Abstract

Electric vehicles will replace combustible automobiles to enhance driving performance and cut emissions, all of which will contribute to sustainable development. The potential to lengthen an electric vehicle's range is necessary for proper EV operation. BLDC motor drives are the most viable for electric vehicles as they have a simple structure, less weight, a broader speed range, noiseless operation, strong starting torque, accurate and precise control, and high dynamic responsiveness as compared to a DC motor. But torque oscillations cause increased noise, vibrations, and inefficiencies. The most popular controllers are direct torque control (DTC) and field-oriented control (FOC). But DTC has disadvantages, including problems with control at low speeds with huge current and torque pulsation formation. Hence, a field-oriented control (FOC) of a BLDC motor utilizing sinusoidal pulse width modulation (SPWM), space vector pulse width modulation (SVPWM), a fuzzy/PID logic control scheme (FLC/PID), and finally a bio-intuitive spider web-based algorithm control scheme has been compared. The torque pulsation values, the controller expense for each case, as well as the settling time and peak overshoot for the speed obtained are explored to evaluate the effectualness of the techniques for electric vehicle implementation. The system assessment is performed using the MATLAB/Simulink platform.

Access provided by Autonomous University of Puebla. Download conference paper PDF

Similar content being viewed by others

Keywords

1 Introduction

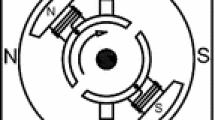

The performance of an electric traction drive is defined by the electric motor, which is a vital part. In contrast to an AC motor, a DC motor requires a commutator and brushes, which are subject to wear and tear and need frequent maintenance. Some of the most popular AC motor drives for electric vehicle applications alongside their pros and cons are presented in [1]. Because of the benefits of BLDC motors, such as higher torque-to-weight ratio and compact size, they are a viable option for lighter electric vehicles [2].

Harmonics triggered by back-EMF and flux linkage are both non-existent in a BLDC motor's stator since it is coreless. Mutual torque generates only an effectual ripple [3]. Torque ripple is the fundamental issue of BLDC motors used in industrial applications. In the literature, multiple control methods to reduce torque ripples for a BLDC motor-fed electric vehicle have been reported. The most popular controllers are direct torque control (DTC) and field-oriented control (FOC). The FOC is also known as vector control, which is a type of current vector control created for variable frequency motor drives and voltages, resulting in electromagnetic field control [4]. Unlike the FOC, the DTC does not necessitate the use of a current regulator, a complicated coordinate transformation, or a large number of parameters. But DTC has disadvantages, including problems with control at low speeds with huge current and torque pulsation formation [5]. Contemporary DTC utilizes torque and flux hysteresis controls, resulting in higher torque and flux fluctuations [6, 7]. PI controllers have major deficiencies, notably in response to a change in load conditions. Hence, using a blend of fuzzy and PID methodologies, a controller has been designed to supervise the BLDC motor's speed and torque ripple control [8]. In industrial applications, there are several different pulse width modulation techniques available. Out of this, the SVPWM outperforms SPWM in terms of DC bus utilization harmonic distortion, reducing BLDC torque ripple and enhancing BLDC speed regulation effectiveness [9]. The DC-link capacitor for the drive is large and hefty, and the working temperature reduces its endurance. The cost and size of the driver can be reduced with greater torque ripples by avoiding the use of a DC-link capacitor. A sophisticated control method using a combination filter, which is a regulated capacitor, with a spider web-based controller is proposed [10, 11].

In this work, field-oriented control of a BLDC motor employing conventional sinusoidal pulse width modulation (SPWM), space vector pulse width modulation (SVPWM), fuzzy/PID logic regulator, and ultimately a bio-intuitive spider web algorithm controller has been assessed to check the torque pulsation values, the controller price for each case, as well as the settling time and peak overshoot for speed to test the accuracy of the methodologies.

