Abstract

12 years old trees from 20 progenies/provenances of Japanese larch (Larix kaempferi, [Lamb.] Carr.), planted in Quebec, were sampled to study the variation in selected mechanical properties. Two standard wood samples and one 10-mm diameter increment core were taken from each tree at breast height. The parallel-to-grain compliance coefficient and ultimate crushing strength were evaluated on the standard samples at air-dry conditions. The dynamic compliance coefficient was measured on increment cores using an ultrasonic wave propagation method. Differences in all mechanical properties among progenies/provenances were significant. Lowest static compliance coefficient and highest ultimate crushing strength were found in progenies/provenances 8934, 7795, 7283, 8962, 8907, 7794, and 8939, being the most interesting for a lumber end-use. Among them, progenies/provenances 7283, 8934, 7794, 7795, 8962, and 8907 also showed lowest dynamic compliance coefficient. The latter coefficient tended to be lowest near the pith and then increased outward towards the bark. There was also a highly significant correlation between static mechanical properties, and a moderate correlation between static and dynamic compliance coefficients. Ultimate crushing strength was moderately correlated to wood density.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

The genus Larix consists of about 10 species distributed throughout the northern hemisphere. Larches are well adapted to northern climates and grow very quickly when planted under adequate conditions (Perron 2011). Larix species are the most productive conifers in eastern Canada, having a rotation age that is often shorter than 30 years. Some species and hybrids of larches have shown high growth rates and effective adaptation to different site conditions in North America (Isebrands and Hunt 1975; Loo et al. 1982; Einspahr et al. 1983; Chui and MacKinnon-Peters 1995).

Only tamarack (Larix laricina) is native to eastern Canada (Farrar 1995). However, it does not occur in extensive natural stands and comprises only a small proportion of Canada’s total growing stock by forest type. However, tamarack and exotic larches are versatile species that can be used for several purposes, as wood products (interior/exterior), pulp and paper, and composite products (Zhang and Koubaa 2008). Tamarack belongs to the North American species group (N), also including exotic larches, and each piece of lumber is stamped with the common designation Hem-Tam (N) (NGLA 2003). However, tamarack has traditionally been cut and processed with other softwood species that are normally marketed under the SPF species grouping [spruce (Picea sp.) -pine (Pinus sp.) -fir (Abies sp.)] (Zhang and Koubaa 2008).

During the 1970s, Quebec province started a larch improvement program to find the most productive and best-adapted provenances, hybrids, and clones for this region (Stipanicic 1975). The results of the initial plantation trials showed that Japanese larch had the highest yield. It produced an average total volume of 0.386 m3 per tree at 22.8 years old, against 0.337 m3 at 23.8 years and 0.255 m3 at 22.6 years for European larch (Larix decidua) and tamarack, respectively (Verville 1981). Nowadays, some 125 million young trees are planted annually in Quebec public and private forests, to complement the regeneration of harvested areas. 1.13 millions of seedlings coming from miscellaneous softwoods, including larch, were planted in the Quebec region (NFDP 2015). In 2007, 80% of the plants came from a genetically improved source (MRNF 2007). In the boreal forest, despite less favorable growing conditions, the additional volume of lumber obtained by planting improved material is significant, given the extension of the territory and the amount of tree seedlings planted (Rainville et al. 2003). However, little is known with regard to their wood properties.

Initially, tree improvement programs focused mainly on volume growth, stem form, adaptability, and disease resistance. However, the influence of enhanced growth on wood properties has become a serious concern among tree breeders. Nowadays, the goal of the selection process includes the improvement of wood quality traits, or at least the minimization of impairing some key wood properties (Pâques et al. 2010). For many years, wood basic density was considered as the most important feature in wood quality research because it is closely related to most relevant wood properties and it is relatively easy to measure (Apiolaza 2009). More recently, breeders began to shift their focus to wood stiffness or modulus of elasticity (MOE), primarily because non-destructive equipment for its measurement is currently more available. (Jacques et al. 2004; Urhan et al. 2014). In North America, assessing wood quality of standing trees using acoustic velocity typically involves inserting two sensor probes into the sapwood and introducing acoustic energy into the tree through a hammer impact. Recent studies showed that the obtained results can be used to make unbiased predictions of tree-level MOE (Paradis et al. 2013; Fischer et al. 2015; Chen et al. 2015). However, postharvest non-destructive testing has usually not been used until recently. Nowadays, methods including E-rating, machine stress rating (MSR), and ultrasound veneer grading are the standard procedures for evaluating wood stiffness and strength (Brashaw et al. 2009).

