Abstract

You will be able to understand the following after reading this chapter:

Access provided by Autonomous University of Puebla. Download chapter PDF

Similar content being viewed by others

You will be able to understand the following after reading this chapter:

-

Principles and application of different external techniques of fracture fixation such as bandages, splints, slings, casts, and modified Thomas splint

-

Basic principles and techniques of internal fixation such as intramedullary pins/nails, bone plate, and screws, minimally invasive percutaneous osteosynthesis, and ancillary fixation devices such as orthopedic wires and screws

-

Indications, biomechanics, and different types of external skeletal fixation systems, linear ESF systems for small animals, transfixation pinning and casting, bilateral linear ESF system for large animals, circular ESF, epoxy-pin fixation, and complications of ESF

-

Splint and bandage, the most economical orthopedic application, can be used as a first aid to stabilize fractures temporarily, to prevent preoperative or postoperative swelling or as a primary fixation method in closed fractures of the distal limb bones especially in lightweight animals.

-

Velpeau sling is used to hold the shoulder joint in flexion, while Ehmer sling is used to stabilize the hip joint.

-

Fiberglass cast, a synthetic alternative to the plaster of Paris cast, is preferred for both small and large animal applications as it has greater strength and durability, is lightweight, sets quickly, and allows immediate weight-bearing on the limb.

-

Intramedullary (IM) Steinmann pin is the most widely used internal fixation device in veterinary practice as it can resist bending forces well and maintain bone alignment due to its central position in the medullary cavity. Cross IM pinning can provide stable fixation of small segment fractures, such as supracondylar femoral fractures, with minimal damage to the growth plate.

-

Interlocking nail system is useful to repair comminuted long bone fractures, as the nail is secured to the bone cortex using fixation bolts that provides rotational stability and prevents collapse of fracture segments. Locking plate with threaded screw holes is biomechanically superior to conventional dynamic compression plate.

-

In minimally invasive plate osteosynthesis technique, a bone plate is applied in a bridging fashion through small incisions without exposing the fracture site.

-

External skeletal fixation (ESF) is a versatile and minimally invasive orthopedic procedure with excellent mechanical properties allowing early return to function of the affected limb.

-

The circular and hybrid ESF systems can provide stable fixation of long bone fractures and are effective to treat fractures in angularly placed bones such as the tibia and transarticular stabilization of fractures with small bone segments near the joint.

-

The epoxy-pin fixation technique, wherein the bent fixation pins are incorporated within the epoxy mold to construct the connecting side bars, can be easily applied with minimal facilities and can provide stable fixation of fractures in different species of animals weighing up to about 100 kg.

Fracture fixation techniques can be broadly classified as external fixation techniques, internal fixation techniques, and external skeletal fixation techniques. The basic principle of any technique is to provide stable bone fixation by immobilizing the fractured bone segments to enable early bone healing and functional recovery of the injured limb. The way and the extent to which it is achieved, however, differ among the techniques, apart from the fracture configuration and location.

2.1 External Fixation Techniques

External fixation or external coaptation, often called as conservative fracture management, refers to immobilization of fractures and other skeletal abnormalities with devices applied externally, without the use of any invasive technique. External coaptation has been the most widely used technique for fracture management in man and animals for centuries. Although materials may have changed, techniques largely remain the same with few modifications. Among the external fixation techniques practiced today, bandage and splints, plaster/synthetic cast, modified Thomas splints, and splint-cast combinations are widely used in both small and large animal practices [1,2,3,4,5,6]. As external coaptation techniques are relatively inexpensive and non-invasive, they are frequently applied even in situations where they are not ideal or where there is a high probability of complications (where probably surgical fixation is recommended), mostly due to financial or other constraints. Nevertheless, external coaptation is an integral part of every form of orthopedic therapy, be it to prevent swelling, as a first aid to treat fractures temporarily, as a primary means of fixation in specific fractures, or as an additional support in various conditions such as internal fixation of comminuted unstable fractures, arthrodesis, tendon suturing, etc. Proper case and technique selection is essential for successful outcomes.

2.1.1 Bandages

Application of bandage and splint is the simplest and probably the most economical orthopedic application (Fig. 2.1). It does not need any special materials or instruments and can be easily applied. It looks quite easy to apply bandage and splints, but it may get loosened when not tight enough or may cause serious complications when too tight.

Application of bandages may help to cover the wounds and prevent preoperative or postoperative swelling and as a first aid stabilize fractures temporarily. For bandaging, the animal is properly restrained in lateral recumbency, and the affected limb is held upwards. In forelimb applications, the elbow joint is held in fully extended position, whereas in the hindlimbs, the stifle joint is held partially extended. Help can be taken from an assistant to keep the limb in extended position using an anchor tape/adhesive tape applied along the limb extremity or a cotton bandage tied around and above the toes. Cotton stripes are put between the toes, and adequate padding of the limb is done by wrapping an even layer of cotton roll around the limb, starting from the distal end, including the fractured bone, and up to above the joint proximally. Cotton gauze is then firmly applied by twisting over the cotton padding from the distal to the proximal end, so as to leave 1–2 cm of cotton strip out of the bandage proximally. The cotton gauze is then quickly twisted back from the proximal to the distal end, with each new twist covering 1/2–2/3 of the previous. This ‘to and fro’ covering of cotton gauze is done for 3–4 times. The distal end of the limb may be covered using additional gauze flaps placed from the dorsal to the plantar aspect and then secured with twisting the bandage roll around the limb. Finally, after making sure that the bandage is uniform and firm, if needed, additional coverings are reinforced. An adhesive tape is then wrapped around the limb in a circular fashion intermittently to secure the bandage. The bandage so applied should be changed every 3–4 days depending on the case situation, especially in cases with open wounds/fractures.

Elastic bandage can be used to protect from postoperative oedema and swelling. Normally, the bandage is directly applied over the skin, and if there is a need to keep the bandage for more than 3–4 days, it may be applied over the first layer of the cotton padding. While applying the bandage over the limb, it is important to make sure that the pressure is adequate with same level of elasticity. The end of the bandage is secured with an adhesive tape to prevent loosening, and the proximal edge of the bandage is stuck to the skin.

Robert-Jones bandage is used to prevent soft tissue inflammation and to temporarily immobilize the stable limb fractures below the elbow or stifle joint [7]. In this technique, 3–4 thick layers of cotton padding are done around the leg (as described above), which is then tightly and uniformly compressed by covering with cotton gauze roll. Thick cotton padding around the limb prevents any chance of vascular compromise while tightening the gauze roll. If the outer covering is not tightened firmly, there is possibility of slipping of bandage. This can be prevented by applying adhesive tape along the lateral and medial side of the leg from proximal to distal (with a long tail projecting at the tip of the toe) before the cotton is applied and turning it backwards (180°) to stack it to the bandage before completion. This ‘massive’ bandage often causes inconvenience to the animal. Hence, the modified Robert-Jones bandage having much less cotton padding is commonly used in small animals and small ruminants (Fig. 2.2). The bandage can incorporate splints or casts to increase its rigidity. Two to four wooden or aluminum stripes can be sandwiched between the layers of the bandage equally around the leg or a half-leg; molded thermoplastic cast (caudal half for the front leg, cranial half for the hind leg) can be used to make the bandage stiff and strong. The tips of the toes may be excluded while bandaging, which may allow for daily inspection, but too much exposure and constriction around the toe should be avoided not to obstruct the venous blood flow causing swelling. The Robert-Jones bandage is effective for short-term applications only. The elastic bandage provides the compression to the surface of the limb for very short duration, lasting for not more than 24–48 h; hence, it is inappropriate for any use beyond 1–2 days.

