Abstract

Infrastructure such as residential buildings, industrial structures and nuclear power plants are at risk of fire damage during their service. High-temperature exposure impacts the physical, mechanical and thermal characteristics of concrete structural members. Due to the failure of cement gel structure at the nanoscale, being subjected to high temperatures causes significant deterioration. At micro-scale, when subjected to high temperatures, the dehydration of cement mix, porosity increases, pore pressure changes and variations in the percentage of moisture of concrete can be identified. At macro scale, inadequate pore pressure is observed due to loss of strength, reduced durability, structural cracking, increased drying shrinkage, aggregate colour changes, thermal expansion, cracking, creep, and spalling. The amount of heat transfer through concrete is determined by its thermal characteristics, which depend on temperature, while the strength loss and deterioration in concrete are determined by its mechanical properties.

Access provided by Autonomous University of Puebla. Download conference paper PDF

Similar content being viewed by others

Keywords

1 Introduction

Concrete is chosen as the major building material, due to several benefits, including strength and durability properties. Concrete structures must satisfy the essential fire safety standards in line with building regulations [1, 2]. Fire remains the most hazardous environmental condition to which structures are exposed, implementing suitable fire protection precautions for the building’s structural elements is an important element of building design [3]. In recent years, fire damages are frequently reported worldwide as a seriously threatening issue. When subjected to high temperatures, concrete undergoes structural damage through spalling and exposure of bar along with mechanical degradation of the concrete at the micro and meso levels. The density and porosity of the concrete, as well as its initial strength, moisture content, and heating rate, all impact the thermomechanical characteristics of a concrete structure when it is subjected to elevated temperatures. The range of temperatures related to building fires also has an impact on these characteristics. This chapter focuses on the thermally induced changes in concrete at elevated temperature.

2 Materials Behaviour of High-Temperature Concrete

Materials behaviour that will be studied in this chapter is supplementary cementitious materials, fibres, and aggregates. With the combination of cement gel structure, aggregate, and fibres, concrete acts as a heterogeneous material. The behaviour of the structure at various high temperatures is therefore difficult to characterize since each of these materials reacts independently when subjected to thermal conditions [4]. Several physicochemical changes take place as concrete is heated up, changing the material’s thermo-mechanical characteristics [5]. In Fig. 1, effects of increasing temperature in concrete at various stages has been shown. From 20 to 80 °C, there is a gradual capillary water loss caused by the expansion of the water. Later on, from 80 to 100 °C dehydration of Ettringite and decomposition occurs where in physically bounded water in a cement matrix and aggregates evaporate, which leads to an increase in the microcracking due to capillary porosity. Concrete starts to dehydrate and decompose by losing its water and C–H–S gel at 100–200 °C [6]. Concrete strength is either maintained or increased at 300 °C as the cement gel layers become denser. However, concrete losses its strength and stiffness significantly over 300 °C [7]. From 400 to 600 °C, microcracking of cement paste takes place due to CH decomposition. In the range of 600–800 °C, it undergoes the second stage of C–H–S breakdown during which its compressive strength is substantially reduced. From 800 to 1200 °C temperature, an intense microcracking of the concrete takes place due to dehydrated phases [8].

Effects of increasing temperature in concrete at various stages [9]

2.1 Fibres

To avoid spalling at high temperatures, different types of fibre reinforcement based on steel, glass, carbon, basalt, jute, polyvinyl alcohol (PVA), polypropylene (PP), polyacrylonitrile (PAN), etc., are used. The highest preference, for the reduction of explosive spalling, is using hybrid-fibre reinforcement. The advantages of incorporating fibres in concrete structures improve mechanical and durability properties [10]. Studies on the influence of steel and polypropylene fibres on the mechanical characteristics of concrete after being exposed to high temperatures are shown in Table 1. In general, fibres made up of steel improve the mechanical properties of concrete when subjected to high temperatures, such as compression, flexural, and splitting tensile strength, as testing temperatures are lower than the steel fibres melting point. Hence, throughout the testing phase, ductility provides significant resistance to failure under strain [11]. Concrete reinforced with steel fibres resists thermal spalling better than concrete reinforced with polypropylene fibres [12].

