Abstract

Sample material from spruce (Picea abies), beech (Fagus sylvatica) and ash (Fraxinus excelsior) with radial and tangential section was treated by diffuse coplanar surface barrier discharge (DCSBD) plasma generated in air at atmospheric pressure. Plasma activated samples exhibited significantly lower water uptake times of 50 μl droplets and minimal differences in wetting between the two cutting planes (radial and tangential), when compared to the untreated surface. Simultaneously, more uniform spreading of the droplets and increased area of wetting on the activated surface were achieved. The plasma treatment had no effect on the water absorption coefficient of the wood samples. FTIR measurements confirmed the presence of oxygen containing functional groups and structural changes in lignin on the activated wood surface. The minimal heating of the treated samples suggests this method to be applicable to treat heat sensitive wooden materials.

Zusammenfassung

Fichte- (Picea abies), Buche- (Fagus sylvatica) und Escheproben (Fraxinus excelsior) mit den Schnittrichtungen radial und tangential wurden mit einem Atmosphärendruck DCSBD-Plasma behandelt. Im Vergleich zu den unbehandelten Oberflächen zeigten die plasmaaktivierten Proben deutlich geringere Wassereindringzeiten für ein 50 μl Tröpfchen und das Benetzungsverhalten zwischen den beiden Schnittebenen (radial und tangential) wies nur minimale Unterschiede auf. Gleichzeitig wurde eine gleichmäßigere Ausbreitung und eine größere benetzte Fläche auf den aktivierten Oberflächen erreicht. Die Plasmabehandlung hatte keinen Einfluss auf den Wasseraufnahmekoeffizienten der Holzproben. Die FTIR-Messungen zeigten die Bildung von funktionellen Gruppen, die polaren Sauerstoff enthalten, sowie strukturelle Veränderungen im Lignin auf der aktivierten Holzoberfläche. Durch die geringe Erwärmung der behandelten Proben ergibt sich die Möglichkeit der Behandlung von temperaturempfindlichen Holzwerkstoffen.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

1 Introduction

The durability and the protection of wood and wood products against weathering depend on the safety precautions applied. It is essential to protect wood against penetration of water, wood-destroying fungi or insects. Furthermore, such protection coatings can have decorative effects, like colouring. For this purpose, there are many different coating methods available, for example, painting, spraying, dipping and impregnation. A detailed understanding of the surface properties of wood is essential for developing better wood protection agents and techniques. Especially the water absorption coefficient is a significant parameter for water transport calculations in building physics and impregnation (Niemz et al. 2010a, 2012). The amount of data concerning the water absorption coefficient of wood is very limited. Both, the kind of wood as well as the cutting plane of the material have a strong influence on surface wetting and consequently on coating properties of wood and need to be investigated.

Plasma treatment has been demonstrated to favourably alter the surface properties of wooden materials. The use of low pressure plasmas for surface modification and activation of wood (Mahlberg et al. 1998; Podgorski et al. 2000) is unfavourable due to the inherent need of vacuum systems coupled with batch processing resulting in high operational costs. Plasma sources operating at atmospheric pressure hold the biggest promise for industrial applications. Such a setup is easier to assemble and can operate even in open air which is economically highly beneficial. Another advantage is that it is relatively easy to integrate in an in-line production with high throughput. As corona treatment (Sakata et al. 1993; Podgorski et al. 2000) is not considered to have proper effectiveness, the focus in the last decade shifted towards dielectric barrier discharges (DBDs). Normally, in DBD systems the discharge space is surrounded by two insulated electrodes and filled with gas. Between these electrodes a high alternating voltage is applied. This generates a discharge in the gas with many microfilaments. Samples are consequently treated in the space between the electrodes. Several studies (Rehn and Viöl 2003; Rehn et al. 2003; Mertens et al. 2006; Wolkenhauer et al. 2007, 2008, 2009; Asandulesa et al. 2010; Avramidis et al. 2010, 2012b; Busnel et al. 2010) have pointed out that the wettability and adhesive properties of wood are enhanced by DBDs. The activation of wood is attributed to the cleavage of chemical bonds of the wood constituents and introduction of polar functional groups, mainly aldehyde and carboxyl groups (Klarhöfer et al. 2010). It was shown that wood extractives responsible for wood hydrophobicity are degraded by DBD plasma too (Avramidis et al. 2012a). This way the coating of wood is improved as most adhesives are water based (Frihart 2012). With this treatment the use of chemical agents to make the wood surface more wettable becomes obsolete (Niemz et al. 2010b).