2.1.2 Splints

Splints cover only a part of the limb surface, unlike casts which encircle the entire limb. They are indicated in stable closed fractures distal to the proximal 1/3 of the radius or tibia (mostly with intact ulna or fibula). Open fractures with wounds and unstable comminuted fractures are contraindications for its use. Splints can be either prefabricated (mostly made of plastics or aluminum) or custom-made (plaster/fiberglass cast or thermoplastics). Preformed splints are more convenient but they often do not fit adequately. The disadvantage with wooden or plastic sticks is that they do not adapt to the leg (the leg is adapted to the splint), whereas the cast splint can adapt to the contours of the leg. Hence, wooden sticks or plastics can only be used for first aid and for temporary stabilization of fractures and not preferred for definitive treatment (Fig. 2.3). Thermoplastic material is also not used as definitive fixation device as it also does not adapt to the contours of the leg and hence may not provide stable fixation of fracture segments. Molding several layers of casting tape to the limb produces better fracture stability and a more comfortable fit for animal applications. Plaster of Paris can be easily molded along the contours of the leg and is quite resistant against bending load; however, it is not resistant against humidity and may lose its strength upon wetting. Newer synthetic cast materials such as fiberglass cast are strong and can mold to the shape of the limb, but it is costly and more expensive.

Splints should be applied along the length of a fractured leg, distally from the point of the toes/hoof and proximally up to the joint above the fracture site. It should include the carpal joint in metacarpal fractures and the tarsal joint in case of metatarsal fractures, whereas in fractures distal to the elbow (distal 2/3 of radius-ulna) or stifle (distal 2/3 of tibia-fibula) joints, the splint should extend up to the olecranon and tibial tuberosity, respectively (Fig. 2.4). Half/hemi-splint, covering half of the leg surface is generally ideal, as it provides support to the broken bone, allows for swelling, and is easily removed. In forelimbs, the splint is applied along the caudal surface of the antebrachium, as the ulna is longer and courses more superficially than the radius. In hindlimbs, the splint is applied along the cranial surface of the crus as the tibia is located at the cranial aspect and the presence of the Achilles tendon caudally may not allow its proper placement.

For application of splint, under deep sedation, the animal is restrained with the fractured limb downwards but slightly tilted on its back. Fracture segments are reduced and the limb is held extended. The whole leg is then padded with a thin cotton layer, covering the areas of bony prominences, followed by a layer of cotton gauze bandage. A 6–8-layer plaster strip is immersed in warm water (till the air bubbles stop coming), squeezed to remove excessive water, compressed uniformly, and applied at the right place. When still wet, the plaster is contoured to the surface of the limb and allowed to harden. The splint edges are then smoothened by trimming with a pair of scissors (POP) or a saw (fiberglass), and the splint is properly placed. The uncovered part of the leg is padded with the cotton to fill the gap. The plaster splint along with the cotton is then secured around the limb by applying cotton gauze roll from the distal to the proximal end.

In large animals, splint and bandage is often used for temporary stabilization of fractures in straight long bones such as the metatarsus, metacarpus, and radius-ulna (Fig. 2.5). It can also be used as a primary fixation method, especially in lightweight animals. Under sedation, the animal is restrained in lateral recumbency with the fractured leg held uppermost. A long length of cotton gauze/rope is loosely tied around and just above the hoof, to help reduce the fracture by applying traction and counter-traction and to keep the limb in extended position with the help of an assistant. After sprinkling talcum powder over the limb, ‘adequate’ padding of the limb is done by wrapping an even layer of cotton around the limb. A roll of cotton gauze is then firmly wrapped around the limb starting from the distal extremity of the limb and moving upwards, leaving about 1–2 cm cotton strip out of the bandage at the proximal end. After a layer of bandaging, two wooden/metal splints of appropriate length are placed at 90° to each other (one on the medial/lateral aspect and another on the caudal/cranial aspect). In heavy animals, 3–4 splints may be used and are secured by tying cotton gauze roll/ropes around. The width and thickness of the splint may vary as per the animal’s size, but it should not be very light (may break during weight-bearing) or very heavy (may interfere with normal weight-bearing). The length of the splint should span from the hoof up to the joint above the fracture site. The cotton gauze roll is then wrapped over and above the splints by incorporating them within. Depending on the case, several layers of wrapping are done. Extra turns of gauze roll are taken at the distal and proximal ends to secure the splints properly, and at the level of the joints, extra layers of wrapping are done in figure of ‘8’ fashion to provide additional support against bending stress. Before applying the final layers of the bandage, the anchor tapes/ropes are released by loosening/cutting, and the extra length of cotton sticking out is reflected back and included in the bandage. The splint and bandage is then secured by applying adhesive tape rolls around at places, especially at the distal extremity, proximal end, and at the level of joints.

2.1.3 Slings

Slings are infrequently used for external coaptation in animals [7]. Velpeau sling is used to hold the forelimb joints (carpus, elbow, and shoulder) in flexion by bandaging the limb against the body, thus preventing weight-bearing on the affected limb (Fig. 2.6). It is indicated in stabilization of minor fractures of the scapula and humerus or reduced shoulder luxation. The sling can be applied in standing awake animals or in recumbent animals under general anesthesia. The paw and carpus are held in a slightly flexed position, and cotton padding is done followed by wrapping of the elastic bandage roll. By placing the padded portion in the axillary region, the wrap is continued to cover the elbow and shoulder, holding the limb to the side of the torso and encircling the body. Padding is ideally wrapped behind and in front of the opposite limb alternatively to prevent its slippage. While bandaging, a small window may be left at the distal end of the limb to visualize the toes.

Velpeau sling: (a) the paw of the affected limb is loosely wrapped around (lateral to medial) using a gauze bandage; (b) by keeping the carpus, elbow, and shoulder joints in flexed position, the gauze bandage is taken over the lateral aspect of the limb and chest and brought behind the opposite axilla; (c) several such layers of gauze are applied taking around the flexed carpus; (d) gauze bandaging is completed by taking several layers of wrap around the chest and secured

Ehmer sling, which is more popular in veterinary practice, prevents the patient from weight-bearing on the bandaged hindlimb (Fig. 2.7). It is indicated to provide stability following reduction of a cranio-dorsal luxation of the hip joint. The sling if applied properly helps to abduct and internally rotate the femur and thus keep the femur head within the acetabular cavity. This is not indicated in ventral dislocation of the hip, as abduction of the limb may lead to re-luxation. The technique includes soft padding of the hind paw and metatarsal region followed by elastic gauze application starting from the lateral surface of the paw. The gauze roll is then progressed upwards on the medial side and over the quadriceps. By flexing the leg, the bandage roll is continued laterally over the thigh and medial to the hock joint to take it around the paw. This process is repeated 2–3 times and then the gauze bandage is wrapped around the body by keeping the limb close to the body in a flexed position. At the end, the gauze bandage is fixed using one or two pieces of adhesive tape to prevent loosening of the bandage. The sling is kept in place for about 10–15 days to achieve full stability of the joint, constantly observed, and if get wet or loosened, it is reapplied.

Application of Ehmer sling: (a) the hind paw and metatarsal region are soft padded and the elastic gauze is applied starting from the lateral surface of the paw and is then progressed upwards on the medial side and over the quadriceps; (b) by flexing the leg, the bandage roll is continued laterally over the thigh and medial to the hock joint to take it around the paw; (c) rolling of bandage is repeated 2–3 times; and (d) the gauze bandage is wrapped around the body by keeping the limb close to the body in flexed position and secured using clips or adhesive bandage application

2.1.4 Plaster Cast

Plaster cast is the most widely practiced external fixation technique in both small and large animals [2, 6,7,8]. Plaster bandage consists of a cotton bandage impregnated with plaster of Paris that hardens upon wetting. Plaster of Paris is anhydrous calcium sulfate that has been heated. In the presence of water, the soluble form of calcium sulfate becomes insoluble (hardening) with production of heat (exothermic reaction):

2.1.4.1 Indications and Contraindications

It is indicated in fractures below the mid-diaphysis of the radius or tibia (below the elbow or stifle joint) and is most suitable for straight limb applications like fractures of the metacarpus, radius-ulna, and metatarsus. Plaster should be used in only those fractures which can be closely reduced and maintained with at least 50% of the bone ends in contact. Further, fractures that are expected to heal relatively rapidly are chosen for cast application to reduce the chances of cast-related complications. Plaster cast is contraindicated in proximal bones such as the femur and humerus, as the joints above (hip and shoulder joints) cannot be stabilized adequately by a cast. Generally, it is not indicated in open fractures with soft tissue injury.

Plaster should be applied in fresh cases with no or little soft tissue swelling or when the inflammatory swelling has subsided (after 3–4 days of initial injury), to prevent cast loosening and slippage. Until then, the limb may be immobilized using temporary splinting and bandaging.

