnation yields in pine sapwood, further studies using pressure treatment are suggested. Indeed, this method presented favorable results to apply chemical and natural preservatives in pine wood specimens (Kirker et al. 2016; Temiz et al. 2014).

3.2 Natural extractives and wood durability

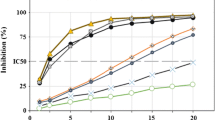

High resistance of wood is suitable to counter wood decay caused by environmental factors such as insect and fungal deterioration (Gérardin 2016). In this study, the principal aim was to evaluate the effect of pomegranate peel and M. azedarach aqueous solutions to improve the resistance of pine and beech woods against fungal contamination. For that, impregnated and leached wood samples were exposed to C. puteana and C. versicolor during 6 weeks. Figure 1 shows the results of weight losses for control and treated samples. Compared to the control, impregnated and leached samples presented a better resistance to fungi. The only exception of this effect was observed with the lower concentration of M. azedarach solution (5%). No significant differences were observed after leaching tests. According to impregnation yield results, it is also observed that natural extractives bestow upon impregnated and leached samples a protective effect in a dose-dependent manner. This impact is demonstrated by the diminution in weight losses according to concentrations. For pomegranate treatment, the optimal results were obtained using the higher solution concentration (20%) in pinewood and against C. puteana. Indeed, loss weights (less than 5%) of impregnated and leached samples were comparable to those obtained with the commercial fungicide veraxyl. On the other side, a concentration of 7% of M. azedarach solution was significantly more efficient in both wood specimens and with both fungal strains, compared to control. In addition to this, it is also observed that in general, impregnated samples presented higher fungal resistance than leached samples. This phenomenon is currently found in literature. For instance, copper-based and natural extract treatments increased wood decay by 18 and 30%, respectively after leaching tests (Temiz et al. 2014; Sen et al. 2009). Finally, pomegranate treatment seems to be more effective to protect pine wood from C. puteana than beech from C. versicolor. Nevertheless, the inverse behavior was observed for M. azedarach treatment with a better protection of beech wood against C. versicolor. The mechanisms of action of fungal wood attack are complex and need to be better understood. Nevertheless, it is known that while brown rot-fungi (i.e., C. puteana) preferentially select wood polysaccharides, white rot-fungi (i.e., C. versicolor) are known to degrade hemicellulose and lignin more particularly (Monrroy et al. 2011; Leonowicz et al. 1999). Indeed, the deterioration process of white-rot fungi targets cell-wall penetration in order to depolymerize cellulose making wood degradation easier (Wang and Gao 2003). Within this process, fungi orchestrate different pathways such as Fenton reactions and generation of reactive oxygen species like hydroxyl radicals (Jensen et al. 2001).

Weight losses of beech wood and pine sapwood with and without treatments in response to fungal exposure to C. versicolor and C. puteana respectively after 6 weeks. Impregnated and leached samples were compared to their corresponding controls; ns no significant changes; **p < 0.01. P maritime pine, B beech wood, GC1 Pomegranate concentration at 5%, GC2 Pomegranate concentration at 10%, GC3 Pomegranate concentration at 20%, MC4 M. azeradach concentration at 5%, MC5 M. azeradach concentration at 7%, V veraxyl treated sample, L leached sample

Taking into consideration the results obtained for weight losses, durability classes of woods were calculated according to values stipulated in CEN/TS 15083-1 (2005) standard. In this guideline, beech wood and pine sapwood are classified in the lowest value (5) corresponding to not durable wood materials. As demonstrated in Table 2, natural extractives of pomegranate peel and M. azedarach are able to improve durability classes of pine and beech wood. The only exception concerned M. azedarach solution at 5% where class durability was not increased. Once again, the highest concentration of pomegranate peel solution resulted in a maximum class durability (1), equalizing the results obtained with the commercial fungicide veraxyl. These results reinforce the efficiency and potential of the use of natural strategies to prevent fungal contamination in wood industry. Nevertheless, further studies need to be performed to improve the efficiency of natural products in different types of wood. Indeed, retention of organic compounds within impregnated wood tissues is one of the biggest hurdles to develop effective technologies based on the use of natural compounds (Singh and Singh 2012). To obtain a better fixation of plant extracts, the use of additives that chemically bond with the extracts and thus, easily penetrate into the wood structure may be useful; otherwise, extracts can be accumulated on the wood surface and easily leach (Sen et al. 2009). Important progresses have been realized in recent years, for example, in situ enzymatic polymerization of biocides was performed to render them water-insoluble. In this manner, Rättö et al. (2004) managed to bind phenolic preservatives into wood by adding lactase to the treatment solution. Moreover, Tondi et al. (2012) showed that combining boron with tannin can increase leaching resistance and thus, treatment durability. Another promising approach is the co-impregnation of biocides with water repellants (Panov and Terziev 2009). In fact, a trial combining waterborne resin acids with organic biocides proved to be an excellent water repellency system (Schultz et al. 2006).

