Abstract

Epoxy resin has been widely used in the field of high-voltage insulation because of its excellent insulation, heat resistance and mechanical properties. The performance of epoxy resin is closely related to its microscopic molecular composition and cross-linked structure. The use of molecular dynamics simulation methods can carry out structural design, formula screening and performance analysis of epoxy resin materials from a microscopic perspective. This chapter systematically introduces the current research status of molecular simulation of epoxy resin, principles of cross-linking model construction, and modeling calculation methods. And further combined with cases, the research method of using molecular dynamics simulation technology to carry out monomer selection, structure optimization and molecular modification of epoxy resin cross-linked systems was introduced. This chapter aims to summarize the modeling and calculation methods of epoxy resin cross-linked molecular models, point out the advantages of molecular dynamics simulation in the research of epoxy resin, and promote its application in the field of epoxy material research.

Access provided by Autonomous University of Puebla. Download chapter PDF

Similar content being viewed by others

1 Introduction

The application of molecular dynamics (MD) simulation method in the field of polymers has developed rapidly and has become a mature research tool [1]. Due to the complex structure of epoxy cured material, which is different from linear polymers, it is a three-dimensional network structure formed by the reaction of epoxy oligomers with curing agents [2]. Therefore, how to obtain an accurate molecular model of epoxy resin crosslinking network is a key problem in the application of MD simulation method in epoxy resin research.

In order to obtain an accurate epoxy resin crosslinking network model, the development of its construction method has gone through two main stages: one-step crosslinking method and iterative crosslinking method. The one-step crosslinking method is to crosslink the reactive sites within a certain cut-off distance to form an epoxy resin crosslinking network [3, 4]. It is characterized by a small number of model molecules and low network conversion rate or crosslinking density. The iterative crosslinking method, in which a system equilibrium is performed after the formation of a crosslinked bond, followed by a continuation of the crosslinking reaction until the end of the crosslinking, is characterized by a high network conversion rate or crosslink density [5,6,7]. Compared with the one-step crosslinking method, the iterative crosslinking method is more in line with the actual polymer model and has received more attention from scholars. Wu and Xu [5] used “active” molecular fragments of Bisphenol A diglycidyl ether (DGEBA) and IPD for modelling. When the truncation distance was 4–10 Å and the distance between the two reaction sites was minimum, a crosslinking bond was formed between the two reaction sites. After the formation of the crosslinking bond, energy minimization and MD simulation are performed to eliminate the unreasonable structure and interaction caused by the formation of new construction. Then, the above process is repeated until the conversion is within the experimental value. This method can achieve a high conversion rate, but the calculation time is long. Varshney et al. [6] and Wu et al. [5] used “active” molecular fragments for modelling. Within a certain truncation distance, all potential non-crosslinked reaction pairs were identified and crosslinked bonds were formed. Next, a multi-step relaxation process is used to relax the new topology generated by the introduction of new bonds, angles, dihedral angles, etc. Then the bonding and relaxation processes are repeated until the crosslinking reaction is completed. This method can effectively improve the computational efficiency.

To further improve computational efficiency and avoid manual operation errors, more and more researchers are using computer modelling with the help of scripting programs. Xin et al. [8] wrote an epoxy resin crosslinking reaction program in Perl language based on the iterative crosslinking method and compared it with experimental data to verify the validity of the model. The algorithmic flow of the crosslinking procedure is shown in Fig. 1. Liu [9] wrote an epoxy resin crosslinking reaction program in Perl language, refined the iterative process and investigated the structure–property relationship of epoxy resin.

Flowchart of a perl-based scripting program [10]

In recent years, the iterative crosslinking method based on the use of scripting procedures for epoxy crosslinking calculations has been widely used, but the constructed epoxy resin crosslinking systems are all epoxy-amine curing systems. However, the epoxy resin systems for high voltage insulation used in electrical insulation are epoxy-anhydride curing systems with different cross-linking mechanisms. The rapid acquisition of an accurate and realistic epoxy-anhydride crosslinking model is the basis for the study of existing resins and the development of new resins.

