Abstract

Rosin was used to improve the physical and mechanical properties of fast-growing poplar wood using the impregnation method. The rosin was dissolved in ethanol with different concentrations and the wood was impregnated with the solutions obtained. The weight percent gain, density, equilibrium moisture content (EMC), anti-swelling efficiency (ASE), and mechanical properties of the treated wood were measured in detail. The crystalline structure, morphology, rosin distribution, and dynamic wettability were also evaluated. Results showed that the density of the wood increased from 0.34 to 0.44 g/cm3 after the treatment with 20 % rosin solution. When the rosin content increased by 5, 10, 15 and 20 %, the ASE after 5 days water immersion increased to 15.6, 20.6, 30.3 and 36.0 % and EMC reduced by 17.8, 26.5, 36.2 and 42.7 %, respectively. Particularly, the modulus of rupture, modulus of elasticity, and compression strength of the 20 % rosin impregnated wood increased by 12.8, 18.9, 31.6 %, respectively. In addition, the dynamic wettability of wood was significantly changed by the rosin treatment. The rosin within wood could occupy the wood lumens, cell corners, and middle lamella, and partly penetrated wood cell walls, which was revealed by field emission scanning electron microscope and confocal laser scanning microscope.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

1 Introduction

Wood is widely used in furniture, construction, and decoration due to its renewable and environmental friendly properties. Hygroscopic wood is very sensitive to water and biological attacks, especially for fast-growing wood, which limits its applications. As one of the main fast-growing tree species with short plantation rotation, poplar has been a popular species in the pulp, paper and veneer industries.

In order to overcome the drawbacks of wood, such as low mechanical properties, high moisture absorption, and dimensional instability, attempts have been made, including treating wood with small organic molecules (Li et al. 2005; Vukusic et al. 2006; Yan et al. 2014), impregnation with resin, wax, polymer or inorganic particles (De Vetter et al. 2009; Scholz et al. 2010), and in situ polymerization of monomers within wood (Dong et al. 2014; Trey et al. 2012). However, most of the treatments involved harmful chemicals or reagents, which pose environmental concerns (Hill 2006). It is desired to create more durable wood products without chemicals (La Mantia and Morreale 2011). A new approach was the combination of wood and biomass resources [lactic acid (Noel et al. 2009), ethylene glycol (Trey et al. 2010), and furfuryl alcohol (Dong et al. 2015), etc.] to produce wood products with high performance and environmental friendly character.

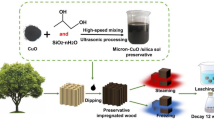

As a natural polymer extracted from pine trees, rosin is abundant, renewable, and low-cost. The major component of rosin is abietic acid, a partially unsaturated compound with three fused six-membered rings and one carboxyl group, which give it good hydrophobic properties (Nguyen et al. 2013a). Over the past years, it has been widely used in papermaking as a sizing agent and polymers synthesis as a natural filler or a source of monomers (Belgacem and Gandini 2008). Because of its hydrophobic character and affinity for wood, rosin has the potential to improve the properties of wood. Several studies have been reported on using rosin and its derivation for copper fixation in wood preservation and water repellency of wood joints (Mansouri et al. 2012; Nguyen et al. 2013a, b; Pizzi et al. 2012). The chemical reactivity of rosin mainly comes from the double-bond system and the carboxyl group (Belgacem and Gandini 2008). However, it is difficult to form covalent bonds between rosin and wood. The impregnation of rosin into wood could only be physical incorporation, similar to the wax treatment. Compared with wax, rosin has the advantage of crystallinity, constant molecular mass and higher melting point, which could improve the properties of wood via the impregnation. Moreover, the good solubility of rosin in ethanol would simplify the impregnation process and solvent recovery process. Although 3 % (by weight) rosin could improve the water resistance of wood significantly, limited improvement in the dimensional stability was found (Dahlen et al. 2008). To the best of the authors` knowledge, there was no report on rosin impregnation modification and assessment of mechanical properties of the rosin modified wood. Additionally, the analysis of the agent distribution in wood would provide a better understanding of the property enhancement mechanism.

In this study, the properties of rosin impregnated poplar wood were explored, such as water resistance, dimensional stability, modulus of rupture (MOR), modulus of elasticity (MOE), compression strength (CS), and surface hardness. Additionally, the crystalline structure, morphology, rosin distribution, and dynamic wettability were also characterized.

2 Materials and methods

2.1 Materials

The rosin was obtained from Guangxi province of China. Anhydrous ethanol was purchased from Beijing Chemical Works (Beijing, China).