3.3 Total phenol content determination

After having demonstrated that natural extracts had a beneficial impact on wood durability, further analyses were performed to determine the total content of phenols and to characterize the phenolic profile of natural solutions and wood samples.

3.3.1 Total phenol content

Total phenol content of wood species at different stages (with and without impregnation and leaching treatments) are shown in Fig. 2. As demonstrated, wood species in natural state presented lower amounts of phenolic content which probably explains their low natural durability. Indeed, phenolic content as well as the type of phenols is directly involved in wood durability (Mounguengui et al. 2016; Aloui et al. 2004; Schultz and Nicholas 2000). This relation has already been observed in other specimens like oakwood and Handroanthus serratifolius which presented elevated amounts of phenolic compounds (i.e. elagitannins, quercetin and flavonoids) and thus a higher resistance to fungal deterioration (Guilley et al. 2004; Rodrigues et al. 2012).

Total phenol content of maritime pine and beech sapwood without treatment and after impregnation treatment and leaching tests. Treatments were compared to the corresponding control. ns no significant changes; *p < 0.05; **p < 0.01. P maritime pine, B beech wood, GC1 Pomegranate concentration at 5%, GC2 Pomegranate concentration at 10%, GC3 Pomegranate concentration at 20%, MC4 M. azeradach concentration at 5%, MC5 M. azeradach concentration at 7%

Analyses conducted on natural extracts demonstrated elevated phenol contents. Indeed, pomegranate peel presented a phenolic content value of 492.629 ± 42.25 mg GAE/g DW while M. azedarach extract point out values of 204.721 ± 40.78 mg GAE/g DW. It has to be noted that actually most of the studies to determine phenol content in natural samples mainly involve solvent extractions. Despite this, the phenol concentrations obtained in this study were higher than those found in literature. For instance, a recent study performed by Gullon et al. (2016) evaluating methanol–water extracts from Spanish pomegranate peels reported a phenolic concentration of 19.30 mg GAE/g DW. As well, experiments conducted by Nasr et al. (1996) using pomegranate peel methanolic-water extracts from Tunisia reported phenolic concentrations of 216.9 ± 7.3 mg GAE/g DW. Compared to the current results, phenol content of pomegranate peel seems to be related to regional localization and climatic conditions but also to extraction conditions. Concerning M. azedarach extract, Kuppusamy et al. (2016) characterized several natural extracts reporting that aqueous extracts of M. azedarach barks presented higher content in minerals and total phenol values of 6.4 ± 2.1 GAE/g DW. In parallel, another study also conducted on M. azedarach barks highlighted the presence of tannins, flavonoids and phenolic compounds while phenol contents were estimated by 54.94 ± 0.20 and 82.68 ± 0.03 mg GAE/g DW for aqueous and methanolic extracts respectively (Kumar et al. 2012). Differences in phenol concentrations between the current results and literature may also be explained because of the genetic variability and storage conditions of plants. In fact, as demonstrated by Romero et al. (2016) and Kevers et al. (2007), genetic variability, growth environment and storage conditions are determinant factors leading to important modifications of phenol concentrations.