2.1.4.2 Biomechanics

Full cylindrical cast of adequate thickness, which conforms to the limb and immobilizes the joints above and below the fracture site, can effectively neutralize bending and rotational forces; however, it is generally unable to resist compressive, shear, and tensile forces. A cast applied straight is better able to resist fracture forces than that applied angularly. As the cast is applied around the limb (bone surrounded by soft tissues), there exists a certain distance between the cast and the bone; therefore, the level of fixation stability achieved is much less than internal fixation and also external skeletal fixation, where the bone segments are directly immobilized using fixation implants. Hence, the bones having least coverage of soft tissues, such as radius-ulna, metacarpus, and metatarsus, are better suited for cast application.

Fracture immobilized by a cast heals by secondary healing, i.e. through external callus formation (suggesting adequate stability to allow revascularization and callus formation), but stability is insufficient to allow primary bone union (micro-movement at the fracture site persists).

2.1.4.3 Technique

Usually, the animal is restrained in lateral recumbency with the fractured limb positioned upwards, under deep sedation or general anesthesia. An assistant can help to maintain proper alignment of bone segments and ensure the correct positioning of the limb. In small animals, adhesive tapes (anchor tape) may be placed along the medial and lateral sides of the foot extending about 10 cm beyond the toes, to hold the limb in an extended position. A cotton bandage may also be tied around the toes to hold the limb and apply tension. In large animals, rope restraint may be used; in heavy animals, the limb can be pulled by applying traction using the wires placed through the holes drilled in the hoof wall.

In general, the limb is placed in a comfortable position, with the normal standing angle preferred during casting. The limb should be dry before cast application. The talcum powder may be sprinkled over the limb (shaving is not needed), and an even layer of cotton is applied around the leg in order to protect bony prominences. The cotton padding is extended 1–2 cm beyond the cast to prevent direct contact with the skin. Over-padding should be avoided to prevent cast loosening; further, it may impair immobilization by allowing movement of fracture segments within the cast. A tube of stockinette firmly fitting the limb may be slipped along the length of the limb (Fig. 2.8). If not, a roll of cotton bandage may be used to wrap the limb in spiral fashion. An assistant (may be two are required in large animals) can hold the limb in traction by grasping the stockinette/cotton bandage above and the anchor tape/rope below the area to be covered by the cast.

Application of plaster cast: (a) adhesive tapes applied along the medial and lateral sides of the foot extending beyond the toes to hold the limb in extended position; (b) a stockinette is slipped along the length of the limb (adopted from Leighton, R.L. 1991. Principles of conservative fracture management: splints and casts. Semin Vet Med Surg. 6 (1): 39–51.)

Plaster of Paris bandage is soaked in warm water for a few seconds until air bubbles cease to appear. It is then removed from the water, squeezed, and wrapped over the limb, starting at the fracture site from the distal to the proximal (Fig. 2.9). Subsequently, remaining POP bandages are applied one by one along the entire limb except for the toe pads in dogs and hooves in large animals. A strip of a few (6–8) layers of plaster can be made wet and applied firmly along the caudal surface of the limb to provide greater strength to fixation (Fig. 2.10). During cast application, formation of folds or indentations should be prevented as they may cause injury and necrosis of the underlying skin. Overstretching and tightening of the plaster cast around the limb should also be avoided.

Application of plaster cast: (a) POP bandage is soaked in warm water for a few seconds until air bubbles cease to appear; (b) POP bandage is removed from the water and squeezed; (c, d) POP bandage is then wrapped around the limb, starting at the fracture site from the distal to proximal (adopted from Leighton, R.L. 1991. Principles of conservative fracture management: splints and casts. Semin Vet Med Surg. 6 (1): 39–51.)

Application of plaster cast: (a) a strip of a few layers of plaster (6–8) is made wet, (b) it is then applied firmly along the caudal surface, and the tapes and the stockinette are reflected back onto the cast at both ends, and (c) the final layers of cast are applied, molded by rubbing the layers of cast using a wet hand; a wet plastic sheet may be used to smoothen the surface, and it is then allowed to dry (adopted from Leighton, R.L. 1991. Principles of conservative fracture management: splints and casts. Semin Vet Med Surg. 6 (1): 39–51.)

The strength of the cast can be increased and weight reduced by incorporating the splints within the cast, especially in large animals. Two wooden/metal rods can be placed 900 to each other. In large animal applications, a ‘U’-shaped walking bar (metal strip) may be placed under the hoof and incorporated into the cast (Fig. 2.11). This can reduce the loading forces on the distal limb and thus help protect the fracture site.

The plaster is molded by rubbing with wet hand after each layer before hardening. And before applying the final layers of cast, the tapes and the stockinette are reflected back onto the cast at both ends. If a rope is used, one should not forget to untie the knot (if applied) before allowing the cast to set. At the end, a wet polythene sheet may be pressed over the wet cast to smoothen the surface.

The plaster cast should generally extend from the toe/hoof up to above the level of the joint proximal to the fracture site. In heavy animals, the full-limb cast extending up to the elbow or stifle joint should be applied even if the fracture is in the metacarpus or metatarsus, especially if it is at the proximal end of the bone near the carpal/tarsal joint. The thickness of the cast may vary depending on the case. In small animal applications, 4–5-layer thick cast is usually adequate; in calves weighing up to 150 kg, 6–8-layer thick cast may be required; and in adult large animals, 12–16-layer thick casts may be needed. The cast should be thicker at the level of the joints (applied in figure of 8 fashion), especially at the hock joint (hindlimb) to resist the stress concentration due to the angulation and movement of the joints.

The plaster is then allowed to become dry and hard before letting the animal bear weight on the limb. This may take about 30–45 min in small animals and about 1–2 h in large animals. However, complete drying and hardening of the cast (attaining full strength) may take 24–72 h depending on the thickness.

‘Bi-halving’ can be done after applying the cast, allowing it to set, and then making it into two halves by cutting longitudinally along the medial and lateral aspects of the cast. After placing back the halved cast on the limb, it is then wrapped with an elastic bandage to hold it firmly. Bi-halving a cast allows examination of the underlying soft tissues if need arises and allows easy removal of the cast if swelling develops, and it can be reapplied. This technique is often used in small animals and rarely practiced in large animals, as bi-halving reduces the fixation strength of the cast considerably.

2.1.4.4 Post-application Care and Management

In open fractures, for drainage and daily dressing of the skin wound, an opening (window) is made in the cast at the level of the wound. The window at the wound site can also be left at the time of cast application. One should remember that creating a ‘window’ in the cast will reduce its strength considerably and make the window site prone for breakage, especially when it is at the level of joints.

Complications can occur with application of cast both in small and large animals [2, 9,10,11]. The toes/hooves are inspected several times during the first 48 h for any swelling, coldness, or constriction. If the toe/hoof gets swollen or gets cold, pressure at the end of the cast should be relieved by removing the cast, and the cast may be reapplied after swelling subsides. Similarly, if the cast gets loosened and slips (due to subsiding of inflammatory swelling present earlier), the cast should be reapplied.

The plastered animal should be kept in a dry place (to prevent the cast from getting wet) with soft bedding (to prevent slippage). Wetting is more common in hindlimbs due to urination; it weakens the cast and may lead to its breakage. Plastic (polythene) sheets may be wrapped around the cast to prevent wetting.

Cast may be retained for up to 3–4 weeks in young dogs, sheep, and goats and 4–6 weeks in adult dogs, sheep/goats, and calves. In adult large animals, clinical union of fracture (development of bridging callus with adequate fracture stability) may normally take place by 8–10 weeks, but often, it may require 12–16 weeks or more. Plaster is removed using a saw after radiographic fracture union (complete bony union with obliteration of fracture line), which generally takes a few weeks to months after the clinical union. After removal of the cast, the affected limb is massaged to promote circulation. Movement is restricted till the limb regains its normal function.

2.1.5 Fiberglass Cast

Fiberglass cast, unlike traditional plaster cast, is strong, lightweight, and radiolucent. Due to its desirable qualities, fiberglass cast has become the preferred type of casting both in human and veterinary orthopedics [12,13,14,15,16].