2 System Description

The system shown in Fig. 1 incorporates the dynamics of a BLDC motor with an AC input to feed a full-bridge diode rectifier, which in turn feeds an inverter to a BLDC motor drive-fed electric vehicle with a large DC-link capacitor for the cases analyzed with PWM controllers like SPWM, SVPWM, and fuzzy/PID controller. When using a spider web-based controller, torque ripples are minimized by coupling a tiny capacitor and a switch. A load torque value of Tm is applied to the drive, to calculate the torque and speed of the motor under various loading conditions. When the BLDC motor is connected to the rectifier-fed inverter arrangement, one switch is always ON during any phase of the motor's operation, while the other switch alternates between being ON and OFF based on the outputs from the Hall sensor. This is known as the buck converter operation of the BLDC motor [11].

Depending on whether the phase current is kept at the reference current or not, the rectified voltage level for a particular reference current is divided into zones 1 and 2. Zone 2 features a non-linear and unexpected phase current. Since torque and phase current are connected, it is clear from (1) that electromagnetic torque Te becomes unmanageable in zone 2 [11]. Here ω will be the angular velocity (rads−1) and t is the time in seconds.

The selected BLDC motor drive's transfer function can be illustrated in (2).

where ωm is the speed of the motor, \({V}_{d}\) is the DC-link voltage, τm is the mechanical time constant, τe is the electrical time constant, and ke is the back-EMF co-efficient. The converter transfer function is given in (3). Gain Kc is used to tune the controller utilizing the Ziegler–Nichols tuning approach.

2.1 Sinusoidal Pulse Width Modulation (SPWM) and Space Vector Pulse Width Modulation (SVPWM)

To generate SPWM signals for an inverter, the triple sinusoidal outputs are probed with a high-frequency carrier triangle signal. The sinusoidal frequency is 50 Hz and the carrier wave frequency is 5 kHz. Gate pulses are generated by the comparator and used to activate the inverter switches. The more advanced PWM variant known as SVPWM is perfect for use with variable frequency drives. There are only eight possible layouts for a voltage source inverter. Only two of the eight have zero switching states, while the other two have zero output voltages, making them non-switching states. Only six of the eight have non-zero output voltages [4].

2.2 Fuzzy/PID Controller with SVPWM

The suggested methodology [11] utilizes Mamdani-type fuzzy set theory, with the integration of common PID controllers [12]. Modifications in fault factors are transferred into linguistic terms with a single output of torque constraint, and membership functions for speed error and deviation in speed have been chosen. The reason for choosing the speed to generate the torque limit is that iq and id will be generated using speed and change in speed errors E and Ce, respectively, for an FOC-controlled system. The iq generated will be proportional to the torque produced. Computational simplicity exists because the triangular membership functions are chosen for both input and output. The output value is the torque limit, as shown in Fig. 2b, which has a clear linear variation with the degree of membership function, whose value ranges from 0 to 1. The input values are speed error and change in speed error, as shown in Fig. 2. Three distinct labeling linguistics have been established, namely, NE—negative error, ZE—zero errors, and PE—positive error, with the corresponding H—high, M—medium, and L—low as listed in Table 1. The defuzzification method chosen will be the centroid method to be processed into a crisp value [13].

2.3 Spider Web-Based Controller

To produce the pulse, an open-loop control approach with two main stages is used. The back emf generated by the BLDC motor is evaluated first, and then the spider jumps between two positions by either making a new web or eating the old web. The pulses given to the inverter are based on the angle switch in the mode of operation of a BLDC motor. In the second step, the spider compares the back-emf value with the input voltage of the inverter, and whenever the value of the back emf falls below the input voltage, the capacitor has to discharge. Hence, a pulse is generated and fed to the switch placed along with a capacitor [14].

3 Simulation Results and Discussion

The BLDC motor specifications chosen are given in Table 2. With an input voltage of 310 V, the rectifier is connected with the large DC-link capacitor, which can be calculated using (4), wherein V is the peak Vdc, frequency is denoted by f, and C is the capacitance of the big DC-link capacitor [14].

