Abstract

Digitalization and decarbonization are two strong trends which shape modern energy systems. The renewable energy sector, especially within the wind power domain, is also impacted by these trends. In addition to up-to-date information and communication technologies (ICTs), such as artificial intelligence (AI), distributed ledger technology (DLT), and Internet of Things (IoT), digital twins (DTs) are gaining a considerable momentum in recent years. In this chapter, we present an interactive digital twin platform for offshore wind farms’ development. The platform is developed based on Industry 4.0 standards such as OPC UA (Unified Architecture) and is combined with augmented reality to enhance user experiences. Unity3D is utilized for model development and visualization of the wind farms and their environment. The interactive digital twin platform can be installed either in tablets or smartphones, which makes usage easy. To demonstrate the interactive capability of the platform, we consider the Hywind Tampen floating wind farm as a use case. This floating wind farm consists of 11 wind turbines with a total capacity of 94.6 MW. Upon its completion, Hywind Tampen is the largest floating wind farm in the world.

Access provided by Autonomous University of Puebla. Download chapter PDF

Similar content being viewed by others

1 Introduction

During the last two decades, modern power systems are rapidly decarbonizing toward higher market shares of renewables by using wind and solar energy. Especially, wind farms are attractive solutions to handle energy crisis and to reduce greenhouse gas emissions, whereby offshore wind farms are particularly appealing due to their minimum environmental effects and the abundance of wind. According to the GE Renewable Energy Report [1], it is expected that the offshore wind industry will grow from 17 to 90 GW in the next decade and that offshore wind power will account for 15% of the global wind industry going forward. Such an expectation seems not exaggerated, noting that the Global Wind Report concludes that 2020 was a record year for the global wind power industry despite the impacts of COVID-19 with 93 GW of new capacity installed—a 53% year-on-year increase [2]. In addition to the decarbonization aspects, power systems, including the offshore wind industry, are using the advantage of digitalization technologies to increase efficiency, to provide safer solutions, and to reduce the cost of existing conventions. The offshore wind sector accommodates a very fruitful playground for the joint use of decarbonization and digitalization practices. In other terms, offshore wind applications can be considered as one of the most important drivers toward the Digital Green Transition of the entire energy sector.

Offshore wind farms are usually located hundreds of kilometers from their control centers. To operate the wind farms, sophisticated Supervisory Control and Data Acquisition (SCADA) systems are used to give operators complete control and to collect and analyze data. For several years, SCADA systems have been successfully implemented in the wind farm industry, providing valuable information about the present status of individual wind turbines. In the era of Industry 4.0, where data from physical assets like wind turbines can be accessed via the internet, disruptive technologies such as digital twins can potentially be used to support or replace the SCADA system. A digital twin offers a much more advanced level of information and perspective since it can provide not only the present status but can also depict the past and the future. According to Subhankar [3], the digital twin concept has started to revolutionize wind operations.

A wind farm can be considered as a cyber-physical system, in the sense that the system can be controlled or monitored by computer-based algorithms. Digital twins can be used not only for monitoring the conditions of offshore wind farms, but also to simulate different scenarios for operational purposes. A digital twin can be defined as “a virtual representation of a physical asset enabled through data and simulators for real-time prediction, optimization, monitoring, controlling, and improved decision making” (Rasheed et al. [4], p. 21980) or simply as the current digital representation of a product or a system that mimics a company’s machines, controls, workflows, and systems [5]. Pal [3] emphasizes an important benefit of a digital twin when he defines it as a digital “mirror” of a physical asset allowing users to see what’s going on “under the hood” without the need for being physically present. The latter is enabled by placing sensors that can collect real-time data and operational status on the physical asset, for example, a turbine, that can then be sent to a computer program for interpretation in the form of raw data or a three-dimensional (3D) representation [6]. Figure 1 illustrates such a setup.