The most widely employed parallel plate DBD geometry (Rehn and Viöl 2003; Wolkenhauer et al. 2007, 2009; Avramidis et al. 2010, 2012b) causes difficulties in the treatment of thick wood samples in air, because a very high voltage (several tens of kV) must be applied to generate the discharge which raises some serious working safety issues. In addition, a thick material (several centimetres) causes high resistive power loss in the electrical circuit. However, this can be alleviated when the sample placed in the discharge gap works itself as the second electrode (Rehn et al. 2003).

The diffuse coplanar surface barrier discharge (DCSBD), presented in this article, provides a promising alternative to the above-mentioned setup. This source of low-temperature atmospheric pressure plasma has planar electrode geometry with a higher volume power density compared to volume DBDs (Odrášková et al. 2008). The DCSBD consisting of a high number of microdischarges is confined in an approximately 0.3 mm thick, macroscopically homogeneous plasma layer (Šimor et al. 2002). In this case, the thickness of the treated material has minor influence on the voltage applied for the discharge and thus there is negligible power loss by the material. The typically applied high voltage of DCSBD of up to 20 kV (peak to peak) is significantly lower than for conventional volume DBDs employed by Rehn and Viöl (2003), Rehn et al. (2003), Wolkenhauer et al. (2007, 2009) and Avramidis et al. (2010, 2012b). Nonetheless, the desired surface changes are achieved at treatment times in order of seconds for various materials like nonwoven textiles, paper, polymer and metal surfaces (Tóth et al. 2007; Černák et al. 2009; Homola et al. 2012; Prysiazhnyi et al. 2012). Results of DCSBD plasma activation of Pedunculate oak (Quercus rubur L.) and parameters of the discharge have been previously reported by Odrášková et al. (2008). For obtaining optimal treatment efficiency, the distance of sample and ceramics needs to be lower than the effective thickness of the plasma layer. Hence the oak samples were brought into direct contact with the discharge ceramics. The study pointed out that the treatment lowers the pH value of wood which is explained by introduction of polar acidic functional groups. Substantial ageing of DCSBD activation was observed in the first 3 days after the treatment.

The main purpose of this study was to extend previous research on DCSBD treatment of wood (Odrášková et al. 2008) by investigating another two kinds of hardwood (beech, ash) and one softwood (spruce). All samples were treated in an up-scaled plasma reactor capable of processing larger material samples to effectively simulate in-line conditions. In order to validate the thermally non-damaging character of the process, the temperature of the plasma panel and of the wooden material during and after surface treatment was measured. The interaction of water with the surface of wood was evaluated with respect to wood species and cutting plane of the samples. Furthermore, the water absorption coefficient was measured to obtain information on the influence of DCSBD activation of the bulk of the wood samples. Wettability studies were supported by FTIR spectroscopy of wood samples.

2 Materials

Radial and tangential cuts of spruce (Picea abies), beech (Fagus sylvatica) and ash (Fraxinus excelsior) were investigated in this study. The chosen hardwoods have distinct microstructure: beech belongs to diffuse-porous hardwoods and ash to ring-porous hardwoods (Thomas 2000). Wood planks were cut in a way to get twin samples. The twin samples are pairs of directly adjacent specimens taken from the same starting material. The samples were planed and sanded by paper with grit size 100 to a dimension (length × width × thickness) of 150 × 10 × 20 mm³. Polishing was done by a belt sanding machine in the longitudinal direction. In connection to this treatment, the samples were stored in a climate chamber at 20 °C and 65 % relative humidity until constant mass was reached. The initial moisture content of the samples was around 12 %. The density of the samples was determined in this state (see Table 1). The acronym SD stands for the value of the standard deviation.

The four thin lateral faces of the samples were sealed with epoxide resin. After setting the edges of the front and bottom faces were sanded to have no resin overlap. After this procedure, the samples were moved again to the climate chamber and stored at the same conditions. Prior to the plasma treatment the samples were sanded one last time to remove the uppermost aged layer. To remove the sanding dust from the surface the samples were blown with compressed air.