3.3.2 Phenolic profile of natural extracts and wood samples

In order to obtain more information about the phenolic compounds occurring in natural extracts and wood samples, a qualitative characterization by HPLC-DAD was performed. Compounds were respectively identified by comparing the retention time and UV–Vis spectra with commercial standards. Figure 3 shows the results of the phenolic composition in natural extracts as well as in wood samples with and without treatment. As demonstrated, wood specimens presented two types of phenols: vanillin and catechin. It can also be demonstrated that levels of vanillin were equal in both wood species but catechin levels differed depending on wood type. While in beech wood, catechin was presented in higher proportions, in pine wood the latter compound was not detected. The presence of this compound is similar to other studies realized on methanolic extracts of beech barks where catechin was the major compound (Hofmann et al. 2015). Concerning pine sapwood, compounds such as flavonoids, phenolic acids and proanthocyanidins have already been identified (Iravani and Zolfaghari 2011). However, this is not the case in this study which demonstrates the impact of the solvents within phenolic extraction.

Profile of phenolic compounds characterized by HPLC of (1) beech and maritime pine wood (2) aqueous extracts of M. azedarach and P. granatum L. and (3) treated wood samples after impregnation and leaching tests. Values of punicalagin A, B and ellagic acid were equally divided between ten. P maritime pine, B beech wood, GC1 Pomegranate concentration at 5%, GC2 Pomegranate concentration at 10%, GC3 Pomegranate concentration at 20%, MC4 M. azeradach concentration at 5%, MC5 M. azeradach concentration at 7%, L leached sample

Regarding the phenolic compounds of natural extracts, pomegranate solution presented a more complex profile than that from M. azedarach. In M. azedarach extract, catechin was identified as the main compound with traces of gallic acid. Moreover, catechin also remained as the principal compound after impregnation and leaching tests. The only exception corresponded to the M. azedarach concentration at 5% (w/w) in pine sapwood where catechin was completely eliminated by leaching. As demonstrated in Sect. 3.2, higher concentrations of Melia extracts resulted in less weight losses in wood. These results linked to phenol composition suggests that other minor compounds contained in Melia extract could increase with higher doses and thus increase the antifungal effect. Another proposal can be due to changes in pH conditions. In fact, several studies pointed out that antifungal activity of catechin depends on pH values together with the observation that leaching of treated wood can vary in pH values compared to control (Kumar et al. 2016; Sitheeque et al. 2009; Hirasawa and Takada 2004).

Concerning pomegranate peel phenolic profile, this extract presented at least five different compounds corresponding to punicalagin A and B, catechin, gallic acid and ellagic acid. The presence of punicalagins as well as ellagitannins in this extract is in accordance with previous studies reporting that these phenolic compounds are characteristic of pomegranate fruits (Mena et al. 2012; Fischer et al. 2011; Seeram et al. 2005; Nasr et al. 1996). In addition to these compounds, other studies of pomegranate peel extracts also showed the presence of HHDP-gallagy-hexoside as well as ellagic acid derivatives (Gullon et al. 2016), compounds that were not identified in this study. After impregnation tests, gallic and ellagic acids were found in almost all samples treated with pomegranate extract. On the contrary, punicalagin A and B which were present in the pomegranate extract were not detected in wood samples after treatment. This observation could be explained by the preparation conditions of the extract solution. Indeed, it is well known that ellagitanins may be hydrolyzed at temperatures higher than 30 °C to produce ellagic acid and glucose complex (Charrier et al. 1992, 1995). In addition, punicalagin A and B could probably be hydrolyzed during the extraction process. It has to be pointed out that after leaching tests on both wood specimens, gallic acid was systematically eliminated while ellagic acid concentrations were reduced by around 50%.

In the case of pinewood and after leaching tests, ellagic acid remained as the principal compound. This result suggests that ellagic acid may represent the principal compound in charge of the antifungal effect of pomegranate extract. This suggestion is in agreement with literature since several studies have shown that ellagic acid, being a dimer form of gallic acid, can exhibit antifungal activity (Li et al. 2015). In the case of beech wood, ellagic acid and catechin (initially present in beech wood) were identified. Tests against fungal degradation demonstrated that pomegranate extracts had a better protective effect on beech wood than on pine sapwood. This behavior may be due to a synergic effect between ellagic acid and catechin. Indeed, it is well known that when used alone, several phenolic compounds have no or little effect against fungi. However, combined phenolic compounds could present a better protection (Brand et al. 2006). It is also suggested that C. puteana might be more sensible than C. versicolor to ellagic acid.