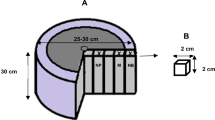

The sound sapwood of fast-growing poplar (Populus spp.) used was purchased from a sawmill in Beijing, China. All the samples were well-defined tangential, radial and longitudinal sections. The size of samples was 20 × 20 × 20 mm3 (R × T × L) for dimensional stability and water resistance tests, 20 × 20 × 300 mm3 (R × T × L) for MOR and MOE tests, and 20 × 20 × 30 mm3 (R × T × L) for CS test. The weight and dimensions of samples were measured oven-dried at 105 °C until constant weight.

2.2 Rosin impregnation

The rosin ethanol solutions with 5, 10, 15, 20 wt% concentrations were used to impregnate the poplar samples (ca. 0.095 MPa for 30 min/atmospheric pressure for 20 h). After the impregnation, all samples were taken out from the rosin solutions by filtration. Then the samples were placed in an oven at 120 °C for 6 h to remove the solvent and redistribute the rosin within the wood. After that, the weight and dimensions of the samples were measured again.

2.3 Physical and mechanical properties measurement

The weight percent gain (WPG) of treated wood samples was calculated as follows:

where W 1 and W 2 are the oven-dried weights of samples before and after the treatment, respectively.

Subsequently, both control and treated wood were immersed in deionized water at room temperature and the weight was measured after different time intervals. Water uptake (WU) is expressed as:

where W 3 is the weight of samples after the immersion in deionized water.

Meanwhile, the radial, tangential, and volumetric swelling after 5 days of immersion were measured using a digital micrometer (±0.01 mm). The volumetric swelling (S) was calculated by Eq. (3). Thereafter the anti-swelling efficiency (ASE) was calculated based on the swelling difference between the control and treated samples as follows:

where V 1 and V 2 are the volume of samples before and after immersion in deionized water, respectively. S u and S t are the volumetric swellings of the control and treated wood samples, respectively.

The samples were conditioned in a climate chamber maintained at 20 ± 2 °C and 82 ± 5 % relative humidity for 6 weeks to reach equilibrium moisture content (EMC), and then the weight and dimensions were measured. S and EMC of the controls and treated samples were calculated by Eqs. (3) and (4), respectively.

MOR, MOE, and CS of all the treated and control samples were tested according to Chinese standard GB/T 1939.1-2009, GB/T 1936.2-2009 and GB/T 1935-2009. Eight samples were measured by a universal testing machine operating at a speed of 10.0 mm/min.

Surface hardness was measured by a TH210 durometer (Beijing TIME High Technology Ltd., China) and expressed as shore D hardness according to ASTM D2240 standard. Each type of sample was measured by 20 tests.

2.4 Characterization of control and treated wood

The morphologies of the control and treated wood samples were characterized by a field emission scanning electron microscope (FE-SEM). The interior portions of the cross planes were exposed by cutting with a surgical blade, mounted on conductive adhesives, gold-sputter-coated, and then observed with the Hitachi SU8010 instrument (Japan) at 500 magnifications using a voltage of 5 kV.

The cross-sections of samples with a thickness of 15–20 μm were sliced using a sliding microtome (Yamato REM-710, Japan), and then sealed on a glass slide in wet conditions (distilled water) under a cover slip. The distribution of rosin in samples was detected by a confocal laser-scanning microscope (TCS SP8, Leica Microsystems, Wetzlar, Germany) with a tenfold objective. The excitation laser wavelength used was 405 nm and the detector ranged from 430–500 nm.

The crystalline structures of the control and treated wood samples were also analyzed by X-ray diffraction (XRD) with Bruker D8 Advance diffractrometer (Germany). The apparatus parameters were as follows: Cu Kα radiation with graphite monochromator, voltage 40 kV, electric current 40 mA, and 2θ scan range from 5° to 40° with a scanning speed of 2°/min.

In addition, the attenuated total reflection Fourier-Transform infrared spectroscopy (ATR-FTIR) analysis for the control and treated wood samples was employed using Nicolet 6700 infrared spectrophotometer (USA) equipped with an ATR accessory with scanning range of 4000–650 cm−1 at the 4 cm−1 resolution for 32 scans.

