Abstract

Every industry uses water in its operations and hence produces wastewater, also called industrial effluent. Industrial effluent contains inorganic salts, heavy metals, pesticides, hazardous organic compounds, microbial contamination, and turbidity. Apart from this, industries also have their own effluents like chemical and biological agents in the wastewater. Hence, industries are a major source of water pollution. The present generation is witnessing harmful effects of such contaminants on aquatic, marine animal, and human health. Stringent quality requirements have been imposed on all the industrial plants to water pollution by effluent. The effluent treatment approach is a combination of different techniques and technologies which is used to treat wastewater so it can be released into the environment. These processes include several primary, secondary, and tertiary treatment and additional treatment steps of effluent treatment. These steps include processes such as filtration, coagulation, aerobic and anaerobic biodecomposition, active carbon adsorption, and disinfection using chemicals or ultraviolet (UV) light, etc. These steps leave a lot of industry-specific contaminants in the water. With the use of advanced technology, it is now possible to achieve minimal or zero liquid discharge (MLD/ZLD) and recovery of water and valuable resources, such as salts. In this chapter, we focused on the different procedures, applications, adaptability, and limitations of these modern techniques available to each industry in a single text. It also serves as a tool for personnel seeking information on different wastewater treatment technologies.

Access provided by Autonomous University of Puebla. Download chapter PDF

Similar content being viewed by others

17.1 Introduction

In India, industrialization, urbanization, and growth in population created an environmental imbalance due to resource exploitation and negligence (see Fig. 17.1). Environmental pollution is becoming a serious concern and creating environment conflicts. Different contaminants like organic matter, chemicals, heavy metal, pesticides, suspended solids, inorganic salts, radioactive waste, oil spillage, and many more when present in river, lake, and groundwater and create health problems to living organisms are called water pollution.

Water pollution by industrial waste is a matter of concern for the society, public, and industries (Sonune and Ghate 2004; Sharma 2015; Rathoure and Dhatwalia 2016). An effective effluent management approach minimizes the volume of waste, decreases the toxicity of wastewater, and recycles and reuses the waste materials. As our finance minister stated in his budget speech in 2019, only 4% of drinking water is available for the 1.5 billion population which is 18% of the world population. (https://www.worldbank.org/en/country/india). Apart from this, India also did not have a proper wastewater treatment system to manage the situation. The wastewater treatment approach needs immediate attention because this field is very emerging. Traditional treatment processes which have been used for many years are not sufficiently effective and stable for every kind of waste. This needs to be improvised for better efficiency and performance by the engineers and technologists in innovative ways to serve for vast numbers of wastes and industries. A balance between environment and development is very important. The imbalance in the environment can be maintained by the highly efficient industrial pollution management approach with waste minimization.

Figure 17.1 shows a depiction of how the industrial effluent is released directly without treatment into water bodies.

India has 17.7% of the world population and 2.4% of surface area, but in the case of water resources, it has less than 4%. According to the Indian NITI Aayog report of 2018, approx. 600 million Indians are facing a huge water shortage to serve their basic needs, and this water shortage problem could also affect the loss in GDP by 2050 (NITI Aayog 2019). This water shortage issue in India can be rectified by the proper waste water treatment plans, because if 80% of untreated waste water can be reused by treatment, 75% of demands can be achieved by 2025 and also will help in saving the GDP (WSP 2016) (Composite Water Management Index 2018). Approximately 33% of India urban wastewater is treated properly and can be possible to reuse (Singh 2019). The percentage of effluent treatment is higher in developed countries. The percentage of wastewater generated, treated, and reused of some developing countries are given in Fig. 17.2).

17.1.1 Industrial Effluents

Industrial effluents are all kinds of impurities like inorganic and organic harmful compounds, microbes, etc. generated by various industries. Along with industries’ main products, lots of by-products are also formed, which are harmful for the environment and need special attention for their further treatment. These by-products could be cost-effective, so the industries keep them for their processing and reuse them. But every industry did not have the proper effluent treatment plans, so they also discharge the remaining waste either they are in the form of solid, liquid, or gases into the water bodies like ponds, lakes, canals, rivers, or sea and solid wastes are dumped on the land or in aquatic bodies, hence increasing the landfill (Awuchi et al. 2020a). Whatever their mode of entry is, they adversely affect the environment. Some important industries which are most polluting are caustic soda, cement, brewery, dyes, fertilizers, iron and steel, oil refineries, paper and pulp, food, pesticides, pharmaceuticals, textiles, thermal power plants, leather, etc. (Table 17.1).

Mostly, effluents have a major number of inorganic salts like calcium and magnesium salts, different carbonates, bicarbonates, and various metal salts, and also, they have poisonous gases, turbidity, organic matter, and microorganisms. The data of treated and untreated wastewater from Indian cities of 30 years are given in Fig. 17.3.

17.1.2 A Glance of Basic Terms Used for Impurities/in the Analysis

-

Turbidity: Turbidity is the dissolved particles, which reduce the clarity of the water.

-

pH: pH is the negative log of hydrogen ion concentration.

-

Alkalinity: It is hydroxyl ions present in the sample.

-

Volatile fatty acids: These are by-products of anaerobic degradation of organic matter from wastewater.

-

Total dissolved solids (TDS)/total suspended solids (TSS): These are the amounts of matter dissolved or suspended in water.

-

Nitrogen: The presence of organic and ammoniacal nitrogen is evidence of recent organic pollution of animal origin.

-

Chloride: Chloride in water may be present due to dissolution of salt deposits.

-

Dissolved mineral matter: Soluble inorganic salts.

-

Dissolved gases: CO2, O2, N2, H2S, and CH4.

-

Microorganisms: Very small animals and plants, difficult contaminants to remove.

-

Chemical oxygen demand (COD): It is the amount of oxygen required to oxidize the polluting chemicals to CO2 and H20. The maximum acceptable COD is 90 ppm.

-

Biological oxygen demand (BOD): It is the amount of oxygen required by the biological microbial mass during the effluent treatment to oxidize the biologically pollutants.