The pulse is then successively supplied to inverter switches using fuzzy/PID-based SVPWM, space vector pulse width modulation, and sinusoidal pulse width modulation. The controller has two control loops: an inner current control loop and an outer speed control loop. As a result, a 220 µF capacitor is selected since it offers the best value on the market. We reduce the cost of the motor drive using a spider web-based strategy by swapping out a large DC-link capacitance for a switch and a small capacitor. The value of small capacitor Cs for the spider web-based controller is given as in (6) where Iavg is the average current taken to the motor from the DC bus which can preserve im(t) at Iref [14]. The switch is simple to operate, no additional materials are required to make sure rapid switching. The switching loss of extra switches is not significant due to the lower switching frequency and current connected with the inverter's MOSFETs.

As illustrated in Fig. 3a, a load torque of 10 Nm is initially applied, followed by a load torque of 20 Nm at 6 s, which causes the torque to develop and the speed to fall below their respective rated values at that time. Additionally, utilizing SVPWM and SPWM approaches, Fig. 3b, c displays the corresponding electromagnetic torque generated by the motor. For SVPWM and SPWM, the torque ripples generated are provided by (7) and (8), respectively.

While Fig. 4a, b shows the torque fluctuations produced by the spider web-based controller and the fuzzy/PID controller, respectively, their pulsation values can be calculated using (7) as 14.63% and 7.89%. According to [15, 16], the settling time (Ts), defined as the amount of time needed for the response curve to reach 5% or 2% of the final value, and the overshooting, defined as the maximum peak value of the response curve measured from the desired response of the system, are the two main parameters that should be minimized. The trial-and-error technique is used to determine the PID controller parameters for the scheme. The optimal option for the gains was established by testing with various iterations. As an outcome, we picked 0.6 as the proportional gain, 6 as the integral gain, and 0.002 as the derivative gain. That can all be incorporated straight into the motor controller. The torque pulsations in Figs. 3b, c and 4b show a lower overshoot value of starting torque due to the presence of PID controllers in these techniques compared to the spider web-based controller approach in Fig. 4a, which helps them to reduce or eliminate steady-state error. As the steady-state error is high in the spider web-based controller approach, the settling time of torque after the application of load torque is increased compared to other techniques.

The speed regulation achieved by PWM controllers is shown in Fig. 5a, b, with fuzzy/PID controllers providing the best speed regulation. The calculated values of percentage overshoot and settling time from the corresponding speed responses are given in Table 3, along with a comparison of cost and torque ripples. The ripples are highest for the SPWM method with 18.42%, with an increased settling time of 3.22 s and a speed overshoot of 2.1%. This method is also costly as a large DC capacitor is employed in it. The SPWM, when compared with SVPWM, draws more current with higher pulsations in the torque profile and has lower maximum voltage values. In the spider web-based controller, although it has higher torque ripples of 14.63%, a longer settling time of 2.26 s, and increased overshoot percentages of 2% compared to the SVPWM method, it utilizes only a small capacitor with switch combination, making it an affordable and durable method. A blend of PID and the fuzzy controller has the least torque ripples of only 7.89% with a decreased settling time of 1.98 s and the least speed overshoot of 0.5% with a large capacitor employed in them. In general, they offer better stability to the system by reducing its steady-state error.

4 Conclusion

A field-oriented control (FOC) of a BLDC motor utilizing sinusoidal pulse width modulation (SPWM), space vector pulse width modulation (SVPWM), fuzzy/PID logic control scheme (FLC/PID), and finally a bio-intuitive spider web-based algorithm control scheme has been compared. For choosing the technique best fit for application to an electric vehicle, we may opt for the fuzzy/PID controller-based technique as it has lessened torque ripples and better speed response with improved overshoot percentage and settling time in its speed response than other techniques and provides a stable operation of the system. The spider web-based controller is the cheapest technique as it uses a small capacitor and switch combination, a contrast to the other techniques where the large capacitor is used but the stability of the system is not guaranteed.

As a future scope of this analysis, the cost of fuzzy/PID controller which is high due to the presence of a large capacitor can be considered to be replaced by smaller rated capacitors. This will make the controller affordable and efficient.

