Abstract

Agricultural by-products are increasingly being used to produce bio-based concretes. Instead of sand, sustainable blocks can be made using natural wastes (sugarcane bagasse was investigated) or agricultural waste materials (cornstalk). These materials are environmentally friendly porous fibers and have excellent sound absorption properties, making them suitable for noise reduction. Click or tap here to enter text. The use of compaction forming technology has allowed the development of a sustainable bio-composites consisting of cornstalks (CS), limestone powder (LP), micro fly ash (FA), gypsum powder (GP), and micro silica flume powder (MSP). The purpose of this experiment was to determine sustainability-based block (SSB)’s apparent density, compressive strength, and thermal conductivity with respect to forming pressure, CS content, and fly ash content. The microstructure changes of typical SSB samples were also analyzed using scanning electron microscopy (SEM). SSB’s compressive strength can be effectively improved by increasing FP, while its apparent density and thermal conductivity are less affected. From 30 to 50%, CS content resulted in a 47% decrease in thermal conductivity and a significant 47% decrease in compressive strength. Thermal conductivity decreased by 9.48% with 20% FA, LP, but apparent density decreased only slightly. The compressive strength of SSB can be increased by 4.17% by adding 10% FA as an admixture to LP and MSP. Thermal conductivity was predicted using a linear empirical model based on apparent density. Through the microstructure changes within SSB, it was also possible to identify the micromechanics underpinning the bonding between LP, FA, MSP, and CS. Building thermal insulation with SSB is based on the findings of the study and aims to develop a SSB brick or block and cheaper block.

Access provided by Autonomous University of Puebla. Download conference paper PDF

Similar content being viewed by others

Keywords

1 Introduction

The issue of climate change and the need to reduce carbon emissions has become a pressing concern for the building industry. Buildings are responsible for a significant portion of the world’s energy consumption and greenhouse gas emissions, with the construction and operation of buildings accounting for nearly 40% of the world’s energy usage and 36% of carbon emissions [1]. Considering this, there is a growing need to develop sustainable building materials and design strategies that can help to reduce the carbon footprint of buildings and move toward net zero carbon emissions [2]. Sustainable building materials refer to materials that are sourced, produced, and used in an environmentally responsible manner, and that have a lower environmental impact than traditional building materials. These materials can include, but are not limited to, materials such as bamboo, straw bale, rammed earth, and reclaimed wood [3]. They can also include products made from recycled materials, such as recycled steel, aluminum, and glass. The use of sustainable building materials can help to reduce the environmental impact of buildings by reducing the amount of energy required to produce and transport the materials, as well as by reducing the amount of waste generated during the construction process [4]. In addition to the use of sustainable building materials, the concept of net zero carbon building involves the integration of energy-efficient systems and technologies, such as solar panels, wind turbines, and geothermal systems, that can help to offset the carbon emissions associated with the building’s energy usage [5]. This can be achieved through a combination of energy conservation and the use of renewable energy sources. The goal of net zero carbon building is to produce as much energy as the building consumes, effectively eliminating its carbon footprint [6].

This paper aims to develop sustainable building materials to develop net zero carbon building, and here developed sustainable based Block which is made from natural waste for this project used sugar cane baggage and cornstalk through compaction forming technology, cornstalk CS and sugarcane baggage bio-composite (CMB) is developed as an eco-friendly sustainable-based block. The engineering properties of CMB were investigated by testing its physical, mechanical, and thermal insulation properties as a function of forming pressure (FP), concrete content (CS), and fly ash content (FA). A scanning electron microscope (SEM) was also used to examine the microstructural properties of typical CMB samples. As a result of these findings, the use of compaction forming technology for manufacturing CMB will become more widespread.