-

Waste Characterization: A waste characterization depends upon the industrial processes that generate a waste. Some industries also characterized their waste from time to time. For this purpose, one should have proper knowledge about the specific industry and the detailed information on processes that generate wastes. This information is very important for the better management of waste. There are some useful factors for waste characterization like their physical status, volume of waste generation, composition of waste, and the constituents of waste for their effective processing. Consult with national and local regulatory agencies for determination of their specific testing requirements and select an appropriate analysis based on the above information (EPA Guide).

17.1.3 Major Sources of Industrial Wastewater

The major source of wastewater is industries like leather industry, textile industry, paper industries, pulp industries, wood industries, fertilizer industries, sugar industries, pharmaceutical industries, food processing industries, and so on which are contributing to this problem (Asamudo et al. 2005). So, if we took the example of only food industries, the food production produces wastewater from many steps like washing and rinsing, sorting, peeling, juicing, blanching, cooking, and cleanup. The amount of wastewater produced from food industries is given in Table 17.2.

As described in Table 17.2, food industries create huge waste and their treatment is also expensive because the waste consists of various organic carbon, nitrogenous organics, inorganics, and suspended and dissolved solids and has high biochemical and chemical oxygen demands (https://www.watertechonline.com/wastewater/article/15550688/wastewater-treatment-challenges-in-food-processing-and-agriculture). They must be treated very efficiently so that they will not harm the receiving waters due to excessive nutrients or oxygen demand when directly discharged to sewers (European Environment Agency 2001).

Other industries like the electronic industry generated very toxic contaminants like toxic heavy metals, oil, and grease. Textile industries involve various processing of clothes like yarn manufacturing, cleaning, and fabric finishing. Different industries produce different pollutants containing effluents with various characteristics. The safety values of toxic contaminants in the industrial effluent are regulated by governmental authorities from time to time. Kulkarni et al. (2000) reported contaminants and their discharge levels in the effluent as given by the Indian Pollution Control Board (Table 17.3).

Heavy metals like lead, cadmium, chromium, arsenic, nickel, zinc, etc. are when present in the wastewater effluents adversely affect humans, animals, and plants. The summarized form of the heavy metal sources and their adverse effects on health are given in Table 17.4.

17.1.4 Risk Assessment Involved in Waste Management

As the name suggests, risk assessment is the estimation of the risk/hazard which can occur in a planned activity. So, in the case of the waste management approach, we first evaluate the risk assessment in a systematic and defined way to avoid any consequences later. This process is important to understand the basics principles by everyone like the public, industries, and all interested stakeholders before making any environmental decision. Being a good citizen, we all want our waste to be managed safely and perfectly so that we and our mother nature are safe. Risk assessment has several steps mainly risk identification, exposure check, and risk characterization. Therefore, firstly the identification source/location of risk like the waste management unit is important. Then, the pathway of risk like toxic chemicals and heavy metal should be avoided to the people for exposure to ensure their safety, and direct drainage from the industries to the water bodies should be strictly inhibited. Finally, we characterize the risk to know how much the hazard can affect us and what kind of health problems we can face if we come across the hazard. In this process, health standard information and exposure assessment must be integrated and analyzed to arrive at quantitative estimations of various health problems like cancer risks. I must say that the risk assessment procedure is an ongoing process in any study.

17.2 Need for Industrial Wastewater Treatment

The saying “the solution to pollution is dilution” is famous. All of the mentioned industries produce their effluents continuously and this wastage is released into the environment (Awuchi and Echeta, 2019) and causes harm to aquatic organisms. The industrial pollution management approach is not well organized in most of the developing countries, thereby creating a big mess (Dao-Tuan et al. 2018; Awuchi et al. 2020b). Different industries produce different effluents and need specific way of treatment. If we talk about India, to manage the wastewater, lots of challenges have been encountered due to rapid urbanization, weak quality control systems, lack of resources, and strict regulations. With the help of new techniques, we can minimize this harm by making recycled treated wastewater. These industries can use this refined water for their personal use like boiler feed water, chemical synthesis, and other usage. Many advanced processes are established for a long time, but there is always a scope for improvement (Crini and Lichtfouse 2019). Technologists and researchers are tirelessly looking for the improved version of processes with great efficiency and performance. Sustainability is everything that is required for our well-being and it depends on our natural environment. The main application of advanced technology should be focused on nutrient removal and recovery, removal of all contaminants, water security, energy conservation, conservation of renewable energy sources, etc.

17.3 Methods of Industrial Wastewater Treatment

17.3.1 Fundamental Methods

Every industry has their responsibility to treat their waste properly and they are also benefited by the treatment of wastewater. The primary benefit of industrial waste treatment is the reuse of treated effluents by meeting compliance of regulatory bodies like CPCB, SPCB, etc. Other benefits are improved water quality, increased employment in construction and operation of wastewater treatment plants, and increased recreation uses, such as fishing, boating, and swimming, as a result of increased purity of water. Some major benefits of wastewater treatment are environmental sustainability, good public relations and improved industrial image, improved mental health of citizens, and improved conservation practices (Nemrow 2005).

The different physicochemical properties of industrial wastewater for different parameters are determined by using standard methods of analysis of wastewater (APHA 2005) as listed in Table 17.5.

The varying contaminations of wastewater also need a variety of methods to remove the contamination (Tchobanoglous et al. 2003). When we study the numerous publications and review articles, we clearly see that several industrial effluent treatment methods are proposed and mentioned by different industries like coagulation, precipitation, oxidation, solvent extraction, evaporation, carbon adsorption, ion exchange, membrane filtration, electrochemistry, and different biological processes (Henze 2001, Chen 2004; Forgacs et al. 2004; Anjaneyulu et al. 2005; Crini et al. 2007, Morin-Crini et al. 2017). But it’s very difficult and confusing to choose the most appropriate method.