Besides augmented reality frameworks, digitalization and digital twining of wind farms and associated energy systems consist of various building blocks such as communication technology, blockchain technology, data analytics, and visualization methodologies. There are several types of digital twins that exist in literature, such as digital twin prototype, digital twin instance, and digital twin aggregate [7]. Each of these digital twin types serves different purposes. In this chapter, we introduce the concept of an interactive digital twin. We define an interactive digital twin as a digital twin that can be used to assist asset development and optimization through interactive simulation based on augmented reality. The importance of the interactive simulation is emphasized in the review of digital twin solutions [8], especially by applying VR, AR, and MR technology in heavy industries [9]. The Unity3D platform is evaluated to provide good performance to visualize the interactive simulation [10].

In what follows, the potential use and need of digital twins in the field of wind power will be discussed. In addition, we present insight to the development of an interactive digital twin platform for offshore wind farms and its associated electromechanical components. The digital twin platform is combined with augmented reality to enhance user experience. The interactive digital twin platform is based on the OPC UA (Unified Architecture) for communication, Unity3D for simulation and visualization, and Vuforia for augmented reality. We use the Hywind Tampen wind farm as a use case. The digital twin enables users to simulate different wind speeds and wind directions, as well as the associated geometry and capacity of each wind turbine. These features additionally enable users to simulate different scenarios related to further development and optimization of the wind farm.

2 Digital Twins of Offshore Wind Farms

Digitalization has been on the agenda of the offshore wind industry in the past fifteen years. Digital twin technology is expected to lower the Levelized Cost of Energy (LCoE) for offshore wind farms so that they can compete with fossil-based energy resources. In the offshore wind industry, digital twins can be used to reduce design, construction, and operational costs. In the design phase, digital twin powered by high-performance computing shorten analysis time. Furthermore, digital twins also enable automated and interoperable design workflows. Within the construction phase, if we introduce 4D construction simulation on the physical assets, then we can achieve improved sequence planning and scheduling of the project. As regards operational and maintenance phase, we can improve risk management by using digital twins from the design to operation stages. Moreover, we can also leverage augmented reality models for digital retrofit and maintenance. Figure 2 shows an illustration of a digital twin for an offshore wind farm. By having a digital representation of the physical wind farms, the operator can simulate different scenarios and predict component failure that may occur in the future.

To demonstrate the value of interactive digital twins for the wind industry, in the next sections, we design an interactive digital twin for the Hywind Tampen floating wind farm. The wind farm, upon its completion, will be the largest floating wind farm in the world and consists of 11 wind turbines with a combined capacity of 94.6 MW (8.6 MW each). The wind farm is intended to provide electricity for the Gullfaks and the Snorre oil field and is estimated to meet about one-third of the annual electricity power demand. Furthermore, it is expected to reduce 200,000 tons of carbon emission per year.

3 Development of an Interactive Digital Twin Platform

In this section, we describe the structure of our proposed interactive digital twin platform. The platform was developed at the Department of ICT and Natural Sciences, Norwegian University of Science and Technology (NTNU). It has been used for teaching and research purposes. The platform is continuously improved by students and researchers. The functions marked in gray color in Fig. 3 are customized options, while the remaining functions are classified as standard functions provided by the interactive digital twin platform. Figure 3 also shows the schematic diagram of the platform, which consists of three component layers: the data source layer, the simulation layer, and the visualization layer. These three layers are all connected by a communication protocol based on OPC UA.

3.1 The Data Source Layer

Digital twins require data from various sources with different data types to facilitate the creation of a virtual model that can represent the behavior of real physical assets and their operation. Once we have a digital twin in place, it can be used to create simulations and to predict and analyze how the physical twin will perform. Data sources to be used in a digital twin can be of many types, such as visual data, measurement data, and historical data. In the interactive digital twin platform that we have developed, data sources are classified into three main types: static data source, semi-real data source, and real data source.

-

The static data source includes data files which are normally created automatically when we set up a simulation scenario. It can be configuration files for parameters and scenarios or just logs data for sample scenarios.

-

The semi-real data source is the simulation model file, which involves the model equations or constrains to create the simulated data.

