Abstract

The insulator of DC gas-insulated transmission line (DC-GIL) will accumulate surface charge under the action of thermal-electric coupling field, which will cause local electric field distortion and make insulator flashover along the surface. In this paper, the actual GIL model is used for simulation. Based on the 3D horizontally mounted GIL model, the surface charge accumulation characteristics of transient DC GIL tri-post insulators under the action of thermal-electric coupling field are studied by COMSOL finite element simulation software. The results show that the surface charge density and the electric field intensity increase by 168 and 19.37% when the temperature gradient is considered at the same position on the belly of the tri-post insulator. Therefore, the distribution of surface charge and electric field under the action of temperature gradient field should be considered when designing and optimizing GIL tri-post insulators.

Access provided by Autonomous University of Puebla. Download conference paper PDF

Similar content being viewed by others

Keywords

1 Introduction

With the construction of hydropower stations, trans-river transmission lines and urban integrated pipeline corridors, gas-insulated transmission lines have been widely used in power systems for their advantages of low loss, low environmental impact and high reliability [1,2,3]. Currently, GIL equipment has been widely used in AC power grid, while its application in DC power grid is rarely reported [4]. The main reason is that under the action of DC voltage, GIL will produce surface charge accumulation on the surface of the insulator, and the accumulation of charge will cause local electric field distortion, resulting in the decrease of insulator flashover voltage [5].

Therefore, many scholars have conducted in-depth research on the characteristics of insulator surface charge accumulation under the action of temperature gradient. Winter et al. [6] considered the influence of temperature on the conductivity of insulating materials. The research shows that when the temperature of the insulating material is greater than 278 K, the dominant way of charge accumulation is through the body conduction of the insulating material, but the influence of convection and radiation on the interior of GIL is not considered in this study. Zhou et al. [7] studied the surface charge distribution under different temperature gradients and considered the influence of convection and radiation within GIL. The research shows that the surface charge accumulation of insulators is aggravated when temperature gradient exists.

The emphasis of the above work is to analyze the surface charge accumulation and electric field distribution of basin insulators under temperature gradient. In the actual operation of GIL, not only basin insulators but also tri-post insulators are used. Because of the geometry of the tri-post insulators, the electric field distribution of the tri-post insulator is more uneven than that of the basin insulator. The uneven distribution of electric field will lead to uneven distribution of charge on the surface of the three post insulators. Therefore, the existing research on basin insulators cannot be directly applied to the evaluation of the insulation of tri-post insulators.

In order to solve the above problems, a ± 500 kV three-dimensional tri-post insulators insulator simulation model is established in this paper. The surface charge and electric field distribution of a tri-post insulator in the presence of temperature gradient are studied. The research results can provide reference for the insulation evaluation of DC-GIL in long-term operation.

2 The Construction of Simulation Model

2.1 Geometric Model

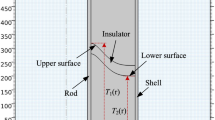

In order to study the surface charge distribution of a tri-post insulator with temperature gradient, a three-dimensional geometric model is established. As shown in Fig. 1.

2.2 Principle of Heat Transfer

In this paper, the effects of convection, radiation and heat conduction on the interior of GIL are considered. The heat conduction is:

where: ρ is density; Cp is the specific heat capacity at constant pressure; q is the conduction heat flux; qr is radiant heat flow; κ is thermal conductivity; T is the absolute temperature; Q is the extra heat source, which is zero for insulators and gases.

The effects of radiation between the high voltage guide rod and the insulator, between the insulator and the metal shell, and between the metal shell and the atmosphere are considered. As follows:

where, eb(T) is the radiated power of all wavelengths; nr is the refractive index; σSB is Stefan-Boltzmann constant; qr is net inward radiant heat flux; εse is the surface emissivity; G is the incoming radiation heat flow.

Convection is a very important heat transfer mode in GIL, and Navier–Stokes equation is used to deal with convection in this model. The specific content of heat transfer can be referred to our previous research [8].

2.3 Charge Accumulation Principle

The current density in the insulating gas is shown below

where, ∂D/∂t is displacement current density; e is the primary charge; E is electric field intensity; n+ and n− are positive and negative ion concentrations respectively; b+ and b− are positive and negative ion mobility; D+ and D− are the diffusion rate of positive and negative ions.

The transport equation of ions is shown in Eqs. (6) and (7)

where, ∂nIP/∂t is the production rate, and its value can be obtained from [9]. kr is the composite coefficient, whose value can be obtained from [10].