2 Design Principle of Epoxy Resin Crosslinking Model Based on Iterative Crosslinking Method

2.1 Reaction Mechanism of Anhydride Curing Epoxy Resin

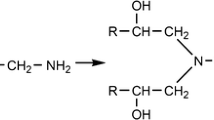

The main reactions of anhydride with epoxy resin in the absence of accelerator are as follows, as shown in Fig. 2: (a) The hydroxyl group in the epoxy resin first opens the anhydride ring to form a carboxylic acid with an ester chain; (b) The carboxylic acid reacts with the epoxy group in the epoxy resin to form a secondary hydroxyl group; (c) The generated hydroxyl group reacts with another anhydride group, while reaction (d) takes place simultaneously; (e) The generated secondary hydroxyl group reacts with another epoxy group, ultimately forming a three-dimensional crosslinked network of epoxy resin.

2.2 Design Principles of Epoxy Resin Crosslinking Model

The mechanism of the epoxy resin anhydride curing reaction shows that the crosslinking reaction is the alternating ring-opening polymerization of curing agent and epoxy compound [2]. It has also been shown that the homopolymerization of epoxy groups can also occur in the presence of catalysts or excessive epoxy at high temperatures [10]. The curing temperature of epoxy resin for high voltage insulation is below 473.15 K, and the epoxy resin is not excessive. The curing reaction mechanism of epoxy anhydride does not include homopolymerization. Therefore, in this paper, the construction of an epoxy-anhydride crosslinking system was implemented using a Perl-based scripting program based on the reaction mechanism of anhydride-cured epoxy resins (Fig. 2). First, the pre-crosslinking model is processed:

-

(1)

A model of the epoxy resin, the curing agent monomer and a molecular model of the carboxylic acid-containing monoester structure generated by the ring-opening reaction of the epoxy resin with the curing agent (as shown in Fig. 2a and hereinafter referred to as the primary crosslinked structure) were constructed. Labelling the epoxy resin with the C atom in CH2 in the epoxy group and one C atom in the anhydride group of the primary crosslinked structure as reaction atom R1 and the O atom in –OH in the carboxyl group of the primary crosslinked structure as reaction atom R2.

-

(2)

The molecular model of the monomer and primary cross-linked structure constructed in (1) is used to construct an amorphous model of the epoxy-anhydride system at a specific value of the molar ratio of the epoxy group to the anhydride group, which is ready for use after equilibration in MD. Then, in order to simplify the script, the following design was made in the script program while ensuring the accuracy of the epoxy-anhydride crosslinking model: labelling the O atom in the carboxyl and hydroxyl groups generated by the reaction as the reaction atom R2, with R1 and R2 being the reaction atom pair; Suppose that each reactive group has the same activity; The reaction is diffusion controlled and each reaction is carried out simultaneously. Finally, the automatic crosslinking program flow chart is shown in Fig. 3.

The flowchart is described as follows:

-

(1)

For the amorphous model of the epoxy-anhydride system with labelled reaction atoms, first set the cross-linking temperature T, the target crosslinking degree TCD, and the range of cut-off radius for the formation of crosslinked bonds.

-

(2)

The radius of the current stage is Rn, the maximum truncation radius is Rmax, and the distance between the reaction atom pairs is calculated as d. If d < Rn, the atomic pair generates a new crosslinked bond according to the reaction principle, followed by a 50 ps NPT molecular dynamics equilibrium to ensure the rationality of the new structure; If d > Rn then proceed to step (3);

-

(3)

Set Rn = Rn + 0.5 Å and repeat step (2). Until Rn is greater than Rmax or the target crosslinking degree is reached, the crosslinking process is completed.