-

The real data source is normally provided by the control system. This includes the output of the sensor systems at run time to control the behavior of the physical assets.

3.2 The Simulation Layer

Model-based simulation can be used in the engineering design and optimization phase. Simulation is usually performed to do “what if” scenarios based on dynamic models of the system. In practice, complex systems such as wind farms can be simulated at their component level by using different software. To capture the dynamic behavior of the overall system, each simulated component needs to be simulated at the same time. This process is called co-simulation. Using a Functional Mock-Up Interface (FMI) is one way to exchange data between dynamic models. It is an independent standard, which includes Model Exchange (ME) and co-simulation (CS). It defines a container and a combination of XML files, model files, etc., into a single file. The model file is called Functional Mock-Up Unit (FMU). The difference between an FMU-ME and an FMU-CS is whether the simulation tool includes solver (FMU-CS) or not (FMU-ME). FMI Version 1.0 was released in 2010. It consists of all the basic FMU concepts such as ME and CS. In 2014, FMI Version 2.0 was published. It adds some functionality compared to the previous version, such as support for directional derivatives, and clarifies ambiguities in the 1.0 standard. On February 19, 2022, the FMI Version 3.0 Beta.4 was pre-released, supporting two kinds of clock-based simulations: Synchronous Clocked Simulation and Scheduled Execution. This version is designed for real-time co-simulation. In our development, we used FMU 2.0 CS since the original model file for wind turbine is in MATLAB and since it only supported FMU-CS. The simulation layer has one core mission into controlling functions as playback, manage data service and data tags in the engineering mode, as well as, among others, management of data bank and user accounts. It also includes connections to static, semi-real, and real data sources.

3.3 The Visualization Layer

The visualization layer has one primary objective in supporting the operator mode and the editor mode with the user role. The editor can freely configure different scenarios with inventory (wind turbine, oil rig, etc.) and dashboard widgets (slider, button, input fields, charts, gauges, etc.), while the operator can access them during daily operation, labeled as “Customized scenario online view” in Fig. 3. The functions “Visualization toolbox and library” and “AR visualization” are essential for the interactive digital twin, while the others are optional. For example, machine learning (ML) in the analysis toolbox can be added for data prediction.

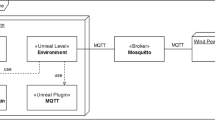

3.4 The Communication Protocol

There are several communication protocols that can be used as our solution. To simplify the development and easier deployment of clients, we choose to use Node-RED to act as a bridge, as shown in Fig. 4, to synchronize serial port data to OPC UA server namespace. Node-RED is a flow-based programming tool, originally developed by IBM’s Emerging Technology Services team, now being part of the OpenJS Foundation. Node-RED has leveraged a robust API platform that provides a wide variety of online services for securing and programming hardware devices to connect physical assets to digital assets. It is perceived highly efficient and easy to understand for rapid prototyping, especially if the number of variables is less than 100. OPC UA and serial communication blocks from Node-RED are deployed to connect sensor data into the digital platform.

4 Experimental Case Study

The experimental setup consists of physical asset and its digital twin. The physical asset includes wind turbines, a fan to generate the wind, and sensor systems to measure temperature, wind speed, and wind direction. The schematic diagram for the experiment is provided in Fig. 5. The commissioning site consists of physical assets. Data from the sensor systems will be transmitted into the server.

The experimental setup is based on our proposed solution. It has been implemented in Unity3D providing a customized interactive 3D visualization platform, MATLAB Simulink and Simscape as model simulator, FMU/FMI for co-simulation, OPC UA as communication protocol, and using the Node-RED tool offering APIs and online services, all providing standardization of interfaces and data format. The following subsections describe steps in the experiment.

4.1 Data Source

In this experiment, the data files are the project data format defined to save the log data, scenario configuration, and parameters for the behavior model. It connects the built-in script in the Unity3D platform pertaining to the simulation layer. The simulation model file in MATLAB works as the data simulator to export the simulated data from more complex physical models to the simulation layer by FMU/FMI (Sect. 3.3). The control system is the core of the physical twin, which is implemented by the use of Arduino UNO and a group of sensors and motors. It is connected to OPC UA protocol by the use of typical industrial serial port.