Parallel to the grain compression is important to evaluate the strength of wood mainly for lumber manufacturing. Parallel to the grain crushing strength determines the load a short post or column will carry. However, the compliance coefficient in this direction is the reciprocal of the Young’s modulus. It is known that this parameter is closely related to the Young’s modulus obtained by static bending (the difference between both MOEs being the shear contribution to MOE determined by static bending). Actually, wood stiffness is one of the most important characteristics of wood for structural lumber purposes in North America. (Forest Products Laboratory 2010). Increasingly, at larger mills, lumber grades are determined by MSR (Shmulsky and Jones 2011), which measure primarily the modulus of elasticity by bending. This translates into a set of cost-competitive products that extend the use of lumber into high strength applications (NRCAN 2017; Canadian Wood Council 2017).

The present work is part of an extensive wood quality study of Japanese larch progenies/provenances grown in Quebec. Previous papers showed that density and shrinkage could be used as preliminary selection criteria of the best progenies/provenances according to a given utilization (Cáceres et al. 2017, 2018). The main objective of this study was to provide information on two mechanical properties, namely static compliance coefficient (s11) and ultimate crushing strength parallel-to-grain measured in standard samples for the selection of the best progenies/provenances for a potential structural end-use. In addition, a non-destructive method was used to estimate the dynamic compliance coefficient from an increment core. A better knowledge of these mechanical properties would promote the further utilization and plantation of the best Japanese larch progenies/provenances in the Quebec Province.

2 Materials and methods

2.1 Study area and sampling

The material for this study was obtained through a larch breeding program established in Quebec. Japanese larch (Larix kaempferi, [Lamb.] Carr.) trees came from an 12 year old experimental plantation, which was located in the township of Batiscan (46°31′N and 72°15′W), in the Mauricie region. According to Zhu et al. (2000), the limit between juvenile and mature wood in Japanese larch varies between age 15 and 21 years depending on the plantation site. Therefore, it would be reasonable to state that all the material used in this experiment was composed of juvenile wood. The plantation had a total surface of 1.76 ha, where 8000 seedlings were initially planted (1 m × 1 m). After three selective thinning procedures done by the Minister of Natural Resources of Quebec, only 400 trees remained in order to transform the plantation into a seed orchard. 7 trees of each of the 20 different progenies and/or provenances tested in the breeding program were obtained from the final selective thinning intervention. Provenance is defined as the original geographic area from which seed or other propagules were obtained and progeny is the offspring of improved varieties obtained by breeding (Zobel and Jett 1995). The geographic and genetic origins of the material as well as the diameter at 0.4 and 2.85 m from the ground are shown in Table 1.The obtained stems were straight and did not present decay. The stems were cross-cut at 15 cm from the ground to obtain 140 butt logs of 3 m length. Each log was then cut in two halves lengthwise. One-half was used to obtain two standard samples immediately above and below 1.3 m from the ground for the evaluation of static parallel to the grain compression. One increment core of 10 mm in diameter was also obtained from pith to bark at breast height for the evaluation of the dynamic compliance coefficient (Fig. 1). Only knot-free cores were used.

2.2 Dynamic and static parallel to the grain compression assessments

The increment core was withdrawn from the half-log with a low-speed hand drill and conditioned at 20 °C and 65% of relative humidity (RH). The resultant equilibrium moisture content (EMC) was on average 15%. Once equilibrium was reached, the dynamic compliance coefficient s11 was measured as described by Bucur (1981, 1983), Herzig (1991), and Yang and Fortin (2001).