2 Literature Review

A recent literature review has examined the current state of research on sustainable building materials and their potential to contribute to the development of net zero carbon buildings [7]. The literature reviewed focused on materials such as bamboo, rammed earth, and reclaimed wood and how they can be used to reduce the embodied energy and carbon emissions associated with traditional building materials, such as concrete and steel. The literature reviewed found that bamboo, which is a fast-growing and renewable resource, has the potential to be a highly sustainable building material. It requires minimal energy input to process and has a high strength-to-weight ratio, making it suitable for use in construction. Rammed earth, which is made from locally sourced soil, can be created with minimal machinery, and has a low embodied energy, making it an environmentally friendly alternative to traditional brick or block construction. Reclaimed wood, meanwhile, reduces the demand for new wood products and can help to preserve old-growth forests [8]. The literature also highlighted the importance of considering the entire lifecycle of building materials, from extraction and production to disposal or reuse. It emphasized that the use of sustainable building materials in the construction of new buildings and retrofitting existing buildings can significantly reduce the carbon footprint of the built environment and move closer to achieving net zero carbon emissions. Additionally, the literature reviewed also discussed the importance of incorporating sustainable materials into the building design and construction process. It suggests that architects, builders, and designers should work together to ensure that sustainable materials are integrated seamlessly into the building design, to achieve the desired aesthetic and functionality. In conclusion, this literature review has demonstrated that sustainable building materials such as bamboo, rammed earth, and reclaimed wood have the potential to make a significant impact in the construction of net zero carbon buildings. The use of these materials can help to significantly reduce embodied energy and carbon emissions, while also sequestering carbon, thus reducing the overall carbon footprint of buildings. It also emphasized the importance of considering the entire lifecycle of building materials and the need to incorporate them into the building design and construction process to achieve a sustainable built environment.

2.1 Cost–Benefit Analysis

The carbon benefit analysis of SBB compares the amount of CO2 emitted when the blocks are utilized as a fuel source to the amount emitted when the blocks are not used as a fuel source. SBB is an organic energy source manufactured from wood chips, sawdust, and agricultural waste that is renewable and sustainable [5, 6]. SBB are carbon neutral as a fuel source because they do not emit carbon dioxide into the environment as they disintegrate. Rather than relying on nonrenewable energy sources, SBB retains and utilizes carbon as a source of energy, lowering the total carbon footprint. To quantify the carbon benefit of SBB, a lifecycle assessment may be performed, which comprises examining all carbon emissions created during the manufacture of SBB, from harvesting and shipping to manufacturing. The carbon footprint linked with nonrenewable energy sources, like coal and oil production and transportation, must also be evaluated as part of the carbon benefit analysis. A carbon benefit analysis suggests that SBB is a sustainable and ecologically friendly alternative to fossil fuels and can cut greenhouse gas emissions and prevent climate change. In India, agricultural waste management is a serious concern. Among the agricultural wastes produced each year are paddy straw, sugarcane bagasse, cotton stalks, and maize husks. The burning of agricultural waste in the fields pollutes the air, degrades the soil, and causes health concerns. Greenhouse gas emissions are created because of the combustion of agricultural waste. Agricultural waste, which is frequently utilized to manufacture biomass solid bricks, has grown in popularity in recent years. This substance can be used as fuel by the brickmaking industry, for example. By converting agricultural waste into solid bricks through biomass solid brick manufacture, the environmental effect of burning agricultural waste may be mitigated.

3 Materials and Methodology

3.1 Methodology

Research methodology is the process of locating, selecting, analyzing, and evaluating information on a certain topic. It is possible to evaluate a study’s overall validity and reliability by looking at the methodology section of the article. Two critical difficulties were raised in the introduction, and both are addressed in the approaches section. What methods were used to collect or create the data? As far as I know, that’s how it was looked upon. Ultimately, the ultimate purpose of research is to find the truth that has been hidden and has not yet been disclosed by other ways of investigation. The purpose of research is to reveal answers to open-ended issues via the use of scientific techniques. The following general classifications may be used to categorize research objectives: To get acquainted with a phenomena or to obtain fresh insights into it is to familiarize oneself with it, to correctly depict the qualities of a certain person, circumstance, or group of people (studies with this object in view are known as descriptive research studies), for the purpose of determining the frequency with which something happens or with which it is connected with another (studies with this goal in mind are referred to as diagnostic research studies), a hypothesis about a causal link between two variables is being tested. Good research must be systematic, logical, empirical, and replicable. Keeping that in mind a research study must contain a solid and properly structured research methodology.