2.1.5.1 Advantages over Plaster Cast

Fiberglass cast is made of water-activated polyurethane resin combined with bandaging materials, so it offers greater strength and durability. It weighs less and hence more comfortable to the patient. The setting time is very quick and therefore needs less care and restraint during application, and the animal can be allowed to use the limb almost immediately. Fiberglass cast is radiolucent and hence allows better radiographic evaluation of fracture repair. It is also water impermeable (waterproof); therefore, the inside padding does not get wet. If the cast gets wet, it quickly becomes dry.

2.1.5.2 Drawbacks

Fiberglass cast is costlier than traditional plaster cast; hence, it may be a constraint in veterinary practice. As fiberglass cast hardens quickly, there is less time to apply. The synthetic materials leave less room for swelling; if more tightly applied, it may lead to vascular compromise. Knitted fiberglass and resin bandages are less moldable than a traditional plaster, so sometimes a less comfortable fit is achieved. Fiberglass bandage is less smooth and more likely to snag clothing or to cause skin bite injuries.

2.1.5.3 Technique

Technique of application of fiberglass cast is almost similar to that of plaster cast. The fractured limb is first padded with cotton or any other waterproof padding material. Then, the knitted fiberglass bandage is wrapped around the limb in several layers (Fig. 2.12). The use of stockinettes and/or cast padding is essential to avoid direct contact between the cast and the skin. Wearing of protective gloves is a must during its application to prevent sticking of the cast material (once get stick, it is difficult to remove).

When the cast material is immersed in water, it should be squeezed firmly before applying. Cast should be applied quickly, to prevent premature hardening. Application of 3–4 layers of the cast is enough in small animals and 6–8 layers in large animals. Further, application of additional support strip or splints is not needed (stronger than plaster cast). The cast may be smoothed with a smoothing gel or lubricating gel.

2.1.5.4 Post-application Care and Management

A fiberglass cast requires less care and maintenance than a plaster cast, and weight-bearing can be allowed as early as 15–20 min post-application. The limb immobilized with a fiberglass cast should be watched carefully in the first 24–48 h after the application for any swelling, coldness, or bad odor, as there is less room for swelling. Complications are more in equine patients (skin is more sensitive) than bovines. In case of any doubt, the cast should be removed and reapplied after the swelling subsides. For removal of the cast, an electric/power saw is needed, as it is difficult to cut the cast using a hand saw. While cutting the cast, it is taken care to prevent any possible injury to the skin.

2.1.6 Modified Thomas Splints

Modified Thomas splint (Schroeder-Thomas splint) is a whole limb traction splint, wherein the fracture ends are brought together and held in alignment by application of traction in specific directions using traction tapes/ropes/bandages, which are anchored to the supporting side rods [6, 7, 17]. This technique is not widely used in practice nowadays due to the advent of better internal and external skeletal fixation techniques; however, if properly used, it can give satisfactory results in many types of fractures, especially in small lightweight animals. Modified Thomas splint and cast combination has been used successfully for treatment of different long bone fractures in large ruminants too.

2.1.6.1 Indications and Contraindications

Modified Thomas splints are generally indicated for treatment of fractures at the distal femur and humerus, tibia-fibula, and radius-ulna in dogs, cats, sheep, goats, and young calves. Splint-cast combination is indicated in heavy animals. It is either used as a sole method of fracture fixation or as an ancillary method along with internal fixation techniques such as intramedullary pins.

Modified Thomas splint is not indicated in long oblique and comminuted fractures, where it is difficult to reduce the fracture segments by close method and prevent overriding of bone ends. Further, fractures near the joints, unless properly reduced, may lead to malunion and degenerative joint disease.

2.1.6.2 Materials Required

Aluminum rods (for dogs, cats, sheep/goats) or steel rods (for calves/foals) of varied diameter (5–7 mm is adequate in most cases; in adult large animals, 8–12 mm rods may be needed depending on the size of the animal), rod bender, pin cutter, cotton roll, gauze bandage, and adhesive tape are needed.

2.1.6.3 Technique of Application

Under deep sedation/tranquilization (general anesthesia may be preferred where severe overriding of fracture segments is present), the animal is restrained in lateral recumbency with the fractured leg held upwards. The splint is customized to the individual case, so as to fit well to the front limb or hindlimb of the patient.

Firstly, the aluminum rod is bent to make a ring (1½ circle, taking the help of a splint mold or any cylindrical object of appropriate size) to properly fit in the patient’s groin or axilla and secured using adhesive tapes (Figs. 2.13 and 2.14). The size of the ring should be kept adequate to accommodate wrapping of the ring with cotton roll and bandages. For hindlimb splint, the ring diameter should be the distance from the tuber ischii to the tuber coxae. For the forelimb, the distance from the axilla to the midpoint on the scapula should be the diameter of the ring. The ring is bent inwardly (toward medial side) at 45° angle from the vertical rods. The ring is then wrapped with a thin strip of cotton roll and secured with gauze bandage and adhesive tape. Sufficient padding is done at the bottom of the ring to protect the groin/axilla region when the splint is applied with the limb under traction.

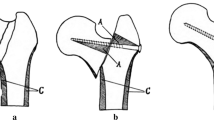

Application of Modified Thomas splint: (a) an aluminum rod is bent to make a ring (1½ circle) and secured using an adhesive tape; (b) the ring is bent at 450 angle from the vertical rods; (c) the limb is temporarily inserted into the rings to determine the length of side rods, and the side bar is bent at the level of the stifle and hock; (d) the extra length of the rod is cut and joined to give the final shape

The limb is temporarily inserted into the rings to determine the length of side rods. The length of the splint should be slightly longer than the extended limb. If the length is too long, it will hinder locomotion; and if it is short, proper tension cannot be applied. The total length of the rod is calculated as 2(3D + 1) + 2 L + 20, where D = diameter of the ring and L = length of the splint bar. For the forelimb, the diameter (D) is the length from axilla to midpoint of the scapula, and the length of bar (L) is the distance from axilla to the tip of the toe in an extended leg, whereas for the hindlimb, the diameter (D) is the length from tuber ischii to tuber coxae, and the length of bar (L) is the distance from the thigh to the tip of the toe in an extended leg.

For forelimb splint, both splint rods (cranial and caudal) are bent slightly at the level of the elbow to conform to the standing angle, whereas for the hindlimb, the caudal as well as the cranial rods can be bent to conform to the standing angles of stifle and hock joints, or the caudal rod can be kept straight without any bend and the cranial rod may be bent at stifle and hock (Fig. 2.15). The distal end of side rods is bent inwards and secured together using adhesive tape.

In bovine calves, iron/steel rods may be used in place of aluminum rods to construct the splint to provide greater strength to fixation (Fig. 2.16). Rings have to be secured by welding (rather than by adhesive tape), and an oval-shaped iron sheet of the size of hoof is welded at the distal end of side rods to provide a suitable anchorage for the hoof. The side rods of the splint are generally kept straight without any angulation/bending. The whole length of side rods may be tightly wrapped with gauze bandage, which is then anchored with adhesive tapes at different places.

At the distal extremity of the limb, adhesive tape strips are attached, one on the dorsal and another on the palmar/plantar surface, and the extended portions of the adhesive tapes are stuck together below the toes (dogs/cats) or hooves (sheep/goats) (Fig. 2.17). A thin layer of cotton roll is wrapped around the limb over the tape strips (from toe up to the knee/hock joint), which is then covered with a firm wrap of gauze bandage and anchored at places using circular wrap of adhesive tape to ensure that the tape strips applied on the limb do not slip while applying traction. In large animals, cotton rope may be anchored above the fetlock using a loose slip knot in place of adhesive tape strips to enable traction with greater force.

Anchoring the limb in MTS: (a) adhesive tape strips are applied on the dorsal and palmar/plantar aspect, and the extended portions of the adhesive tapes are stuck together below the toes; (b) wrapped around the limb using cotton roll and gauze bandage; and (c) securing the tape strip to the ‘U’ bottom of the splint under tension

The limb is inserted into the ring (bend should be held toward the inner/medial side of the limb) and ensured that the ring is properly and firmly fit in the region of the groin/axilla. Traction is applied at the extremity of the limb by tensioning the tapes/ropes and the tape strip/rope is secured to the ‘U’ portion of the splint under tension, in such a way that the leg is slightly rotated inwardly. Then, as per the fracture location and displacement of bone segments, the traction is applied at different levels, and the bones are fixed to the frame using cotton strips or bandages.

