Abstract

Critical temperature for phase transition depends on the atomic cohesive energy that is the product of bond number and bond energy. The skin of a solid generally melts prior to the bulk (supercooling) and some interfaces melt at temperatures higher than the bulk melting point (superheating). Group IIIa and IVa atomic clusters show superheating because of the bond nature evolution. A dual-shell model describes the T C for ferromagnetic, ferroelectric, and superconductive phase transitions because of the involvement of both the long- and the short-range interactions. Activation energy for diffusion and epitaxial growth is proportional to the atomic cohesive energy; growing temperature controls the crystal size and associated properties.

Access provided by Autonomous University of Puebla. Download chapter PDF

Similar content being viewed by others

Keywords

These keywords were added by machine and not by the authors. This process is experimental and the keywords may be updated as the learning algorithm improves.

-

Critical temperature for phase transition depends on the atomic cohesive energy that is the product of bond number and bond energy.

-

The skin of a solid generally melts prior to the bulk (supercooling) and some interfaces melt at temperatures higher than the bulk melting point (superheating).

-

Group IIIa and IVa atomic clusters show superheating because of the bond nature evolution.

-

A dual-shell model describes the T C for ferromagnetic, ferroelectric, and superconductive phase transitions because of the involvement of both the long- and the short-range interactions.

-

Activation energy for diffusion and epitaxial growth is proportional to the atomic cohesive energy; growing temperature controls the crystal size and associated properties.

1 Cohesive Energy

1.1 Definition

The cohesive energy of a solid (E coh) is an important quantity used to accounting for the binding strength of a crystal. The E coh is equal to the energy dividing the entire crystal into the individually isolated atoms by breaking all bonds involved. The E coh is given as: E coh(N) = NE B = Nz b E b, if no atomic CN imperfection is considered. The cohesive energy for an atom in the bulk, or atomic coherency, E B, is the sum of the bond energy E b over all its atomic CN, E B = z b E b, for a specific atom in the bulk, E Bz = zE z is the cohesive energy for an atom with z neighbors.

The heat required for releasing an atom from a solid is the right atomic cohesive energy. Phase transition by loosening the atom requires energy that is a fraction of the E B. The atomic E B varies with, not only the atomic CN, but also the CN reduction induced bond strength gain. The under-coordinated surface atoms will be generally less thermally stable than those inside the core interior, unless the strength gain of the remaining bonds overcomes the effect of coordination reduction, E Bz > E B. For large bulk materials, effects of surface CN imperfection is negligible but, for small particles, surface effects become dominant because of the appreciably large fraction of such under-coordinated atoms at the surface.

The mean value of the E Bz is responsible for the fall (undercooling) or rise (overheating) of the T m of a surface and a nanosolid. The E Bz is also responsible for other thermally activated behavior such as phase transition, catalytic reactivity, crystal structural stability, alloy formation (segregation and diffusion), and stability of electrically charged particles (Coulomb explosion), as well as the crystal growth and atomic diffusion, atomic gliding displacement that determine the ductility of nanosolids.

1.2 Known Mechanisms

1.2.1 Surface Area Difference

One approach to determine the E coh of a nanosolid is to consider the difference between the surface area of the entire particle and the overall surface area of all the constituent atoms being isolated one from another [1]. For a spherical dot with R radius and N atoms of diameter d 0, the E coh equals to the energy required to generate the area difference, \( {\Delta }S \), between the isolated N atoms and the nanodot without changing the volume:

Letting the surface energy per unit area at 0 K be γ 0, and then the overall E coh(N) is,

\( E_{\text{coh}} (\infty ) = \pi Nd_{0}^{2} \gamma_{0} \) is the cohesive energy of the N atoms without the effect of atomic CN imperfection. The factor α varies with the shape and dimensionality of the solid. For a cube, the factor is 9/4 [1]; for a spherical dot, it is 1/2.

Considering situations of both the isolated and the embedded nanosolids with involvement of the interface and surface contributions [2]:

yields the mean atomic cohesive energy,

where β is the ratio of the interface area to the entire surface area, k denotes the degree of cohesion between the nanocrystal and the matrix with atomic cohesive energy E B. For a nanocrystal wholly embedded in the matrix, β = 1 and k = 1; for an isolated crystal, β = 0 and k = 0 [3].