An industrial wastewater purification process consists of different levels like preliminary treatment (physical and mechanical), primary treatment (physicochemical and chemical), secondary treatment (biological processes), tertiary treatment (physical and chemical advanced level), and treatment of the sludge formed. All these steps like primary, secondary, and tertiary treatment and biological unit processes like aerobic and anaerobic and their applicability also depend on the composition of waste (Crini 2005; Cox et al. 2007). At first the pollutants are removed manually, and then primary physical operations used are screening, flocculation, sedimentation, floatation, and filtration. Afterward, pollutants are removed by converting them into nonharmful products. Chemical processes mainly change the pollutant composition by reaction of pollutants with chemicals present in the treatment system. Biological agents like microorganisms convert the organic substances in presence or absence of oxygen through enzymatic action. Predominant chemical processes are coagulation, precipitation, adsorption, and disinfection. The overall purpose of different treatment techniques is waste minimization, and the waste can be minimized by adopting techniques of volume reduction, strength reduction, neutralization, and equalization and proportioning. The main focus in industry should be on waste minimization through volume reduction, and it can be achieved by better process control, improved equipment design, use of different or better-quality raw materials, good housekeeping, and preventive maintenance (Nemerow 2007). The next objective is strength reduction of waste and it can be done by change of process, equipment modification, by-product recovery, equalization, and proportioning of waste. Then we can check the pH of waste and try to neutralize that with some neutralizing agents. Without neutralization of waste, the microbes in biological treatment systems may be killed or inactivated and the more acidic or basic waste can be harmful for the flora and fauna of the aquatic system.

17.3.2 Conditions on Which Fundamental Methods Are Chosen

As of now, we have learned about industrial effluents; their sources, composition, and constitution; the need for effluent treatment; and some fundamental practices which we consider prior to serving our purpose. All industrial effluents have their own composition and they require some specific type of treatment among primary, secondary, tertiary, or some more advanced methods. The review of literature on this topic is very vast and versatile, so before choosing the methods, we should consider some fundamental criteria of that particular wastewater stream. The major criteria that required our attention are characteristics of the wastewater stream (components, salt content, suspended solids, flow rate, variation in water quality or quantity), desired removal or purification rate (emission limits, process requirements), technical feasibility (removal rates, fouling, corrosion, scale-up experience), local economic background (energy and chemical costs), infrastructure (site condition, availability of energy, chemicals and technical personnel, resources, existing effluent treatment plan), local engineering and operation staff, investment and operating budget, and time schedule (Leonhauser et al. 2014).

17.3.3 Treatment Levels

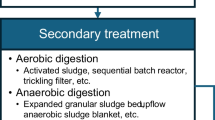

Treatment levels are mainly preliminary, primary, secondary, tertiary, or advanced. The purpose of the preliminary level is water conditioning. Physical treatment is used for removal of suspended solids and chemicals for pH adjustment and removal of toxic metals. Secondary treatment is used to remove biodegradable organic materials (Kesalkar et al. 2012). A summarized form of different processes/methods is shown in Table 17.6 and Fig. 17.4.

Different levels of industrial effluent management (source: Crini and Lichtfouse 2019)

Primary treatment is the first step in which suspended solids (SS) are separated from the wastewater. As a result of surface charge on small particles in the effluent, larger solid particulates remain in a suspended manner in it. This is also termed as MLSS (mixed liquor suspended solids) (Kulkarni et al. 2014). Sedimentation and screening operations usually accomplish the separation process in primary treatment. The method of removing large matters from sewage by passing through screens is termed as screening. We use a tool named screen with uniform-size openings for removing bigger suspended or floating matter in sewage. Screens are classified as (1) racks or bar screens, (2) perforated or fine screens, and (3) comminuters or cutting screens (Warren et al. 1993).

Secondary treatment is the further treatment of the effluents left from the primary level and, it is typically performed by indigenous water-borne microorganisms in a managed habitat. Basically, in secondary treatment, degradation of biological content of the sewage derived from human waste, food waste, soaps, and detergent was conducted by indigenous water-borne microorganisms in a managed habitat. Residual suspended solids and the organic matter with high BOD are removed by different biological processes. The effluents from secondary treatment have less BOD and low suspended solids (SS) value than primary treatment. The most biologically degradable organic materials are removed during biological treatment, but some resistant material which is known as refractory organic materials still left as a residue in the effluents. These materials might be end products of biological decompositions or artificial products, such as oils, chlorophenols, nitro-compounds, synthetic detergents, pesticides, PCE, etc. (Sharma and Sanghi 2013).

Tertiary treatment is the third and the advanced level of wastewater treatment. This step removes stubborn leftover wastes that were completely removed in the secondary treatment. The unit operations and processes in tertiary treatment include precipitation, activated carbon adsorption, coagulation, filtration, electrodialysis, reverse osmosis, advanced oxidation processes like wet oxidation process, Brine treatment, ozonation, etc. and, at the same time, are often used for local treatment of industrial effluents (Crittenden et al. 2005, I.D.A.Y. 2011). These unit operations and processes are applied in treatment of specific components of waste such as refractory organics removal, heavy metal removal, etc.

The conceptual approach of the treatment includes the removal of suspended particles, dissolved organic matters and handling of sludge for disposal as shown in Fig. 17.5.

A schematic diagram of ETP workstation (source: https://www.nrail.com/etp.html)

Now we discuss about some effluent treatment methods used in different industries according to their necessity:

-

Removal of suspended solids is mainly performed by filtration, coagulation, sedimentation, and floatation.

-

The methods employed for the removal of dissolved inorganic solids like heavy metals are also very important. So, the treatment of solids is also known as the brine treatment which includes evaporation, electrodialysis, ion exchange, membrane filtration processes like reverse osmosis, etc. The evaporation processes are the most widely used because they are more tolerant of organics, hardness salts, or hydrocarbons; in addition, they produce the highest purity effluent, even the distillate quality.

-

Organic dissolved solids are result of discharge of organic wastewater in the water bodies, which result in depletion of oxygen because microorganism consumed the dissolved oxygen to oxidize the biodegradable organic matter.