2.1.6.4 Application of Traction

The fracture site is supported and secured to the side rods with the help of cotton strips/bandages for applying traction at least at two locations (one above and one below the fracture site) around the non-fractured bones of the limb.

To apply traction, the cotton strip/bandage is secured to the side bar toward the direction at which the traction is desired (say, cranial). It is then wrapped around the portion of the limb by taking it through the medial, caudal, and lateral sides and bringing it back to the original side bar with firm traction, to allow pulling of that portion of the limb toward the side bar (cranial). Few more layers of similar wrappings may be done to provide additional support. The cotton bandage is then encircled around the limb including both side rods 2–3 times and secured using an adhesive tape.

In middle or distal diaphyseal fractures of humerus, the side rods are bent at a more acute angle at the elbow, and both the foot and the radius-ulna are drawn caudally by using traction bandages (Fig. 2.18). In middle or proximal diaphyseal fractures of the radius-ulna, the side rods are only slightly angled at the elbow to provide an almost straight pull on the limb; the traction is applied caudally at the lower limb as well as at the humerus.

In fractures of the femur or tibia, the lower limb cotton strip/bandage should secure the foot in caudal position. The proximal strip should pull the tibia and stifle (in femoral fractures) or the femur (in tibial fractures) toward the cranial side (Fig. 2.19).

In fractures of carpals/metacarpals, the side bars of the splint are more acutely bent at the hock corresponding to the normal standing angle of the joint. The distal bandage strip should hold the foot caudally and the proximal strip should draw the femur cranially.

Once the splint is properly secured and traction applied appropriately, the entire splint may be covered with a stockinette or cotton bandage rolls and secured using adhesive tapes at desired places, before allowing the weight-bearing on the limb.

2.1.6.5 Postoperative Care

The animal must be checked frequently for any injury at the groin or axilla that may have been caused due to rubbing of the ring. The splint is kept in place for 3–6 weeks as per the fracture type and location or till the radiographic healing occurs. All skin wounds created by rubbing of splint, if any, may be treated with antibiotic ointment/powder.

2.1.7 Thomas Splint-Cast Combination

2.1.7.1 Indication

Modified Thomas splint-cast combination is indicated for treating closed radius-ulna and tibial fractures in heavy large animals, in which full-limb cast alone does not provide adequate immobilization [2, 18,19,20]. Generally, it is not recommended in very young animals and also in cases of severe comminuted fractures and in fractures near the joint (metaphyseal or epiphyseal fractures).

2.1.7.2 Biomechanics

The fractured limb is spared from weight-bearing stresses, which are taken by the splint rods, preventing collapse of the fracture segments. Adequate immobilization of fracture segments allows healing of the bone by external callus formation.

2.1.7.3 Technique

Under sedation or general anesthesia, the animal is positioned in lateral recumbency with the affected limb held upwards. The limb is held in extended position using a tape strip/traction rope tied above the pastern. Alternatively, holes can be drilled in the hoof wall of both distal phalanges, and a suitable size wire threaded through these holes can be used to apply traction and subsequently secure the limb with the splint rod.

An appropriate size steel rod (10–12 mm) is bent from the middle of the rod (using a template) to make a ring (1½ circle), with the extended part of the rod to make the legs (side rods) of the splint (Fig. 2.20). The splint ring should be large enough to properly fit into the axilla or groin region without causing any harm to the bony prominences. Care is also needed to avoid exerting pressure on the scrotum in bulls and udder in dairy cows. The ring is bent at its middle to about 30–40° toward the inner/medial side, and the rod extending from the ring is cut to the limb length. The contralateral normal limb may be used to measure the normal length of the limb.

A second piece of the rod is bent to a U-shaped bar, cut to the length of limb, and fixed to the extended bars of the ring and to the ring itself using adhesive tapes or welded in case of iron/steel rods to provide adequate strength to the splint. The distal end of the splint may be welded to a steel plate, conforming to the hoof. The side rods are not generally bent but kept straight.

The ring is padded using cotton roll and bandages and secured using adhesive tape. The inner portion of the ring must be adequately padded to avoid pressure sores. The side bars of the splint may be padded with foam rubber pipe/cotton roll and bandages for insulation.

The limb is inserted into the ring and the distal end of splint (U-bar) is attached to the foot using the wires threaded through the hoof wall. The splint is firmly anchored in the axillary or groin region so that maximum load can be transferred. However, the limb is fixed to the splint with minimum traction (traction applied should only be sufficient to keep the limb extended and hold the bone segments in alignment) to avoid pressure sores at the contact points of the splint in the axillary or inguinal area and to prevent interference in venous drainage and locomotion.

The cast (preferably fiberglass/POP) is applied first directly over the fractured limb constructing a lightweight cast. Care is taken to prevent medial bowing of the limb by supporting the carpus or hock joint with a sling of plaster bandage. The cast is fixed to the splint using a casting tape, and the splint is then incorporated within the cast to make a splint-cast unit, which would help to prevent limb movement and rotation during locomotion.

In the forelimbs, the limb is attached to both side rods of the splint throughout the length, whereas in the hindlimbs, the thigh is attached to the cranial rod, the hock is attached to both side rods, and the limb below the hock is attached to the caudal side bar of the splint using a casting tape. Generally, the total cast material required is less (about 1/3 to ½ less) than the full-limb cast alone. It is better to extend the cast proximally up to the medial aspect of the ring to strengthen the splint and also to prevent the opposite limb from getting entrapped and to prevent urine and manure accumulation between the skin and the cast.

2.1.7.4 Postoperative Care, Management, and Complications

The animal must be assisted while getting up during the first few days until it learns to rise on its own without help, especially a heavy animal [13]. The animal must be watched frequently to make sure that it is not lying on the splint side. The animal must be inspected for any loosening of the cast around the fracture site leading to slipping of the splint, which can occur after the initial soft tissue swelling subsides. Refracture may be seen in some cases of slipped splint. Hence, in such cases, the splint-cast should be replaced. The animal must also be checked frequently for any injury or decubital ulcers in the flank and inguinal area under the ring; decubital ulcers may also occur due to prolonged recumbency and struggling to rise. They should be checked and treated properly. Splint-cast is kept in place for 6–8 weeks depending on the type and location of fracture and animal’s age and weight.

Laxity in the immobilized limb immediately after removal of the cast is common, which can be reversed gradually by regular exercise. Poor alignment and lateral deviation/outward rotation of the limb are common complications; however, it generally does not adversely affect the fracture healing and functional recovery of the limb.

2.2 Internal Fixation Techniques

Internal fixation of fractures by open reduction provides good alignment and rigid fixation of the bone segments. In small animal practice, internal fixation is the preferred method for fixation of long bone fractures, especially of the femur, humerus, and tibia. It can be achieved either by intramedullary fixation techniques like pinning/nailing or by extramedullary techniques like bone plating. Screws, wires, and staples are generally used as ancillary fixation devices along with plates and nails.

2.2.1 Intramedullary Pin/Nail

Intramedullary (IM) Steinmann pins are most commonly and widely used for fracture fixation in veterinary practice [21,22,23]. Nail/IM pin can be used either alone or along with other ancillary techniques like cerclage wiring. Due to their central position within the medullary cavity, IM pins can resist bending forces well and maintain alignment. Single IM pin cannot, however, resist compression and rotational forces. The technique of IM pinning is simple and needs minimum instruments, such as variable size Steinmann pins, Jacobs chuck with handle and key, and pin cutter in addition to the general surgical instruments. There are different types of IM pinning techniques.

2.2.1.1 Single IM Pin

It is indicated in simple transverse or slight oblique diaphyseal fractures of long bones (mostly the femur, humerus, and tibia). The pin can be introduced either by normograde technique (through one end of the bone) or by retrograde technique (through the fracture site) [21] (Fig. 2.21). In retrograde pinning, after exposing the fracture site through standard surgical incision, the fracture segments are identified and reduced either manually or using forceps. While separating and exteriorizing the bone segments, the bone ends are protected by covering with finger tips, so that the sharp bone ends do not damage the surrounding soft tissues and especially the vessels and nerves. At the exposed distal end of the proximal bone segment, a Steinmann pin of adequate diameter is inserted into the medullary cavity using a chuck until the pin exits the proximal bone cortex (Fig. 2.22). Subsequently, the chuck is reversed and the pin is withdrawn from the proximal end up to the level of fracture site. The bone segments are then aligned and the pin is driven into the medullary cavity of the distal bone segment until it reaches the distal metaphysis or epiphysis, where a resistance to pin insertion is felt. At this time, the chuck is removed, and the extra length of the pin is cut short at the proximal end using a pin cutter. The cut end of the pin is then pushed into the metaphysis/epiphysis by gently hitting the cut end of the pin using the T-handle. Rotating the pin at the point of final seatment should be avoided as it may loosen the pin and predispose to pin migration. Subsequently, the skin is drawn over the cut end of the pin and an interrupted suture may be applied.