3 Methods

3.1 Plasma treatment

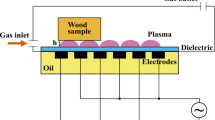

The employed experimental device (see Fig. 1) resembles in many details the one used by Odrášková et al. (2008). The DCSBD electrode element consists of 15 pairs of screen-printed stripe-like silver electrodes on the bottom side of Al2O3 (96 % purity) ceramics (228 × 92 × 0.6 mm³). The 1.5 mm wide electrode stripes are separated by 1 mm gaps. Electrical insulation of electrodes and thermal stabilization of the electrode element is achieved by the dielectric insulating oil circulating in the cooling system. The discharge is generated on the upper surface of the ceramics and at full coverage by the microdischarges the plasma area has dimensions of 196 × 78 mm2. The reactor body is made up of a flat horizontal desk with a slot for the DCSBD plasma panel, held in a solid plastic frame. The plasma panel is aligned to have the upper surface of the ceramics at the same level as the surface of the horizontal panel of the reactor. This ensures smooth sliding movement of the samples through the plasma area. Samples are being moved by a motorized sample holder with continuous regulation of the movement speed. Two micro switches ensure the reversal of the movement direction after each transition through the plasma zone.

The plasma reactor was driven by a LIFETECH VF700 generator, supplying 14 kHz sinusoidal high voltage. The total power of the system was measured by a plug-in wattmeter and was kept constant at 400 W for all experiments. The corresponding average plasma power density was 2.3 W/cm2. Activation of the samples was achieved in direct contact between the wood surface and the electrode element hence the average wood–ceramic distance was estimated to be comparable with the grit size i.e., 100 μm. The porous structure and surface roughness of wood allows the plasma to exist in these conditions, as mentioned by Odrášková et al. (2008). The velocity of the movement was 2.6 ± 0.2 cm/s with a corresponding treatment time of about 3 s for one complete transition through the plasma zone. Higher treatment times were obtained by repeated transitions. All treatments were done in air at atmospheric pressure with a typical plasma treatment time of 6 s. Further prolonging of treatment would result only in marginal improvement of the wetting properties (Ráhel’ et al. 2008). However, some of the temperature measurements required overexposure of the samples to the plasma.

3.2 Plasma panel and material temperature

Measurements of the surface temperature of the DCSBD panel and the thermal effects on the samples were performed by a thermographic camera Varioscan 3021 ST. All measurements were carried out at ambient air temperature of 20 °C. Pictures of the DCSBD plasma panel (without a sample) were taken 0.5, 3, 6 and 9 min after the working power of 400 W was reached. The surface temperature of softwood (spruce) and hardwood (beech) samples was determined for a treatment duration of 6 and 9 s. Thermographic pictures of the sample surface were taken within about 5 s after finishing the treatment. All pictures were evaluated with the software IRBIS (V2.2).

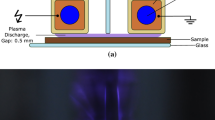

The temperature inside the samples during treatment was measured with a glass fibre optic system (FOTEMP-1, Fa. Optocon GmbH). The main advantage of this system is that it is not influenced by the strong electric fields produced by DCSBD. Blind holes with a diameter of 1.5 mm were drilled into the central area of the same spruce and beech samples with a height adjustable milling machine (see Fig. 2). The drill was stopped when residual wood thicknesses of 1, 2, 3, 4 and 5 mm were reached. Then the fibre optic sensor was inserted to the bottom of the holes.