2.5 Contact angle measurement

Contact angle measurements on the surfaces of samples parallel to the grain were performed with an optical contact angle apparatus (OCA 20 DataPhysics Instruments GmbH, Filderstadt, Germany). The SCA 20 software was used for data acquisition and analysis. Sessile droplets (3 μL, measured with a microsyringe) of deionized water were placed on the planed wood tangential or radial surface. The drop angles of the right and left side were collected at intervals of 0.1 s for a total duration of 180 s, and the average angles were calculated to evaluate the dynamic wettability. Three drops per sample were captured, four samples were tested, and 12 measurements of contact angles were obtained.

3 Results and discussion

3.1 Physical and mechanical properties assessment

After the rosin treatment, the mean WPG values increased from 9.9 to 31.9 % and the density was increased by 29.4 % from 0.34 of the control to 0.44 g/cm3 of 20 % rosin treated wood, as shown in Table 1. Compared with the control, EMC and S of 20 % rosin treated wood were reduced by 42.7 and 40.1 %, respectively. These results indicated that the rosin could penetrate into the wood matrix, adhere to wood cell walls and occupy the wood voids in the 120 °C treatment. As a result, the rosin treatment improved the water resistance of poplar wood at high relative humidity. In addition, ASE was also improved by rosin impregnation ranging from 15.6 (5 % rosin treated wood) to 36.0 % (20 % rosin treated wood). Dahlen’s study showed the low concentration rosin solution treatment resulted in a limited increase in dimensional stability (Dahlen et al. 2008). However, the high concentration solution treatment could have positive effect on ASE to a certain degree. On the other hand, the improvement of ASE also indicated that the rosin penetrated in wood cell walls, because lumen filling could not lead to any increase in dimensional stability (Hill 2006). Generally, the wood dimension changes can be attributed to the hygroscopic characteristics of wood (Sun et al. 2010). The higher water resistance in treated samples could reduce the rate of dimensional change of the samples. Although the WPG was not provided, Nguyen et al. (2013a) treated poplar wood using 4 % anionic rosin emulsion sizing agent and reported that ASE was about 20 %. Compared to the rosin emulsion, rosin dissolved in molecular state will more easily penetrate in wood voids. The wax impregnation of pine sapwood showed 87 % WPG and exhibited about 43 % ASE at 65 % relative humidity (Esteves et al. 2014). Therefore, the rosin treatment with suitable loading could be an efficient way to improve water resistance and dimensional stability of wood.

Water absorption of the control and treated samples as a function of time is shown in Fig. 1. Compared with control samples, the water uptake of all the treated samples remarkably decreased. The water uptake of control samples reached 193.6 %, while that of 20 % rosin treated samples reduced to 87.04 % after 12 days immersion in water. The transport of water from cell lumens into adjacent cell walls occurs rapidly by diffusion (Banks 1973). However, because of the affinity for wood, rosin could cover wood lumens and block the wood voids, which increased the physical properties and act as mechanical barrier in water transport process.

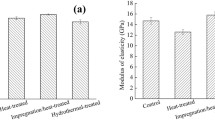

The mechanical properties of the control and treated samples were also evaluated and the results are shown in Table 2. The MOR, MOE, CS, and hardness of samples increased with increasing rosin loading. Compared with the control group, MOR and MOE of the 20 % rosin impregnated wood increased by 12.8 and 18.9 %, respectively, while CS increased by 31.6 %. A previous study by Nguyen et al. (2013a) showed there were no significant differences in MOR, MOE, and CS between the control and treated wood samples. The low rosin concentration (1.0–4.0 %) did not affect MOR or MOE because it was difficult for the rosin emulsion to distribute within wood uniformly. The wax impregnation also showed there were slight increases in MOR and MOE (Esteves et al. 2014). Generally, MOE and MOR of other wood modifications, such as acetylated wood and furfurylated wood, were unaltered or slightly improved (Dong et al. 2015; Li et al. 2009), while the heat treatments lead to a reduction of most strength properties of wood (Xie et al. 2013). Due to the filling of rosin within wood, the hardness was improved and the maximal increase was 30.9 % compared with the control sample.

Generally, impregnation modification aims at filling the cell wall micro pores of the wood substance. However, the wood properties can only be efficiently improved with the modification agents located in the cell walls rather than in the lumens (Klüppel and Mai 2013). This finding suggested that the physical and mechanical properties improvement of the rosin impregnation wood samples was due to the efficient filling of cell walls. The rosin molecule dissolved in solution could penetrate into the wood cell walls, swell the cell walls, and undergo subsequent precipitation after evaporation of the solvent.