The increment core was divided into two segments of 25 mm of length (radial direction): one closer to the bark and one closer to the pith. Each 25-mm core segment was placed between two ultrasonic sensors (transmitter and receiver) of 12.7 mm in diameter, and a 1 MHz pulse was propagated in the axial direction through the core. Previous studies have shown that a core of 25 mm in length is adequate for a transducer of 12.7 mm in diameter (Labrecque 1992; Yang and Fortin 2001). The time for the wave to pass through the segment was measured to 10− 9 s. The diameter of each segment was measured to the nearest 0.001 mm, which was equal to the distance traveled by the wave. Wood density at the time of testing is required, thus the volume of the segment was determined by a mercury displacement method and its weight was measured to the nearest 0.001 g. The dynamic compliance coefficient in the axial direction, s11, was calculated using the following equation

where DH air-dry density at time of testing (nominal EMC) (kg/m3). v velocity of wave propagation (m/s).

The velocity of wave propagation into wood was corrected using a 10 mm diameter Plexiglas cylinder reference block. This correction compensates for time errors caused by the presence of coupling agents and by the transport of electrical waves within the measuring circuit. More details of this correction can be found in Herzig (1991) and Yang and Fortin (2001). It should be noted that the effect of Poisson’s ratio on the segments was not considered and no corrections were applied. Therefore, compliance coefficients should be considered apparent as proposed by Bucur (1981).

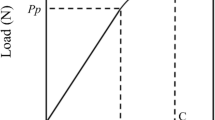

Afterwards, the second half-log was cut into one full-length board at a radial position as close to the bark as possible to obtain a sample of 25 mm in width. All boards were conditioned at 20 °C and 65% RH until reaching a constant mass. Conditioning resulted in an equilibrium moisture content (EMC) of 15%. Two standard samples of 25 (T) × 25 (R) × 100 (L) mm3 per board were obtained just above and below breast height (1.3 m from the ground) (Fig. 1). Compression tests parallel-to-grain were carried out on a Tinius Olsen universal testing machine according to ASTM D-l43 specifications for small clear specimens. Strain in the axial direction was measured over a 50 mm span in the central part of the specimen, using a two-side clip gauge with a linear variable differential transformer. The crosshead speed was set to 0.03 mm/min. These tests permitted the establishment of the static compliance coefficient in the longitudinal direction (s11), which is the reciprocal of the MOE. Ultimate crushing strength in the longitudinal direction (σL) was obtained from the maximum load at failure and the cross-sectional area. In all cases, calculations were made using the cross-sectional area measured at the time of testing. Data analysis was done with the average of the two standard samples taken above and below breast height.

2.3 Statistical analysis

Data were analyzed using the Statistical Analysis System 9.4 software (SAS Institute 2012, Cary NC). Raw data was first evaluated with the Box-Cox method showing the more fitted transformation to obtained normally distributed data. The transformation was only applied when normality was not initially reached. An analysis of variance (ANOVA) was used to evaluate variation in the static compliance coefficient, ultimate crushing strength and the dynamic compliance coefficient. For increment core samples, data structure followed a split-plot design with progeny/provenance in the main plot and radial position in the subplot. For ASTM samples the only source of variation was the progeny/provenance. Means comparison tests were done at 5% probability level if necessary. Finally, the normality was verified with Shapiro–Wilk’s test, and the homogeneity of variance was verified with the graphical analysis of residuals. Correlation and regression analyses on mechanical properties and standard samples density (data from Cáceres et al. 2017 was used) were also performed.