Retrograde technique of IM pin fixation in the femur: (a) insertion of IM pin through the distal end of proximal fragment using a chuck; (b) the pin inserted through the proximal cortex; (c) the pin is withdrawn from the proximal end up to the level of fracture site; (d) the bone fragments are aligned and the pin is then driven into the distal bone fragment; and (e) the pin is seated in the distal metaphysis/epiphysis

In normograde technique of pinning, the Steinmann pin is inserted from one end of the bone. Normograde pinning is often done by closed/blind method in recent incomplete or simple transverse and sort oblique fractures with minimal displacement of bone segments after closed reduction [24, 25]. In long oblique/spiral and comminuted fractures, open reduction and fixation are always done. Once the pin reaches at the fracture site, the bone segments are reduced and the pin is then inserted into the medullary cavity of the opposite bone segment. The pin is driven up to the level of metaphysis and ensured that it is properly seated, and then, the extra length of the pin is cut close to the skin level.

There are some basic principles of IM pinning [23, 26]. One should not use pin fixation for non-reconstructable and unstable fracture configurations (comminuted fractures) and where uncontrolled loading is predicted. One should have a pack of large number of pins of different diameter and always select two pins of the same length, one pin for insertion and one pin to be used as a ‘measuring pin’ to estimate the depth of pin insertion in the medullary cavity. It is always better to select a smaller-diameter pin first, because we can easily remove and replace it with a larger pin, if needed. But if we use larger diameter pin first, it cannot be replaced by a smaller pin, and it may lead to pin loosening and migration. Assessment of pin seating can be done by (i) feeling resistance to further insertion, (ii) a measuring pin, or by (iii) radiographic examination. One should not cut and countersink a pin unless we are absolutely certain of its proper position, which can be confirmed by radiography or by image intensifier.

The retrograde pinning has the advantage of simpler passage of pin and easier selection of pin diameter, whereas normograde pinning has the advantage of accurate placement of pins and better purchase at the smaller bone segment (mostly used in metaphyseal/epiphyseal fractures). The diameter of the pin should be near to that of the medullary cavity, i.e. 70–90% of medullary cavity diameter (Fig. 2.23). The pin should run the whole length of the bone and then anchored at the distal metaphysis or epiphysis. The main limitation of single IM pin fixation is its inability to resist rotational forces and inability to hold the bone fragments in comminuted fractures. The use of full-cerclage or hemi-cerclage wires along with single IM pin provides greater stability against the rotational forces, especially in long oblique/spiral fractures.

2.2.1.2 Stack Pins

The use of more than one pin (of relatively small diameter) is indicated in transverse or slight oblique fractures of long bones to provide more stable fixation [27]. It is also indicated in long bones with relatively large medullary cavity, where a single pin cannot fill the medullary cavity adequately (calves and foals in particular). The use of more number of pins can snugly fit the medullary cavity and thus provide enhanced stability against shear and rotational forces [21]. Each pin is inserted through a separate proximal hole into the medullary cavity, preferably allowing the opposite ends of the pins to diverse within the opposite metaphysis (Fig. 2.24). This technique also cannot completely resist the rotational forces and sometimes may lead to pin loosening and migration.

Technique of stack pinning: (a) more than one pins (3–4) are inserted through the proximal fragment through separate holes in the cortex; (b) bone fragments are reduced and the pins are driven across the fracture line into the distal fragment; (c) if needed, one or two more pins are inserted between the multiple stack pins to snugly fit in the medullary cavity; and (d) all the pins are then seated in the distal metaphysis, and the extra length of the pins is cut short at the proximal end

2.2.1.3 Rush Pins

Rush pins, described by Dr. Leslie Rush, are solid curved cylindrical pins [22, 28]. Rush pin has a hooked end, which helps to drive and seat the pin in the bone, and another end is tapered that helps to bounce off the opposite inner cortex of the bone and thus prevent penetration of the bone cortex. Rush pins are indicated for the stabilization of metaphyseal/epiphyseal fractures of long bones, especially at the distal femur and proximal humerus or tibia. Two pins are passed from opposite sides (normally medial and lateral) of the cortex in the smaller bone segment (Fig. 2.25). The pins are inserted at about 30° angle to the long axis of the bone so that they cross each other above the fracture site and then glance off the endosteal surface of the diaphyseal bone to provide spring loaded tension. Bending the pins into a slight curve prior to insertion (prestressing) is useful to prevent penetration of the opposite cortex. Paired Rush pins held in spring loaded tension are expected to provide rotational stability. Rush pinning is contraindicated in very young animals, where the soft bony cortex (with relatively large medullary cavity) may get easily penetrated by the pin. Rush pinning may damage the growth plate leading to its rapid closure and shortening of the bone. Rush pins are also contraindicated in cases where there is longitudinal crack in the bone segment.

Technique of Rush pinning: (a) two proper size Rush pins are inserted on opposite sides of the small distal fragment, alternatively, at an acute angle (300) to the long axis of the bone to exit at the fracture site; (b) bone fragments are held in reduction and the pins are alternatively driven into large proximal fragment; (c) once the pins are driven completely, they glance off the opposite cortex and are held in spring loaded tension; and (d) the pin can be removed using Rush pin driver/extractor and a mallet

2.2.1.4 Cross IM Pins

Cross intramedullary pins (two small diameter Steinmann pins/K-wires) can also be used instead of Rush pins, and they are allowed to exit from the opposite end of the bone to facilitate pin removal in the later stage. This dynamic cross IM pinning using small diameter pins provides stable fixation of small fracture segments (mostly supracondylar femoral fracture or proximal tibial fracture) with minimal injury to the physeal plate [29, 30]. The technique of pin insertion and removal is easier than Rush pinning (Fig. 2.26). As the pins are inserted from the outer surfaces of the condyles, there is generally no interference with the extension and flexion of the joint. Further, the pins are crossed and remain in spring loaded tension; hence, fracture fixation is more stable with rotational stability, and pin migration is also rare.

Cross IM pinning of supracondylar femur fracture: (a) two relatively small diameter pins are inserted from opposite cortices of the small distal fragment, alternatively, at an acute angle (300) to the bone axis to exit at the fracture site; (b) bone fragments are held in reduction and the pins are alternatively driven into the proximal fragment so that the pins are crossed in the medullary cavity above the fracture site; (c) the pins are further progressed into the proximal fragment to glance off the opposite cortex and exit from the proximal end; and (d) the pins are withdrawn from the proximal end so as to seat into the distal end just below the articular surface; and (e) the extra length of the pins is cut from the proximal end

2.2.1.5 Kuntscher Nail

‘Clover leaf’ of ‘V’-shaped Kuntscher nails are hollow IM nails with an ‘eye’ at either ends [31]. They have the advantage of lightweight and can provide three-point fixation. They are indicated in transverse or short oblique fractures of the long bones, especially the femur, humerus, and tibia, where the cortex is good with no longitudinal cracks [22]. The technique is preferred in calves, foals, small ruminants, and large dogs, where medullary cavity diameter is large. The medullary cavity is first reamed using a reamer, and then using a guide wire, a proper diameter K-nail is introduced through one end of the bone (normograde technique, through the trochanteric fossa in femur), driven across the fracture site (after reducing the bone segments using bone clamps) and placed in the distal metaphysis (Fig. 2.27). It is important to cut the nail at one end (lower) to the desired length before insertion by measuring the length of the medullary canal (using preoperative radiograph or using a guide wire during surgery) so that the other end of the nail with the ‘eye’ will be left on the upper side to facilitate removal of the nail after fracture repair. K-nail is removed by a K-nail extractor, which is attached to the nail through the ‘eye’. K-nail extractor is a must during insertion of K-nail as well as for its removal.