-

For the removal of organic matters, the biological methods are most efficient. Microorganisms are most sensitive to environmental conditions like temperature, pH, dissolved oxygen level, toxic chemicals like heavy metals, pesticides, and amount of organic matter in wastewater. These microbes degrade the biodegradable organic matter present in industrial wastewater. These methods can be aerobic or anaerobic depending upon the depth and mechanism of purification. Aerobic treatment means treatment of organic waste of wastewater in presence of oxygen, while anaerobic treatment means treatment of organic wastes of wastewater in absence of oxygen. Aerobic systems include lagoon, activated sludge processes, completely mixed system, aeration ponds, trickling filters, and aerobic composting. Anaerobic digestion takes place in four steps, i.e., hydrolysis, acidogenesis, acetogenesis, and methanogenesis.

-

The removal of some persistent other organic materials like chemical solvents, pesticides, dyes, medicinal wastes, and paint which are difficult to treat with conventional methods and need some specific treatment. These methods include distillation, ozonation, advanced oxidation processing, vitrification, incineration, adsorption, and landfill disposal.

Some of the important processes which involved for the industrial effluent treatment are as follows.

17.3.3.1 Sedimentation

In sedimentation, heavy particles settle to the bottom. Sludge word used for particles that gather at the bottom of a container. This process depends on viscosity of wastewater and size and specific gravity of suspended particles. Sedimentation collects and settles down solids, which are then transported to drying beds to dry out the sludge.

17.3.3.2 Filtration

Coagulation and filtration are the conventional water purification systems. Filtration is the process of passing water through a filter or porous media that removes particulates. Filters are made of sand and charcoal layers, and the filter membranes used are in different sizes. It’s a primary level process because only small particles (less than 0.1 mm can be removed in filtration). The microorganisms that are less than this size can’t be treated so they go for further treatment. Filtrations are of many types like rapid sand (remove suspended solids) and flow sand filtration. Flow sand filtration was an old method, whereas rapid sand has many advancements (http://www.who.int/water_sanitation_health/dwq/S12.pdf.).

17.3.3.3 Coagulation

This technique involves adding aluminum or iron salts like aluminum sulfate, ferric sulfate, or ferric chloride to the untreated water. These compounds are known as coagulants and they have a positive charge (Government of Canada Drinking water report, 2015).

In this, tiny dirt particles stick together after mixing. These collected particles together generate larger, heavier particles, or coagulate (this process is sometimes also called flocculation). After that, these bended particles were easily removed through sedimentation and filtration. This process is the primary level of the wastewater treatment; after this, water goes for the secondary treatment because coagulation is not able to remove microorganism like virus and bacteria. Figure 17.6 clearly defines the basic function of coagulation, flocculation, and sedimentation.

Process of coagulation, flocculation, and sedimentation in one frame (source: https://www.safewater.org/fact-sheets-1/2017/1/23/conventional-water-treatment

17.3.3.4 Floatation

Floatation is the process in which suspended solids and colloidal substances come to the surface of water with the help of air/gas bubbles as the transport medium. The impurities higher than water will also be elevated to the surface of the floatation tank with the help of buoyant forces of air bubbles. The floatation technique has major applications in the removal of a wide variety of heavy metal ions. So, floatation contributes a major role for the purification of water and also to the effective separation of various pollutants (George and Kosta 2018).

17.3.3.5 Evaporation

Evaporation helps to vaporize the water and hence dissolve solids changed into residues at the bottom. It is a very basic technique like sedimentation which we often performed in the laboratories for separation of components. It is an effective application for heavy metals, removing salts and various toxic chemicals from solution. Evaporation also produces a high-quality, reusable distillate where water conservation is a priority.

17.3.3.6 Skimming

Skimming is a primary level process to remove floating matters like oil with the help of different skimming tanks.

17.3.3.7 Electrodialysis

Dialysis is the diffusion of solute from higher concentration to lower concentration with the help of selective permeable membrane. It is used to purify the solution of different chemicals. In electrodialysis, ionic components of a solution are separated through ion selective membranes. Different cations and anions move to their respective electrodes through the membrane.

17.3.3.8 Ion Exchange Method

Ion exchange method is similar to the adsorption theory. In this process we use zeolites due to their pore size and adsorbent properties. Basically, they are aluminosilicate minerals and behave as ion exchangers. In this method, atoms with higher charge have a greater affinity for ions with smaller hydrated radii that are preferentially adsorbed. It helps in the removal of nitrates and phosphates, some special toxic ions, and hardness of water by exchange of their sodium ions for calcium and magnesium ions.

17.3.3.9 Reverse Osmosis

It is a well-known process which is used in our household also for drinking water purification from tap water. In this, the basic principle is just opposite than osmosis. That is to say, water from the solution passes through a semipermeable membrane and solute remains in the solution. By applying pressure more than osmotic pressure across the membrane, solvent is made to pass from high strength wastewater to low strength wastewater. In this way dissolved solids can be removed by using reverse osmosis.

17.3.3.10 Activated Sludge Process

Activated sludge is also a biochemical method used for the wastewater treatment with the help of microorganism and air. In this method, a typical activated sludge process includes an aeration tank with oxygen supply through the surface aerator mixed into the wastewater (Subramani and Arulalan 2012). In the next step, settling tank is used to allow the waste sludge to properly settle. A portion of the waste sludge is recycled into the aeration tank and the remaining waste sludge removed for additional treatment and final disposal.

17.3.3.11 Hydrocyclone Oil Separators

As the name tells, a cyclone kind of atmosphere is created in hydrocyclone oil separator for the effluent treatment with very high centrifugal force (very high rpm). This high centrifugal force separates the water and oil droplets. Separators are designed in such a way that the both separated oil and water are discharged from the different ends of the cyclone. Finally, treated water is collected for further treatment.

17.3.3.12 Trickling Filter Process

This process is a kind of aerobic treatment that utilizes microorganisms attached to a medium to remove organic matter from wastewater. Filters are made up of a fixed bed of rocks, coke, gravel, slag, polyurethane foam, sphagnum peat moss, ceramic, or plastic media over which sewage or other wastewater flow downward. Waste treatment with trickling filters is a well-characterized treatment technology. A microbial layer is formed and it involves the adsorption of organic compounds in wastewater. Air diffusion into the slime layer gives the oxygen necessary for the biochemical oxidation of organic compounds (https://sswm.info/factsheet/trickling-filter). A typical complete trickling filter system is shown in Fig. 17.7.