3.3 Droplet tests and wetted area

For these tests, both radial and tangential cuts of spruce, beech and ash were used. On the tangential cutting plane the convex side was measured. At first the water uptake times before and after plasma treatment were evaluated on one side of the samples, then the reference samples (corresponding twin samples) were measured to investigate differences between the surface properties of the twin samples series used. The reference samples were without any contact with the plasma. This provided the best comparison of the results for further experiments because for these measurements only the reference twin samples were used as the untreated samples for comparison. The droplet tests were performed according to the works published by Rehn and Viöl (2003), Rehn et al. (2003) and Odrášková et al. (2008). A 50 μl water droplet was placed on the sample surface from the height of 5 mm using a metal template with a pattern of drilled holes. The water uptake time was measured from the impact of the droplet to the complete penetration into the wood material (until no optical reflection by the water film could be seen). First, the water uptake time of the droplet of the untreated surface was measured. Plasma treatment and subsequent evaluation of the uptake time of the activated surface was carried out after the sample dried up completely. The droplet was put to the same position as for the untreated surface. The measurements were performed on four pairs of samples per cutting direction, each of them consisting of a reference and an untreated/plasma activated twin sample. On every sample four droplets of water were placed.

The wetted areas of droplets were highlighted by addition of the colorant uranin (Fa. Kremer Pigmente). Uranin was chosen due to its solubility in water. Furthermore, it shows no influence on the optical reflection and subsequently on the uptake time. These measurements were done on the opposite side of the samples, for example in the case of the tangential cut on the concave side. The samples wetted with coloured droplets (50 μl) were scanned by a Canon scanner (CanoScan LiDE 200) at 600 dpi and the images were processed with the program ImageJ (Version 1.46r) to obtain black and white pictures (Fig. 3). The pixels of the wetted surface were counted and converted to an area.

Examples of wetted beech samples (tangential cut): 1 scanned picture of reference sample, 2 picture 1 processed with ImageJ, 3 scanned picture of treated sample, 4 picture 3 processed with ImageJ

Beispiele von benetzten Buchenproben (Tangentialschnitt): 1 gescanntes Bild einer Referenzprobe, 2 Bild 1 nach Bearbeitung mit ImageJ, 3 gescanntes Bild einer behandelten Probe, 4 Bild 3 nach Bearbeitung mit ImageJ

3.4 Contact angle

Water contact angles of samples were determined by sessile drop method on the contact angle measuring instrument Krüss DSA30. Droplets with a volume of 2 μl were placed on the surface of wood samples. The values of contact angles were measured from the initial shape of droplets when contact with the surface was established. The samples were analysed within 15–20 min after the treatment. The average values of the contact angles were calculated from two samples for each cut (15 droplets per sample).

3.5 Water absorption coefficient

Determination of the water absorption coefficients and the presentation of the results were done according to the EN ISO 15148:2002. The samples were placed on two rests inside a box filled with water (Fig. 4). If needed, a weight was placed on the samples (1) to prevent buoyancy. The samples (2) were partially immersed in water with a height level (3) of 5 ± 2 mm during the whole measuring period. The tangential cuts were dipped into the water with the convex side facing down.

Schematic of the experimental setup for the measurement of the water absorption coefficient: 1 grid for load against buoyancy, 2 sample, 3 water level

Schema des experimentellen Aufbaus zur Messung des Wasseraufnahmekoeffizienten: 1 Gitter mit Auflast gegen den Probenauftrieb, 2 Prüfkörper, 3 Wasserspiegel

The uptake of water was determined by weighing after given time steps i.e., 5, 20 min, 1, 2, 4, 8 and 24 h (Niemz et al. 2010a). Excess liquid was removed by a sponge prior to the weighing.

The water absorption coefficient is determined as follows: At first, the area-related mass increase ∆m t is calculated at given time steps using following equation

where m t is the mass of the sample at the time t (kg), m i is the initial mass of the sample before the experiment (kg) and A is the liquid uptake area (m2). After a short stabilization phase the points of the relation ∆m t (√t) may be approximated by a line. By extrapolating this fitting line to zero time it intersects the Y-axis at the value \( \Updelta m^{\prime}_{0} \). The water absorption coefficient A W is then calculated with the equation

where \( \Updelta m^{\prime}_{tf} \) is the value of ∆m from the extrapolated line at time t f , and t f is the duration of the test (24 h in this case).

3.6 ATR-FTIR spectra

ATR-FTIR (attenuated total reflection-fourier transform infrared) analysis of the wood surface was performed utilizing a Bruker vertex 80v spectrometer and a MIRacle™ (Pike Technologies) ATR sampling accessory (diamond crystal, single reflection). Data were collected from 50 scans of the spectral range from 4,000 to 600 cm−1 with 4 cm−1 resolution. Final spectra were background corrected and interpretation of the relevant absorption bands was carried out according to Pandey and Pitman (2003) and Tshabalala et al. (2012).