Technique of K-nailing: the medullary cavity is reamed using a reamer (a); a guide wire (b) is introduced into the medullary cavity (which will help measure the length of the bone and also guide the insertion of the nail); a proper diameter and length K-nail (c) is inserted along the guide wire (normograde) using the K-nail driver (d) and mallet (e) and seated in the distal metaphysis; K-nail extractor (f) attached to the nail through the ‘eye’ facilitates extraction of the nail

2.2.1.6 Interlocking Nail

Interlocking intramedullary nail is a relatively new and an advanced device used mostly in human and small animal practice [32,33,34,35,36,37]; however, in recent years, it is becoming popular in large animal applications too [38,39,40,41,42,43]. The first interlocking nail (ILN) was described by the German surgeon Gerhard Küntscher in 1939. Johnson and Huckstep in 1986 first reported the use of ILN fixation in experimental dogs with comminuted femoral diaphyseal fracture, which required fluoroscopic guidance. Dueland and his colleagues from the USA in 1993 first reported the use of veterinary ILN system with an alignment guide (jig) for insertion of transverse locking screws. Since then, it is being used more frequently in small animal fracture fixation.

Interlocking nail is basically a cylindrical intramedullary (IM) nail with transverse cannulations secured (locked) in position by proximal and distal transfixing screws/bolts, which secure the nail to the bone cortex, thereby effectively neutralizing bending, rotational, and axial forces. It is performed using an image intensifier or a jig system.

Unlike a bone plate, the ILN allows biological osteosynthesis with minimal soft tissue trauma and vascular injury. Interlocking nail system is useful to repair simple and comminuted fractures of different long bones such as the humerus, femur, and tibia. Due to its mechanical advantages, the ILN provides rigid and stable bone fixation by neutralizing all the forces at the fracture site. As the implant is placed in the middle of the medullary cavity along the bone’s biomechanical axis (like IM Steinmann pin), it effectively counteracts bending force. As the nail is secured to the cortex using fixation bolts, it provides rotational stability (resists axial and rotational forces unlike IM Steinmann pins) and prevents collapse and overriding of bone segments at the fracture site. Intramedullary position of ILN, unlike eccentric placement of bone plates, makes it more resistant to compressive, torsional, and bending forces. By increasing the number of fixation bolts in each bone segment and the locking mechanism in the nail, the strength of fixation can be increased, which is particularly important in large animal fracture fixations. The ILN also allows dynamization at the fracture site in delayed or non-healing cases.

Different systems of interlocking nails are available today, such as regular interlocking nails (Dueland), angle-stable interlocking nails (Dejardin), inverse interlocking nails (Unger and Brückner, Germany), etc. However, the Dueland ILN system is the basic and first ILN system exclusively commercialized for use in veterinary practice and currently available commercially in India (Fig. 2.28).

The ILN is a solid steel rod with transverse openings usually at both ends. The one end of the nail has a trocar point to help in insertion and proper anchoring of the nail. The other end has negative threading (on the inner side), which helps to fix the alignment guide through the extension rod. The diameter of the nail generally ranges from 4 mm to 10 mm (Table 2.1), and any diameter nail can be custom-made. The lengths of 6–10 mm diameter nails vary from 120–230 mm, and 4 and 4.7 mm diameter nails vary from 68 to 134 mm. The number of holes in the nail vary from 3 (2 at one end and 1 at other end) to 4 (2 holes at both ends). The hole diameter varies from 2 to 4.5 mm. The holes are placed 22 mm apart in model 22 series (normally used for repair of diaphyseal fractures) and are placed 11 mm apart in 11 series (mostly used for repair of metaphyseal fractures). 4.0/4.7 mm nails are available only in the model 11 series.

Jig is an aiming device, which is fixed to the ILN using nail extension to facilitate correct placement of locking bolts/screws along the transverse openings of the nail without the need for image intensifier. The jig is attached to the nail with an extension so as to position it parallel to the nail with the jig holes corresponding to the nail holes. The nail extension, available as short or long extension, is temporarily attached to the nail to facilitate deep placement of the proximal nail end so that it does not protrude out of the bone once implanted. Locking screws (threaded)/bolts (smooth) are fixed in the cis- and trans-cortex of the bone through the hole in the nail, so that the nail is locked with the bony cortex and the bone and nail can act as a single unit.

Interlocking nails are commonly placed in different long bones, namely, femur, humerus, and tibia. The surgical approach for placement of ILN is same as IM pin fixation. The nail is introduced into the medullary cavity of long bones in normograde technique, either by closed or open approach (Fig. 2.29). Using a bone awl/Steinmann pin, a hole is created in the proximal bone cortex, which is enlarged with successively larger diameter reamers to a size that allows passage of the nail into the bone. The proper diameter nail with adequate length that can fit into the medullary cavity is chosen. A guide wire is passed in the proximal bone segment from the fracture site, so that it exits through the bone cortex and the skin at the proximal end. The nail attached to the jig is driven into the bone along the guide wire so that it is well seated in the proximal bone segment. Subsequently, the fracture segments are reduced, and the nail is further driven into the distal bone segment up to the level of metaphysis (till there is resistance to insertion). The holes for fixation screws/bolts are then drilled through predetermined sites by giving small stab incisions in the soft tissue and are directed through the bone and through the holes in the nail by utilizing the jig that aligns the drilling site with the holes in the nail.

Technique of interlocking nail fixation: using a chuck (a) fixed with Steinmann pin (b), a hole is drilled in the proximal cortex; the intramedullary cavity is reamed with a corresponding size reamer (c); a guide wire is introduced into the medullary cavity in normograde manner, and a proper length nail (d) is selected; before insertion of the nail, holes along the jig arm corresponding to the holes in the selected nail should be noted; the nail attached to the extension (e) insertion tool (g) and firmly anchored to the jig (f) is inserted into the medullary cavity along the guide wire; the jig-nail unit is rotated to align in medio-lateral plane (desired for screw/bolt placement); then, interlocking screws/bolts are fixed first by drilling holes by placing guide sleeve/drill guide (h) and drill bit (i) in the corresponding hole in the jig; the most distal bolt is placed first, followed by other bolts in proximal and distal fragments as per the situation. At the end of fixation, the jig along with extension-insertion tool is detached from the nail by unscrewing, so that the nail will remain within the bone

If the screws/bolts are fixed in both proximal and distal bone segments, the fixation is called static (load-bearing mode), which is commonly used in small animals, especially in comminuted fractures with instability. Two screws/bolts fixed on both bone segments provide stable fixation. When the screw/bolt is fixed in only one bone segment, either proximal or distal, it is called dynamic fixation (load-sharing mode) allowing micromotion at the fracture site. Dynamic fixation does not neutralize rotational and axial forces and weight-bearing results in axial compression promoting bone healing. In large animal fixations, as many fixation bolts as possible should be used in proximal and distal bone segments to provide greater stability. In fractures of the distal metaphysis/epiphysis of the femur, the nail can be introduced through the intercondylar fossa to achieve greater purchase in the smaller distal segment. In canine femur, 4–8 mm nails are generally adequate. In bovine femur and humerus, 14–18 mm diameter straight nails are optimum, whereas in the tibia, 12–14 mm angular nails are adequate.

General guidelines for ILN fixation include selection of proper nail (appropriate diameter, length, and model) based on preoperative radiographs of the fractured bone and the contralateral intact bone. A Steinmann pin is used to create a hole in the bone cortex, and it is then passed in a retrograde (in femur/humerus) or normograde (tibia) fashion to establish an intramedullary channel in the proximal bone segment. Intramedullary reaming is not generally required and may be avoided to reduce endosteal injury and cortical ischaemia. ILN should be tightly fit with the jig for proper alignment of holes in the jig and nail, and the holes in the jig through which fixation bolts (proximal and distal) need to be fixed should be ascertained based on the fracture location and configuration. The holes should not be drilled very close to the fracture site and should be at least 1 cm away. Undue pressure on the arm of the jig should be avoided while driving the nail (as it may lead to mal-alignment between the jig and nail) and ensure that the nail is properly seated in the distal metaphysis. Before drilling for transfixation bolts, if needed, the jig may be rotated to orient transfixation holes in the medio-lateral plane. The guide sleeve should always be used before inserting the drill/tap guides, and the holes are drilled using long drill bits without putting any pressure on the jig arm to ensure accurate drilling. A transfixation hole may be drilled in the proximal bone segment first, and the drill bit is left in situ to temporarily stabilize the jig to ensure accurate drilling in the distal bone segment. Before drilling any transfixation holes in the distal segment, it is ensured that the distal bone segment is rotationally aligned with proximal segment. After drilling at the most distal hole and inserting the drill bit in the distal bone segment, rotate the distal segment to ascertain that the distal drill bit has engaged the nail; if engaged, the nail will not rotate with the distal segment, and if not, the nail will freely rotate. Care should be taken while placing the distal-most screw as there is every chance for getting misplaced. It is better to fix two fixation bolts on both bone segments, but in distal metaphyseal fractures, at least one bolt/screw should be placed in the small distal bone segment. It is also advised not to leave an empty hole at the fracture site.