A typical complete trickling filter system (source: https://www.wikiwand.com/en/Trickling_filter)

17.3.3.13 Use of Smart Capsules

Lead is a highly toxic metal which could cause many health problems if present in discarded industrial wastewater. Encapsulation technology is a potential advanced method for the removal system for lead ions and some other ions from polluted sources. The three types of capsules under investigation include carbon nanotubes, polymer swelling capsules, and alginate-based capsules. These capsules provide likely means for remediation of contaminated water (Tylkowski and Jastrząb 2017). This technology has many benefits over the other methods like its simplicity, its wide spectrum, selective extractants, large special interfacial area, ability for concentration of metal ions from dilute solutions, and less discharge to the environment.

17.3.3.14 Wet Air Oxidation (WAO)

WAO is a well-established technique for wastewater treatment, especially for toxic and wastewater. It is a flameless combustion procedure. Its driving force is enhanced solubility of oxygen in aqueous solutions at different conditions. WAO results in the oxidation of organic compounds to CO2 and H2O and into other less hazardous products like acids.

17.4 Applications of Effluent Treatment Plan

The major applications of effluent treatment plan are as follows:

-

To recycle and reuse of wastewater

-

To reduce the consumption of water

-

To reduce water expenditure

-

To meet regulatory standard

-

To reduce the pollution for sustainable development

17.5 Status of Gorakhpur, Uttar Pradesh, in Effluent Treatment (Case Study)

The Gorakhpur city is situated in the plain of Saryu of mid-Gangetic valley and at the confluence of Rapti and Rohini River (en.wikipedia.org/wiki/Gorakhpur). Approximately 70% domestic water supplied is released as wastewater. Types of industries in Gorakhpur can be largely split up into food products, cotton textiles, beverages, tobacco and tobacco products, wool, silk and synthetic fiber textiles, terracotta products, jute, hemp and textiles, hosiery and garments, leather products, wood products, paper products, printing materials, chemical and chemical products, transport equipment and parts, rubber and plastic products, metal products, nonmetallic mineral products, basic metal industries, machineries, electrical machinery and apparatus, repairing and servicing industries, etc. According to the Uttar Pradesh pollution control board recent data of 2020 (UPPCB), a total of 252 industries are running except small-scale industries (https://cpcb.nic.in/Actionplan/Gorakhpur.pdf). The monitoring of pollution sources has been supervised by the UP Pollution Control Board with the help of District Ganga Committees/Zila Paryavaran Samitis. Establishment of sewage treatment plants is done by UP Jal Nigam and Nagar Nigam Gorakhpur, and regular monitoring of river water quality is done by UPPCB/District Environment Committee. A sewage treatment plant in Ramgarh Tal lake, Gorakhpur, UP, has been shown in Fig. 17.5. As per the information given by Gorakhpur development authority (GDA) office who is working tirelessly in cleaning of the lake, there are in total 24 drains falling in Ramgarh Tal of which 6 are major drains and 18 are minor drains. All these drains falling directly in Ramgarh Tal have been intercepted and diverted and are being treated in STPs 15 MLD and 30 MLD capacities each. Work on tapping and diversion of all the minor drains are under process (http://www.indiaenvironmentportal.org.in/files/file/Ramgarh-lake-Gorakhpur-pollution-report-NGT.pdf). Gorakhpur Development Authority is setting up a STP (sewage treatment plant) near Padley Ganj that is not sufficient, and according to a recent study (Kumari and Singh 2017), the value of various physicochemical properties of the lake is way higher than limits by the general standard for India set by the Central Pollution Control Board (Fig. 17.8).

17.6 Effects of Industrial Pollution

17.6.1 On Human Health

-

Irritation of eye, nose, throat, respiratory tracts, asthmatic attacks, etc.

-

Increases mortality rate and morbidity rate.

-

Chronic pulmonary diseases like bronchitis and asthma can happen due to high concentration of SO2, NO2, particulate matter, and photochemical smog.

-

Heavy metals like lead, cadmium, mercury, and arsenic may enter the body through lungs and cause poisoning.

-

Synthetic pesticides can remain as residues to create adverse health effects, such as respiratory problems, reproductive issues, endocrine system disruption, neurological damage, and cancers.

17.6.2 On Animal Health

-

Contaminants accumulate and magnify in the environment and affect the animals.

-

Poisoning of the animals may happen if they consumed the contaminated food.

-

All the toxic metals (fluorine, arsenic, chromium, and lead) and pesticides are responsible for most livestock damage.

17.6.3 On Plants

Environmental pollution has serious adverse effects on plants. The major pollutants affecting plants are SO2, O3, NO2, NH3, HCN, ethylene, herbicides, peroxyacetyl nitrate, etc. In the presence of pollutants, the healthy plants suffer from neurosis, chlorosis, abscission, epinasty, etc.

17.7 Control of Industrial Pollution

The utmost aim is for the control of pollution to maintain safety of man, material, and machinery. The implementation of control measures should be based on the principle of recovery or recycling of the pollutants and must be taken as an integral part of production to make waste an asset. Some important control measures are:

-

1.

Control at source: It involves suitable alterations in the choice of raw materials and process in treatment of exhaust gases before finally discharged in the environment.

-

2.

Selection of industry site: The industrial site should be properly examined considering the climatic and topographical characteristics before establishment.

-

3.

Industrial waste management: The industrial wastes should be properly treated before their discharge. There should be strict rules and regulations for the treatment of waste.

-

4.

Plantation: Intensive plantation in the region considerably reduces the dust, smoke, and other pollutants.

-

5.

Stringent government action: Government should take stringent action against industries which discharge higher numbers of pollutants into the environment than the level prescribed by the Pollution Control Board.

-

6.

