Abstract

Acid mine drainage (AMD) is one of the primary environmental concerns in the coal mining industries. It is relatively more common in the coalfield deposited influenced by marine environment. The Makum coalfield, the largest Tertiary coalfields in India, is located in Assam and well known for generating AMD. The assessment of potential AMD has been done using the acid base accounting (ABA) study which serves as the principal tool for predicting the post mining water quality. In this paper a detailed mineralogical study of overburden, the static ABA test for both coal and overburden samples along with their leaching studies have been conducted. The coal seams and laminated carbonaceous shale contain significant amount of pyrite. Mineralogical study of the overburden reveals that dolomite is the dominant controlling mineral with trace amounts of calcite for neutralizing the acid generated by the oxidation of pyrite. The relatively higher amount of dolomite is found to be associated with siltstone and non-laminated (massive) carbonaceous shale. The ABA results indicated that all the coal seams, and few overburden materials have acid generating potential. Concentration of Cr, Cu, Mn, Ni, Pb and Zn in overburden is above their respective crustal abundances. However, Pb is above its crustal abundance in coal. Leaching experiment infers that overburden containing high pyrite has more potential for releasing metals relative to those having less pyrite. Concentrations of Mn, Ni and Pb in the leachate are found to be much higher than their respective water quality guideline. Abnormally high concentration of Mn is found to be associated with the dissolution of siderite. Coal releases significantly high concentration of Ni. The results of ABA and leachate study are nearly consistent with the direct mine discharge quality.

Access provided by Autonomous University of Puebla. Download chapter PDF

Similar content being viewed by others

Keywords

11.1 Introduction

Acid mine drainage (AMD) is a commonly occurring environmental problem associated with coal mining, and it can even last for decades after the mining has been ceased. AMD is characterized by low pH, high SO42− and metal concentrations, particularly Fe. It is caused by the oxidation of sulfide minerals present in coal when they come in contact with atmospheric oxygen and water. AMD is one of the major sources of water pollution that affect the lotic system in numerous interactive ways resulting in serious ecological disasters [1].

Assessment of acid drainage potential is important in the management of large scale disturbances of surface or subsurface materials, especially if they contain significant amounts of sulfide minerals [2, 3]. This assessment is usually carried out through ABA study. This is the most common method for predicting the post mining water quality, and has become a widely adopted technique for overburden characterization [4, 5]. It involves the determination of acid production potential (APP) and neutralization potential (NP) of the overburden materials.

The role of carbonates and silicates in consuming acid generated during oxidation of sulfides viz. pyrite, pyrrhotite and arsenopyrite in determining the water chemistry resulted due to mining activities is well established and reviewed [6]. Carbonate minerals, mainly, calcite and dolomite are very crucial in determining the post-mining water quality and neutralize AMD and helps in inhibition of pyrite oxidation [7]. Static tests have been conducted for determining the NP of several carbonates-, aluminosilicate-minerals and with different rock types [8, 9]. The calcite and dolomite have maximum acid neutralizing capacity. Silicate minerals—pyroxene, amphibole, feldspars, micas, chlorite and clay—have relatively much lower NP, however, olivine, serpentine and wollastonite show significantly elevated NP value than the former silicate minerals. Siderite (FeCO3), though it is a carbonate mineral, has zero NP value [10]. Hence, the type and occurrences of minerals at the mines help to understand the potential environmental impact due to mine discharges.

Release of metals through leaching of overburden and coal subsequent to oxidation of sulfide minerals is a potential source for contaminating water [11, 12], sediment [13] and soil [14] around both active and abandoned coal mines. Leaching of trace elements is one of major pathways for entering into the ecosystem [15]. The concentrations of various elements in both overburden and coal, and their leaching behavior are critical to understand the impact by AMD. Laboratory-scale batch leaching techniques have been widely used, and provide information on leaching potential of elements on either shorter or longer time duration in order to determine the potential impacts of mine overburden at the disposal site [16].