Interlocking nail can be placed in semi-closed manner; hence, soft tissue morbidity and vascular interference are lesser leading to biological osteosynthesis as compared to plating. It also permits early weight-bearing and return of limb function. The nail can be removed after bone healing, but it is not necessary to remove it if there are no complications.

The common complications with ILN include malpositioning of the nail in the medullary cavity leading to mal-alignment of the nail and jig and damage to the threaded proximal end of the nail. Misplacement of locking bolts/screws in the distal hole of the nail is also common. Other complications may include bending and breakage of screws and angular deformation of the nail. Complications of bone healing such as delayed union, non-union, and osteomyelitis can also be seen at times.

Hybrid ILN-ESF systems have been developed to improve the bending and torsional stiffness and overcome slack and interfragmentary movements. Type I ESF can be connected to ILN by tie-in configuration using an ILN extension or extended locking bolts. ILN can also be combined with epoxy-pin fixation using extended locking bolts. These hybrid fixators have the advantage of achieving dynamization at the fracture site by controlled destabilization. Further, it also facilitates easy removal of ILN after bone union. However, complications such as difficulty in postoperative care, poor patient tolerance, loosening of external pins, pin-tract infections, and additional soft tissue trauma offset the mechanical advantages of hybrid constructs. Attempts have also been made to combine ILN with bone plates (plate-ILN construct) to achieve maximum mechanical advantages of both implants in a single system so that all the forces acting at the fracture site can be more effectively neutralized.

The angle-stable ILNs have been developed to enhance the construct stability of the standard ILN by improving the torsional and bending deformation and by reducing slack and interfragmentary motion. The basic design of an angle-stable ILN is almost similar to standard ILN, with some modifications. The locking bolt has a threaded conical central part that matches with the shape and threads of the nail holes to create an angle-stable rigid fixation between the bolt and nail. The solid triangular end of the bolt is designed to engage the cis-cortex and is driven into the nail, and the thinner cylindrical end is designed to engage the trans-cortex. The locking bolts are available in different diameters, and they can be cut to appropriate length as per the requirement. The AS-ILN has been designed in an hourglass shape, which reduces damage to medullary circulation and increases overall construct stability. The core diameter of the nail is relatively less; hence, it is easy to insert without reaming the medullary cavity. The bullet-shaped distal tip of the nail minimizes tissue trauma, especially injury to the joint. AS-ILN is currently available in 6 mm, 7 mm, and 8 mm diameters, ranging in lengths from 122 to 203 mm.

Even though interlocking nail systems from different manufacturers are available for use in small animals, ILN systems for use in large animal fracture repair are not freely available commercially. Mostly, the implants developed for use in human applications are being used in large animals, but they are not strong enough due to their tubular designs, which compromise the fixation strength. However, a prototype of equine interlocking nail (manufactured by IMEX Veterinary, Longview, TX, USA) [44, 45] and bovine interlocking nails (Nebula Surgical Pvt. Ltd., Rajkot, India) [39, 41] for use in the humerus, femur, and tibia of young horses and bovines has been developed.

2.2.1.7 Interlocking Nails for Bovine

The ICAR-Indian Veterinary Research Institute has developed interlocking nails for fixation of fractures in bovine tibia and femur. The tibial ILN developed using 316L stainless steel has a diameter of 12 mm and length of 250 mm (Fig. 2.30). The nails are solid and have 9 holes, either all holes threaded or non-threaded (smooth), along its length to facilitate application to a variety of diaphyseal fracture configurations. The direction of holes is cranio-caudal. The nails are given a cranial angular bend of 10° at the proximal one-fifth of length to facilitate easy insertion and alignment with the medullary cavity of the tibia. Locking bolts are of 4.9 mm diameter (self-cutting trocar tip, self-tapping) and are either standard bolts (high pitch) for nails with non-threaded holes or a modified locking bolts (with low pitch), having two types of threads, the proximal part with threads complementary to hole threads to snugly fix the bolt with the nail in locking fashion (in nails with threaded holes) and the distal part with threading as of standard locking bolt (Fig. 2.31).

The nail-bone (buffalo tibia) constructs (with 10 mm mid-diaphyseal transverse ostectomy) developed using 4 or 8 standard locking bolts and 8 modified locking bolts were subjected to axial compression and 3-point cranio-caudal bending and torsion tests using a universal testing machine. ILN-bone constructs with 8 bolts were significantly stronger than the constructs with 4 bolts under compression, bending, and torsion loads [39]. The constructs with 8 modified bolts showed highest mechanical values. The compressive stiffness was 1.852 ± 0.04 MPa, yield load 18.475 ± 0.40 kN, and ultimate failure load 21.6 ± 0.39 kN. Bending moment was 419.03 ± 10.61 Nm, stiffness 0.583 ± 0.01 MPa, yield load 6.15 ± 0.17 kN, and ultimate failure load 6.33 ± 0.16 kN. Yield loads under compression and bending in constructs with modified bolts were significantly higher than in constructs with standard bolts. Under torsion, the constructs with 8 modified locking bolts showed ultimate failure load of 265.53 ± 10.23 Nm and ultimate failure displacement of 31.79 ± 0.82°. Both in vitro mechanical tests and clinical studies have shown that ILN developed for bovine tibia was sufficiently strong to stabilize diaphyseal fractures in young adult cattle and buffaloes weighing up to about 250–350 kg.

The ILNs developed for bovine femur (with solid or tubular shaft) measured 16 mm in diameter and 240 mm in length. The tubular nail has an inner diameter of 10 mm. The nails had 8 threaded holes (4 each in the proximal and distal part), for fixation of 6 mm locking bolts (Fig. 2.32). The nails were subjected to in vitro mechanical tests and clinical application.

For mechanical testing, nail-bone constructs were prepared using cadaver buffalo femur bones. The constructs developed using either solid or tubular ILNs (with eight 6-mm diameter, self-cutting trocar tip modified locking bolts, 40–75 mm length) with 5-mm mid-diaphyseal osteotomy were subjected to compression and cranio-caudal bending and torsion tests [41]. The compressive stiffness (MPa), yield load (kN), and ultimate failure load (kN) recorded for solid and tubular nails were 5.77 ± 0.23 and 5.35 ± 0.12, 46.89 ± 0.66 and 45.22 ± 0.86, and 51.39 ± 0.52 and 49.98 ± 0.51, respectively, with no significant difference between the solid or tubular nail constructs. The bending stiffness (MPa), bending moment (Nm), yield load (kN), and ultimate failure load (kN) for solid and tubular nail-bone constructs were 1.07 ± 0.05 and 0.86 ± 0.09, 680.55 ± 10.83 and 622.59 ± 23.13, 8.32 ± 0.25 and 7.36 ± 0.31, and 9.49 ± 0.28 and 8.18 ± 0.35, respectively (bending moment and failure load significantly different between the nail constructs). Under torsion testing, ultimate failure load (kN) and failure displacement (°) recorded for solid and tubular nail-bone constructs were 331.56 ± 4.87 and 312.48 ± 2.71 and 20.27 ± 0.39 and 18.33 ± 0.37, respectively (failure load significantly different between the nail constructs). These results suggested that solid nails were mechanically more stronger than tubular nails, but both solid and tubular nails were sufficiently strong to immobilize femur fractures in young adult cattle and buffaloes weighing at least 250–350 kg.