Polypropylene fibre can be incorporated to enhance the material properties to resist cracking, and also improves the behaviour of concrete under tension. Polypropylene fibre has melting and ignition points around 150 °C and 400–500 °C. When polypropylene fibre-reinforced concrete is open to temperatures higher than 400 °C, the residual compression, flexural, and splitting tensile strengths decrease [13]. Accordingly, concrete reinforced with polypropylene fibres resists thermal spalling better over concrete without fibres [14]. At room temperature, ultra-high-performance concrete with the incorporation of steel and polypropylene fibre has slightly lower compressive strength than concrete with steel fibre additions, certainly as a result of the material’s lower density [15]. To achieve high thermal resistance, polypropylene fibre should be used at an optimal dose of between 0.1% and 0.5%. As fibre length increases, reinforced concrete with polypropylene fibres ability to withstand high temperatures also increases [16].

2.2 Supplementary Cementitious Materials

Portland cement is partially replaced with low-cost, pollution-free, natural pozzolanic materials or industrial by-products, lowers the greenhouse gas emission during Portland cement production. To reduce cost, cement usage, industrial waste, and enormous CO2 emissions, cement is largely substituted by supplemental cementitious materials [18, 19]. In order to enhance the characteristics of concrete, fly ash (FA), ground granulated blast-furnace slag (S), metakaolin (K), and silica fume (SF) are now often used as a partial substitution for cement in concrete [20]. Table 2 shows some of the supplementary cementitious materials that were partially replaced with cement when it is exposed to high temperatures.

2.3 Behaviour of Aggregates at Elevated Temperatures

Concrete is widely used construction material, and as a result, it has a significant effect on the environment and is essential for the construction industry [22]. At high temperatures, a thermal differentiation in cement paste and aggregate occurs, when aggregates expand by losing their thermal stability at high temperatures and cement paste shrinks. Microcracks begin to form in the ITZ and cement paste as a result, which lowers the concrete’s ability to perform mechanically. As a result, the aggregate’s thermal behaviour is dependent on their chemical composition, mineralogy, and petrographic origin [23, 24]. When subjected to high temperatures, concrete behaves in a way that has lower thermal strain coefficient and results in internal crystalline stresses and failure, which determines its mineralogical composition and differentiates it apart from other materials characteristics of thermal expansion [25]. When heated, the minerals go through several physical and chemical changes. Hence, there is neither thermal reaction nor weight loss, considering the absence of peaks in the DTA curves from Fig. 2 [26]. At elevated temperatures up to 600 °C, the limestone and dolomite are stable. At 700 °C, there is a decomposition of carbon aggregates into CaO and CO2. The melting point of different types of aggregates are igneous rock is over 1000 °C, granites is over 1200–1250 °C, and basalt is over 1050 °C. This variation in melting temperature is because of the mineralogical composition [27].

Differential thermal analysis of aggregates, 10 °C/min heating rate [25]

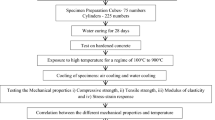

3 Mechanical Characteristics of Concrete at High Temperature

At high temperatures, mechanical characteristics of constituent materials, like compression, flexure, tensile strength, elastic modulus, stress–strain response, and P-M interaction curve, determine whether reinforced concrete sections resist fire. At high temperatures, mechanical tests are typically executed on concrete samples which are generally cubical or cylindrical in shape of different sizes in comparison to specimen measurements at room temperature, in accordance with standards. A range of specimen sizes has been used in tests for mechanical properties since there are no established test standards for conducting high-temperature mechanical characterization [3].

3.1 Compressive Strength

At elevated temperatures, compressive strength is the main factor to consider in the design of fire resistance. The w/c ratio, ITZ phase, curing parameters, type, size of aggregates, and types of admixtures affect the compressive strength of concrete at ambient temperature [28]. Compressive strength of concrete specimens decreases at high temperatures. Removing some of the variables also affects the mechanical properties, such as mix proportions, test modalities, specimen size, stressed conditions, and hot/residual states, the data in Fig. 3 shows the residual compressive strength of unstressed cube specimens, at high temperatures [17]. The residual compressive strength can be used to distinguish between two phases despite inconsistent findings. The compressive strength decreases from ambient to 300 °C by up to 20% of its initial value. From 300 to 800 °C, the compressive strength also dramatically declines [29].