3 Epoxy-Anhydride Crosslinking Model Construction

The crosslinking network model of DGEBA/methyl-tetrahydrophthalic anhydride (MTHPA) was constructed, which can be decomposed into two main stages: (1) Constructing an amorphous model; (2) Based on the mechanism of anhydride curing reaction, the formation of DGEBA/MTHPA crosslinking network was realized by using the automatic crosslinking program written in Perl language.

In the first step, the core module “Materials Visualizer” in “Materials Studio 7.0” software is used to construct the molecular models of DGEBA and MTHPA monomers and the molecular model of DGEBA-MTHPA primary crosslinking structure. Considering that the actual average degree of polymerisation of DGEBA in the experiments ranges from 0.1 to 0.2 [11], the degree of polymerisation is set to 0 when building the molecular model of DGEBA. The molecular model is then geometrically optimized and the reaction atoms are labelled. The molecular formulas and molecular structure diagrams of epoxy resin DGEBA, curing agent MTHPA and primary crosslinking structure DGEBA-MTHPA are shown in Figs. 4 and 5. Subsequently, the “Amorphous Cell” module was used to construct 10 amorphous models containing 8 DGEBAs, 18 MTHPAs and 2 DGEBA-MTHPAs (the molar ratio of epoxy group to anhydride group is 1:1). Periodic boundary conditions are used to eliminate boundary effects, and the model construction temperature is 300 K and the density is 0.6 g/cm3.

In the second step, Geometry Optimization in the Forcite module is used to optimize the structure of all amorphous models, selecting the structure with the lowest energy for further MD. In order to eliminate the stresses generated during the modelling process and make the model more realistic, MD simulations of NVT at 100 ps and NPT at 200 ps are performed sequentially, with the temperature of 300 K and the pressure of 1 atmosphere. The COMPASS force field is selected for dynamic process, Andersen [12] and Berendsen [13] methods are used for temperature and pressure control respectively, and the van der Waals and electrostatic interaction calculation methods are Atom-based and Ewald methods respectively.

The third step is to embed the general program script of epoxy resin/anhydride curing agent automatic crosslinking reaction in “Materials Studio 7.0”, which is compiled according to the anhydride curing reaction mechanism and the design principle of epoxy-anhydride system crosslinking method. Set the target cross-linking degree (taking 89% crosslinking degree as an example), set the temperature at 300 K, and set the truncation radius and maximum truncation radius at 3.5 Å and 7.5 Å respectively. The epoxy-anhydride crosslinking model at the target crosslinking degree can be obtained by running the crosslinking program. The molecular structures of the DGEBA/MTHPA amorphous and crosslinked models are shown in Fig. 6. Taking the crosslinking degree of 89% as an example, the basic parameters of the system before and after crosslinking are shown in Table 1.

In the fourth step, after optimizing the structure of the obtained epoxy-anhydride crosslinking model, MD simulation of NVT and NPT ensemble was carried out successively at 600 K, and the simulation parameters are consistent with the previous paper. Finally, the 600 K crosslinked-anhydride model is “annealed” to cool it down: The crosslinked models are simulated at 600 K for 100 ps NVT and 200 ps NPT respectively and are heated up to 600 K and then cooled down by “annealing” from 600 to 300 K, with a temperature interval of 20 K and a kinetic equilibrium time of 100 ps at each temperature. Then the crosslinked structure models of epoxy-anhydride at different temperatures are output for the subsequent calculation of structure and performance parameters.