3.2 Morphologies observation and rosin distribution

The cross section morphologies of the control and treated wood observed by FE-SEM are shown in Fig. 2. The natural porous structure of the control sample is easily observed, such as the large vessels (Fig. 2a). For the treated wood sample in Fig. 2b and c, the volume of void spaces in the samples was considerably reduced after rosin impregnation, indicating that rosin could adhere to the vessel walls. Additionally, the part of vessels marked with black arrow (Fig. 2c) was filled with rosin. When the concentration of rosin is 20 %, as shown in Fig. 2d, most of the vessels were filled. Furthermore, it was obvious that the rosin deposited in the large vessels, formed a uniform film covering the walls, and aggregated into the spherical on wood lumens (black arrows in Fig. 2d). Since the softening point of rosin was at about 70 °C, it can distribute on the wood lumens and tightly adhere on the lumen walls when treated at 120 °C (Lee et al. 2004). The improvement of physical and mechanical properties could be attributed to the blocking effect of the rosin treatment. Most impregnations undergo polymerization of monomer within wood cell walls that cause maximum level of swelling of the wood substrate, such as the furfurylation and phenol formaldehyde resin impregnation (Deka and Saikia 2000). However, the rosin impregnation is similar to wax treatment and the swelling effect was not obvious, which resulted in inconspicuous improvement of dimensional stability.

Since rosin is of fluorescence characteristic, it allows to determine the amount of rosin by the fluorescence spectra (Zhu et al. 2014). Therefore, the confocal laser-scanning microscope (CLSM) is able to show the location of rosin in wood. Given the autofluorescence from lignin in cell walls, the signals of lignin were removed from all samples. As expected, only traces of fluorescence are seen on the control sample in Fig. 3a. As for rosin treated wood samples, the fluorescence intensity of rosin was remarkable, especially for the 20 % rosin treated wood. With the increase in concentration of rosin, the occupied cell lumens were further increased and some of the cell corners and middle lamella also showed fluorescence intensity. In addition, the cell wall color was deeper than that of the control. These phenomena indicated that rosin could enter into the wood structure, occupy the wood cell lumens, cell corners, and middle lamella, and partly penetrate wood cell walls. The result also accounted for the improvement of physical and mechanical properties of rosin treated wood.

3.3 Dynamic wettability analysis

Figure 4 shows the contact angles as a function of time for both tangential and radial surfaces of the control and treated wood samples. All the sections of samples were planed prior to the measurement in order to reduce the influence of surface roughness, ageing, and the residue of rosin. As shown in the tangential section, the contact angles decreased quickly for all samples in the initial 10 s. The sample treated with 5 % rosin had a very similar tendency to that of the control in the initial 10 s. The initial contact angles of the treated samples increased with rosin concentration. Subsequently, the contact angle stabilized to a relative equilibrium state. It was obvious that the treated wood samples showed much greater contact angles than the controls. In addition, the higher the rosin concentration, the greater the contact angle was obtained. This was due to the hydrophobic nature of rosin. Generally, a higher WPG meant more superior hydrophobicity and worse dynamic wettability. The WPG values of the 15 and 20 % treated wood were close, and the distribution of rosin on wood cell wall was even. Therefore, they showed similar contact angle values, and higher values than that of 5 and 10 % treated wood. The contact angles at the radial section showed the same tendency. The tangential section had lower contact angles than the radial section for all samples. That was attributed to the different wood structure in the different cutting directions (Lux et al. 2013). Additionally, with the increase in rosin concentration, the tangential and radial sections had a similar tendency and their data were increasingly almost uniform. These phenomena indicated that the rosin impregnation not only improved the hydrophobicity of wood, but also reduced the discrepancy of wettability between tangential and radial sections.

3.4 ATR-FTIR spectrum and XRD analysis

Figure 5 shows the ATR-FTIR spectra of the wood, pristine rosin, and rosin treated wood. The obvious transmittance peaks of the control wood can be assigned as follows: 3344 cm−1 (O–H stretching); 2895 cm−1 (C–H stretching vibration); 1737 cm−1 (C=O stretching of the acetyl group); 1592 and 1505 cm−1 (aromatic skeletal vibration); and 1030 cm−1 (C–O of primary alcohol) (Pandey 1999). The peaks of the rosin in the treated wood were prominent, such as bands at 2926 and 2867 cm−1 (C–H stretching vibration of methyl and methylene), 1692 cm−1 (C=O stretching vibration). In addition, these bonds were enhanced by the increased concentration. It was revealed that the impregnation of rosin penetrated in wood (Liu et al. 2009; Ma et al. 2013; Wang et al. 2003). No new peak was observed in the rosin treated wood. The main reason was that the reactivity of rosin was weak and it was difficult to form covalent bonds between the rosin and cellulose, which needs further work to improve the process. However, there may be hydrogen bonds formed by the reason of the affinity between hydroxyl groups in wood and carboxyl groups in rosin, which could improve the interaction between the rosin and wood.