Environmental risk assessment: Environmental risk assessment should be conducted regularly which intends to identify and evaluate the potential and harmful impacts of the industries on the natural ecosystem.

-

7.

Implementation of Environmental Protection Act: Environment Protection Act should be strictly followed and the culprits of the environment should be punished strictly.

17.8 Industries Approach Toward Waste and Limitation of Industries

In 2019, the Indian economy was the world’s fifth largest by nominal GDP and third largest by purchasing power parity. There are more than 680,000 + manufacturing companies in India (en.wikipedia.org/wiki/List_of_companies_of_India). If we talk about the textile industry, a recent report published by the US government says that 50 on 80 garments are found to have NPE (nonylphenol ethoxylates), which is a toxic chemical that is released during the processing of clothes. The waste created by textile industries, mainly deposits in landfill, can cause serious effects to humans and ecology (https://waste-management-world.com/a/trash-talking-textile-recycling) (Environmental Protection Agency 2017). Decomposition of such materials releases toxic greenhouse gases and is also polluting the water bodies directly and indirectly (Bertram 2016).

Welspun is the brand that sells recycled fabrics made from recycled plastic bottles (Aishwariya 2018). Two hundred polyethylene terephthalate (PET) bottles can cover up a normal-sized sofa (Charter et al. 2017). There are some more brands like Lutradur ECO that also use disposed drinking PET bottles. The reputed brands like Armani, H & M, Repreve, and Marks and Spencer also use recycled fibers and make fashionable clothing (Francoise et al. 2018). Nike has started the efforts to save the environment by reducing the size of the shoe box, monitoring the effluent discharged, recycling the cloth hangers, and recycling and using the yarns to make new apparels and footwear. Eco-friendly paper-making industry is an upcoming industry that finds old fabrics as an excellent building material. Biomass, agro-waste, and old cotton textiles serve in building the matrix in the handmade paper which is a great effort. (https://www.valmet.com/board-and-paper/recycled-fiber/). Recycled fibers are also used in automobile interiors, agro-textiles, reinforcement in geotextiles, acoustics, textiles for building construction purpose, upholstery, package textiles, and food packing materials (Zander et al. 2017). Among the other industries, the leather industry generates vast amounts of wastewater due to their tanning processes; it also produces 200 times more waste than total product output which occurs in solutions (Chojnacka et al. 2021). The non-tanned waste was used as a raw material for glue, gelatin, technical fats, protein sheaths, and even feed and fertilizers (Katarzyna et al. 2021). Agricultural and food processing wastewater treatment is also important due to the production of methane gas and biogas as a by-product by anaerobic treatment. As we know, methane gas is used in the generation of heat and electrical energy, and it also reduces the volume of waste and the most important factor, i.e., carbon footprint. Food industry is a very vast industry because it includes poultry and meat processing, dairy products, brewery, and oil production which generate high amount and a variety of wastes. So, they need specialized and costly treatment due to the contaminant loadings and the variability of the different wastes encountered in a plant. It’s a tough task to summarize the recycling, reusing, and making the industrial waste useful for all the industries (Awuchi and Igwe 2017) (The 2030 WRG 2009). All the industries and regulatory authorities are doing their job to achieve the minimal or zero liquid discharge (MLD/ZLD).

But every field has some limitations. For instance, every process of wastewater treatment has some advantages and disadvantages. Some limitations are the following:

-

Poor policy support of prevention by regulatory authorities and governments.

-

The disposal of certain wastes, such as batteries and paper, is strongly discouraged because of their potential hazard.

-

The lack of guidance for choosing the methods and resources.

-

The lack of investments in waste management and other sectors such as transport and energy.

-

Insufficient waste management system.

-

The unavailability of adequate service infrastructure, such as emergency management, waste recycling and disposal services, sewerage services, reticulated water supply, electricity, gas, communications, and transport access.

-

Wastewater discharges are difficult to manage due to pollutant volume, composition, and variability. It is tough to assess the physical and chemical characteristics of the effluent to determine a cost-effective and efficient process for industrial wastewater treatment.

-

Its drainage controls to isolate potentially contaminated areas from discharge to the environment.

Environmental pollution is an unfortunate necessity of all industrialization and urbanization. Consequently, a large amount of hazardous chemicals are released into the environment and create the environment pollution (Metcalf and Eddy, 2003, Souza et al. 2004). So, protecting our environment on every level (country and worldwide) and especially the problem of water pollution should be our topmost priority. So, it’s important to develop cheap, effective, and novel methods for the treatment of wastewater for the best use of that. To make pollutant-free and drinkable water from industrial wastewater, treatment is a challenging task and most important necessity in the present scenario. However, this is a difficult task (Sonune and Ghate 2004; Anjaneyulu et al. 2005; Crini 2005; Crini et al. 2007; Barakat 2011; Sharma and Sanghi 2013). Every method has its benefits and drawbacks. In this chapter, we have discussed many levels of treatment, and the process involved in that, but only a few are commonly used by the industrial sector for economic and technological reasons. Adsorption method, specially adsorption onto activated carbons, is nevertheless often cited as the procedure of choice to remove many different types of pollutants because it gives the best results in terms of efficiency and technical feasibility at the industrial scale (Crini and Lichtfouse 2019).

17.9 Conclusion

We are dealing with water scarcity, not only in India but worldwide also. Water can be saved by adhering strictly to these industrial pollution management approaches. We know about the adverse effect of these pollutants on environment and human health, so industrial waste management should ensure the safety of the environment as well as human health. The first step of waste management should be segregation of waste according to their characterization. Industrial wastewater treatment involves the processes used for wastewater treatment produced by industries as an undesirable by-product. Treatment levels of wastewater are often identified as primary, secondary, and tertiary. In these levels various methods are employed according to the waste characterization and resources available. With the use of advanced technology, it is now possible to achieve the zero liquid discharge (ZLD) and maximize the recycle/reuse of the waste. Risk assessment is also a very important step for the evaluation of potential risk. Firstly, separation of suspended/dissolved solids from the wastewater has been treated in primary level treatment, and then further treatment of the effluent was performed by secondary treatment by biological processes. Tertiary treatment is the advanced level of wastewater treatment which includes various techniques to deal with stubborn wastes. In the case of India, its cities need an effective and dedicated effort from everyone including the government, regulatory authorities, industry personnel, and even the citizens also. A complete (100%) reuse and recycling of wastewater gives a win-win situation for everyone mentioned above that even our mother nature will be thankful to us. There should be establishment of marketing of treated water to decrease the use of scarce freshwater and freshwater conservation can be encouraged. A joint effort of government agencies, nongovernment organizations, and the public is needed to overcome this problem.