3.2 Materials

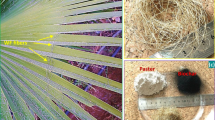

The raw materials used in this study include CS, sugarcane baggage, limestone powder, silica fume, gypsum powder, and FA. The CS was harvested at a farm in the northern India. CS was crushed and screened in the laboratory to a size of 5–15 mm, and we used CS and SCB for our samples. The materials used in the preparation of SBB are lime powder, fly ash, and silica fume. An Indian Refractory Plant supplied pellets of specific surface area of 230 m2 = kg and average particle size of 1.05 mm. Following calcination at 1500 °C for 6 h, MgO powder had a purity of 89.5%. Fine Chemical Plant of Northern Province, India supplied the glue and fiber used in the experiment. It was calcined using commercial MK with a 700 °C calcination temperature. Indian Power Plant supplied the SBB and FA as an admixture. Aggregates and fluid CS and sugarcane baggage are bonded together to form concrete, which hardens over time. Concrete made from Portland CS and sugarcane baggage is the most common type of concrete used today. CS and sugarcane baggage is a major constituent of concrete that is causing alarming environmental damage. For every ton of CS and sugarcane baggage produced, approximately 0.9 tons of carbon dioxide are released into the atmosphere. Greenhouse gases such as carbon dioxide are largely responsible for global warming. Thus, we need to investigate alternative concrete ingredients to reduce the environmental impact of concrete. Green concrete replaces hazardous materials in concrete with eco-friendly materials. Various industrial by-products are used to make green concrete, including fly ash, silica fume, metakaolin, and GGBS. Because these by-products are harmful to the environment, they are used in concrete in a way that ensures their safe disposal and that reduces CS and sugarcane baggage production, another threat to the environment. Researchers have worked on alternatives to CS and sugarcane baggage for years, but this paper examines their work. Lastly, various materials have been compared as alternatives or partial replace CS and sugarcane baggage s of CS and sugarcane baggage.

3.3 Sample Preparation

The binder of Fly ash and gypsum consists of Limestone with a B1, B2, and B3 fixed mass ratio, determined from a preliminary test based on chemical properties of materials and shown in Table 1, the detail about procedure of making block. The premix total mass (TMP) was calculated based on sample size and CS content (defined as the mass ratio of CS to TMP). The FA content was determined by the mass ratio of FA to fly ash binder. Raw materials were weighed accurately (0.01 g) using an electronic balance. The mixing process involved adding dry cementitious materials (limestone, gypsum, silica fume, and FA) to a mixer, then mixing uniformly at low speed with a Los Angeles machine and vibration machine. Water was gradually added, and mixing continued during casting. The samples were cured in a standard room and tested after reaching the designated curing age.

4 Results

4.1 Mechanical Properties

Compression Strength

Unlike traditional structures, modern structures (such as masonry units) don’t support loads. A minimum compressive strength requirement of 4.87 MPa was specified by ASTM for CS and sugarcane baggage blocks. The Indian standard, on the other hand, specifies a minimum compressive strength of 1.35 MPa. In addition to matrix strength and aggregate strength, CS and sugarcane baggage concentration and water-to-CS and sugarcane baggage ratio all influence the compressive strength of concrete. The compressive strength has been reported to decrease in several studies after agricultural waste was substituted for aggregates. A 15% replaces and sugarcane baggage of coarse aggregates with pistachio shells reduced the compressive strength of concrete by 24%. Waste material derived from periwinkle shells also gave similar results. Concrete containing agricultural waste showed less strength than concrete containing coarse aggregate, even when farm waste was substituted for coarse aggregate (Table 2).