At high temperatures, concrete’s residual compressive strength [17]. ft,20, Compressive strength at ambient temperature; ft,θ, Compressive strength at elevated temperature

3.2 Flexural Strength

In Fig. 4, it is clearly indicating that when concrete is at high temperatures, its flexural strength reduces. With increasing temperatures, concrete reduces its residual flexural strength over time. Depending on the replacement ratio, using cement-replacement materials also leads to a little improvement [30]. Concrete does not undergo any significant volumetric, physical, or chemical changes up to 100 °C before the free moisture evaporates. Evaporation of the free moisture occurs between 93 and 200 °C, during which there are minimal volumetric, chemical, and physical changes. The breakdown of the C–S–H and sulphoaluminate phases takes place between 200 °C and 300 °C, and surface cracking appears. Flexural strength decreases to 40–65% of its initial strength between 400 and 600 °C [31].

At high temperatures, concrete’s residual flexural strength [17]. ft,20, Flexural strength at ambient temperature, ft,θ, Flexural strength at elevated temperature

3.3 Tensile Strength

The majority of the elements impact the tensile strength are homogeneous to those that affect its compressive strength, and also by incorporating steel fibres its tensile strength increases [3]. Tensile stresses are usually responsible for the crack’s development in structure, and the formation of microcracks in structural members during a tension state damages the member [32]. Tensile strength can be particularly crucial in situations when spalling develops in concrete structures, when exposed to fire. Figure 5 shows that the tensile strength has a slight multilinear declining tendency with increasing temperature. Spalling can be decreased by having a higher tensile strength [33]. Permeability, type of fire exposure, and tensile strength are the variables that influence the spalling caused by fire [34].

Tensile strength experimental data show a slight multilinear declining tendency with increasing temperature [35]. ft,20, Tensile strength at ambient temperature, ft,θ, Tensile strength at elevated temperature

3.4 P–M Interaction Curve of Concrete at Elevated Temperature

P–M interaction curve is used to characterize the structurally reinforced member that responds under axial forces and biaxial bending moments. To determine the strengths of reinforced concrete members at ambient temperature considers ultimate limit for concrete’s compressive strain is 0.003 per ACI code [36] or Eurocode-2 [37]. Yet, several studies recommended methods that do not constrain the ultimate strain. A P-M curve is an important method of evaluating the structural performance of components made of reinforced concrete at high temperatures. Figure 6. shows the effect of fire on reinforced concrete columns. The thermo-mechanical properties and rebar at high temperatures should be reflected in reinforced concrete columns fire resistance [38]. At high-temperature loads, its ultimate strain limit is less noticeable than it is when concrete is at ambient temperature. Due to reduction in strength, temperature, and creep strain, concrete that is exposed to both temperature and mechanical stresses exhibits dramatically higher strains. As a result, practical techniques like the 500 °C isothermal approach are used [2].

Effect of fire on reinforced concrete columns [39]

3.5 Modulus of Elasticity

Fire resistance influences the concrete’s modulus of elasticity, which declines as temperature increases which as shown in Fig. 7. Exposure of concrete to high temperatures, hydrated cement products to disintegrate and bonds will break down at micro level, reducing the elastic modulus. The w/c ratio, age of concrete, conditioning technique, quantity of materials, kind of aggregates affects the modulus of elasticity [28]. The amount of moisture and microstructure of hydrated cement concrete are mainly responsible for the degradation in elastic modulus with temperature. Due to shrinkage and micro cracking caused by moisture loss, the modulus of concrete degrades up to 400 °C. Elastic modulus reduces from 400 to 750 °C as a result of the degradation of the aggregate-paste bond due to thermal variations and the early stages of Ca(OH)2 and C–S–H disintegration [15]. Resistance to deformation of concrete is measured by the Modulus of elasticity, which helps to determine the development of stresses, deflections, and moments in the structural elements.

At high temperatures, concrete’s residual modulus of elasticity [17]

The physical characteristics of concrete deteriorate at high temperatures. Whereas, during the drying process, when the temperature rises, bond dissociation and a reduction in stiffness lead elastic modulus to decline [40]. By incorporating fibres, modulus of elasticity improves when compared to ordinary concrete. Figure 8 illustrates the residual modulus of elasticity varies for different fibre contents at high temperatures. Around 150 °C, it is noted that fibre-reinforced concrete has a minimal percentage decrease in elastic modulus. At 300–500 °C, loss in elastic modulus is increased by 40–70%. However, as the percentage of fibre is increased, the residual modulus of elasticity drastically decreases by 25%.