References

Aishwariya S (2018) Waste Management Technologies in Textile Industry. Innov Energy Res 7(3):211. https://doi.org/10.4172/2576-1463.1000211

Anjaneyulu Y, Sreedhara CN, Samuel SRD (2005) Decolourization of industrial effluents–available methods and emerging technologies: a review. Rev Environ Sci Biotechnol 4(4):245–273

APHA (2005) Standard methods for the examination of water and wastewater, 21st edn. American Public Health Association, Washington, DC, New York

Asamudo NU, Daba AS, Ezeronye OU (2005) Bioremediation of textile effluent using phanerochaete chrysosporium. Afr J Biotechnol 4(13):1548–1553

Awuchi CG, Igwe SV (2017) Industrial waste Management: brief survey and advice to cottage, small and medium scale Industries in Uganda. Int J Adv Acad Res 3(1):26–43. ISSN: 2488-9849

Awuchi CG, Echeta KC (2019) Current developments in sugar alcohols: chemistry, nutrition, and health concerns of sorbitol, xylitol, glycerol, arabitol, inositol, maltitol, and lactitol. Int J Adv Acad Res 5(11):1–33. ISSN: 2488–9849

Awuchi CG, Hannington T, Awuchi CG, Igwe VS (2020a) Industrial waste Management, treatment, and health Issues: wastewater, solid, and electronic wastes. Eur Acad Res 8(2):1081–1119

Awuchi CG, Gospel AC, Otuosorochi AI, Somtochukwu IV (2020b) Industrial and community waste management: global perspective. Am J Phys Sci 1(1):1–16. ISSN 2519-5549. https://www.iprjb.org/journals/index.php/AJPS/article/view/1043

Barakat MA (2011) New trends in removing heavy metals from industrial wastewater. Arab J Chem 4:361–377. https://doi.org/10.1016/j.arabjc.2010.07.019

Bertram RF, Chi T (2016) A study of companies business responses to apparel E-commerce’s environmental impact. Int J Fashion Design Technol Education 11:254–264

Bishnoi NR, Garima (2005) Fungus: an-alternative for bioremediation of heavy metal containing wastewater: a review. J Sci Ind Res 64:93–100

Charter M, Polonsky MJ (2017) Greener marketing: a global perspective on greening marketing practice. Routledge

Chen G (2004) Electrochemical technologies in wastewater treatment. Sep Purif Technol 38(1):11–41

Chojnacka K, Skrzypczak D, Mikula K, Witek-Krowiak A, Izydorczyk G, Kuligowski K, Bandrów P, Kułażyński M.(2021) Progress in sustainable technologies of leather wastes valorization as solutions for the circular economy. J Clean Prod. Volume313, 127902 DOI: https://doi.org/10.1016/j.jclepro.2021.127902 2021.

Composite Water Management Index (2018) A Tool for Water Management.

Cox M, Négré P, Yurramendi L (2007) Industrial liquid effluents. INASMET Tecnalia, San Sebastian, p 283

Crini G, Lichtfouse E (2019) Advantages and disadvantages of techniques used for wastewater treatment. Environ Chem Lett, Springer Verlag 17(1):145–155

Crini G, Montiel AJ, Badot PM (2007) Treatment and purification of polluted industrial water: membrane processes, bioadsorption and chemical oxidation. Presses Univ, Franche-Comte

Crini G (2005) Recent developments in polysaccharide-based materials used as adsorbents in wastewater treatment. Prog Polym Sci 30(1):38–70

Crittenden JC, Trussell RR, Hand DW, Howe KJ, Tchobanoglous G (2005) Water treatment principles and design. John Wiley & Sons:2

Dao-Tuan, A, Nguyen-Thi-Ngoc, A; Nguyen-Trong, K; Bui-Tuan, A; and DinhThi-Hai, V Chen, Yuanfang, Duong TQ. (2018) Optimizing vehicle routing with Path & Carbon Dioxide Emission for municipal solid wastes collection in Ha Giang, Vietnam, Industrial Networks & Intelligent Systems, Springer International Publishing, 221, pp. 212–227, doi:https://doi.org/10.1007/978-3-319-74176-5_19.

Environmental Protection Agency (2017) Textile Mills Effluent Guidelines. EPA. 06–30.

European Environment Agency (2001) Copenhagen, Denmark. "Indicator: Biochemical oxygen demand in rivers.

Forgacs E, Cserháti T, Oros G (2004) Removal of synthetic dyes from wastewaters: a review. Environ Int 30(7):953–971

Francoise R, Bertram, Chi T (2018) A study of companies’ business responses to fashion e-commerce’s environmental impact. Int J Fashion Design Technol Educ 11(2):254–264. https://doi.org/10.1080/17543266.2017.1406541

George ZK, Kosta AM (2018) Flotation in water and wastewater treatment. Processes 6:116 . https://doi.org/10.3390/pr6080116

Government of Canada Drinking Water report (2015). https://www.watertechonline.com/wastewater/article/15550688/wastewatertreatment-challenges-in-food-processing-and-agriculture

Henze M (ed) (2001) Wastewater treatment—biological and chemical processes. Springer, Berlin

http://www.indiaenvironmentportal.org.in/files/file/Ramgarh-lake-Gorakhpur-pollution-report-NGT.pdf.

https://waste-management-world.com/a/trash-talking-textile-recycling.

https://www.safewater.org/fact-sheets-1/2017/1/23/conventional-water-treatment

International Desalination Association Yearbook (2011).