4.2 Simulation

The Unity script includes a simplified wind turbine power calculation model, while the simulation layer supports the critical FMU/FMI support. The package Unity-FMI-Addon is imported to auto compile the corresponding .dll file and function definition codes. Afterward, all port variables could be read and write during the simulation process, while the .dll file has been converted as a Unity asset file (.asset). The execution of the simulation is strictly controlled by the time step function with the given time value and input variable values. The output variables marked as data tags are parts of the data sources of the visualization layer, such as output power, power coefficients, wake loss.

4.3 Visualization

The visualization layer reflects the reality using the visualization toolbox and libraries. In our solution, Unity3D is chosen as the development tool due to its powerful technologies for efficient and high-quality visual effects and AR support (Sect. 5). The Universal Render Pipeline is used for wave and wind simulation. The visualization layer includes parameters and configuration of visual effects for different users. To get a good balance between quality and render speed, design engineers normally conduct experiments by using different parameters. For example, wind effects could be implemented by the use of a particle system, Unity3D, or other third-party packages.

Finally, in an operator mode, the wind farm and wind condition can be controlled and set by parameters through sliders, input fields, and buttons. Output results are displayed both on gauges and line charts on the user interface and on 3D bar graphs on the top of each wind turbine. The editor mode gives the user access to more detailed data and configuration options based on requirements and applications.

5 Interactive Digital Twin Based on Augmented Reality (AR)

Augmented Reality (AR) provides an easy and more understandable visual representation of digital assets for users to interact. The AR technology is supported by a growing trend of mobile application developments. The option allows users to immediately access the digital assets from common gadget such as tablets and smartphones to obtain data and to adjust physical assets via technologies like Internet of Things (IoT), without requiring special tools or hardware or making use of a specific software. There are several solutions that can be used to implement this technology in the industry. In this chapter, we address AR solutions based on Unity3D and Vuforia.

Unity3D provides its own AR toolkit for which most digital platform-related solutions can be easily integrated. Unity’s AR toolkit is a framework that enables developers to create an application and then deploy it to different mobile and wearable AR devices. Another alternative solution for AR is PTC Vuforia which is a powerful AR platform commonly used in industry. It offers different SDKs to build applications through Android, iOS, Windows platforms, and Unity3D equipped with a variety of features and trackable targets such as images, objects, and environments.

The Vuforia engine Unity3D SDK is the solution that we choose for applying and experiencing with the AR landscape on the experimentally implemented Unity3D wind farm platform. The AR scene in Unity3D implemented in the Vuforia plugin can be exported into different platforms such as Android, iOS, Windows, and macOS. Since it is easy to export and install, the Android system was considered as chosen as the preferred option for this experiment. Regarding the implementations, the .apk application can be created and exported by Unity3D and installed easily on mobile devices. After opening the application, the phone camera needs to be projected into a recognizable image considered as the target in Unity3D. The result is a unique intuitive landscape to be used to connect and interact with the created Unity3D visualization platform. It is easy to use and accessible from anywhere without requiring specific devices and tools.

Per se, the platform provides real-time data exchange and a bidirectional communication flow that gives the users the capability of processing wind farm data from the physical assets, as well as giving commands and getting feedback from both sides. All features available in the Unity3D platform are accessible in the AR scene, such as interacting with the wind farm by adding and removing objects, adjusting all settings, connecting to real-time data through the OPC UA. Any modifications by the user result in changes in the Unity3D and physical platform and vice versa. Figure 6 shows our interactive digital twin platform installed in Android, enabling users to simulate different scenarios and to predict energy output in the future.