4 Results and discussion

4.1 Thermal properties of the DCSBD setup

The results of the surface temperature measurements of DCSBD panel are shown in Table 2. The average temperature T AM was calculated from the total area of the plasma panel. A relatively uniform temperature distribution on the surface of the ceramics was quickly obtained after reaching the desired working power. After that, no relevant temperature fluctuations were observed, even for longer time periods. As one can see, the temperature of the discharge ceramics does not exceed 60 °C. The surface temperature of the samples was measured immediately after treatment for 6 and 9 s. The average temperature T AM of the sample surface was obtained from the whole area of the treated face. The beech samples reached higher surface temperature than the spruce samples. The heat transport in porous systems depends on the density and the structure of the material. Thus, the higher density of beech leads to a higher temperature. The highest temperatures T max were obtained at the centre of the samples. Based on this information the temperature of the wood bulk during the plasma treatment was measured in holes, drilled from the backside in the centre of the samples.

The temperature changes ΔT for increasing material thickness are plotted as a function of the treatment time (see Fig. 5). Excessive duration of plasma treatment was used for studying the sample heating. The temperature rise at 1 mm depth is largest for both types of wood and gradually decreases with increasing material thickness. The temperature inside the beech sample reaches higher values than for spruce which is explained again by the higher density of beech.

The findings of this section clearly demonstrate the low temperature of the DCSBD setup. Low rates of sample heating were achieved without introduction of gas flow for cooling the process. For a typical treatment time of 6 s the sample surface temperature rises only by around 10 °C, hence DCSBD is non-destructive and can be safely recommended for continuous treatment of wooden material of any thickness. This is in contrast to other studies where it was desirable to interrupt the treatment to avoid thermal damage (Wolkenhauer et al. 2007, 2009). Sample heating could be reduced further just by enhancing the efficiency of the cooling system.

4.2 Surface wettability

The wettability of all wood samples was greatly enhanced upon plasma treatment. Activation by DCSBD resulted in a substantial decrease in the water uptake times, as can be seen in Fig. 6. The absolute values of the water uptake time of treated samples are between 20 and 60 s (120 s for spruce, radial section) with an average value of about 30 s (60 s for spruce, radial section). This means practically immediate absorption of water by the treated wood surface. The variation in water uptake times of the used twin sample series indicates good comparability between the reference and treated beech and ash samples. The difference between spruce twin samples could be explained by the higher resin content in spruce and its uneven distribution in the material. For the untreated surface, the tangential plane has a lower water uptake time than the radial plane because of the different wood structure in the different cutting directions. Still, random differences in properties of individual wood samples are more prominent than the differences observed between the cutting planes. The rather small differences between the cutting planes after plasma activation point out another useful property of the treatment, namely that it suppresses the influence of the wood microstructure on the surface wettability. This is especially true for both tested hardwoods. The variance for spruce can be explained by the higher ratio of resin in the softwood matrix which is in the radial section more exposed via the closely packed annual rings.

Table 3 summarizes the relative reduction of the water uptake time upon plasma activation. Due to the generally low wettability of hardwoods, this improvement is in both cutting directions larger for the tested hardwoods than for softwood. Odrášková et al. (2008) achieved 88 ± 7 % improvement on DCSBD treated oak samples (radial cut), which is comparable to the results of this study on beech and ash.

Plasma treatment resulted in a notable increase of the wetted area by the 50 μl droplets (Fig. 7) and more importantly, ensured uniform coverage of the surface by the wetting liquid. This can be deduced from the shape of the droplet traces (see Fig. 3): on the untreated surface the liquid spreads mainly along the grain and the sanding direction, while after treatment the wetting becomes nearly omnidirectional. This applies to both cutting planes for all three tested wood species. The differences between the cutting planes were rather small with some inconsistency for spruce. The wetted area increased almost twice for spruce and threefold for beech. For comparison, Asandulesa et al. (2010) achieved only about 40 % improvement in wetted area on beech using a He DBD treatment. Such difference could be explained by less efficient interaction of reactive species in He discharge with the wood constituents. Untreated ash samples had wetted areas comparable to that of the activated beech surface, with one order of magnitude lower liquid uptake time (see Fig. 8). Plasma treatment did not increase the wetted area of ash samples significantly. The improvement of only 23–31 % indicates that plasma activation mainly accelerated the rate of liquid spreading on the surface. After DCSBD activation the uptake times and wetted areas of both ash and beech were similar, hence comparable liquid penetration depth can be assumed. The anomaly of ash clearly demonstrates the influence of the microstructure of wood species on the wetting properties.