The occurrence of AMD at Makum coalfield of India was earlier reported and well studied [17, 18]. Beside, a significant amount of work has been carried out on the petrography [19], leaching behavior [20], metal distribution [21] and variation of sulfur in coal seams of Makum coalfield [22, 23]. However, mineralogy of overburden, ABA study of both overburden and coal, and metal leaching potential from overburden have received less attention. Therefore, an attempt has been made to study the ABA of overburden and coal from the Makum coalfield along with their metal leaching potential.

11.2 Geological Setting

Makum coalfield in Tinsukia district of Assam is the largest Tertiary coal deposit in India (Fig. 11.1) and covers about 100 km2. It consists of three open cast coal mines, Tikak, Tirap and Ledo and two underground collieries such as Baragolai and Tipong. A total reserve of 453 million tonnes of coal has been estimated by the Geological Survey of India (unpublished, 2019).

Makum coalfield consists of five workable coal seams. Two seams having thickness of 18 m and 6 m are very prominent in the study area. Other seams are highly irregular and sporadic in nature. Coal seams belong to the Tikak Parbat Formation of Oligocene age. It comprises of sandstone, siltstone, mudstone, carbonaceous shale and coal seams. The coal is classified as semi-bituminous in rank with low ash, high sulphur (2–6%) and volatile matter content with very high caking properties [24]. Three forms of Sulphur–sulphate, pyrite and organic sulphur were observed in the Assam coal and about 70–80% of total sulphur remains in organic form [22]. Chandra et al. [25] and Rajarathnam et al. [23] indicated the formation of Makum coalfield under marine influence.

11.3 Materials and Methods

Seventeen overburden samples of sandstone, shale and siltstone; 13 coal samples were collected from different collieries of the Makum coalfield (Fig. 11.1). The solid samples were powdered and passed through 60 mesh for ABA test. The static ABA test was carried out by determining the NP and APP of both coal and overburden. The difference between NP and APP is termed as net neutralization potential (NNP) and the ratio of NP to APP is known as neutralization potential ratio (NPR). The NP, APP and NNP have been expressed in CaCO3 equivalent tons/1000 tons (parts per thousand, ppt). The paste pH, which is a quick measure of acid generation or acid neutralization capacity of materials, was measured based on Price et al. [26] and less than 4.0 was considered potentially acid generating [27]. The paste pH was determined by placing 10 g samples in 50 ml beakers. Ultrapure water was added to the sample at 1:1 solid/solution ratio. The slurry was mixed for 5 s and pH was determined after 10 min by the pH electrode.

The NP of overburden and coal was determined following the standard Sobek method [27]. Fizz test was performed, prior to the Sobek method to determine the requisite amount and strength of HCl needed to be added for dissolving the carbonates. Fizz ratings are shown in Table 11.1. The NP was determined by adding HCl to 2 g of samples, and heated at nearly 90 to 95 °C without boiling until no bubble can be visible. After digestion, distilled water was used to bring the volume in the beaker to 100 ml. The beaker was heated for a minute and then cooled. The digested samples were titrated to pH 7 by using NaOH having normality same as that of the HCl used during the digestion step.

The SobPer method was also employed for comparison because of inability of the Sobek method to allow sufficient time for oxidation of Fe2+ [10]. In the SobPer method, all steps of the Sobek method are to be followed. After titration to pH 7.0, a further digestion using H2O2 was required for complete oxidation of Fe2+ as siderite is very common in the overburden and coal. 0.5 ml of 30% H2O2 was added to the suspension of the Sobek method and slightly boiled for 1 min. Then the solution was allowed to stand at room temperature before retitration to pH 7.0. When there was decrease in pH or the solution turned dark or green after second titration, a further H2O2 treatment was required. Total amount of NaOH consumed during all the titrations was used in determination of NP. However, NP measured from the SobPer method was used in all the calculations. APP was calculated by multiplying 31.25 with wt% of pyritic sulphur. This is based on the assumption that sulphide sulphur is acid generating; and sulphate and organic sulphur are nonacid generating [28].