A test program was developed to demonstrate the compressive strength of CS blocks. Based on the results, the type of waste used, as well as the percentage of replaced CS and sugarcane baggage, significantly affect the block’s compressive strength decreased as the waste content increased. This may be because agricultural residue has a lower mechanical resistance than sand, as well as the fact that the mortar with agricultural materials added has a greater share of water than CS and sugarcane baggage. The compressive strength of agricultural waste may also decrease, as shown in Table 3, because it is lighter than river sand. Since coconut husk is denser than other agricultural waste, CS and sugarcane baggage blocks containing coconut have greater compressive strengths than those containing sugarcane bagasse, as coconut husk is denser than other agricultural waste materials. Meanwhile, sugarcane yields the lowest compressive strength among the considered agricultural waste materials. In accordance with ASTM C129, most CS and sugarcane baggage blocks meet the specified minimum requirements, except for those with a B1mix ratio. ASTM C129-compliant CS and sugarcane baggage blocks made with coconut husk may be made using a B1 mix ratio. There is no need to incorporate coconut husk in a B1 ratio for the density of the four types of CS and sugarcane baggage blocks that do not contain coconut husk. For example, pistachio shells, sawdust, and coconut husks are all thought to have a similar compressive strength as CS blocks.

Flexural Strength

The ability of a block to withstand flexural loads can be estimated by measuring the flexural stress. In general, a fracture occurs on the tensile side of the block that is closest to the middle of the cross-section. Figure 10 illustrates that flexural all have a role in flexural strength. Similarly, the compressive and flexural strengths of agricultural material decreased. Table 4 represents the flexible strength of cornstalk block in different ratio of materials. Pistachio shells were also utilized, and it was recognized that decreasing their effective binding would decrease the flexural strength. When oil palm shells were used as coarse aggregates, the concrete lost 39% of its compressive strength compared to the control concrete at 30% replace and sugarcane baggage. The present findings are consistent with those obtained by adding coconut husk to the CS and sugarcane baggage mortar. The flexural strength was found to decrease by 23% and 46% at 20% and 50% substitution, respectively, compared with that of the control hardened mortar. The type of waste was considered in this experiment. CS and sugarcane baggage blocks containing coconut husk have higher flexural strength than those containing straw. The experimental results were evaluated using linear regression to generate a proportionality equation relating the flexural strength (ft) of the CS and sugarcane baggage blocks to their compressive strength (fcu) in the conventional form ft = a fcu b.

4.2 Micro-structure Analysis

Figure 11 shows the typical micro images with 10,000 magnifications of CMB, which has 20%, 25%, and 35% CS, respectively, because of SEM tests on SBB. In this study, strong adhesion and excellent biocompatibility of MPC binder were observed between MPC binder and CS. The bonding between MPC and CS was significantly weakened by the addition of CS to the MPC. Particularly after the CMB with 45% CS was cemented with MPC, the strength gain was decreased due to incomplete cemented CS [9]. During the testing of SBB, one of the main mechanisms of agglomeration was improved by the addition of struvite to the MPC, increasing the agglomeration effect between the two products. The microstructure of SBB with CS contents of 45, 10, 15, and 20% is presented under the CS content of 45%. In SBB, FA particles tend to fill the micropores between CS and MPC as the FA content increases. A conglomerate structure is formed inside the SBB by the production of struvite and FA [10]. Additionally, as the FA content exceeds 10%, the porosity also increases significantly. MPC may have weakened its bond with CS due to excessive FA particles delaying hydration. The scanning electron microscopy analysis for CS Block for 7 days casting minerals and it gives the same type of results for 14 days and 28 days, then only with the list of 7, 14 and 28 days results we can analyze the micro structural CS block.