4 Conclusion

In the present study, aqueous extract of pomegranate peel and M. azedarach were tested as antifungal treatment against C. puteana and C. versicolor in order to increase wood durability of beech and maritime pine species. Natural extracts demonstrated to have interesting phenolic compounds highlighting the presence of ellagic acid and catechin. Moreover, the applied treatments conferred resistance to fungal attack by reducing weight losses of wood thus resulting in an increase in wood durability even after leaching tests. Promising results were obtained using a simple and easily industrialized process of extraction and treatment. Even if leaching resistance has to be improved before industrialization, this study demonstrates that the use of natural alternatives to synthetic biocides is possible for wood treatment.

References

Akacha M, Chaieb I, Laarif A, Haouala R, Boughanmi N (2017) Effects of Melia azedarach leaf extracts on nutritional behavior and growth of Spodoptera littoralis. Tunis J Plant Prot 12:61–70

Akhtar Y, Yeoung Y-R, Isman MB (2007) Comparative bioactivity of selected extracts from Meliaceae and some commercial botanical insecticides against two noctuid caterpillars, Trichoplusia in and Pseudaletia unipuncta. Phytochem Rev 7:77–88

Aloui F, Ayadi N, Charrier F, Charrier B (2004) Durability of European oak (Quercus petraea and Quercus robur) against white rot fungi (Coriolus versicolor): relations with phenol extractives. Holz Roh Werkst 62:286–290

Al-Zoreky NS (2009) Antimicrobial activity of pomegranate (Punica granatum L.) fruit peels. Int J Food Microbiol 134:244–248

Andrei GM, Lampuri JS, Coto C, de Torres RA (1986) An antiviral factor from Melia azedarach L. prevents Tacaribe virus encephalitis in mice. Experientia 42:843–845

Ayed N (2011) La pomme de Carthage (Grenade de Tunisie). Le Maghreb Magazine, Tunisie 2:98–100

Brand MA, Anzaldo J, Moreschi JC (2006) Novos produtos para o tratamento preservante da madeira: perspectivas da pesquisa e utilizaçao (new products for the preservation of wood: perspectives of research use). Floresta 36:129–138

Brimner TA, Boland GJ (2003) A review of the non-target effects of fungi used to biologically control plant diseases. Agric Ecosyst Environ 100:3–16

Brocco VF, Paes JB, Costa LG, Brazolin S, Donaria M (2017) Potential of teak heartwood extracts as a natural wood preservative. J Clean Prod 142:2093–2099

Carpinella MC, Ferrayoli CG, Palacios SM (2005) antifungal synergistic effect of scopoletin, a hydroxycoumarin isolated from Melia azedarach L. fruits. J Agric Food Chem 53:2922–2927

CEN/TS 15083-1 (2005) Durability of wood and wood-based products—determination of the natural durability of solid wood against wood-destroying fungi, test methods—Part 1: basidiomycetes. CEN European Committee for Standardization

Charrier B, Marques M, Haluk JP (1992) HPLC analysis of gallic and ellagic acids in European oakwood (Quercus robur L.) and eucalyptus (Eucalyptus globulus). Holzforschung 46:87–89

Charrier B, Haluk JP, Metche M (1995) Characterization of European oakwood constituents acting in the brown discolouration during Kiln Drying. Holzforschung 49:168–172

EN 350-2 (1994) Durability of wood and wood based products—Natural durability of solid wood—Part 2: Guide to natural durability and treatability of selected wood species of importance in Europe. European Committee for Standardization

EN 84 (1997) Wood preservatives—accelerated ageing of treated wood prior to biological testing—leaching procedure. European Committee for Standardization

Endo EH, Garcia Cortez DA, Ueda-Nakamura T, Nakamura CV, Dias Filho BP (2010) Potent antifungal activity of extracts and pure compound isolated from pomegranate peels and synergism with fluconazole against Candida albicans. Res Microbiol 161:534–540

Fischer UA, Carle R, Kammerer DR (2011) Identification and quantification of phenolic compounds from pomegranate (Punica granatum L.) peel, mesocarp, aril and differently produced juices by HPLC-DAD-ESI/MSn. Food Chem 127:807–821

Gérardin P (2016) New alternatives for wood preservation based on thermal and chemical modification of wood—a review. Ann For Sci 73:559–570