Overburden and coal samples were sieved through 230 mesh for the detailed mineralogical study carried out by X-ray powder diffraction (XRD) using CuKα and CoKα targets. The sulphide-sulphur content of coal and overburden was measured using ASTM D 2492 and [29] methods respectively. The samples were powdered and sieved (<54 μm) for chemical analysis. Major oxides and trace elements such as Cr, Cu, Mn, Ni, Pb and Zn in overburden were determined using Philips PW 2400 Wavelength Dispersive X-ray fluorescence spectrometer (WDXRF) with Rh target using press pellets. Major oxides of coal were determined from ashed coal (850 °C) samples using WDXRF. Major elemental concentrations were determined from fused beads of ashed coal while total S analysis was done on pressed pellets of whole coal prepared with wax as the binding material. The concentrations of Cr, Cu, Ni, Mn, Pb and Zn in coal were determined by AAS (Perkin Elmer Aanalyst 300) from the digested whole coal using a mixture of HNO3, H2O2 and HF.

Leaching of overburden and coal was carried out at liquid to solid ratio of 20:1 following USEPA (1994) in order to access the potential release of metals under natural weathering. The mixture of powdered overburden with deionized water (pH maintained at 4.2 by adding sulphuric and nitric acids) was gently shaken in an incubator shaker prior to measuring the pH in unfiltered splits collected after 1, 2, 4, 6 and 9 day intervals. Subsequently, the filtrates were analysed for determining the concentrations of the selected metals employing an AAS.

11.4 Results and Discussion

11.4.1 Mineralogy

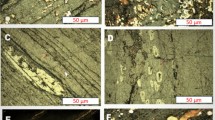

The XRD patterns of overburden materials from the Makum coalfield are shown in Fig. 11.2. Quartz is the dominant mineral in overburden followed by kaolinite and siderite in most of the samples. However, in some overburden, dolomite is the most dominant mineral. Plagioclase has moderate occurrence. Pyrite, calcite, gypsum, melanterite and muscovite occur as minor quantity in most of the samples though in some samples pyrite was present in moderate quantity. Dolomite is abundant in overburden from the Baragolai and Ledo collieries. At Baragolai, Tirap and Ledo collieries, some overburden materials show prominent small peak at 7.6 Å which is assigned to gypsum. The overburden material at Tirap colliery shows sharp and prominent peaks of melanterite at 5.49, 4.92, 3.78, 2.27 Å. The detail mineralogy of overburden samples are given in Table 11.2. From the mineralogical study it is observed that pyrite is associated with the laminated carbonaceous shale, whereas dolomite is the dominant mineral in siltstone and non-laminated carbonaceous shale. The splintery shale, sandstones and sandy shale are found to contain trace amount of carbonates.

11.4.2 Acid Base Accounting

Various results of ABA test are given in Table 11.3. It is observed that the NP measured by the SobPer method is always lower than that of the Sobek method. A similar trend was noticed by several researchers [3, 10, 30], and attributed to the insufficient time for oxidation of Fe2+ to Fe3+ in the Sobek method. Since most of the samples of overburden and coal contain siderite, Sobek method has resulted in the overestimation of NP, but SobPer method is found to give more accurate NP due to complete oxidation achieved by addition of H2O2.

It is observed that the NP value in the overburden ranges from −67.92 to 580 ppt; APP between 0.09 and 41.25 ppt, NNP between −109.1 and 579.9 ppt and NNR between −1.65 and 6444 in the overburden. Further, very high NP of overburden is associated with Baragolai and Ledo collieries while it is intermediate at Tipong, and low at both the Tikak and Tirap. Very high NP values can be attributed to the presence of relatively higher amounts of dolomite and trace amount of calcite which is corroborated with high concentration of CaO and MgO which is up to 20.7 and 9.3% respectively. At Baragolai, it is observed that acidity generated by the oxidation of pyrite (8%) is neutralized by the presence of dolomite (48%). The negative NP at Tikak and Tirap is due to the oxidation of pyrite that is present up to 25% of the total mineral content while trace amounts of dolomite and calcite along with high amounts of quartz and kaolinite are found to be insufficient to neutralize the acid produced. The presence of pyrite is also associated with high concentration of SO3 up to 5.8%. Melanterite which is a common efflorescent salt and often the first mineral to be deposited from aqueous solution at sites of pyrite oxidation has been observed in overburden from Tirap.