At high temperatures from 0 to 600 °C, residual elasticity modulus for various fibre compositions [41]

3.6 Stress–Strain Response

The reaction of mechanical characteristics is governed by the stress–strain relationship, and these properties are widely utilised as data in mathematical models [42]. When temperature rises, material property of concrete degrades, which is a characteristic of concrete behaviour. Exposure of concrete to high temperatures, the stress–strain relationship peak, shifts downwards and rightwards and the curves become flatter, as shown in Fig. 9. These studies suggest that while concrete’s peak stress and elasticity modulus decreases as temperature increases, peak strain increases.

At high temperatures, concrete’s stress–strain response [28]

4 Thermal Properties of Concrete at High Temperature

Thermal conductivity, specific heat, thermal diffusivity, mass loss, and spalling are among the thermal characteristics that affect concrete at high temperatures. The effectiveness of a substance that affects heat conduction is called thermal conductivity. The steady-state and transient circumstances are two distinct types of heat transfer across materials [43]. In a steady-state, the heat flow is continuous and time-independent. While in transient method, the temperature is time-dependent and fluctuates with time. To determine the thermal conductivity of concrete, transient approaches are often used over steady-state [44]. The thermal conductivity of typical concrete varies from 1.4 to 3.6 W/m °C at ambient temperature [45]. Due to concretes high specific heat, which is the quantity of heat per unit mass, a structure’s temperature stability can be increased. Concrete density, type of aggregate, and amount of moisture content have the most impacts on specific heat. At elevated temperatures, differential thermal analyser (DTA) is often operated to assess specific heat at temperatures of 600 °C and above [46, 47]. The severity of spalling is decreased in the temperature range of 20–750 °C by adding polypropylene fibres to ultra-high-performance concrete without significantly altering the mechanical properties [15].

4.1 Thermal Conductivity

When it comes to concrete, the thermal conductivity value varies. It generally differs with some of the factors like mix proportion, type of aggregates, moisture content, permeability, and density of concrete. The thermal conductivity increases along with concrete density, moisture content, and temperature [48]. Thermal conductivity for fibre-reinforced concretes has a comparable pattern to that of normal concrete when steel and polypropylene fibres are added. Therefore, the thermal conductivity is unaffected by fibres in the temperature ranging from 20 to 800 °C [33]. By incorporating various waste materials, such as recycled aggregates and building and demolition trash that may also contain ceramics, glass, and other materials, there are several elements that might affect the thermal conductivity of concrete [49]. Concrete’s thermal conductivity drastically changes at 120 °C temperature, according to ASTM STP 882 standard curve given in below Fig. 10.

Thermal conductivity versus temperature of normal weight concrete as per ASTM STP 882 [50]

4.2 Specific Heat

Concrete undergoes various physical and chemical changes at high temperatures, and specific heat is considered in the form of thermal capacity. With an increasing w/c ratio, specific heat increases dramatically and is mostly influenced by moisture content [3]. According to Eurocode-2, Fig. 11 shows how specific heat capacity varies with temperature. At temperatures below 200 °C, moisture content has a significant effect. When temperatures are lower than 800 °C, the aggregate type has negligible effect on heat capacity. Concrete specific heat capacity with moisture contents of 1.5% and 3%, respectively, increases by a factor of 2.2 and 1.6 at 100 °C, according to Eurocode 2.

Variations in concrete’s specific heat capacity at high temperatures [51]

4.3 Mass Loss

Concrete loses moisture when exposed to high temperatures, which causes a reduction in density. Concrete is often divided into normal and lightweight concrete based on its density. Moreover, the aggregate type has a major impact on the mass of concrete at elevated temperature [52]. The difference in concrete mass made of siliceous and carbonate aggregates up to 1000 °C temperatures is seen in Fig. 12. Up to approximately 600 °C, neither siliceous nor carbonate aggregate concretes experience significant mass loss [53].