1.2.2 Atomic CN Difference

By considering the effect of surface CN imperfection, Tomanek et al. [4] derived the E B for an individual atom denoted i:

E R representing the repulsive interaction is negligible at equilibrium. The mean E B in a nanosolid is obtainable by summing all bonds over all the N atoms:

A theory established based on the framework of the latent heat and the size-dependent cohesive energy agrees with experimental data results of W and Mo nanosolids [5].

1.3 BOLS Formulation

The BOLS notation considers variation of atomic E coh from atoms in the skin only. Using the same spherical dot containing N atoms with N i atoms in the ith surface shell, the average \( \left\langle {E_{\text{coh}} \left( N \right)} \right\rangle \), or \( \left\langle {E_{\text{B}} \left( N \right)} \right\rangle \) is,

where E coh(∞) = Nz b E b represents the ideal situation without CN imperfection. The z ib = z i /z b is the normalized CN and E ib = E i /E b ≅ C −m i is the binding energy per coordinate of a surface atom normalized by the bulk value. For a free surface, ΔB < 0; for an intermixed interface, ΔB may vary depending on the interfacial bond energy.

The following scaling relationships formulate the size dependence of E B,

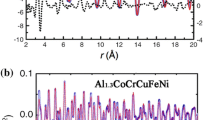

where γ i ~ τC i /K and γ′ i ~ τ i /K are the surface-to-volume ratio in the corresponding formulations. Figure 14.1 shows the match between these notations and measurements of the size-dependent \( \left\langle {E_{\text{B}} \left( K \right)} \right\rangle \) of Mo and W nanosolids [6]. From a numerical viewpoint, one could hardly tell which model is preferred to others though physical indications of the compared models are different.

1.4 Atomic Vacancy Formation

As an element of structural defects, atomic vacancies, or point defects are very important in materials and have remarkable effect on the physical properties of a material such as electrical resistance, heat capacity, and mechanical strength. A vacancy formation is associated with local strain, densification, quantum entrapment, and polarization.

Atomic vacancy formation needs energy to break all the bonds of the specific atom to its surroundings, which is the same to the atomic E B though structure deformation or relaxation is involved upon vacancy formation. However, the structural deformation or relaxation costs no additionally external energy. Vacancy volume should be greater than the atomic size because of the atomic CN imperfection induced contraction of bonds surrounding the vacancy. The measured EB is subject to accuracy. For instance, the E B of a Mo atom varies from 2.24 to 3.30 eV [8]. Theoretical efforts can predict the EB of limited numbers of metals and alloys, but the theories are rather complicated [9].

1.4.1 Brook’s Convention

Brooks [10] assumed the crystal is isotropic and considered the formation of a vacancy as an equivalent to creating new surface, equal to the area of one unit cell, being approximately the spherical surface of the atomic volume. He also assumed that the surface tension of the hole would shrink the vacancy size by distorting the rest of the crystal elastically. Then, the E B for atomic vacancy formation inside a bulk solid equals the minimum of the sum of the increased surface energy and distortion energy,

G is the shear modulus and γ0 the surface energy per unit area surrounding the vacancy. Introducing the size effect to the d0, G, and γ0, the relative change in the mean E B in a nanoparticle becomes,

where E p and d p are the corresponding vacancy formation energy and mean atomic diameter in the nanosolid.

An extension of Brook’s approach to nanostructures assumed that the G and the γ0 of a nanosolid remain the bulk values [11]. The key factor influencing the E p of a spherical dot of diameter D is the size-dependent atom size. Assuming that a small shrink of εD (ε ≪ 1) results from the hole volume contraction, the surface energy variation Δγ, and the strain-dependent elastic energy f of the particle become,

At equilibrium, the total energy F, or the sum of Δγ and f, is minimal, that is, dF/dε = 0, and then, the strain of the particle becomes

The average size d p of an atom shrinks due to the presence of G and γ0, \( d_{\text{p}} = d_{0} \left( {1 - \varepsilon } \right). \)