Katarzyna C, Dawid S, Katarzyna M, Anna W, Krowiak GI, Ksawery K, Paulina B, Marek K (2021) Progress in sustainable technologies of leather wastes valorization as solutions for the circular economy. J Clean Prod 313:127902

Kesalkar VP, Kesalkar IP, Sudame AM (2012) Physio-chemical characteristics of wastewater from paper industry. Int J Eng Res Appl (IJERA) 2(4):137–143

Kulkarni A, Deshpande M, Pandit AB (2000) Techniques of wastewater treatment, introduction to effluent treatment and industrial methods. Resonance:56–68

Kulkarni S, Mahendrakar H, Belwal S, Rao BM (2014) Transformation of sewage water to potable water. J Eng Technol Res 2(4):63–68

Kumari M, Singh A (2017) Hematological and biochemical changes induced by water pollutants in fishes collected from Ramgarh Lake of Gorakhpur (U.P.) India. Int J Life Sci Sci Res 3(1):792–799

Leonhauser J, Pawar J, Birkenbeul U (2014) Novel Technologies for the Elimination of pollutants and hazardous substances in the chemical and pharmaceutical industries. Chapter 5. In: Book: industrial wastewater treatment, recycling, and reuse

Lohchab RK, Saini J (2017) Industrial Pollution Management. book January Publisher. IAHRW Publications Private Limited. ISBN: 978–93–821201-7-9

Metcalf L, Eddy HP (2003) Waste water engineering. Tata McGraw Hill Pub. Co., New Delhi

Morin-Crini N, Crini G, Roy L (2017) Eaux industrielles contaminées. PUFC, Besancon 513:37 –47

Nemerow NL (2007) Industrial waste treatment. Elsevier Inc., Oxford

Nemrow NL (2005) Industrial collaborative solutions. In: Agaedy FJ, Nemrow NL (eds) Environmental solutions. Elsevier Inc., Oxford, pp 249–295. (ISBN: 978-0-12-088441-4)

NITI Aayog (2018) Government of India, Composite Water Management Index: A Tool for Water Management, India. https://niti.gov.in/writereaddata/files/document_publication/2018-05-18-Water-Index-Report_vS8-compressed.pdf.

NITI Aayog (2019) Government of India, Composite Water Management Index, India. https://niti.gov.in/sites/default/files/2019-08/CWMI-2.0-latest.pdf.

Rathoure AK, Dhatwalia VK (eds) (2016) Toxicity and waste management using bioremediation. IGI Global, Hershey

Sharma S K, Sanghi R (2013) Waste water reuse and Management: Amazon.com 256.

Sharma SK (2015) Green chemistry for dyes removal from wastewater. LLC Wiley, Bilverely

Singh S (2019) Hidden risks and untapped opportunities: water and the Indian banking sector, India. World Wildlife Fund for Nature (WWF)India. http://www.indiaenvironmentportal.org.in/files/file/hidden_risks_and_untapped_opportunities.pdf

Sonune A, Ghate R (2004) Developments in wastewater treatment methods. Desalination 167:55 –63

Souza RR, Bresolin IT, Bioni TL, Gimenes ML, Dias-Filho BP (2004) The performance of a three-phase fluidized bed reactor in treatment of wastewater with high organic load. Braz J Chem Eng 21(2):219–227

Subramani T, Arulalan K (2012) Evaluation of the efficiency of surface aerator in the activated sludge process treatment of food processing effluent. Int J Modern Eng Res 2(4):1518–1528

Tchobanoglous G, Burton LF, Stensel DH (2003) Wastewater engineering (treatment disposal reuse) / Metcalf & Eddy, Inc, 4th edn. McGraw-Hill Book Company. ISBN 0-07-041878-0.

The 2030 Water Resources Group (2030 WRG) (2009) Charting Our Water Future. McKinseyCompany. https://www.mckinsey.com/~/media/mckinsey/dotcom/client_service/sustainability/pdfs/charting%20our%20water%20future/charting_our_water_future_full_report_.ashx.

Tylkowski B and Jastrząb R (2017) Smart capsules for Lead removal from industrial wastewater. Met Ions Life Sci. 2017: 17 /books/9783110434330/9783110434330-004/9783110434330-004.xml. doi: https://doi.org/10.1515/9783110434330-004.

Warren L, Mc C, Smith JC, Harriott P (1993) Unit operations of chemical Engg. McGraw-Hill, Inc: New Delhi 931

World Bank Water and Sanitation Program (WSP) and International Water Management Institute (IWMI) (2016) Recycling and Reuse of Treated Wastewater in Urban India: A Proposed Advisory and Guidance Document, Sri Lanka. http://www.iwmi.cgiar.org/Publications/wle/rrr/resource_recovery_and_reuse-series_8.pdf.

Zander NE, Gillan M, Sweetser D (2017) Composite Fibers from Recycled Plastics Using Melt Centrifugal Spinning. Materials 10:1044

Acknowledgment

Geeta Singh and Seema Mishra are grateful to the University Grants Commission, New Delhi, for the research grant UGC-Start up grant (F.30- 505/2020(BSR)) and to Department of Science and Technology (SEED Division), New Delhi, for the project grant SEED/TIASN/2018/74.

Author information

Authors and Affiliations

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2023 The Author(s), under exclusive license to Springer Nature Singapore Pte Ltd.

About this chapter

Cite this chapter

Singh, G., Mishra, S. (2023). Industrial Pollution Management Approach. In: Singh, R.P., Singh, P., Srivastava, A. (eds) Heavy Metal Toxicity: Environmental Concerns, Remediation and Opportunities. Springer, Singapore. https://doi.org/10.1007/978-981-99-0397-9_17

Download citation

DOI: https://doi.org/10.1007/978-981-99-0397-9_17

Published:

Publisher Name: Springer, Singapore

Print ISBN: 978-981-99-0396-2

Online ISBN: 978-981-99-0397-9

eBook Packages: Earth and Environmental ScienceEarth and Environmental Science (R0)