Variations in concrete mass using various types of aggregates at high temperatures [3]

4.4 Spalling of Concrete

The development of high pore pressure, thermal stresses, and a combination of both plays significant roles in the explosive spalling of concrete at high temperatures [54]. Due to the development of high pore pressure, the bound water in cement paste and the water in capillary pores in concrete both changed from liquid to vapour. A temperature gradient is created by heating the surface of concrete pushing moisture both out of the surface and into the inside. Depending on the permeability of the concrete, this causes pore pressures to increase to their highest level away from the surface and causes explosive spalling [55]. The inside of the structure will experience thermal strains as a result of temperature differences from the heated surface to the inner core areas of the concrete. As the heating rate picks up, these gradients will increase. Depending on the mechanical and thermal characteristics of the concrete, various strains caused by the temperature gradient will result in tensile and compressive stresses [54]. Figure 13 shows the explosive spalling of concrete caused by thermal stress as well as pore pressure.

Explosive spalling caused by thermal stress and pore pressure [54]

5 Microstructural Properties

5.1 SEM Analysis

Concrete mix is exposed to different loads and high-temperature circumstances, the Scanning Electron Microscope (SEM) permits analysis of the mechanism of concrete mix’s micro-cracks at micro-scale. Generally, crushed samples are often examined to determine the microstructural characteristics and the interface between the cement matrix and aggregates of the specimens. The concrete structure is internally denser as C–H–S gel is block shaped at ambient temperature. As concrete is exposed to 500–750 °C, there is an increase in the pore size as well as cracks in the matrix which leads to the deterioration of concrete due to larger pores and the formation of cracks at higher temperatures [56,57,58].

The microstructure characteristics of concrete are slightly enhanced by the inclusion of fibres. As shown in Fig. 14, steel fibre diameter changes with temperature as a result of massive amounts of water vapour building up in the porosity next to the steel fibre and matrix, which also causes rust and oxidation [59]. The polypropylene fibres loose their solid structure at 200 °C and create additional pores in the matrix [13].

SEM image of steel-fibre-reinforced concrete that has been exposed to high temperatures [59]

5.2 Porosity Analysis of Concrete

When concrete is subjected to high temperatures, one method for determining the porosity and pore network at the meso and micro scale level is High-Resolution Computed Tomography (HRCT) and micro tomography. Figure 15 shows the micro tomography of concrete samples at different elevated temperatures i.e., at 27, 100, 400, 500, and 800 °C. With an increase in the temperature up to 800 °C, at the meso scale level, the porosity increases up to 800%, as observed by HRCT. At the micro scale level, porosity is increased up to 1400% as observed by Micro Tomography. Hence, a further rise in temperature results in the development of a pore network, which deteriorates the concrete specimen [60].

Micro tomography samples at different elevated temperatures. a original sample specimen, b 27 °C, c 100 °C, d 400 °C, e 500 °C, f 800 °C [60]

6 Research Gaps

-

1.

Most of the studies on mechanical and thermal properties of concrete consider temperatures up to 800 °C only, which is less than the temperature of actual fires.

-

2.

There are limited studies on structure evolution at meso, micro, and nano scale levels when exposed to high temperatures beyond 1000 °C.

-

3.

There is a lack of studies on non-destructive techniques like imaging-based analysis of concrete at elevated temperatures.

-

4.

There are very few studies on thermal analysis like Thermal gravimetric analysis (TGA), Differential Thermal Analysis (DTA), and Dynamic Mechanical Analysis (DMA) of cementitious materials.

7 Conclusions/Summary

-

1.

As the temperature increases, a general decrease is observed in the mechanical characteristics of concrete such as—compressive, flexural and tensile strength, modulus of elasticity and stress–strain response. A noticeable decrease in the strength of concrete is observed after 400 °C.

-

2.

Spalling and microcracking in concrete are reduced with the inclusion of a small amount of steel and polypropylene fibres, which enhances mechanical and durability properties.

-

3.

Mechanical and durability properties are enhanced by incorporating supplementary cementitious materials. Because the composite has smaller average particle size than cement, it enhances the microstructure of the concrete specimen by reducing porosity.

-

4.

A variety of behaviour is observed in constituent materials at elevated temperatures, which depends upon the chemical composition, mineralogy, and crystallographic arrangement of aggregates.

-

5.