The NP value for coal varies from −162.7 to 8.62 ppt. The lowest NP is associated with Tipong and the highest is found at Ledo colliery. The APP ranges between 10.93 and 45.31 ppt with maximum at Tipong. The NNP is negative for all the coal and ranges from −3.57 to −208 ppt while NPR varies from −3.59 to 0.70. The relatively higher APP is possibly due to the abundance of reactive framboidal and very finely disseminated pyrite [17, 23]. All the coal samples contain more than 0.3 wt.% of pyritic-sulphur which is considered to be the threshold for generating AMD [26]. The pyritic-sulphur concentration in coal is above the threshold and ranges from 0.35 to 1.45 wt.% where as in overburden it lies between 0.003 and 1.32 wt.%. Therefore, the post-mining discharge quality is largely depends on the concentration of pyrite in both coal and overburden, and their neutralization potential.

A strong positive correlation between APP and S is observed which indicates that the APP is related to the pyrite content and high concentrations of S (Fig. 11.3a). On the other hand, high NP is associated with large amounts of dolomite besides traces of calcite in overburden. It is further established that high NP is due to high concentrations of Ca and Mg as strong positive correlation between Ca and NP (Fig. 11.3b), and Ca and Mg have been observed (Fig. 11.3d). No strong correlation between AP and Fe is found (Fig. 11.3c). It is possibly due to the fact that Fe is not only present as pyrite but also as siderite, which does not contribute to AP.

It has been reported that the pH of mine discharges at Baragolai and Ledo collieries are found to be mildly alkaline (Table 11.3). It is due to abundance of dolomite and calcite. Mine discharges from the Tikak and Tirap coal mines are highly acidic which is attributed to the more pyrite content in overburden. The pH of the mine discharge from Tipong ranges from 2.3 to 4.2 [17].

The NNP and NPR are commonly used to assess the post-mining water quality more accurately than both NP and APP [5]. The criteria for evaluating mine discharge quality based on NNP and NPR are given in Table 11.4. Based on these, all the coal measures are found to have potential for acid generating (Fig. 11.4). However, based on NPR value, it is found that most of the overburdens can generate net alkalinity except two samples, R-5 and R-9, showing negative NPR. The NNP of most of overburden ranged between 0 and 12 ppt indicating their capacity for generating either acidic or alkaline discharges; but in case of few samples it is much above the threshold for generation of alkaline discharge. NNP result is also negative for the same overburden samples which have acid generating capacity by using NPR. However, the NPR shows a good relationship with paste pH. Therefore, the NPR can be used as better predictor for the post mining discharge quality than NNP.

11.4.3 Metal Concentration and Leaching Study

Among the heavy metals in overburden, it is found that Mn has the highest concentration range, 158–1623 mg/kg, followed by Cr (105–433 mg/kg), Ni (41–309 mg/kg), Zn (5.8–199 mg/kg), Cu (4.5–66 mg/kg) and Pb (13–38 mg/kg). Most of these metals are above their respective crustal abundances and Ni showed the highest enrichment followed by Cr (Fig. 11.5). Similarly, in coal Cr ranges from 0.2 to 26.6 mg/kg, Cu 3.1–48.5 mg/kg, Mn 7.8–115.9 mg/kg, Ni 2.5–211 mg/kg, Pb 14.6–36.9 mg/kg and Zn 11.3–99.4 mg/kg. In contrast to that of overburden, except Pb, all other heavy metals are below their respective crustal abundances in coal.

Time-dependent leaching of metals from overburden and coal was carried out as described earlier. The change in pH and concentrations of metals leached with time are given in Table 11.5. During the leaching of sandstone and siderite-bearing shale, the initial pH of leachate is found to be acidic; however, the pH increases with time and becomes alkaline after 6 days (Fig. 11.6). It is due to dissolution of carbonates present in trace amounts and consumption of H+ by silicates. Shale with higher dolomite content has produced alkaline leachate. After the day 1 the leachate pH has been found to be 7.6 and increased to 8.1 at the end of 9 days. Presence of higher amount of dolomite in overburden has consumed the initial acidity and leachate becomes alkaline. Coal and overburden, those are rich with pyrite, have generated acidic leachate throughout the experiments. The leachate pH has been found in the range of 2.1–2.5 and 1.6–2.9 for coal and pyritic-shale respectively. The leachate from pyrite-rich overburden and coal remains acidic due to the oxidation of pyrite that is responsible to produce acidity (Fig. 11.6).