3 Results and discussion

The ANOVA of the static compliance coefficient and the ultimate crushing strength in compression parallel-to-grain of the standard samples showed a significant effect of progeny/provenance on these properties (Table 2). The static compliance coefficient varied from 5.8 × 10− 5 /MPa for progeny/provenance 8934 to 9.7 × 10− 5 /MPa for progeny/provenance 7279. The overall mean (7.5 × 10− 5 /MPa, Table 3) was lower compared to plantation tamarack grown in Quebec (11.6 × 10− 5 /MPa) (Beaudoin et al. 1989) and other exotic larches (10.2 × 10− 5 /MPa for Larix gmelinii and 11.5 × 10− 5 /MPa for Larix sibirica, in lumber bending) grown in Ontario (Chauret and Zhang 2002). Plantation Japanese larch was also less deformable than balsam fir (10.3 × 10− 5 /MPa), black spruce (8.1 × 10− 5 /MPa), jack pine (9.5 × 10− 5 /MPa), and tamarack (9.5 × 10− 5 /MPa) grown in natural conditions (Jessome 2000). S11 values of Japanese larch were obtained at 15% EMC while s11 values of other species were reported at 12% EMC. In other words, adjusted values of Japanese larch at 12% will even show a higher MOE than common commercial softwood species.

Furthermore, the ultimate crushing strength varied from 28.7 MPa for the progeny/provenance 6689 to 37.3 MPa for the progeny/provenance 8934 (Table 3). The overall mean (33.2 MPa, Table 3) was comparable to that reported by Bastien and Keller (1980) (36.9 MPa) but lower than that obtained by Charron et al. (2003) (40 MPa) for plantation Japanese larch. Moreover, the compression strength parallel-to-grain studied was similar to that of natural balsam fir (34.3 MPa, Jessome 2000) and plantation tamarack (33.9 MPa, Beaudoin et al. 1989). However, plantation Japanese larch wood would be less resistant than black spruce (41.5 MPa), jack pine (40.5 MPa), and tamarack (44.8 MPa) woods growing in a natural environment (Jessome 2000). The latter values were obtained at 12% EMC, while strength values in this study were obtained at 15% EMC. The results found by Jessome (2000) for tamarack at green and 12% EMC conditions allowed making an adjustment of the present results at 12% EMC. Thus, the ultimate crushing strength increased to 32.6 MPa for the progeny/provenance 6689 and to 41.2 MPa for the progeny/provenance 8934. The overall mean value of all progenies/provenances increased to 37.1 MPa. In this case, ultimate crushing strength of the progeny/provenance 8934 will be comparable to values reported for black spruce and jack pine, but it still remains lower compared to natural tamarack under similar EMC conditions.

Multiple means comparison tests showed that progenies/provenances classes have a wide range, with significant overlap among classes (Table 3). This could be in part due to the small number of replicates used, all coming from a single site, hence limiting the environmental variation within progenies/provenances. Further studies with a higher number of sampled trees and more than one site would be needed to increase the discrimination power among progenies/provenances. However, general trends can be drawn towards the strength improvement for lumber end-use by an early-selection of the adequate progenies/provenances. Accordingly, the best progenies/provenances for both static compliance coefficient and ultimate crushing strength were 8934, 7795, 7283, 8962, 8907, 7794, and 8939. These progenies/provenances would have the less deformable (low s11) and more strength resistant (high σL) wood.

The dynamic compliance coefficient, measured on increment cores closest to the bark, varied from 6.5 × 10− 5 /MPa for progeny/provenance 7283 to 9.8 × 10− 5 /MPa for progeny/provenance 8927. The overall mean was 7.9 × 10− 5 /MPa (Table 3), which is similar to the values obtained by the static compression test. The multiple means comparison tests also showed a significant overlap among classes. There was a correspondence with the best progenies/provenances previously selected in the static compression test, namely: 7283, 8934, 7794, 7795, 8962, and 8907. However, results from the ultrasonic method should be taken with caution. It showed progeny/provenance 7290 as one of the less deformable but the static compression tests (static σL) did not show the same result (Table 3).Various sources of error could have reduced the efficiency of this method, as it will be discussed later.