The mix proportion, aggregate type, moisture content, permeability, and density of concrete are some of the parameters that impact thermal conductivity. Moisture content has a major effect on specific heat.

-

6.

Thermal conductivity reduces with increasing temperature.

-

7.

Due to loss of moisture content, concrete loses density (or mass) at elevated temperatures. Beyond 600 C temperature, a considerable mass loss occurs in concrete.

References

Joint ACI/TMS Committee 216 (2012) Masonry Society (U.S.) Code requirements for determining fire resistance of concrete and masonry construction assemblies: an ACI/TMS Standard

EN 1992-1-2 (1992) Eurocode 2: design of concrete structures—Part 1-2: general rules—structural fire design

Kodur V (2014) Properties of concrete at elevated temperatures. ISRN Civil Eng 2014:1–15

Khoury GA (2000) Effect of fire on concrete and concrete structures. Prog Struct Eng Mater 2(4):429–447. https://doi.org/10.1002/pse.51

Pimienta P, Alonso MC, McNamee RJ, Mindeguia JC (2017) Behaviour of high-performance concrete at high temperatures: some highlights. RILEM Tech Lett 2:45–52. https://doi.org/10.21809/rilemtechlett.2017.53

MC Alonso, U Schneider (2019) Degradation reactions in concretes exposed to high temperatures. In: Physical Properties and Behaviour of High-Performance Concrete at High Temperature, Springer, pp 5

Malik M, Bhattacharyya SK, Barai SV (2021) Thermal and mechanical properties of concrete and its constituents at elevated temperatures: a review. Constr Build Mater 270:121398

Naus DJ (2005) The effect of elevated temperature on concrete materials and structures—a literature review. Technical Report

Pavani HP, Tezeswi TP (2020) Micro-structure based multi-scale thermo-mechanical characterization of portland cements. Doctor of Philosophy in Civil Engineering

Fort J, Vejmelkova E, Pavlíkova M (2016) High-temperature testing of high-performance fiber reinforced concrete. In: AIP Conference Proceedings. American Institute of Physics Inc

Zheng W, Li H, Wang Y (2012) Compressive stress-strain relationship of steel fiber reinforced reactive powder concrete after exposure to elevated temperatures. Constr Build Mater 35:931–940. https://doi.org/10.1016/j.conbuildmat.2012.05.031

Chen B, Liu J (2004) Residual strength of hybrid-fiber-reinforced high-strength concrete after exposure to high temperatures. Cem Concr Res 34:1065–1069. https://doi.org/10.1016/j.cemconres.2003.11.010

Noumowe A (2005) Mechanical properties and microstructure of high strength concrete containing polypropylene fibres exposed to temperatures up to 200 °C. Cem Concr Res 35:2192–2198. https://doi.org/10.1016/j.cemconres.2005.03.007

Kim YS, Lee TG (2013) An experimental study on the residual mechanical properties of fiber reinforced concrete with high temperature and load. Mater Struct 46:607–620. https://doi.org/10.1617/s11527-012-9918-y

Banerji S, Kodur V (2022) Effect of temperature on mechanical properties of ultra-high-performance concrete. Fire Mater 46:287–301. https://doi.org/10.1002/fam.2979

Gao D, Yan D (2012) Li X (2012), Splitting strength of GGBFS concrete incorporating with steel fiber and polypropylene fiber after exposure to elevated temperatures. Fire Saf J 54:67–73

Ma Q, Guo R, Zhao Z, Lin Z, He K (2015) Mechanical properties of concrete at high temperature—a review. Constr Build Mater 93:371–383

Li X, Snellings R, Antoni M (2018) Reactivity tests for supplementary cementitious materials: RILEM TC 267-TRM phase 1. https://doi.org/10.1617/s11527-018-1269-x

Paul SC, Mbewe PBK, Kong SY, Savija B (2019) Agricultural solid waste as source of supplementary cementitious materials in developing countries. Materials 12:1112

Toutanji H, Delatte N, Aggoun S, Duval R, Danson A (2004) Effect of supplementary cementitious materials on the compressive strength and durability of short-term cured concrete. Cem Concr Res 34:311–319. https://doi.org/10.1016/j.cemconres.2003.08.017