References

Kumar M, Moulik B (2021) Dynamic modeling and analysis of control techniques of an induction motor drive for application in an electric vehicle. In: Proceedings–international conference on computing, communication, and intelligent systems 2021, ICCCIS, pp 1037–1042

Gadewar SV, Jain AM (2017) Modelling and simulation of three phase BLDC motor for electric braking using MATLAB/simulink. Int J Electr Electron Data Commun 5(7):48–53

Maharajan MP, Xavier SAE (2019) Design of speed control and reduction of torque ripple factor in BLDC motor using spider based controller. IEEE Trans Power Electron 34(8):7826–7837

Gujjar MN, Kumar P (2017) Comparative analysis of field-oriented control of BLDC motor using SPWM and SVPWM techniques. In: Proceedings–2nd IEEE international conference on recent trends in electronics, information & communication technology 2017, RTEICT, pp 924–929

Korkmaz F, Topaloğlu İ, Çakir MF, Gürbüz R (2013) Comparative performance evaluation of FOC and DTC controlled PMSM drives. In: Proceedings-4th international conference on power engineering, energy and electrical drives 2013, POWERENG, pp 705–708

Patil MS, Medhane R, Dhamal SS (2020) Comparative analysis of various DTC control techniques on BLDC motor for electric vehicle. In: Proceedings-7th international conference on smart structures and systems 2020, ICSSS, pp 1–6

Kumar KVP, Kumar TV (2016) Direct torque control of brush less DC motor drive with modified switching algorithm. In: Proceedings-IEEE international conference on power electronics, drives and energy systems 2016, PEDES, pp 1–5

Apribowo CHB, Musyaffa’ A, Maghfiroh H (2021) Fuzzy logic controller and its application in brushless DC motor (BLDC) in electric vehicle-a review. J Electr Electron Inf Commun Technol 3(1):35–43

Li B, Wang C (2016) Comparative analysis on PMSM control system based on SPWM and SVPWM.In: Proceedings-Chinese control and decision conference 2016, CCDC, pp 5071–5075

Fathima A, Vijayasree G (2021) Design of BLDC motor with torque ripple reduction using spider-based controller for both sensored and sensorless approach. Arab J Sci Eng 47(3):2965–2975

Samitha Ransara HK, Madawala UK (2015) A torque ripple compensation technique for a low-cost brushless DC motor drive. IEEE Trans Ind Electron 62(10):6171–6182

Nanda B (2015) Fuzzy logic based field oriented control of permanent magnet synchronous motor. Int J Electr Electron Data Commun 3(8):27–33

Dhamodharan RV, Kowsalya M, Priyadharshini G (2015) SVPWM based performance analysis of BLDC motor. Int J Adv Res Electr, Electron Instrum Eng 4(3):1570–1576

Veni KSK, Kumar NS, Gnanavadivel J (2017) Low-cost fuzzy logic-based speed control of BLDC motor drives. In: Proceedings-2017 international conference on advances in electrical technology for green energy 2017, ICAETGT, pp 7–12

Chowdhury R (2020) Cob-web building controller for reduced torque ripples in BLDC motor drive. Int J Res Appl Sci Eng Technol 8:725–732

Sharma PK, Sindekar AS (2016) Performance analysis and comparison of BLDC motor drive using PI and FOC. In: Proceedings-international conference on global trends in signal processing, information computing and communication 2016, ICGTSPICC, pp 485–492

Ahmed AM & Ali-Eldin A, Elksasy M, Areed F (2015) Brushless DC motor speed control using both PI controller and fuzzy PI controller. Int J Comput Appl 109:29–35

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2024 The Author(s), under exclusive license to Springer Nature Singapore Pte Ltd.

About this paper

Cite this paper

Chowdhury, R.R., Koperundevi, G. (2024). Performance Evaluation of Brushless Direct Current Motor for an Electric Vehicle with Various PWM-Based Controllers. In: Goyal, S.K., Palwalia, D.K., Tiwari, R., Gupta, Y. (eds) Flexible Electronics for Electric Vehicles. FLEXEV 2022. Lecture Notes in Electrical Engineering, vol 1065. Springer, Singapore. https://doi.org/10.1007/978-981-99-4795-9_2

Download citation

DOI: https://doi.org/10.1007/978-981-99-4795-9_2

Published:

Publisher Name: Springer, Singapore

Print ISBN: 978-981-99-4794-2

Online ISBN: 978-981-99-4795-9

eBook Packages: EnergyEnergy (R0)