4 Epoxy-Anhydride Crosslinking Model Applications

4.1 Preferred Epoxy Resin Monomer for High Voltage Insulation

There are many types of epoxy resins and curing agents, and the curing products of different epoxy resins and curing agents have complex structures and vary greatly in thermodynamic properties. Therefore, the selection and matching of epoxy resin and curing agent base materials, as well as the correlation between the microstructure of epoxy materials and their macroscopic properties, are of great research significance. In this section, DGEBA, dicyclopentadienyl alicyclic epoxy resin (DCPDE), MTHPA and maleic anhydride (MA) anhydride curing agents are selected as monomers to construct crosslinking structure models of four epoxy resin systems: DGEBA/MTHPA, DGEBA/MA, DCPDE/MTHPA and DCPDE/MA. The effect of the crosslinking degree on the microstructure and thermodynamic properties of epoxy has been investigated by MD simulations. Multiple parameters of the four epoxy crosslinking systems are compared, and the correlation between the microstructure and thermodynamic properties of the epoxy resin substrates is constructed. The molecular structures of the epoxy resins DGEBA, DCPDE and the anhydride curing agents MTHPA and MA are given in Fig. 7 (Table 2).

The microstructure of a material is intrinsically important in influencing its performance. Analyzing structural parameters and predicting macroscopic performance is crucial for the optimization of epoxy resins and curing agents. Therefore, in this section, relevant parameters such as free volume, mean square displacement, glass transition temperature, coefficient of thermal expansion and modulus are calculated for the four epoxy resin systems.

The basic calculations used to characterize the structural and performance parameters are based on the following.

(1) Free volume ratio

According to the free volume theory, the volume VT of liquid and solid substances consists of two parts: one is the volume V0 occupied by molecules, and the other is the unoccupied volume Vf, namely the free volume. That is:

The free volume is dispersed within the material in the form of “pores” and provides space for the molecules to move so that the molecular chains can move. Free volume is one of the important microscopic features of polymeric materials which is often used to explain the glass transition of epoxy resins, and has a correlation with mechanical properties. Direct comparisons of free volume values are of little significance due to the differences in volume between the different crosslinking models. This book introduces the free volume ratio (FFV) to compare the free volume characteristics of different systems, which is defined as:

(2) Mean square displacement

During the MD process, the position of the molecule in the model is constantly changing and the mean square displacement (MSD) of the molecule characterizes the ability of the molecule to move in the model. The mean square displacement of a molecule is defined as:

where R(t) and R(0) respectively represent the displacement vector of any atom i in the system at time t and at the initial moment, respectively. For a system with N atoms, the mean square displacement can be expressed as:

(3) Glass transition temperature

Glass transition is a transition that can occur in both amorphous polymers and amorphous regions of crystalline polymers. According to the free volume theory, the glass transition temperature (Tg) is a transition temperature at which the polymer chain segments transition from freezing to moving, which macroscopically shows that the material changes from glass state to rubber state and loses its high stiffness. Therefore, Tg is the highest temperature of epoxy resin as an insulating support material. In general, an increase in temperature will lead to a decrease in the density of the material, and the curve of polymer density with temperature will show an inflection point at the Tg temperature value. Therefore, the information such as density and temperature of the model under each crosslinking degree during the “annealing” cooling process can be extracted and the Tg of epoxy resin can be predicted by the temperature corresponding to the inflection point of the density curve with temperature. The specific method is shown in Fig. 8, where linear fitting is performed on the density values on both sides of the inflection point, and the intersection of the two lines is Tg.

(4) Coefficient of thermal expansion

The Coefficient of thermal expansion (CTE) is one of the main physical properties of a material and can be used to calculate the internal stress due to thermal expansion, and is an important indicator of the thermal stability of a material. Its calculation formula is:

where V0 is the volume of the initial system, here taken as the volume of the system at 300 K, and P is taken as one standard atmospheric pressure. Epoxy resins correspond to different states (glassy and rubbery) before and after the glass transition and their CTE can change abruptly. A linear fit to the volume-temperature data before and after the glass transition, respectively, gives the rate of change of volume with temperature in both states. As shown in Fig. 9.