Ramzi S, Hajiloo H (2022) The effects of supplementary cementitious materials (SCMs) on the residual mechanical properties of concrete after exposure to high temperatures—review. Buildings 13:103. https://doi.org/10.3390/buildings13010103

Habert G, Miller SA, John VM, Provis J, Favier A, Horvath A, Scrivener K (2020) Environmental impacts and decarbonization strategies in the cement and concrete industries. Nat Rev Earth Environ 1:559–573

Fib Bulletin 46 (2008) Fire design of concrete structures—structural behaviour and assessment. Technical Report, Lausanne, Swiss

Niry Razafinjato R, Beaucour AL, Hebert RL, Ledesert B, Bodet R, Noumowe A (2016) High temperature behaviour of a wide petrographic range of siliceous and calcareous aggregates for concretes. Constr Build Mater 123(2016):261–273. https://doi.org/10.1016/j.conbuildmat.2016.06.097

Hager I (2013) Behaviour of cement concrete at high temperature. Bull Pol Acad Sci Tech Sci 61:145–154. https://doi.org/10.2478/bpasts-2013-0013

Khoury GA (1992) Compressive strength of concrete at high temperatures: a reassessment. Mag Concr Res 44:291–309. https://doi.org/10.1680/macr.1992.44.161.291

Hager I, Tracz T, Sliwinski J, Krzemien K (2016) The influence of aggregate type on the physical and mechanical properties of high-performance concrete subjected to high temperature. Fire Mater 40:668–682. https://doi.org/10.1002/fam.2318

Anupama Krishna D, Priyadarsini RS, Narayanan S (2019) Effect of elevated temperatures on the mechanical properties of concrete. In: Procedia Structural Integrity. Elsevier B.V., pp 384–394

Fernandes B, Carré H, Mindeguia JC, Perlot C, La Borderie C (2021) Effect of elevated temperatures on concrete made with recycled concrete aggregates—an overview. J Build Eng 44:103235

Abed M, Nemes R, Lubloy E (2020) Performance of self-compacting high-performance concrete produced with waste materials after exposure to elevated temperature. J Mater Civ Eng. https://doi.org/10.1061/(asce)mt.1943-5533.0002989

Azree M, Mydin O, Roosli R (2012) Prediction of elevated temperature flexural strength of lightweight foamed concrete strengthened with polypropylene fibre and fly ash

Chan YN, Peng GF, Anson M (1999) Residual strength and pore structure of high strength concrete and normal strength concrete after exposure to high temperatures. Cement Concr Compos 21:23–27

Khaliq W, Kodur V (2012) High-temperature mechanical properties of high strength fly ash concrete with and without fibers. ACI Mater J 109(2012):665–674

Ali F, Nadjai A, Silcock G, Abu-Tair A (2004) Outcomes of a major research on fire resistance of concrete columns. Fire Saf J 39:433–445

Van der Merwe JE (2022) Evaluation of concrete tensile strength as a function of temperature. Constr Build Mater. https://doi.org/10.1016/j.conbuildmat.2022.127179

Building Code Requirements for Structural Concrete (ACI 318–14) (2014) Commentary on building code requirements for structural concrete (ACI 318R-14): an ACI Standard and Report from HIS

EN 1992-1-1 (2004) Eurocode 2: design of concrete structures—Part 1–1: general rules and rules for buildings

Kim HS (2021) Obtaining interaction diagram of concrete section exposed to fire by mathematical optimization. J Build Eng. https://doi.org/10.1016/j.jobe.2021.102993

Kang H, Cheon NR, Lee DH, Lee J, Kim KS, Kim HY (2017) P-M interaction curve for reinforced concrete columns exposed to elevated temperature. Comput Concr 19:537–544. https://doi.org/10.12989/cac.2017.19.5.537

Bernhart D (2004) The effect of support condition on the fire resistance of a reinforced concrete beam. DP. Sc. Thesis, Department of Civil Engineering, University of Canterbury, New Zealand. https://doi.org/10.26021/2919

Shallal MA, Sallal Rashid Al-Owaisy L (2007) Strength and elasticity of steel fiber reinforced concrete at high temperatures shear of concrete beams view project-technical report non-linear analysis of continuous composite beam subjected to fire view project. J Eng Dev 11:125–133