In addition, Table 4 shows the effect of the radial position at breast height (section of the increment cores) on the dynamic compliance coefficient. This coefficient decreased from 20.1 × 10− 5 /MPa near the pith to 7.9 × 10− 5 /MPa near the bark. A similar radial variation was observed in the MOE of plantation tamarack (Beaudoin et al. 1989). This pattern indicates that Japanese larch progenies/provenances could have a tendency to produce wood with stronger mechanical properties at maturity. Therefore, further studies should be done to verify mechanical properties in older trees of Japanese larch. A significant effect of the radial position was also noted on the density values at 15% EMC (Table 4). The density significantly increased from 452 kg/m3 near the pith to 500 kg/m3 near the bark. Beaudoin et al. (1989) and Keith and Chauret (1988) observed similar behaviors for plantation tamarack and European larch, respectively. In addition, the average density at 15% EMC of standard samples (paired samples used for density and shrinkage assessments, Cáceres et al. 2017, 2018) was 474 kg/m3, which is lower compared to the increment core density. This could be due, in part, to differences in the sampling position within the tree, as discussed below.

Correlation analyses were also carried out between the wood mechanical properties and density (Table 5). These two properties had been measured on different samples, having the same size, coming from the same height and the same growth rings (near the bark) but at different cardinal positions (Cáceres et al. 2017). The increment core data (s11) was also introduced, but only the 25 mm section near the bark was considered for correlations. The results of these analyses showed that ultimate crushing strength increases significantly with wood density. However, the correlation coefficients remained low (Table 5). On the other hand, no correlation was obtained between density and static nor dynamic compliance coefficients. Similar results were found for poplar hybrid clones, in correlations between increment core density and both static compliance coefficient and ultimate crushing strength (Hernández et al. 1998). This result confirms previous studies reporting that density would not be as effectively related to stiffness properties in juvenile wood. Anatomical features, such as microfibril angle have been reported as being more important (Cave and Walker 1994; Cown et al. 1999; Yang and Evans 2003; Alteyrac et al. 2006).

Regression analyses were performed to establish relationships between the studied mechanical properties (Table 6). The static and dynamic compliance coefficients correlation was relatively moderate since only 32% of the variance of the static compliance coefficient was explained by the dynamic compliance coefficient. Moreover, considering the regression variation coefficient (CV of 20%), the model would not be useful for prediction (Table 6). These results compare fairly well with those of Herzig (1991) where the R2 obtained was of 18% (CV of 19%) for plantation white spruce. However, Bucur (1983) obtained a higher correlation (R2 of 45%) for natural beech wood. In addition, the present results showed a low correlation between the ultimate crushing strength measured on standard samples and the dynamic compliance coefficient measured on the increment core. Thus, only 15% of variance of the ultimate crushing strength was explained by the dynamic compliance coefficient (Table 6), which implies that there is an important part of the variation of σL that should be attributed to other variables that were not taken into account in this experiment. Nevertheless, the low coefficient of variation (10%) showed that the regression was fairly consistent.

The effectiveness of the ultrasonic estimation can be influenced by the wood physical properties, the geometrical characteristics of the specimen (macrostructural and microstructural features), the environmental conditions, and the measurement conditions of the equipment (Bucur and Böhnke 1994; Legg and Bradley 2016). In the present experiment, the static and dynamic measurements had sampling differences. Samples for each property were different and were taken from neighboring positions within the tree. The dynamic s11 represents the segment of an increment core closer to the bark taken at breast height, while the static s11 represents the average of two clear samples taken immediately above and below breast height. This could imply a certain natural variability (radial and axial) between the two samples. The effects of shape and size of the samples could also have influenced this relationship. However, the acoustic velocity method remains an interesting non-destructive technique to evaluate wood quality. Nowadays, promising equipment is being used to estimate wood stiffness and strength in standing trees (Auty and Achim 2008; Paradis et al. 2013; Fischer et al. 2015; Chen et al. 2015). However, it has not yet been directly applied to the evaluation of lumber in the manufacturing process.

Finally, the relationship between the static mechanical properties measured on the same sample showed the highest correlation. Thus, it is possible to estimate the static compliance coefficient from the ultimate crushing strength (CV of 13%). The variation of this last property accounts for 71% of static compliance coefficient variation (Table 6).