(5) Modulus

MD simulations enable the static normal strain method to be used to calculate the mechanical properties of crosslinked systems, that is, to analyze the stress and strain of a three-dimensional epoxy system with slight deformation, and then obtain its mechanical properties related parameters such as bulk modulus, shear modulus, Young’s modulus, Poisson’s ratio, etc. The process can be described as follows: a small strain is applied to the system, causing the model to undergo uniaxial tensile and compressive deformation along the x, y, and z axes, respectively, i.e., shear deformations in the xy, xz, and yz planes, respectively, and the stiffness matrix Cij can be obtained from the model's response to the strain, which can be described as follows for isotropic materials.

where λ and μ are elastic constants which can be derived from the relevant elements in the stiffness matrix.

The bulk modulus K, Young’s modulus E, shear modulus G and other mechanical properties of epoxy system can be obtained from elastic constants λ and μ. The calculation methods are as follows:

The results of the structural properties of the four groups of epoxy resin systems involved in the calculations are shown in Fig. 10.

The thermodynamic properties of the four groups of epoxy crosslinking models are different. The Tg of the four systems with 90% crosslinking is DGEBA/MA > DCPDE/MTHPA > DCPDE/MA > DGEBA/MTHPA in descending order; the CTE in the glassy state is DCPDE/MA < DGEBA/MA < DCPDE/MTHPA < DGEBA/MTHPA. The DGEBA/MTHPA system has low modulus and the worst mechanical properties; The DCPDE/MTHPA system is the most resistant to shear stresses and the DCPDE/MA system is the best in terms of tensile and compressive stresses. In addition, there is a certain correlation between the microscopic and thermodynamic properties of the epoxy resin base material. There is a positive correlation between FFV and the chain segment kinematic properties of epoxy resins; generally lower FFV and weaker chain segment kinematic models have better thermodynamic properties.

4.2 Study of the Effect of Polymerisation on the Structural Properties of Epoxy Resins

DGEBA is usually a mixture of homologues with different molecular sizes (chain length, molecular weight and polymerization degree). However, most of the current simulation studies have focused on the case where the polymerization degree of DGEBA is 0 and the effect of polymerization degree on the performance of crosslinked epoxy resins has been rarely studied. Previous experimental studies have confirmed that different molecular weights do have an effect on the properties of the cured product. Therefre, it is particularly important to investigate the effects of different polymerization degrees on the structure and properties of epoxy resins at the simulation level.

In this section, DGEBA, a bisphenol A epoxy resin with a polymerization degree of 1 and 2, is used as the base material for the epoxy resin, and MTHPA is used as the curing agent (the molecular structure of the monomer is shown in Fig. 11). The epoxy resins are mixed in different proportions to study the effect of different polymerization levels on the performance of the crosslinked epoxy resin system.

To investigate the effect of polymerization on the performance of crosslinked epoxy resin systems, four types of ratios of 8:2, 6:4, 5:5 and 3:7 are determined for DGEBA (n = 1) and DGEBA (n = 2). Combining the actual epoxy resin with the reaction mass ratio of the curing agent, the molar ratio of the epoxy resin mixed with the anhydride curing agent in this section is epoxy resin: curing agent = 1:2. Therefore, the total number of DGEBA molecules is selected as 30 and MTHPA as 60. And the following molecular models are constructed respectively: (1) DGEBA (n = 1):DGEBA (n = 2):MTHPA = 24:6:60; (2) DGEBA (n = 1):DGEBA (n = 2):MTHPA = 18:12:60; (3) DGEBA (n = 1):DGEBA (n = 2):MTHPA = 15:15:60; (4) DGEBA (n = 1):DGEBA (n = 2):MTHPA = 9:21:60.

FFV, MSD, Tg, CTE and modulus are calculated for different polymerization proportioning models respectively.

Figure 12 reveals the effect of different polymerization degrees on the thermodynamic properties of crosslinked epoxy resins. It is found that as the average molecular weight increased, the Tg of the system first increased and when it exceeded a certain value, Tg decreased to the initial level. The change in average molecular weight has a significant improvement on the glassy CTE of the system, while the effect on the rubbery CTE is not significant. The increase of average molecular weight will have a more significant improvement on the mechanical properties of the system. When the ratio is 6:4 in the polymerization degree model, the increase in each elastic modulus is the largest.