The relation between electric field and potential is shown in Eq. (8), the relationship between electric potential and positive and negative ions is expressed by Poisson equation

where, ε is the dielectric constant.

The current density in an insulator can be expressed as:

where, σI(T) is the bulk conductivity of the solid insulating material, whose value can be obtained from [11].

The charge on insulator surface is mainly conducted by the bulk conduction of insulating material, the gas conduction of insulating gas and the surface conduction of insulator surface. Therefore, the charge accumulation process at the gas–solid interface is represented by Eq. (11)

where, ρs is surface charge density; JIn is the normal current density of the insulating material; JGn is the normal current density of the insulating gas; σs is the surface conductivity of the insulating material, and its value can be obtained from [11]. Et is the surface tangential electric field.

2.4 Boundary Condition

The high voltage electrode and the ground electrode are arranged according to the first type of boundary conditions.

where, φHV is the potential of the guide bar; φGND is the potential of the grounding shell; U is the DC voltage applied; In this paper, U = + 500 kV.

The boundary conditions of Eq. (6) and (7) of ion transport equation are defined according to the direction of current:

On the boundary of current outflow, the first type of boundary condition is set for the concentration of positive ions, and the second type of boundary condition is set for the concentration gradient of negative ions.

On the boundary of current inflow, the first type of boundary condition is set for the concentration of negative ions, and the second type of boundary condition is set for the concentration gradient of positive ions.

2.5 Model Verification

To ensure the correctness of the model, the experimental data in the paper of Winter et al. [6] were compared.

Figure 2 shows the comparison results between the simulated values and the experimental measured values at different times. By comparing with the experimental measured values, the simulated values have a good consistency with the experimental measured values.

Comparison of simulation calculated values with experimental measured values in [6]

3 Simulation Results and Analysis

3.1 Temperature Distribution of Insulators and Pipes

In this paper, the load current is 5000 A, SF6 pressure is 0.5 MPa, and the ambient temperature is 20 ℃. Steady-state temperature distribution of GIL pipeline and tri-post insulators is shown in Fig. 3.

3.2 Accumulation Effect of Temperature Gradient on Insulator Surface Charge Accumulation

In this section, the surface charge distribution of a tri-post insulator under the action of a temperature gradient field is studied. The process of insulator charge accumulation is obtained under the load current of 5000 A and SF6 pressure of 0.5 MPa. Taking no temperature gradient as the basis, the transient accumulation process of surface charge accumulation under the action of no temperature gradient field is compared, as shown in Fig. 4. The results were compared for 10, 50, 100, 1000, 8000 and 10,000 h. The left half of the figure indicates that there is a temperature gradient, and the right half indicates that there is no temperature gradient.

As shown in Fig. 4, when the influence of temperature gradient on surface charge is considered, the speed of charge accumulation is faster than that without consideration of temperature gradient, and the amount of charge accumulated under consideration of temperature gradient is also more than that without consideration of temperature gradient at the same time.

3.3 Surface Charge and Tangential Electric Field Distribution of Tri-post Insulators Under Temperature Gradient Field

The temperature distribution of the GIL pipe and insulator has been obtained in the previous subsection. In this section, the distribution of charge and electric field intensity on the surface of the tri-post insulator interface is compared when there is no temperature gradient. The ambient temperature without temperature gradient is set to 20 °C and SF6 pressure to 0.5 MPa.

As shown in Fig. 5a, a large amount of positive charge accumulates on the surface of the tri-post insulator, and a small amount of negative charge accumulates near the ground housing. The charge density is higher in the presence of a temperature gradient than in the absence of a temperature gradient. When the temperature gradient is not considered, the surface charge density is 8.23 μC/m2 with distance of about 202 mm, and the peak surface charge density is 22.07 μC/m2 at the same position with temperature gradient considered, which increases by 168%.

The actual working condition of GIL shows that surface flashover is a very easy fault for tri-post insulators, and the surface flashover voltage of insulators is closely related to tangential electric field intensity. As shown in Fig. 5b, compared with the condition without temperature gradient, tangential electric field intensity is higher in the condition with temperature gradient than in the condition without temperature gradient. When the temperature gradient is not taken into account, the tangential electric field intensity of distance of 202 mm is 2.22 kV/mm; when the temperature gradient is taken into account, the tangential electric field intensity of the same position is 2.64 kV/mm, increasing by 19.37%.