Gonzalez-Laredo RF, Rosales-Castro M, Rocha-Guzman NE et al (2015) Wood preservation using natural products. Madera y Bosques 21:63–76

Guilley E, Charpentier JP, Ayadi N, Snakkers G, Nepveu G, Charrier B (2004) Decay resistance against Coriolus versicolor in Sessile oak (Quercus petraea Liebl.): analysis of the between-tree variability and correlations with extractives, tree growth and other basic wood properties. Wood Sci Technol 38:539–554

Gullon B, Pintado ME, Pérez-Álvarez JA, Viuda-Martos M (2016) Assessment of polyphenolic profile and antibacterial activity of pomegranate peel (Punica granatum) flour obtained from co-product of juice extraction. Food Control 59:94–98

Guo G, Wang H, Pomegranin Ng T (2009) An antifungal peptide from pomegranate peels. Protein Pept Lett 16:82–85

Hedenstrom E, Fagerlund Edfeldt A, Edman M, Jonsson B-G (2016) Resveratrol, piceatannol, and isorhapontigenin from Norway spruce (Picea abies) debarking wastewater as inhibitors on the growth of nine species of wood-decaying fungi. Wood Sci Technol 50:617–629

Hirasawa M, Takada K (2004) Multiple effects of green tea catechin on the antifungal activity of antimycotics against Candida albicans. J Antimicrob Chemother 53:225–229

Hofmann T, Nebehaj E, Stefanovits-Bányai É, Albert L (2015) Antioxidant capacity and total phenol content of beech (Fagus sylvatica L.) bark extracts. Ind Crops Prod 77:375–381

Hu J, Chang S, Peng K, Hu K et al (2015) Bio-susceptibility of shells of Camellia oleifera Abel. fruits to fungi and termites. Int Biodeterior Biodegrad 104:219–223

Iravani S, Zolfaghari B (2011) Pharmaceutical and nutraceutical effects of Pinus pinaster bark extract. Res Pharm Sci 6:1–11

Jensen KA Jr, Houtman CJ, Ryan ZC, Hammel KE (2001) Pathways for extracellular fenton chemistry in the brown rot basidiomycete Gloeophyllum trabeum. Appl Environ Microbiol 67:2705–2711

Kevers C, Falkowski M, Tabart J, Defraigne JO, Dommes J, Pincemail J (2007) Evolution of antioxidant capacity during storage of selected fruits and vegetables. J Agric Food Chem 55:8596–8603

Kirker GT, Bishell AB, Lebow PK (2016) Laboratory evaluations of durability of southern pine pressure treated with extractives from durable wood species. J Econ Entomol 109:259–266

Kumar SV, Sanghai DB, Rao CM, Shreedhara CS (2012) Histological and physiochemical standardization of Melia azedarach Linn bark Asian Pacific. J Trop Biomed 2:S284–S289

Kumar A, Ryparová P, Škapin AS et al (2016) Influence of surface modification of wood with octadecyltrichlorosilane on its dimensional stability and resistance against Coniophora puteana and molds. Cellulose 23:3249–3263

Künniger T, Gerecke AC, Ulrich A et al (2014) Release and environmental impact of silver nanoparticles and conventional organic biocides from coated wooden façades. Environ Pollut 184:464–471

Kuppusamy S, Thavamani P, Megharaj M, Nirola R, Lee YB, Naidu R (2016) Assessment of antioxidant activity, minerals, phenols and flavonoid contents of common plant/tree waste extracts. Ind Crops Prod 83:630–634

Leonowicz A, Matuszewska A, Luterek J et al (1999) Review: Biodegradation of lignin by white rot fungi. Fungal Genet Biol 27:175–185

Li Z-J, Guo X, Dawuti G, Aibai S (2015) Antifungal activity of ellagic acid in vitro and in vivo. Phytother Res 29:1019–1025

Lucci P, Pacetti D, Loizzo MR, Frega NG (2015) Punica granatum cv Dente di Cavallo seed ethanolic extract: antioxidant and antiproliferative activities. Food Chem 167:475–483