Progenies/provenances 7283, 8934, 7794, 7795, 8962, and 8907 showed the best mechanical properties. Among them, progenies/provenances 8962 and 8907 had the lowest partial and total shrinkage ratios and the lowest partial and total tangential, radial, and volumetric shrinkages as presented in an earlier study based on the same material (Cáceres et al. 2018). Therefore, they would be the more suited progenies/provenances for structural end-uses. Additional studies should be conducted with mature wood to confirm these results.

However, progeny/provenance 8962 had a moderate extractive content (4.8%), moderate to low corrected basic density (371 kg/m3) and one of the lowest growth rates among progenies (136 mm in diameter at 1.2 m, Table 1) which is not interesting from a silvicultural point of view (Cáceres et al. 2017, 2018). In contrast, progeny/provenance 8907 had a high growth rate among progenies (145 mm in diameter at 1.2 m, Table 1), the highest extractive content (6.9%), and a low corrected basic density (366 kg/m3) (Cáceres et al. 2017, 2018). The latter would be interesting for structural and manufactured products (i.e. lighter wood, easier to nail). Consequently, the use of the pre-selected progenies/provenances for lumber production purposes will be influenced by a compromise between the industrial and silvicultural aspects.

4 Conclusion

Japanese larch trees planted in the Quebec region showed higher resistance to mechanical strain and comparable ultimate crushing strength than most of common softwood commercial species grown in natural conditions. The progenies/provenances effect was significant for both static and dynamic compliance coefficients and ultimate crushing strength. The less deformable (low s11) and more resistant (high σL) progenies/provenances were 8934, 7795, 7283, 8962, 8907, 7794, and 8939. Among them, progenies/provenances 8934, 7795, 7283, 8962, 8907, and 7794 were also selected by the ultrasonic method. In addition, the dynamic compliance coefficient and density (15% EMC) decreased and increased, respectively, from pith to bark. This indicates that Japanese larch would have a tendency to produce stronger wood at maturity. Correlations between static compliance coefficient and ultimate crushing strength with dynamic compliance coefficients were relatively moderate and low, respectively. This could be due to differences in sampling positions of specimens used for each property. The pre-selection of the above mentioned progenies/provenances for a lumber end-use would be more useful if the physico-chemical (shrinkage characteristics, density, extractive content) and the silvicultural (growth rate) attributes of wood were considered.

References

Alteyrac J, Cloutier A, Ung CH, Zhang SY (2006) Mechanical properties in relation to selected wood characteristics of black spruce. Wood Fiber Sci 38:229–237

Apiolaza LA (2009) Very early selection for solid wood quality: screening for early winners. Ann For Sci 66:601p1–p10

Auty D, Achim A (2008) The relationship between standing tree acoustic assessment and timber quality in Scots pine and the practical implications for assessing timber quality from naturally regenerated stands. Forestry 81:475–487

Bastien J-Ch, Keller R (1980) Intérêts comparés du Mélèze hybride (Larix × eurolepis Henry) avec les deux espèces parentes. Rev Forest Fr 32:521–530

Beaudoin M, Masanga BO, Poliquin J, Beauregard RL (1989) Physical and mechanical properties of plantation grown tamarack. Forest Prod J 39:5–10

Brashaw BK, Bucur V, Divos F, Goncalves R, Lu JX, Meder R, Pellerin RF, Potter S, Ross RJ, Wang XP, Yin YF (2009) Nondestructive testing and evaluation of wood: a worldwide research update. Forest Prod J 59:7–14

Bucur V (1981) Wood dynamical young modulus determination on increment core. Ann Sci Forest 38:283–298

Bucur V (1983) An ultrasonic method for measuring the elastic-constants of wood increment cores bored from living trees. Ultrasonics 21:116–126

Bucur V, Böhnke I (1994) Factors affecting ultrasonic measurements in solid wood. Ultrasonics 32:385–390

Cáceres CB, Hernández RE, Fortin Y, Beaudoin M (2017) Wood density and extractive content variation among Japanese larch (Larix kaempferi, [Lamb.] Carr.) progenies/provenances trials in Eastern Canada. Wood Fiber Sci 49:363–372