4.3 Study on the Effect of Capping Agents on the Structural Properties of Epoxy Resins

In this section, DGEBA (0 degree of polymerization) is selected as the epoxy resin matrix. MTHPA is the curing agent and ethyl salicylate (ES) is the capping agent. The molecular structural formulae and primary crosslinking structures are shown in Figs. 13, 14 and 15.

In this section, four cases of capping agent ES with 2, 4, 6 and 8% mass fraction of epoxy resin are selected. The components of the system are shown in Table 3.

The cohesion energy density (CED), hydrogen bonding number, FFV, MSD, Tg, CTE and modulus are calculated for different capping agent proportioning models respectively (Fig. 16).

The results indicate that:

-

(1)

With the increase of end-capping agent content, CED and FFV show an upward trend, which is also related to the benzene ring and double bond contained in ES. The order of FFV is pure > 2 wt% > 8 wt% > 6 wt% > 4 wt%, and the order of MSD is 8 wt% < 6 wt% < 4 wt% < 2 wt% < pure, which is due to the synergistic effect of the ES polar group with the methyl group. The number of hydrogen bonds increased with the increase of capping agent content, and the final number remain unchanged.

-

(2)

With the increase of the content of the capping agent, the Tg of the epoxy resin is obviously increased, and the increase is gradually reduced. The thermal expansion coefficients of the ES systems with capping agents are all lower than those of the pure systems; and the trend is to increase and then decrease.

-

(3)

After adding the capping agent ES, the Young’s modulus of each system increases, and the size relationship is the same as the mean square displacement of each system. The bulk modulus and shear modulus of each system do not increase or decrease significantly with the increase of capping agent content.

4.4 Study of the Effect of Matrix Fluorination on the Properties of Epoxy Resins

In this section, bisphenol A epoxy resin DGEBA is used as epoxy substrate and MTHPA is used as an anhydride curing agent. Four monomers, diglycidyl trifluoromethylaniline (DGTFA), dodecafluoroheptanol (FTOH), 4 (-1,1,1,3,3,3-hexafluoro-2-hydroxy-2-propyl) phenol (HFIP) and hexafluorobisphenol A (BPAF), are selected as fluorine-modified reagents to fluorinate the epoxy resin matrix. The molecular formulae of the epoxy resin, curing agent and fluorinated monomer are shown in Fig. 17.

Firstly, the effect of the fluorination method on the structure and properties of the epoxy crosslinking system is investigated. The molecular models of the four groups of fluorinated resins with different matrix fluorination methods and the number of molecules contained in the blank group are shown in Tables 4.

CED, Tg, thermal conductivity and modulus are calculated for the models with different fluorination methods respectively.

(1) CED calculation analysis

Calculations of the cohesive energy density of different fluorinated epoxy systems are carried out at room temperature and the results are shown in Table 5.

The table shows that the epoxy system with the physical fluorination method has the lowest cohesive energy density of 113.26 J cm−3, which indicates that the interaction force of the molecular chain segments of this epoxy system is weak. Among the fluorine-containing systems of the three chemical fluorination methods, the CED of the system using the median fluorinated fluorine-containing monomer is relatively high. Further comparison shows that the BPAF/DGEBA epoxy system has the highest cohesion energy density of 141.69 J cm−3, which indicates that the intermolecular forces in the chain segments of this epoxy system are relatively strong and the interaction forces in the crosslinked network are high.