Abid M, Hou X, Zheng W, Hussain RR (2017) High temperature and residual properties of reactive powder concrete—a review. Constr Build Mater 147:339–351

ASTM E1530 (2006) Standard test method for evaluating the resistance to thermal transmission of materials by the guarded heat flow meter technique. ASTM International, West Conshohocken

Adl-Zarrabi B, Bostrom L, Wickstrom U (2006) Using the TPS method for determining the thermal properties of concrete and wood at elevated temperature. Fire Mater 30:359–369. https://doi.org/10.1002/fam.915

Bazant ZP, Zdenek P, Kaplan MF, Maurice F (1996) Concrete at high temperatures: material properties and mathematical models. Longman

Phan LT, Carino NJ (2000) Fire performance of high strength concrete: research needs

Howlader MK, Rashid MH, Mallick D, Haque T (2012) Effects of aggregate types on thermal properties of concrete assessment of heritage stone and brick masonry buildings under earthquake actions view project simulation of heritage structures view project

Kim KH, Jeon SE, Kim JK, Yang S (2003) An experimental study on thermal conductivity of concrete. Cem Concr Res 33:363–371

Misri Z, Ibrahim MHW, Awal ASMA, Desa MSM, Ghadzali NS (2018), Review on factors influencing thermal conductivity of concrete incorporating various type of waste materials. In: IOP Conference Series: Earth and Environmental Science. Institute of Physics Publishing

Ulf W (1985) Application of standard Fire curve for expressing natural fires for design purpose. Fire Saf Sci Eng ASTM STP 882

Deshpande AA (2019) Effects of elevated temperatures on concrete materials view project a multiscale study of concrete subjected to elevated temperatures. https://doi.org/10.13140/RG.2.2.24685.64489

Lie TT, Kodur VKR (2011) Mechanical properties of fibre-reinforced concrete at elevated temperatures

DiNenno PJ, Drysdale Dougal, Beyler CL (2002) SFPE handbook of fire protection engineering. National Fire Protection Association

So H-S (2016) Spalling prevention of high-performance concrete at high temperatures. In: High-Performance Concrete Technology and Applications. InTech

Stauder J (2017) Fire performance of ultra high-performance fibres reinforced concrete beams and influence of polypropylene fibres on explosive spalling. https://doi.org/10.13140/RG.2.1.3020.6321

Akca AH, Zihnioglu NO (2013) High-performance concrete under elevated temperatures. Constr Build Mater 44:317–328. https://doi.org/10.1016/j.conbuildmat.2013.03.005

Demirel B, Kelestemur O (2010) Effect of elevated temperature on the mechanical properties of concrete produced with finely ground pumice and silica fume. Fire Saf J 45:385–391. https://doi.org/10.1016/j.firesaf.2010.08.002

Arioz O (2007) Effects of elevated temperatures on properties of concrete. Fire Saf J 42:516–522. https://doi.org/10.1016/j.firesaf.2007.01.003

Zhang P, Kang L, Wang J, Guo J, Hu S, Ling Y (2020) Mechanical properties and explosive spalling behavior of steel-fiber-reinforced concrete exposed to high temperature—a review. Appl Sci (Switzerland) 10:2324

Praneeth PH, Tadepalli TP, Agrawal AK (2020) Characterisation of micro- and meso porosity in Portland cement at elevated temperatures. Mag Concr Res 72:304–313. https://doi.org/10.1680/jmacr.18.00321

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2024 The Author(s), under exclusive license to Springer Nature Singapore Pte Ltd.

About this paper

Cite this paper

Krishna Priya Rao, S., Tadepalli, T. (2024). High-Temperature Behaviour of Concrete: A Review. In: Pancharathi, R.K., K. Y. Leung, C., Chandra Kishen, J.M. (eds) Low Carbon Materials and Technologies for a Sustainable and Resilient Infrastructure . CBKR 2023. Lecture Notes in Civil Engineering, vol 440. Springer, Singapore. https://doi.org/10.1007/978-981-99-7464-1_13

Download citation

DOI: https://doi.org/10.1007/978-981-99-7464-1_13

Published:

Publisher Name: Springer, Singapore

Print ISBN: 978-981-99-7463-4

Online ISBN: 978-981-99-7464-1

eBook Packages: EngineeringEngineering (R0)