The concentrations of Mn, Ni and Pb in the leachate has been observed to be higher than their respective water quality guideline values as per the Bureau of India Standards (BIS) (Table 11.6), while concentrations of Cr, Cu and Zn are within their respective limits in leachate from both overburden and coal. Some overburden releases Cr above its permissible limit. Similar to the result obtained from leaching experiments, it has been commonly observed that Mn, Ni and Pb exceed their permissible limits in different coal mine drainages from USA and other countries [17, 32,33,34]. Equeenuddin et al. [17] reported the high concentration of Mn, Ni and Pb in the mine discharges and ground water in the Makum coalfield region.

The leachate generated from the coal and pyrite-rich overburden contains abnormally high metal concentrations with respect to that of the other overburdens. It is attributed to the oxidation of pyrite that causes very low pH (<3). Thus, metals are highly mobilized under strongly acidic environment as solubility of metals increases with decrease in pH [35]. The concentration of Mn in the leachate obtained from siderite dominated overburden is very high (up to 1.76 mg/L) as compared to other non-pyritic ones (up to 0.32 mg/L). It is caused due to its possible association with siderite. Occurrence of Mn in siderite bearing overburden has been earlier reported and indicated siderite as the source for very high concentration of Mn in coal mine drainage [36]. Similarly, abnormally high concentration of Ni (up to 14.5 mg/L) has been found in the coal leachate compared to that of the overburden (up to 4.9 mg/L). This might be due the occurrence of Ni in the exchangebale part of the coal components as it is easily water soluble. Finkelman et al. [37] reported the association of 55% of the Ni in an exchangeable form in coal. Equeenuddin et al. [17] reported abnormally high concentration of Ni (up to 11.13 mg/L) in Makum coal mine drainages relative to that of other places. Therefore, it can be concluded that the results of the leachate chemistry from the mine overburden and coal provides very good information on mine dishcharges and the likely potential metal contamination due to coal mine drainages.

11.5 Conclusion

This study aims to identify the mineralogy of overburden and coal in order to evaluate the acid mine drainage potential vis-á-vis metal leaching characteristics for understanding the impact of mining activities in water, soil and sediment in the Makum coalfield. Dolomite is found to be abundant in the overburden and the most important mineral contributing towards the maximum NP. The coal measures from all collieries are highly acid producing. Siltstones and massive carbonaceous shale are observed to have higher neutralization potential whereas laminated carbonaceous shale are found to be enriched in pyrite and have maximum APP. The results of ABA test is nearly consistent with the direct mine discharge and NPR is found to predict the mine discharge water quality more accurately that that of NNP. Leaching study indicates that the concentration of Mn, Ni and Pb is above their respective allowable limits. Thus, it is proposed that ABA study along with the leaching test of overburden and coal is highly essential to assess the post-mining water quality and its environmental impact.

References

Gray, N. F. (1997). Environmental impact and remediation of acid mine drainage: A management problem. Environmental Geology, 30, 62–71.

Guseva, O., Opitz, A. K., Broadhurst, J. L., Harrison, S. T., & Becker, M. (2021). Characterisation and prediction of acid rock drainage potential in waste rock: Value of integrating quantitative mineralogical and textural measurements. Minerals Engineering, 163, 106750.

Jambor, J. L., Dutrizac, J. E., Raudsepp, M., & Groat, L. A. (2003). Effect of peroxide on neutralization potential values of siderite and other carbonate minerals. Journal of Environmental Quality, 32(6), 2373–2378.

Perry, E. (1985). Overburden analysis: An evaluation methods. In Proceedings Symposium of Surface Mining, Hydrology, Sedimentology and Reclamation (pp. 369–375).

Skousen, J., Simmons, J., McDonald, L. M., & Ziemkeiwicz, P. (2002). Acid-base accounting to predict post-mining drainage quality on surface mines. Journal of Environmental Quality, 31, 2034–2044.

Sherlock, E. J., Lawrence, R. W., & Poulin, R. (1995). On the neutralization of acid rock drainage by carbonate and silicate minerals. Environmental Geology, 25, 43–54.