The analysis shows that the physical fluorination is a simple blending of the fluorinated monomer with the epoxy matrix, with no chemical bonding between the fluorinated monomer and the DGEBA molecule. Therefore, the intermolecular interaction force is weak and the CED of the system is relatively low, resulting in poor compatibility of lend phase and uneven dispersion of the two phases, thus compromising the overall performance of the fluorinated epoxy system. After chemical fluorination, the fluorine-containing segments are grafted into the epoxy resin network system by chemical reaction between the fluorination reagent and the epoxy group on the epoxy matrix. The obtained fluorine-containing epoxy system has stronger intermolecular force, more stable product structure, and relatively high CED parameters.

(2) Synergistic reversal barrier analysis

The essence of molecular segment flexibility is the ease of single bond rotation, which can be expressed by the cooperative torsion barrier of single bond with representative position in molecular segment during rotation. The larger the synergistic torsional potential at key locations for monoliths with approximate molecular structure, the less flexible their corresponding chain segments are.

From the CED calculations, it is clear that the CED values of BPAF/DGEBA and HFIP/DGEBA fluorinated epoxy resin systems are similar. This section therefore further calculates the torsional energy barriers for the chain segments of these two fluorinated monomer-containing molecules. The conformational behavior of the molecular structure is used to compare the information on the local structure and the flexibility of the molecular chain segments in the crosslinked network of the epoxy resin. The conformational analysis of the molecular chain segments of the two fluorinated monomers, HFIP and BPAF, is shown in Fig. 18. Figure 19 gives the calculation results of the co-twisting energy barriers at key bonding positions for HFIP and BPAF monomer molecules. The figure shows that the torsional energy barrier at the two hydroxyl positions of BPAF is 1131.36 kcal/mol higher than the energy barrier of the HFIP monomer molecule. This indicates that BPAF molecular chain segments require more energy to rotate around a single bond and that their molecular chains are more rigid. The analysis suggests that the two fluorinated monomers with similar structures at both ends, the BPAF molecule contains two benzene rings, which bring about a greater spatial resistance, resulting in a less free molecular conformation. Therefore the torsional energy barrier of the BPAF monomer molecule is calculated to be higher and it can be assumed that the BPAF/DGEBA epoxy system is more rigid.

(3) Performance calculation analysis

The results for Tg, thermal conductivity and modulus are shown in Fig. 20.

The analysis of the Tg calculation results shows that after fluorination of the epoxy resin, the introduction of fluorine elements and CF3 groups will effectively improve the heat resistance of the epoxy resin, while the Tg enhancement of the system by fluorinating the resin by physical blending is relatively low, and the Tg enhancement by chemical grafting fluorination is better. The highest Tg enhancement for the DGEBA/MTHPA epoxy system is achieved by the neutral fluorination of BPAF. Combined with the calculation results of micro parameters, it can be found that for the analysis of crosslinking network structure parameters, the system with relatively high polymer CED has relatively strong intermolecular interaction forces and a higher glass transition temperature. From the perspective of the fluorinated monomer configuration, the higher the molecular chain segment co-twisting energy barrier, the more rigid the molecular chain segment and the higher the Tg of the corresponding fluorinated system. Therefore, the glass transition temperature of the BPAF/DGEBA fluorinated resin system is the highest.

The analysis of the thermal conductivity calculations concluded that the epoxy resin material mainly relies on internal phonons for thermal conductivity. When the heat generated by the external environment is transferred to the epoxy molecular chain segments, it will cause the atoms to vibrate, thus enabling the transfer of heat. In the case of fluorinated resins with physical fluorination, the interaction between the fluorinated monomer and DGEBA is weaker, the molecular chain segments are more mobile, the atoms vibrate more vigorously when heated, the phonon excitation number increases and the average phonon free range decreases, so the thermal conductivity of the system is relatively low. The use of dodecafluoroheptanol chemical graft fluorination increases the number of branched molecular chain segments within the epoxy system, and studies have shown that the conformation of the chain segments containing branched chains on the main chain disrupts the symmetry and regularity of the polymer system to a certain extent, resulting in increased energy and more violent atomic vibrations within the crosslinked network. This constrains the average free range of phonons to a certain extent and thus affects the thermal conductivity of the system. The higher thermal conductivity of BPAF/DGEBA compared to the HFIP/DGEBA system may be due to the two benzene rings on the main chain of BPAF, the higher torsional energy barrier of the monomer and the higher energy required to rotate the molecular chain segments. The molecular chain conformation is more stable and the atomic vibrations are weaker, resulting in a higher thermal conductivity.