The uranin-water simultaneously represents an example of a waterborne agent. It is notable to see the uptake times of the solution (Fig. 8) to be in good agreement with the results of pristine water (Fig. 6). Regardless of the generally higher uranin-water uptake times for the reference samples, after treatment their values decline to the same level as for distilled water. This clearly indicates that the uranin dissolved in water has no adverse effect on the interaction of the droplet with the activated wood surface. Similar results are therefore to be expected for other water-based solutions too.

Additionally, the initial values of contact angles (see Fig. 9), with respect to the cutting direction, were measured. For all untreated samples, the initial contact angles were above 70°. After plasma treatment, the contact angle of the hardwoods declined to about 29° (63 % reduction) and in the case of spruce to around 43° (43 % reduction). Slight differences between the cutting planes are observable again, with the tangential section being more wettable.

4.3 Water absorption coefficient

The area-related mass (described in Sect. 3.5) was plotted as function of the square root of the time (see Fig. 10). One curve represents the average of four samples per cutting plane. In the case of both hardwoods the tangential cut exhibited a higher water uptake rate compared to the radial cut. This is in good accordance with the surface properties measured by the droplet tests (Figs. 6, 8, 9). In contrast the water uptake of spruce was found to be practically independent from the cutting plane.

The calculated values of the water absorption coefficients are summarized in Table 4. The highest water absorption was observed for beech and the lowest value for spruce. Compared to spruce, for both cuts the water uptake of beech is more than two times higher. The pit locks of spruce represent barriers for water uptake in the cellular structure, as described by Niemz et al. 2010a, 2012). The water absorption coefficients of plasma treated and reference samples are within statistical error indistinguishable. The differences fall between 1 and 7 %. This implies that the improved water uptake rate of surface layers achieved by DCSBD treatment has no further effect on the penetration of water to the bulk of wood.

4.4 ATR-FTIR spectra

Relevant parts of the obtained ATR-FTIR spectra are shown in Fig. 11. In the range of 1,750–1,500 cm−1 the spectrum has relatively well defined bands with light overlaps. Changes in this region were consistent with the spectra obtained from different parts of the samples. Effects of plasma treatment were detectable in spectra of all three types of wood, namely increase of C=O bonds and slight decrease of the typical lignin band intensities. This is in good agreement with the XPS analysis of DCSBD treated wood which pointed out a decrease of hydrocarbon type C–C and C–H bonds and simultaneous increase of polar C–O and C=O bonds (Ráhel’ et al. 2008). Even though the sampling depth of infrared beam exceeds the thickness of activated layer (Tshabalala et al. 2012), generation of C=O bonds at 1,735 (1,733) cm−1 and 1,652 cm−1 on plasma treated samples was still observable. This implies that after treatment the surface density of C=O bonds is substantially higher than their density in the bulk. It proves that surface oxidation plays a dominant role in DCSBD plasma modification of the wood surface in air. The absorption bands at 1,593 (1,595) cm−1 and 1,504 (1,508) cm−1 associated with aromatic skeletal vibrations of lignin show only minimal decrease upon plasma treatment. It is expected as degradation of lignin by plasma is much slower than for cellobiose (Jamali and Evans 2011).