The XRD characterization of the rosin, control, and treated wood is presented in Fig. 6. The distinct peaks at diffraction angles of 16.1°, 22.2°, and 34.8° of the curve of the control were assigned to (101), (002), and (040) crystal planes of the cellulose of wood, respectively. The diffraction peak at 16.1° of the control sample moved to 15.6° in the curve of the 20 % rosin-treated wood. Because rosin is a glassy material with amorphous nature, it exhibited a specific broad diffraction peak centered at 15.6° (inset of Fig. 6) (Nirmala et al. 2013). In addition, the intensity at this degree was increased with the increase in rosin concentration. Nevertheless, the intensity of diffraction peak at 22.2° remained about the same among the curves of all samples, indicating the incorporation of rosin might have no significant impact on the structure of the wood cellulose. On the other hand, the XRD data also revealed that the rosin was not reactive under the condition in this study, and its effect within wood was physical bulking.

4 Conclusion

The water resistance, dimensional stability, and mechanical properties of poplar wood were significantly improved by the impregnation of rosin. A 42.7 % decrease in EMC was achieved by the impregnation of 20 % rosin. In addition, the high concentration rosin treated wood showed higher dimensional stability and mechanical properties. When the content of rosin was 20 %, ASE of samples was 36.0 %. Compared to the control, MOR and MOE of the 20 % rosin treated wood were increased by 12.8 and 18.9 %, respectively. The FE-SEM and CLSM observations revealed that the rosin in wood could occupy the wood lumens, cell corners, and middle lamella, and partly penetrate wood cell walls. XRD and ATR-FTIR results indicated that the incorporation of rosin was physical bulking that might have no significant impact on the wood structure. Rosin impregnation improved the hydrophobic property of wood and reduced the surface property variation between tangential and radial sections, which was demonstrated by the contact angle analysis.

References

Banks W (1973) Water uptake by scots pine sapwood, and its restriction by the use of water repellents. Wood Sci Technol 7:271–284

Belgacem MN, Gandini A (2008) Monomers, polymers and composites from renewable resources. Elsevier, Amsterdam

Dahlen J, Nicholas DD, Schultz TP (2008) Water repellency and dimensional stability of southern pine decking treated with waterborne resin acids. J Wood Chem Technol 28:47–54

De Vetter L, Stevens M, Van Acker J (2009) Fungal decay resistance and durability of organosilicon-treated wood. Int Biodeterior Biodegrad 63:130–134

Deka M, Saikia C (2000) Chemical modification of wood with thermosetting resin: effect on dimensional stability and strength property. Bioresour Technol 73:179–181

Dong Y, Yan Y, Zhang S, Li J (2014) Wood/polymer nanocomposites prepared by impregnation with furfuryl alcohol and nano-SiO2. BioResources 9:6028–6040

Dong Y, Yan Y, Zhang S, Li J, Wang J (2015) Flammability and physical-mechanical properties assessment of wood treated with furfuryl alcohol and nano-SiO2. Eur J Wood Prod 73:457–464

Esteves B, Nunes L, Domingos I, Pereira H (2014) Improvement of termite resistance, dimensional stability and mechanical properties of pine wood by paraffin impregnation. Eur J Wood Prod 72:609–615

Hill CAS (2006) Wood modification: chemical, thermal and other processes. Wiley, Chichester

Klüppel A, Mai C (2013) The influence of curing conditions on the chemical distribution in wood modified with thermosetting resins. Wood Sci Technol 47:643–658

La Mantia FP, Morreale M (2011) Green composites: a brief review. Compos Part A 42:579–588

Lee CM, Lim S, Kim GY, Kim D, Kim DW, Lee HC, Lee KY (2004) Rosin microparticles as drug carriers: influence of various solvents on the formation of particles and sustained-release of indomethacin. Biotechnol Bioprocess Eng 9:476–481

Li JZ, Furuno T, Zhou WR, Yu ZM (2005) Properties of colloidal silica-fixed and propionylated wood composites (I): preparation and dimensional stability of the composites. J Wood Chem Technol 25:245–255