6 Conclusions and Future Works

Wind power have proved its maturity as an industrial segment and has become one of the most popular energy resources. Recent digitalization advancements such as digital twins are gaining momentum in the wind energy industry. This chapter has provided insight into some of the potential of digital twin development of wind farms by looking into the nuts and bolts of an interactive digital twin platform we developed by the use of Industry 4.0 standards combined with augmented reality to enhance user experiences. To increase the readers’ understanding, a schematic diagram of the platform was provided, followed by descriptions of the data source layer, the simulation layer, and the visualization layer.

As regards the status of the platform, future work aims to improving the accuracy of the dynamic models of the individual wind turbines. It is expected that more advanced and diversified applications of digital twin will be observed in the future. Correspondingly, various other use cases and features are expected to be tested, whereby data management, data protection, and cybersecurity concerns will be covered accordingly.

References

Liang, J., Feng, G. E., & Renewable Energy. (2022). Growth and potential. The offshore wind farm and wind power industry. Online: https://www.ge.com/renewableenergy/wind-energy/offshore-wind

GWEC. (2021). Global wind report. Global wind energy council. Brussel, Belgium. Downloaded 17th of March at: https://gwec.net/global-wind-report-2021/

Pal, S. (2020). How digital twins could transform the wind energy industry. WPED. Online article, downloaded 16th of March 2022 at https://www.windpowerengineering.com/how-digital-twins-could-transform-the-wind-energy-industry/

Rasheed, A., San, O., & Kvamsdal, T. (2020). Digital twin: Values, challenges and enablers from a modelling perspective. IEEE Access, 8, 21980–22012. https://ieeexplore.ieee.org/document/8972429 In Norway, wind energy is only 10% of electricity production.

Miskinis, C. (2018). What does a digital thread mean and how it differs from digital twin. Insights. Challenge Advisory. Downloaded 6th of January 2022 at https://www.challenge.org/insights/digital-twin-and-digital-thread/

Liang, J., Feng, C. M. (2015). 13—Advanced AC and DC technologies to connect offshore wind farms into electricity transmission and distribution networks. In: J.-L. Bessède (Ed.), Eco-friendly innovation in electricity transmission and distribution networks (pp. 263–290). Woodhead Publishing. ISBN 9781782420101, https://doi.org/10.1016/B978-1-78242-010-1.00013-6

Grieves, M., Vickers, J. (2017). Digital Twin: Mitigating unpredictable, undesirable emergent behavior in complex systems. Springer.

Thelen, A., Zhang, X., Fink, O., Lu, Y., Ghosh, S., Youn, B. D., & Hu, Z. (2022). A Comprehensive review of digital twin—Part 1: Modeling and twinning enabling technologies. arXiv preprint arXiv:2208.14197

Vidal-Balea, A., Blanco-Novoa, O., Fraga-Lamas, P., Vilar-Montesinos, M., & Fernández-Caramés, T. M. (2022). A collaborative industrial augmented reality digital twin: Developing the future of shipyard 4.0. In International summit smart city 360° (pp. 104–120). Springer.

Fernandes, S. V., João, D. V., Cardoso, B. B., Martins, M. A., & Carvalho, E. G. (2022). Digital twin concept developing on an electrical distribution system—An application case. Energies, 15(8), 2836.

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2023 The Author(s), under exclusive license to Springer Nature Singapore Pte Ltd.

About this chapter

Cite this chapter

Hasan, A., Hu, Z., Haghshenas, A., Karlsen, A., Alaliyat, S., Cali, U. (2023). An Interactive Digital Twin Platform for Offshore Wind Farms’ Development. In: Karaarslan, E., Aydin, Ö., Cali, Ü., Challenger, M. (eds) Digital Twin Driven Intelligent Systems and Emerging Metaverse. Springer, Singapore. https://doi.org/10.1007/978-981-99-0252-1_13

Download citation

DOI: https://doi.org/10.1007/978-981-99-0252-1_13

Published:

Publisher Name: Springer, Singapore

Print ISBN: 978-981-99-0251-4

Online ISBN: 978-981-99-0252-1

eBook Packages: EngineeringEngineering (R0)