5 Conclusion

DCSBD was successfully employed for surface activation of radial and tangential cuts of spruce, beech and ash samples. It was shown that independent of the wood species water uptake times <60 s can be achieved. Additional to the enhancement in the liquid absorption characteristics, DCSBD treatment significantly reduced the differences in wettability between the radial and tangential cuts. Moreover, a more uniform spreading of the wetting liquid was observed on the activated wood surface. This should ensure excellent adhesion of wood with waterborne adhesives and/or coatings regardless of the cutting plane of wooden material. Plasma treatment was found to be most beneficial for beech because of the more pronounced improvement both in uptake time and the wetted area of water droplets in comparison to the other specimens. From the evaluation of water absorption coefficient it is evident that the plasma activation made no detectable change in the absorption characteristics of the bulk of wood. Since the temperature rise of the samples during continuous treatment was marginal, thermal degradation of wood is completely avoided. Requirements for the low heating rates combined with the short treatment times are all fulfilled by the DCSBD making it suitable for employment on industrial processing lines, without any limitations to the thickness of wooden material.

References

Asandulesa M, Topala I, Dumitrascu N (2010) Effect of helium DBD plasma treatment on the surface of wood samples. Holzforschung: Int J Biol Chem, Phys Technol Wood 64(2):223–227. doi:10.1515/hf.2010.025

Avramidis G, Nothnick E, Wolkenhauer A, Militz H, Viöl W (2010) Holzoberflächenmodifikation mittels Atmosphärendruckplasma. Vakuum in Forschung und Praxis 22(1):25–29

Avramidis G, Klarhöfer L, Maus-Friedrichs W, Militz H, Viöl W (2012a) Influence of air plasma treatment at atmospheric pressure on wood extractives. Polym Degrad Stab 97(3):469–471

Avramidis G, Militz H, Avar I, Viöl W, Wolkenhauer A (2012b) Improved absorption characteristics of thermally modified beech veneer produced by plasma treatment. Eur J Wood Prod 70(5):545–549

Busnel F, Blanchard V, Prégent J, Stafford L, Riedl B, Blanchet P, Sarkissian A (2010) Modification of sugar maple (Acer saccharum) and black spruce (Picea mariana) wood surfaces in a dielectric barrier discharge (DBD) at atmospheric pressure. J Adhes Sci Technol 24(8):1401–1413

Černák M, Černáková L, Hudec I, Kováčik D, Zahoranová A (2009) Diffuse coplanar surface barrier discharge and its applications for in-line processing of low-added-value materials. Eur Phys J Appl Phys 47(2):22806–22811. ISSN 1286-0042

EN ISO 15148 (2002) Hygrothermal performance of building materials and products—determination of water absorption coefficient by partial immersion

Frihart CR (2012) Wood Adhesion and Adhesives. In: Rowell R (ed) Handbook of wood chemistry and wood composites, 2nd edn. CRC Press, Taylor and Francis group, Boca Raton, FL, USA, pp 255–319

Homola T, Matoušek J, Hergelová B, Kormunda M, Wu LYL, Černák M (2012) Activation of poly(methyl methacrylate) surfaces by atmospheric pressure plasma. Polym Degrad Stab 97(6):886–892

Jamali A, Evans PD (2011) Etching of wood surfaces by glow discharge plasma. Wood Sci Technol 45(1):169–182

Klarhöfer L, Viöl W, Maus-Friedrichs W (2010) Electron spectroscopy on plasma treated lignin and cellulose. Holzforschung: Int J Biol Chem Phys Technol Wood 64(3):331–336

Mahlberg R, Niemi HEM, Denes F, Rowell RM (1998) Effect of oxygen and hexamethyldisiloxane plasma on morphology, wettability and adhesion properties of polypropylene and lignocellulosics. Int J Adhes Adhes 18(4):283–297

Mertens N, Wolkenhauer A, Leck M, Viöl W (2006) UV laser ablation and plasma treatment of wooden surfaces—a comparing investigation. Laser Phys Lett 3(8):380–384

Niemz P, Mannes D, Herbers Y, Koch W (2010a) Untersuchungen zum Wasseraufnahmekoeffizienten von Holz bei Variation von Holzart und Flüssigkeit. Bauphysik 32(3):149–153

Niemz P, Mannes D, Koch W, Herbers Y (2010b) Eindringverhalten verschiedener Flüssigkeiten in Holz: einfluss von Netzmitteln und Aufbringungsart. Holztechnologie 51(6):5–11

Niemz P, Sonderegger W, Häring D, Joščák M, Krackler V (2012) Untersuchungen zur Wasseraufnahme von Vollholz und Holzwerkstoffen. Bauphysik 34(3):101–106