4.3 Cost–Benefit Analysis

An overview of the estimated costs associated with each of the three mixtures developed in this study is provided in the following Table 5. As far as raw materials are concerned, modified fly ash, silica fume, and lime powder are the only product that can be sold along with the cost of producing mixed cement. On the other hand, the remaining materials such as cornstalks, modified fly ash, and PPC cement were freely obtained since they are currently discarded in landfills in India and have not been recycled to date. During the time the raw materials for this research were purchased, the unit prices were based on the market prices on the local Indian market in January 2023. During the cost analysis, it was determined that the total cost per m3 varied between USD 11.75 and 12.6. Approximately 2200% more expensive (B2) was registered for the agriculture waste mixes as compared to the control mix, and the cost increased linearly with the increase in the agricultural waste dosage. However, when cornstalks, modified fly ash, and cement-admixed mixtures were substituted with a small dosage of 5%, their costs were comparable to those of the control mix. Based on their dosages from 5 to 20% and corresponding water requirements, cornstalk, modified fly ash, and cement mixes have a cost variation of 0–6%.

5 Discussion and Analysis

Based on the findings of the study on sustainable building materials to develop net zero carbon buildings, the following points can be discussed and analyzed:

-

A net zero carbon footprint in buildings is achieved by using sustainable building materials [11].

-

The study identified various sustainable building materials that can be used in construction, such as cornstalk, straw bale, and hempcrete, and 17% of Agricultural waste.

-

These materials have lower embodied carbon and can also provide improved thermal insulation and air quality 11.2% is good as compared to clay bricks.

-

The weight and cost of the biomass bricks were found to be 40% lighter than the normal clay bricks [12].

-

The average compressive strength of the clay bricks was average 4.97 MPa and of the biomass bricks was 5.37 MPa, and the results show that the biomass bricks have higher compressive strength [13].

-

The study suggests that the adoption of sustainable building materials in construction can significantly reduce carbon emissions up to 97%, which is essential to address the global climate crisis.

-

The study highlights the need for policy interventions and market incentives to promote the adoption of sustainable building materials in construction.

-

Several barriers have been identified as preventing the adoption of sustainable building materials in the construction industry, including the high cost of sustainable building materials, a lack of awareness of their benefits, and the lack of proper regulations.

-

Building materials that are innovative and emerging are sustainable: Based on the study, it is evident that innovative and emerging sustainable building materials can reduce the carbon footprint of buildings, including cross-laminated timber, engineered wood, and bio-based materials. The effectiveness, scalability, and cost-effectiveness of these strategies require further investigation [14].

6 Conclusion

To conclude, the study on sustainable building materials to develop net zero carbon buildings has highlighted the importance of using environmentally friendly resources in the construction industry. Several studies have documented that the use of sustainable building materials, such as bamboo, cork, and recycled materials, can significantly reduce the carbon footprint of buildings. The study has also demonstrated that the use of these materials can improve the overall energy efficiency of buildings and contribute to the reduction of greenhouse gas emissions. A major aim of the study is to provide insights into the challenges and barriers that need to be overcome to increase the adoption of sustainable building materials in the construction industry. Sustainability materials are expensive, there is a lack of awareness and understanding of their benefits, and there are no proper regulations in place. The study has also provided a set of recommendations for further research and practical applications of sustainable building materials in the construction industry. There is a need for further research on the long-term performance of sustainable building materials, for the development of guidelines and standards, and for the creation of financial incentives aimed at encouraging the use of sustainable building materials. Based on the results of this study, it can be concluded that the use of sustainable building materials is an essential part of achieving net zero carbon buildings and reducing the carbon footprint of the construction industry. Researchers have published findings that can be used by architects, builders, and policymakers to make informed decisions regarding the development of the built environment and contribute to its sustainability.