Cáceres CB, Hernández RE, Fortin Y (2018) Shrinkage variation in Japanese larch (Larix kaempferi, [Lamb.] Carr.) progenies/provenances trials in Eastern Canada. Wood Mater Sci Eng 13:97–103

Canadian Wood Council (2017) Machine graded lumber. http://cwc.ca/wood-products/lumber/machine-graded/. Accessed 05 July 2017

Cave ID, Walker JCF (1994) Stiffness of wood in fast-grown plantation softwoods—the influence of microfibril angle. Forest Prod J 44:43–48

Charron S, Jourez B, Marchal M, Hebert J (2003) Comparison study of physical and mechanical characteristics of European (Larix decidua Mill.), Japanese (Larix kaempferi (Lambert) Carr.) and hybrid (Larix x eurolepis Henry) larch woods. Biotechnol Agron Soc Environ 7:5–16

Chauret G, Zhang SY (2002) Wood characteristics and end-use potential of two fast-growing exotic larch species (Larix gmelinii and Larix siberica). In: Grown in Ontario. Report Project No. 3563. Forintek Canada Corp., Quebec

Chen Z-Q, Karlsson B, Lundqvist S-O, García Gil MR, Olsson L, Wu HX (2015) Estimating solid wood properties using Pilodyn and acoustic velocity on standing trees of Norway spruce. Ann For Sci 72:499–508

Chui YH, MacKinnon-Peters G (1995) Wood properties of exotic larch grown in Eastern Canada and Northeastern United States. Forest Chron 71:639–646

Cown DJ, Hebert J, Ball R (1999) Modelling radiata pine lumber characteristics. Part 1: Mechanical Properties of small clears. New Zeal J For Sci 29:203–213

Einspahr DW, McDonough TJ, Joachimides T (1983) Kraft pulping characteristics of European, Japanese, and European x Japanese larch hybrids. Tappi J 66:72–76

Farrar JL (1995) Trees of the northern United States and Canada. Fitzhenry and Whiteside Ltd., Ottawa

Fischer C, Vestøl GI, Øvrum A, Høibø OA (2015) Pre-sorting of Norway spruce structural timber using acoustic measurements combined with site-, tree- and log characteristics. Eur J Wood Prod 73:819–828

Forest Products Laboratory. 2010. Wood handbook—wood as an engineering material. General Technical Report FPL-GTR-190. Madison, WI

Hernández RE, Koubaa A, Beaudoin M, Fortin Y (1998) Selected mechanical properties of fast-growing poplar hybrid clones. Wood Fiber Sci 30:138–147

Herzig L (1991) Évaluation du module d’Young de bois d’épinette par méthode ultrasonore sur carottes de sondage. [Young`s modulus evaluation of white spruce wood by the ultrasonic method in increment cores] Mémoire (M. Sc.), Université Laval

Isebrands JG, Hunt CM (1975) Growth and wood properties of rapid-grown Japanese larch. Wood Fiber Sci 7:119–128

Jacques D, Marchal M, Curnel Y (2004) Relative efficiency of alternative methods to evaluate wood stiffness in the frame of hybrid larch (Larix × eurolepis Henry) clonal selection. Ann For Sci 61:35–43

Jessome AP (2000) Strength and related properties of woods grown in Canada. Special publication SP-514E. Forintek Canada Corp., Quebec

Keith CT, Chauret G (1988) Basic wood properties of European larch from fast-growth plantations in Eastern Canada. Can J For Res 18:1325–1331

Labrecque G (1992) Relation entre les propriétés mécaniques mesurées en flexion statique et le module d’Young dynamique mesuré sur carotte de sondage. [Relationship between static bending properties and dynamic Young’s modulus measured in an increment core] Rapport interne de projet d’études. Département des sciences du bois, Université Laval, Québec

Legg M, Bradley S (2016) Measurement of stiffness of standing trees and felled logs using acoustics: A review. J Acoust Soc Am 139:588–604

Loo J, Fowler DP, Schneider MH (1982) Geographic-variation in specific gravity among Japanese larch from different provenances. Wood Fiber Sci 14:281–286