In conclusion, when the temperature gradient is considered, the surface charge density and tangential electric field intensity of the insulator are both higher than that when the temperature gradient is not considered. In addition, a large amount of charge accumulates at the position of the tri-post insulator near the guide bar, which will cause the electric field distortion at the position of the insulator near the guide bar. Therefore, it is necessary to consider the influence of surface charge and electric field distribution on temperature gradient in the optimal design of tri-post insulator structure.

4 Conclusion

In this paper, a DC GIL surface charge accumulation model was built. By comparing with the experimental data in the Winter paper, the simulation values were in good agreement with the experimental results, thus verifying the accuracy of the simulation model. The surface charge distribution of DC-GIL tri-post insulators under temperature gradient field was studied, and the amount of charge accumulated was more than that without considering the temperature gradient. A large amount of positive charge accumulates on the surface of the tri-post insulator, and a small amount of negative charge accumulates near the ground housing.

When the temperature gradient is not considered, the surface charge density is 8.23 μC/m2 with distance of 202 mm and 22.07 μC/m2 with temperature gradient at the same position, which increases by 168%. The electric field intensity of 202 mm distance is 2.22 kV/mm, and the tangential electric field intensity of 2.64 kV/mm at the same position is increased by 19.37% when the temperature gradient is considered.

References

Li G et al (2020) Research progress of environment-friendly gas insulated pipe technology. Trans China Electrotech Soc 35(1):18 (in Chinese)

Zhang C, Zhang B, Li M et al (2023) Research review on key insulation technologies of high voltage direct current GIL equipment. High Voltage Technol 49(03):920–936 (in Chinese)

Xing YQ, Liu L, Xu Y, Yang Y, Li CY (2021) Defects and failure types of solid insulation in gas insulated switchgear: in situ study and case analysis. High Volt

Tenzer M, Koch H, Imamovic D (2016) Underground transmission lines for high power AC and DC transmission. In: 2016 IEEE/PES transmission and distribution conference and exposition (T&D). IEEE, 2016

Okabe S (2007) Phenomena and mechanism of electric charges on spacers in gas insulated switchgears. IEEE Trans Dielectr Electr Insul 14(1):46–52

Winter A, Kindersberger J (2014) Transient field distribution in gas-solid insulation systems under DC voltages. IEEE Trans Dielectr Electr Insul 21(1):116–128

Zhou HY, Ma GM, Li CR, Shi C, Qin SC (2017) Impact of temperature on surface charges accumulation on insulators in SF6-filled DC-GIL. IEEE Trans Dielectr Electr Insul 24(1):601–610

Chen G, Tu Y, Wang C, Cheng Y, Jiang H, Zhou H, Jin H (2018) Analysis on temperature distribution and current-carrying capacity of GIL filled with fluoronitriles-CO2 gas mixture. J Electr Eng Technol 13(6):2402–2411

Kindersberger J, Wiegart N, Boggs SA (1985) Ion production rates in SF6 and the relevance thereof to gas-insulated switchgear. In: Conference on electrical insulation & dielectric phenomena-annual report 1985. IEEE

Morrow R (1986) A survey of the electron and ion transport properties of SF6. IEEE Trans Plasma Sci 14(3):234–239

Yan SY (2022) Study on the effect of electrothermal complex field on insulator surface charge accumulation in SF6. Shenyang University of Technology, Shenyang, pp 21–27, 2022 (in Chinese)

Acknowledgements

This research is funded by the State Grid Company Headquarters Science and Technology Project “Research on Key Technology of GIS Internal Multispectral Optical Imaging Based on Optical Fiber Transmission” (5500-202216134A-1-1-ZN).

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2024 Beijing Paike Culture Commu. Co., Ltd.

About this paper

Cite this paper

He, X., Shi, Y., Shi, W., Jia, J., Li, X. (2024). Study on Charge Accumulation Characteristics of Tri-post Insulators Under Temperature Gradient Field. In: Dong, X., Cai, L. (eds) The Proceedings of 2023 4th International Symposium on Insulation and Discharge Computation for Power Equipment (IDCOMPU2023). IDCOMPU 2023. Lecture Notes in Electrical Engineering, vol 1102. Springer, Singapore. https://doi.org/10.1007/978-981-99-7405-4_23

Download citation

DOI: https://doi.org/10.1007/978-981-99-7405-4_23

Published:

Publisher Name: Springer, Singapore

Print ISBN: 978-981-99-7404-7

Online ISBN: 978-981-99-7405-4

eBook Packages: EnergyEnergy (R0)