Mansour MMA, Salem MZM (2015) Evaluation of wood treated with some natural extracts and Paraloid B-72 against the fungus Trichoderma harzianum: Wood elemental composition, in-vitro and application evidence. Int Biodeterior Biodegrad 100:62–69

Mena P, Calani L, Dall’Asta C et al (2012) Rapid and comprehensive evaluation of (Poly) phenolic compounds in pomegranate (Punica granatum L.) Juice by UHPLC-MSn. Molecules 17:14821–14840

Monrroy M, Ortega I, Ramírez M, Baeza J, Freer J (2011) Structural change in wood by brown rot fungi and effect on enzymatic hydrolysis. Enzyme Microb Technol 49:472–477

Mounguengui S, Saha Tchinda JB, Ndikontar MK et al (2016) Total phenolic and lignin contents, phytochemical screening, antioxidant and fungal inhibition properties of the heartwood extractives of ten Congo Basin tree species. Ann For Sci 73:287–296

Nasr CB, Ayed N, Metche M (1996) Quantitative determination of the polyphenolic content of pomegranate peel Z Lebensm. Unters Forsch 203:374–378

Ntalli NG, Vargiu S, Menkissoglu-Spiroudi U, Caboni P (2010) Nematicidal carboxylic acids and aldehydes from Melia azedarach fruits. J Agric Food Chem 58:11390–11394

Panov D, Terziev N (2009) Study on some alkoxysilanes used for hydrophobation and protection of wood against decay. Int Biodeterior Biodegrad 63:456–461

Rachokarn S, Piyasaengthong N, Bullangpoti V (2008) Impact of botanical extracts derived from leaf extracts Melia azedarach L. (Meliaceae) and Amaranthus viridis L. (Amaranthaceae) on populations of Spodoptera exigua (Hübner) (Lepidoptera: Noctuidae) and detoxification enzyme activities. Commun Agric Appl Biol Sci 73:451–457

Rättö M, Ritschkoff A-C, Viikari L (2004) Enzymatically polymerized phenolic compounds as wood preservatives. Holzforschung 58:440–445

Rodrigues AMS, Stien D et al (2012) The wood preservative potential of long-lasting Amazonian wood extracts. Int Biodeterior Biodegrad 75:146–149

Romero N, Saavedra J, Tapia F, Sepulveda B, Aparicio R (2016) Influence of agroclimatic parameters on phenolic and volatile compounds of Chilean virgin olive oils and characterization based on geographical origin, cultivar and ripening stage: Effect of agroclimatic parameters on compounds responsible for the flavor of EVOO. J Sci Food Agric 96:583–592

Rowell RM (2006) Chemical modification of wood: a short review. Wood Mater Sci Eng 1:29–33

Saad H, Charrier-El Bouhtoury F, Pizzi A, Rode K, Charrier B, Ayed N (2012) Characterization of pomegranate peels tannin extractives. Ind Crops Prod 40:239–246

Salem MZM, Zidan YE, El Hadidi NMN, Mansour MMA, Abo Elgat WAA (2016) Evaluation of usage three natural extracts applied to three commercial wood species against five common molds. Int Biodeterior Biodegrad 110:206–226

Scalbert A, Monties B, Janin G (1989) Tannins in wood: comparison of different estimation methods. J Agric Food Chem 37:1324–1329

Schultz TP, Nicholas DD (2000) Naturally durable heartwood: evidence for a proposed dual defensive function of extractives. Phytochemistry 54:47–52

Schultz TP, Nicholas DD, Kelly S (2006) A non-leachable waterborne composition of resin acids and wood preserving organic biocides US Provisional patent 60/743 669, filed 22

Seeram NP, Adams LS, Henning SM, Niu Y, Zhang Y, Nair MG, Heber D (2005) In vitro antiproliferative, apoptotic and antioxidant activities of punicalagin, ellagic acid and a total pomegranate tannin extract are enhanced in combination with other polyphenols as found in pomegranate juice. J Nutr Biochem 16:360–367

Sen S, Tascioglu C, Tırak K (2009) Fixation, leachability, and decay resistance of wood treated with some commercial extracts and wood preservative salts. Int Biodeterior Biodegrad 63:135–141

Singh T, Singh AP (2012) A review on natural products as wood protectant. Wood Sci Technol 46:851–870