Li JZ, Furuno T, Zhou WR, Ren Q, Han XZ, Zhao JP (2009) Properties of acetylated wood prepared at low temperature in the presence of catalysts. J Wood Chem Technol 29:241–250

Liu X, Xin W, Zhang J (2009) Rosin-based acid anhydrides as alternatives to petrochemical curing agents. Green Chem 11:1018–1025

Lux C, Szalay Z, Beikircher W, Kovacik D, Pulker HK (2013) Investigation of the plasma effects on wood after activation by diffuse coplanar surface barrier discharge. Eur J Wood Prod 71:539–549

Ma Q, Liu X, Zhang R, Zhu J, Jiang Y (2013) Synthesis and properties of full bio-based thermosetting resins from rosin acid and soybean oil: the role of rosin acid derivatives. Green Chem 15:1300–1310

Mansouri HR, Pizzi A, Leban JM, Delmotte L, Lindgren O, Vaziri M (2012) Causes for the improved water resistance in pine wood linear welded joints. J Adhes Sci Technol 25:1987–1995

Nguyen TTH, Li S, Li J (2013a) The combined effects of copper sulfate and rosin sizing agent treatment on some physical and mechanical properties of poplar wood. Constr Build Mater 40:33–39

Nguyen TTH, Li S, Li J, Liang T (2013b) Micro-distribution and fixation of a rosin-based micronized-copper preservative in poplar wood. Int Biodeterior Biodegrad 83:63–70

Nirmala R, Woo-il B, Navamathavan R, Kalpana D, Lee YS, Kim HY (2013) Influence of antimicrobial additives on the formation of rosin nanofibers via electrospinning. Colloid Surf B 104:262–267

Noel M, Fredon E, Mougel E, Masson D, Masson E, Delmotte L (2009) Lactic acid/wood-based composite material. Part 1: synthesis and characterization. Bioresour Technol 100:4711–4716

Pandey K (1999) A study of chemical structure of soft and hardwood and wood polymers by FTIR spectroscopy. J Appl Polym Sci 71:1969–1975

Pizzi A, Mansouri HR, Leban JM, Delmotte L, Pichelin F (2012) Enhancing the exterior performance of wood joined by linear and rotational welding. J Adhes Sci Technol 25:2717–2730

Scholz G, Militz H, Gascón-Garrido P, Ibiza-Palacios MS, Oliver-Villanueva JV, Peters BC, Fitzgerald CJ (2010) Improved termite resistance of wood by wax impregnation. Int Biodeterior Biodegrad 64:688–693

Sun Q, Yu H, Liu Y, Li J, Lu Y, Hunt JF (2010) Improvement of water resistance and dimensional stability of wood through titanium dioxide coating. Holzforschung 64:757–761

Trey SM, Netrval J, Berglund L, Johansson M (2010) Electron-beam-initiated polymerization of poly(ethylene glycol)-based wood impregnants. ACS Appl Mater Inter 2:3352–3362

Trey S, Jafarzadeh S, Johansson M (2012) In situ polymerization of polyaniline in wood veneers. ACS Appl Mater Inter 4:1760–1769

Vukusic SB, Katovic D, Schramm C, Trajkovic J, Sefc B (2006) Polycarboxylic acids as non-formaldehyde anti-swelling agents for wood. Holzforschung 60:439–444

Wang F, Kitaoka T, Tanaka H (2003) Supramolecular structure and sizing performance of rosin-based emulsion size microparticles. Colloid Surf A 221:19–28

Xie Y, Fu Q, Wang Q, Xiao Z, Militz H (2013) Effects of chemical modification on the mechanical properties of wood. Eur J Wood Prod 71:401–416

Yan Y, Dong Y, Li C, Chen H, Zhang S, Li J (2014) Optimization of reaction parameters and characterization of glyoxal-treated poplar sapwood. Wood Sci Technol 49:241–256

Zhu Y, Wang W, Cao J (2014) Improvement of hydrophobicity and dimensional stability of thermally modified southern pine wood pretreated with oleic acid. BioResources 9:2431–2445

Acknowledgments

This research was supported by “The Fundamental Research Funds for the Central Universities” (No. TD2011-12) and Special Fund for Forestry Research in the Public Interests (Project 201204702).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Dong, Y., Yan, Y., Wang, K. et al. Improvement of water resistance, dimensional stability, and mechanical properties of poplar wood by rosin impregnation. Eur. J. Wood Prod. 74, 177–184 (2016). https://doi.org/10.1007/s00107-015-0998-6

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00107-015-0998-6