Perry, E. F., & Brady, K. B. C. (1995). Influence of neutralization potential on surface mine drainage in Pennsylvania. In Proceedings Sixteenth Annual West Virginia Surface Mine Drainage Task Force Symposium (p. 16).

Jambor, J. L., Dutrizac, J. E., Groat, L. A., & Raudsepp, M. (2002). Static tests of neutralization potentials of silicate and aluminosilicate minerals. Environmental Geology, 43, 1–17.

Jambor, J. L., Dutrizac, J. E., & Raudsepp, M. (2007). Measured and computed neutralization potentials from static tests of diverse rock types. Environmental Geology, 52, 1019–1031.

Skousen, J., Renton, J., Brown, H., Evans, P., Leavitt, B., Brady, K., Cohen, L., & Ziemkiewicz, P. (1997). Neutralization potential of overburden samples containing siderite. Journal of Environmental Quality, 26, 673–681.

Daniels, W. L., Zipper, C. E., & Orndorff, Z. W. (2014). Predicting release and aquatic effects of total dissolved solids from Appalachian USA coal mines. International Journal of Coal Science Technology, 1(2), 152–162.

Shan, Y., Wang, W., Qin, Y., & Gao, L. (2019). Multivariate analysis of trace elements leaching from coal and host rock. Groundwater for Sustainable Development, 8, 402–412.

Equeenuddin, S. M., Tripathy, S., Sahoo, P. K., & Panigrahi, M. K. (2013). Metal behavior in sediment associated with acid mine drainage stream: Role of pH. Journal of Geochemical Exploration, 124, 230–237.

Sahoo, P. K., Equeenuddin, S. K., & Powell, M. A. (2016). Trace elements in soils around coal mines: Current scenario, impact and available techniques for management. Current Pollution Reports, 2, 1–14.

Zhou, C., Liu, G., Wu, D., Fang, T., Wang, R., & Fan, X. (2014). Mobility behavior and environmental implications of trace elements associated with coal gangue: A case study at the Huainan Coalfield in China. Chemosphere, 95, 193–199.

Quevauviller, P. H., Van Der Sloot, H. A., Ure, A., Muntau, H., Gomez, A., & Rauret, G. (1996). Conclusions of the workshop: Harmonization of leaching/extraction tests for environmental risk assessment. Science of the Total Environment, 178(1–3), 133–139.

Equeenuddin, S. M., Tripathy, S., Sahoo, P. K., & Panigrahi, M. K. (2010). Hydrogeochemical characteristics of acid mine drainage and water pollution at Makum coalfield, India. Journal of Geochemical Exploration, 105(3), 75–82.

Rawat, N. S., & Singh, G. (1982). The role of micro-organism in the formation of acid mine drainage in the north eastern coal field of India. International Journal of Mine Water, 1(2), 29–36.

Ahmed, M. (1996). Petrology of Oligocene coal, Makum coalfield, Assam, northeast India. International Journal of Coal Geology, 30(4), 319–325.

Baruah, B. P., Saikia, B. K., Kotoky, P., & Rao, P. G. (2006). Aqueous leaching of high sulfur sub-bituminous coals in Assam, India. Energy & Fuels, 20(4), 1550–1555.

Baruah, B. P., Kotoky, P., & Borah, G. C. (2003). Distribution and nature of organic/mineral bound elements in Assam coals, India. Fuel, 82(14), 1783–1791.

Barooah, P. K., & Baruah, M. K. (1996). Sulphur in Assam coal. Fuel Processing Technology, 46(2), 83–97.

Rajarathnam, S., Chandra, D., & Handique, G. K. (1996). An overview of chemical properties of marine-influenced Oligocene coal from the northeastern part of the Assam-Arakan basin, India. International Journal of Coal Geology, 29(4), 337–361.

Mukherjee, S., & Borthakur, P. C. (2003). Effect of leaching high sulphur subbituminous coal by potassium hydroxide and acid on removal of mineral matter and sulphur. Fuel, 82(7), 783–788.