The modal analysis concluded that the fluorinated modifier can significantly improve the elastic modulus of epoxy resin due to the shorter C–F bond length and higher bond energy in the fluorocarbon chain structure after fluorination modification can significantly improve the elastic modulus of epoxy resin due to the shorter C–F bond length and higher bond energy in the fluorocarbon chain structure after fluorination modification.

References

Sun, Y.G., Guo, Y.F., Yang, H.: A molecular dynamics study of crosslinked epoxy networks: construction of atomistic models. Mol. Simul. 46(2), 121–127 (2020)

Chen, P., Liu, S.P., Wang, D.Z., et al.: Epoxy Resin and Its Applications. Chemical Industry Press (2011)

Yarovsky, I., Evans, E.: Computer simulation of structure and properties of crosslinked polymers: application to epoxy resins. Polymer 43(3), 963–969 (2002)

Gou, J., Minaie, B., Wang, B., et al.: Computational and experimental study of interfacial bonding of single-walled nanotube reinforced composites. Comput. Mater. Sci. 31(3), 225–236 (2004)

Wu, C., Xu, W.: Atomistic molecular modelling of crosslinked epoxy resin. Polymer 47(16), 6004–6009 (2006)

Varshney, V., Patnaik, S.S., Roy, A.K., et al.: A molecular dynamics study of epoxy-based networks: cross-linking procedure and prediction of molecular and material properties. Macromolecules 41(18), 6837–6842 (2008)

Yang, H., Yu, K., Mu, X.M., et al.: A molecular dynamics study of bond exchange reactions in covalent adaptable networks. Soft Matter 11(31), 6305–6317 (2015)

Xin, D.R., Han, Q.: Investigation of moisture diffusion in cross-linked epoxy moulding compound by molecular dynamics simulation. Mol. Simul. 39(4), 322–329 (2013)

Liu, W.S.: Structure and Properties of Crosslinked Epoxy Resin TGDDM: A Molecular Dynamics Simulation. North University of China (2016)

Komarov, P.V., Chiu, Y.T., Chen, S.M., et al.: Highly cross-linked epoxy resins: an atomistic molecular dynamics simulation combined with a mapping/reverse mapping procedure. Macromolecules 40(22), 8104–8113 (2007)

Wang, D.Z.: Production and Application of Epoxy Resin. Chemical Industry Press, Beijing (2001)

Andersen, C.H.: Molecular dynamics simulations at constant pressure and/or temperature. J. Chem. Phys. 4(72), 2384–2393 (1980)

Berendsen, H.J., Postma, J., Van Gunsteren, et al.: Molecular dynamics with coupling to an external bath. J. Chem. Phys. 8(81), 3684–3690 (1984)

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2024 The Author(s), under exclusive license to Springer Nature Singapore Pte Ltd.

About this chapter

Cite this chapter

Fu, K., Xie, Q., Song, J., Xia, G. (2024). Study on the Construction Method of Epoxy Resin Crosslinking Model. In: Xie, Q. (eds) Electrical Materials. Engineering Materials. Springer, Singapore. https://doi.org/10.1007/978-981-99-9050-4_1

Download citation

DOI: https://doi.org/10.1007/978-981-99-9050-4_1

Published:

Publisher Name: Springer, Singapore

Print ISBN: 978-981-99-9049-8

Online ISBN: 978-981-99-9050-4

eBook Packages: Physics and AstronomyPhysics and Astronomy (R0)