Odrášková M, Ráhel’ J, Zahoranová A, Tiňo R, Černák M (2008) Plasma activation of wood surface by diffuse coplanar surface barrier discharge. Plasma Chem Plasma Process 28(2):203–211

Pandey KK, Pitman AJ (2003) FTIR studies of the changes in wood chemistry following decay by brown-rot and white-rot fungi. Int Biodeterior Biodegrad 52(3):151–160

Podgorski L, Chevet B, Onic L, Merlin A (2000) Modification of wood wettability by plasma and corona treatments. Int J Adhes Adhes 20(2):103–111

Prysiazhnyi V, Vasina P, Panyala NR, Havel J, Cernak M (2012) Air DCSBD plasma treatment of Al surface at atmospheric pressure. Surf Coat Technol 206(11–12):3011–3016

Ráhel’ J, Szalay Z, Odrášková M, Tiňo R, Tóth A, Černák M (2008) Modification of wood surfaces by the coplanar barrier discharge. In: Dubovský J, Kúdela J (eds) Interaction of wood with various forms of energy. Technical University in Zvolen, Zvolen, pp 99–103

Rehn P, Viöl W (2003) Dielectric barrier discharge treatments at atmospheric pressure for wood surface modification. Holz Roh Werkst 61(2):145–150

Rehn P, Wolkenhauer A, Bente M, Förster S, Viöl W (2003) Wood surface modification in dielectric barrier discharges at atmospheric pressure. Surf Coat Technol 174–175:515–518

Sakata I, Morita M, Tsuruta N, Morita K (1993) Activation of wood surface by corona treatment to improve adhesive bonding. J Appl Polym Sci 49(7):1251–1258

Šimor M, Ráhel’ J, Vojtek P, Černák M, Brablec A (2002) Atmospheric-pressure diffuse coplanar surface discharge for surface treatments. Appl Phys Lett 81:2716–2718

Thomas PA (2000) Trees: Their Natural History. Cambridge University Press, Cambridge, UK

Tóth A, Černáková L, Černák M, Kunovská K (2007) Surface analysis of groundwood paper treated by diffuse coplanar surface barrier discharge (DCSBD) type atmospheric plasma in air and in nitrogen. Holzforschung 61(5):528–531

Tshabalala MA, Jakes J, VanLandingham MR, Wang S, Peltonen J (2012) Surface characterization. In: Rowell R (ed) Handbook of wood chemistry and wood composites, 2nd edn. CRC Press, Taylor and Francis group, Boca Raton, FL, USA, pp 217–252

Wolkenhauer A, Avramidis G, Cai Y, Militz H, Viöl W (2007) Investigation of wood and timber surface modification by dielectric barrier discharge at atmospheric pressure. Plasma Process Polym 4(S1):S470–S474

Wolkenhauer A, Militz H, Vi l W (2008) Increased PVA-glue adhesion on particle board and fibre board by plasma treatment. Holz Roh Werkst 66(2):143–145

Wolkenhauer A, Avramidis G, Hauswald E, Militz H, Viöl W (2009) Sanding vs. plasma treatment of aged wood: a comparison with respect to surface energy. Int J Adhes Adhes 29(1):18–22

Acknowledgments

In memoriam Prof. Hans K. Pulker. The presented work was financially supported by the “Tiroler Standortagentur” under the project “Physikalisch-chemische Untersuchungen der silikatischen Nano-Infiltration von Hölzern nach Mikrowellentrocknung” within the Translational-Research program, further by the grant “Action Austria-Slovakia” of the Slovak Academic Information Agency (SAIA) No. 2010-10-15-0015 and by the project R&D center for low-cost plasma and nanotechnology surface modifications CZ.1.05/2.1.00/03.0086 funded by European Regional Development Fund.

Author information

Authors and Affiliations

Corresponding author

Additional information

Hans K. Pulker: Deceased.

Rights and permissions

About this article

Cite this article

Lux, C., Szalay, Z., Beikircher, W. et al. Investigation of the plasma effects on wood after activation by diffuse coplanar surface barrier discharge. Eur. J. Wood Prod. 71, 539–549 (2013). https://doi.org/10.1007/s00107-013-0706-3

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00107-013-0706-3