Chandra, D., Chaudhuri, S. G., & Ghose, S. (1980). Distribution of sulphur in coal seams with special reference to the Tertiary coals of North-Eastern India. Fuel, 59(5), 357–359.

Price, W. A., Morin, K., Hutt, N. (1997). Guidelines for the prediction of acid-rock drainage and metal leaching for mines in British Columbia: Part II recommended procedures for static and kinetic testing. In Proceedings of the 4th International Conference on Acid Rock Drainage (pp. 15–30).

Sobek, A., Schuller, W., Freeman, J. R., & Smith, R. M. (1978). Field and laboratory methods applicable to overburdens and minesoils. Industrial Environmental Research Laboratory, Office of Research and Development, US Environmental Protection Agency Report, EPA-600/2-78-054, Cincinnati, Ohio.

Brady, K. B. C., Perry, E. F., Beam, R. L., Bisko, D. C., Gardner, M. D., Tarantino, J. M. (1994). Evaluation of acid base accounting to predict the quality of drainage at surface coal mines in Pennsylvania, U.S.A. In International Land Reclamation and Mine Drainage Conference on the Abatement of Acidic Drainage. Vol. 1: Mine drainage—SP 06A-94 (pp. 138–147).

Sobek, A. A., Skousen, J. G., & Scott, E. F. (2000). Chemical and physical properties of overburdens and minesoils. In R. I. Barnhisel, R. G. Darmody, & W. L. Daniels (Eds.), Reclamation of drastically disturbed lands. Agronomy monograph number 41 (pp. 77–104). American Society of Agronomy, Crop Science Society of America, & Soil Science Society of America.

Haney, E. B., Haney, R. L., Hossner, L. R., & White, G. N. (2006). Neutralization potential determination of siderite (FeCO3) using selective oxidants. Journal of Environmental Quality, 35(3), 871–879.

Perry, E. (1998). Interpretation of acid-base accounting. Chapter 11. In Coal mine drainage prediction and pollution prevention in Pennsylvania. Pennsylvania Department of Environment Protection.

Chon, H. T., Kim, J. Y., & Choi, S. Y. (1999). Hydrogeochemical characteristics of acid mine drainage around the abandoned Youngdong Coal Mine in Korea. Resource Geology, 49(2), 113–120.

Evangelou, V. P. (1998). Environmental soil and water chemistry: Principles and applications. Wiley & Sons.

Sahoo, P. K., Tripathy, S., Equeenuddin, S. M., & Panigrahi, M. K. (2012). Geochemical characteristics of coal mine discharge vis-à-vis behavior of rare earth elements at Jaintia Hills coalfield, northeastern India. Journal of Geochemical Exploration, 112, 235–243.

Saria, L., Shimaoka, T., & Miyawaki, K. (2006). Leaching of heavy metals in acid mine drainage. Waste Management & Research, 24(2), 134–140.

Larsen, D., & Mann, R. (2005) Origin of high manganese concentrations in coal mine drainage, eastern Tennessee. Journal of Geochemical Exploration, 86, 143–163.

Finkelman, R. B., Palmer, C. A., Krasnow, M. R., Aruscavage, P. J., Sellers, G. A., & Dulong, F. T. (1990). Combustion and leaching behavior of elements in the Argonne premium coal samples. Energy & Fuels, 4(6), 755–766.

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2024 The Author(s), under exclusive license to Springer Nature Singapore Pte Ltd.

About this chapter

Cite this chapter

Equeenuddin, S.M., Tripathy, S., Sahoo, P.K., Panigrahi, M.K. (2024). Acid Mine Drainage and Metal Leaching Potential at Makum Coalfield, Northeastern India. In: Das, S.K., Reddy, K.R., Nainegali, L., Jain, S. (eds) Geoenvironmental and Geotechnical Issues of Coal Mine Overburden and Mine Tailings. Springer Transactions in Civil and Environmental Engineering. Springer, Singapore. https://doi.org/10.1007/978-981-99-6294-5_11

Download citation

DOI: https://doi.org/10.1007/978-981-99-6294-5_11

Published:

Publisher Name: Springer, Singapore

Print ISBN: 978-981-99-6293-8

Online ISBN: 978-981-99-6294-5

eBook Packages: EngineeringEngineering (R0)