References

Kazmi SMS, Munir MJ, Wu YF, Hanif A, Patnaikuni I (2018) Thermal performance evaluation of eco-friendly bricks incorporating waste glass sludge. J Clean Prod 172:1867–1880. https://doi.org/10.1016/j.jclepro.2017.11.255

Ahmed ATMF, Islam MZ, Mahmud MS, Sarker ME, Islam MR (2022) Hemp as a potential raw material toward a sustainable world: a review. Heliyon 8(1):e08753. https://doi.org/10.1016/j.heliyon.2022.e08753

Karić N et al (2022) Bio-waste valorisation: agricultural wastes as biosorbents for removal of (in)organic pollutants in wastewater treatment. Chem Eng J Adv 9. https://doi.org/10.1016/j.ceja.2021.100239

Souza AB, Ferreira HS, Vilela AP, Viana QS, Mendes JF, Mendes RF (2021) Study on the feasibility of using agricultural waste in the production of concrete blocks. J Build Eng 42. https://doi.org/10.1016/j.jobe.2021.102491

Jannat N, Hussien A, Abdullah B, Cotgrave A (2020) Application of agro and non-agro waste materials for unfired earth blocks construction: a review. Constr Build Mater 254:119346. https://doi.org/10.1016/j.conbuildmat.2020.119346

Lang L, Duan H, Chen B (2020) Experimental investigation on concrete using corn stalk and magnesium phosphate cement under compaction forming technology. J Mater Civ Eng 32(12):1–11. https://doi.org/10.1061/(asce)mt.1943-5533.0003487

Naga Sai MS, De D, Satyavathi B (2021) Sustainable production and purification of furfural from waste agricultural residue: an insight into integrated biorefinery. J Clean Prod 327:129467. https://doi.org/10.1016/j.jclepro.2021.129467

Odlare M, Lindmark J, Ericsson A, Pell M (2015) Use of organic wastes in agriculture. Energy Procedia 75:2472–2476. https://doi.org/10.1016/j.egypro.2015.07.225

Liberalesso T, Tassi R, Ceconi DE, Allasia DG, Arboit NKS (2021) Effect of rice husk addition on the physicochemical and hydrological properties on green roof substrates under subtropical climate conditions. J Clean Prod 315:128133. https://doi.org/10.1016/j.jclepro.2021.128133

Delhomme F, Prud’homme E, Julliot C, Guillot T, Amziane S, Marceau S (2022) Effect of hemp on cement hydration: experimental characterization of the interfacial transition zone. Results Chem 4:100440. https://doi.org/10.1016/j.rechem.2022.100440

Lahri A, Dixit S (2015) Alternatives to cement in concrete—a review. Int J Sci Eng Res 6(10):50–56 [Online]

Al-Jabri K, Hago AW, Al-Saadi S, Amoatey P, Al-Harthy I (2022) Structural and thermal performance of sustainable interlocking compressed earth blocks masonry units made with produced water from oilfields. Case Stud Constr Mater 17:e01186. https://doi.org/10.1016/j.cscm.2022.e01186

agro waste.pdf

Qaidi SMA, Tayeh BA, Isleem HF, de Azevedo ARG, Ahmed HU, Emad W (2022) Sustainable utilization of red mud waste (bauxite residue) and slag for the production of geopolymer composites: a review. Case Stud Constr Mater 16:e00994. https://doi.org/10.1016/j.cscm.2022.e00994

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2024 The Author(s), under exclusive license to Springer Nature Singapore Pte Ltd.

About this paper

Cite this paper

Rauniyar, A., Krishnaraj, L. (2024). Study on Sustainable Building Materials to Develop Block for Net Zero Carbon Building. In: Gencel, O., Balasubramanian, M., Palanisamy, T. (eds) Sustainable Innovations in Construction Management. ICC IDEA 2023. Lecture Notes in Civil Engineering, vol 388. Springer, Singapore. https://doi.org/10.1007/978-981-99-6233-4_26

Download citation

DOI: https://doi.org/10.1007/978-981-99-6233-4_26

Published:

Publisher Name: Springer, Singapore

Print ISBN: 978-981-99-6232-7

Online ISBN: 978-981-99-6233-4

eBook Packages: EngineeringEngineering (R0)