MRNF (2007) La forêt québécoise et sa gestion. [The Quebec forest and its management]. Ministère des Forêts, Faune et Parcs, Gouvernement du Québec. http://mffp.gouv.qc.ca/publications/forets/comprendre/gestion-forestiere.pdf. Accessed 05 July 2017

NFDP (2015) National forestry database. Silviculture—data compendium. http://nfdp.ccfm.org/data/compendium/html/comp_68e.html. Accessed 14 Nov 2017

NGLA (2003) Standard grading rules for Canadian lumber. National lumber grades authority, New Westminster, BC

NRCAN (2017) Machine stress rated lumber. http://www.nrcan.gc.ca/forests/industry/products-applications/15841. Accessed 14 Nov 2017

Pâques LE, Millier F, Rozenberg P (2010) Selection perspectives for genetic improvement of wood stiffness in hybrid larch (Larix × eurolepis Henry). Tree Genet Genomes 6:83–92

Paradis N, Auty D, Carter P, Achim A (2013) Using a standing-tree acoustic tool to identify forest stands for the production of mechanically-graded lumber. Sensors 13:3394–3408

Perron M (2011) Le mélèze hybride du Québec: performant et racé. [The hybrid larch of Quebec: improved and efficient]. Note de recherche forestière no 3. Ministère des Forêts, de la Faune et des Parcs, Québec

Rainville A, Desponts M, Beaudoin R, Périnet P, Mottet M-J, Perron M (2003) L’amélioration des arbres au Québec: un outil de performance industrielle et environnementale. [Improving trees in Quebec: an industrial and environmental performance tool]. Note de recherche forestière no 127. Ministère des Forêts, de la Faune et des Parcs, Quebec

SAS Institute (2012) SAS package version 9.4. SAS Institute, Cary

Shmulsky R, Jones PD (2011) Forest products and wood science: an introduction, 6th edn. Wiley-Blackwell, London

Stipanicic A (1975) L’amélioration du genre mélèze (Larix sp.) au service de la recherche du Ministère des terres et forêts. [Improvement of the larch species (Larix sp.). In: in the research department of the Ministry of lands and forests]. Note de recherche forestière no 20. Ministère des Forêts, de la Faune et des Parcs, Quebec

Urhan OS, Kolpak SE, Jayawickrama KJS, Howe GT (2014) Early genetic selection for wood stiffness in juvenile Douglas-fir and western hemlock. Forest Ecol Manag 320:104–117

Verville A (1981) Étude physico-mécanique de quelques espèces du genre Larix en plantation. [Physico-mechanical study of some species of the genus Larix in plantation]. Mémoire (M.Sc.), Université Laval

Yang JL, Evans R (2003) Prediction of MOE of eucalypt wood from microfibril angle and density. Holz Roh Werkst 61:449–452

Yang JL, Fortin Y (2001) Evaluating strength properties of Pinus radiata from ultrasonic measurements on increment cores. Holzforschung 55:606–610

Zhang SY, Koubaa A (2008) Softwoods of Eastern Canada: Their silvics, characteristics, manufacturing and end-uses. FP Innovations, Quebec

Zhu JJ, Nakano T, Hirakawa Y (2000) Effects of radial growth rate on selected indices for juvenile and mature wood of the Japanese larch. J Wood Sci 46:417–422

Zobel B, Jett JB (1995) Genetics of wood production. Springer, Berlin

Acknowledgements

Funding for this project was provided by the Ministry of Forests, Wildlife, and Parks of Quebec. The authors thank Ante Stipanicic and Michel Beaudoin for their valuable assistance. The authors also thank Hristo Iliev for his contribution during the laboratory experiments

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Cáceres, C.B., Hernández, R.E. & Fortin, Y. Variation in selected mechanical properties of Japanese larch (Larix kaempferi, [Lamb.] Carr.) progenies/provenances trials in Eastern Canada. Eur. J. Wood Prod. 76, 1121–1128 (2018). https://doi.org/10.1007/s00107-018-1302-3

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00107-018-1302-3