Singh AP, Singh T (2014) Biotechnological applications of wood-rotting fungi: a review. Biomass Bioenergy 62:198–206

Sitheeque MAM, Panagoda GJ, Yau J, Amarakoon AM, Udagama UR, Samaranayake LP (2009) Antifungal activity of black tea polyphenols (catechins and theaflavins) against Candida species. Chemotherapy 55:189–196

Sotillo DR, Hadley M, Holm ET (1994) Phenolics in aqueous potato peel extract: extraction, identification and degradation. J Food Sci 59:649–651

Sultana B, Anwar F, Przybylski R (2007) Antioxidant activity of phenolic components present in barks of Azadirachta indica, Terminalia arjuna, Acacia nilotica, and Eugenia jambolana Lam. trees. Food Chem 104:1106–1114

Tascioglu C, Mesut Y, Selim S, Akcay C (2013) Antifungal properties of some plant extracts used as wood preservatives. Int Biodeterior Biodegrad 85:23–28

Taverna S, Corrado C (2017) Natural compounds: molecular weapons against Leukemia’s. J Leuk 5:1–7

Tehranifar A, Selahvarzi Y, Kharrazi M, Bakhsh VJ (2011) High potential of agro-industrial by-products of pomegranate (Punica granatum L.) as the powerful antifungal and antioxidant substances. Ind Crops Prod 34:1523–1527

Temiz A, Alfredsen G, Yildiz UC, Gezer ED, Kose G, Akbas S, Yildiz S (2014) Leaching and decay resistance of alder and pine wood treated with copper based wood preservatives. Maderas Cienc y Tecnol 16:63–76

Tondi G, Wieland S, Lemenager N, Petutschnigg A, Pizzi A, Thevenon MF (2012) Efficacy of tannin in fixing boron in wood. Bioresources 7:1238–1252

Tondi G, Thevenon MF, Mies B, Standfest G, Petutschnigg A, Wieland S (2013) Impregnation of Scots pine and beech with tannin solutions: effect of viscosity and wood anatomy in wood infiltration. Wood Sci Technol 47:615–626

Wang W, Gao PJ (2003) Function and mechanism of a low-molecular-weight peptide produced by Gloeophyllum trabeum in biodegradation of cellulose. J Biotechnol 101:119–130

Witomski P, Olek W, Bonarski JT (2016) Changes in strength of Scots pine wood (Pinus silvestris L.) decayed by brown rot (Coniophora puteana) and white rot (Trametes versicolor). Constr Build Mater 102:162–166

Yamaguchi LH, Okuda K (1998) Chemically modified tannin and tannin–copper complexes as wood preservatives. Holzforschung 52:596–602

Zabalza BI, Valero Capilla AO, Aranda Usón A (2011) Life cycle assessment of building materials: comparative analysis of energy and environmental impacts and evaluation of the eco-efficiency improvement potential. Build Environ 46:1133–1140

Zahoor M, Manzoor A, Sumaira N, Musarrat A (2015) Cytotoxic, antibacterial and antioxidant activities of extracts of the bark of Melia Azedarach (China Berry). Nat Prod Res 29:1170–1172

Zhang Q, Shi Y, Liu XT, Liang JY, Ip NY, Min ZD (2007) Minor limonoids from Melia toosendan and their antibacterial activity. Planta Med 73:1298–1303

Zhang Z, Yang T, Mi N, Wang Y, Li G, Wang L, Xie Y (2016) Antifungal activity of monoterpenes against wood white-rot fungi. Int Biodeterior Biodegrad 106:157–160

Acknowledgements

We gratefully acknowledge the Laboratory of Biology FCBA of Technological Institute (Bordeaux, France) as well as local Sawmills (Mont de Marsan, France) for the supplied biological and wood material used in this study.

Funding

This project was realized with the financial support of the “Projet Utique CMCU-2012”. Funded by ANR-10-EQPX-16 XYLOFOREST.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Lajnef, L., Caceres, I., Trinsoutrot, P. et al. Effect of Punica granatum peel and Melia azedarach bark extracts on durability of European beech and maritime pine. Eur. J. Wood Prod. 76, 1725–1735 (2018). https://doi.org/10.1007/s00107-018-1340-x

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00107-018-1340-x