1.4.2 BOLS Formulation

The following compares Brook’s approximation and the BOLS correlation on the bond strain of a nanosolid:

where K dc = γ0/(2d 0 G) is the critical value and K remains its usual meaning of dimensionless form of size. Further simplification of Eq. (14.3) leads to the atomic vacancy formation energy in a nanometric system as given in comparison with the BOLS derivative:

where \( \alpha = {{\left( {2gd_{0} + 3} \right)} \mathord{\left/ {\vphantom {{\left( {2gd_{0} + 3} \right)} {\left[ {2d_{0} \left( {g^{2} d_{0} + g} \right)} \right]}}} \right. \kern-0pt} {\left[ {2d_{0} \left( {g^{2} d_{0} + g} \right)} \right]}} \) (~10−1 level) and g = G/γ0 ~10 nm−1. K Ec = α/(2d 0) is the critical value of K. For Pd and Au nanosolids, the critical KEc and Edc values are calculated based on the given G and γ0 bulk values, as listed in Table 14.1.

Figure 14.2 compares the predictions of the two models. At the lower end of the size limit (K = 1.5), the particle diameter contracts by 40 % associated with 12 % reduction in the E B according to Brook’s convention [11]. In comparison, the BOLS correlation predicts a 25 % bond contraction and 70 % lower of the E B for the smallest size. The approximation based on Brook’s relation overestimates the bond contraction and underestimates the E B suppression because of the assumption of size-independent G and γ0. Actually, the atomic vacancy should expand instead as the remaining bonds of the surrounding atoms contract. The strain of the entire nanoparticle arises from surface bond contraction and has little to do with the atomic void inside. One may note that EB varies from site to site due to the difference of atomic CN environment at various locations of the solid.

Comparison of a the bond (particle size) contraction and b atomic vacation-formation energy derived from the BOLS premise and from Brook’s approach for Pd and Au nanosolids (Reprinted with permission from [7])

2 Liquid–Solid Phase Transition

2.1 Undercooling: Skin Pre-Melting

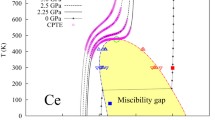

Undercooling and overheating are the mostly attended activities of materials at the nanoscale. In many cases, surface liquidation and evaporation often occur at temperatures lower than the corresponding bulk values [14–16]. Likewise, liquid surface freezes at lower temperatures [17]. For substrate-supported nanosolids with relatively free surfaces, the T m decreases with particle size (termed as undercooling). In contrast, as per the existing experimental evidence for embedded nanosolids, the T m can be lower than the bulk T m for some matrices. However, the same nanosolid embedded in some other different matrices may melt at temperatures higher than the bulk T m (overheating). Overheating of 115 K occurs to Pb(111) films confined in an Al(111) matrix [18]. The T m suppression for a free surface corresponds to the reduced degree of confinement and the increased entropy of the molecules at the surface compared with atoms in the bulk, whereas the T m elevation or depression of the embedded nanosolids depends on the coherency between the nanosolids and the embedding matrix [19, 20].

There is an extensive database describing surface and nanosolid T m suppression [21–26]. For instance, a photoelectron emission study [27] confirmed that lithium (110) surface melting occurs 50 K below the bulk T m (454 K). A temperature-resolved XRD analysis revealed that the T m of nanometer-sized drugs (polymer) also drops (by 33 and 30 K for 7.5-nm-sized griseofulvin and 11.0-nm-sized nifedipine, respectively) in a 1/R fashion [28]. STM measurements of a reversible, temperature-driven structural surface phase transition of Pb/Si(111) nanoislands indicates that the transition temperature decreases with inverse of domain size and the phase transition is independent of the processes of cooling or heating [29].

The T m of a Pd nanowire is lower than the bulk value but higher than that of the cluster with countable number of atoms proceeding in a surface pre-melting manner. A quasi-liquid skin grows from the surface radially inward for both cluster and wire, followed by a breakdown of order in the remaining solid core at the transition temperature [30].

The size effect on the nanosolid melting has been modeled in terms of classical thermodynamics and atomistic MD simulations [31–46]. In general, the size-dependent T m(K) follows the empirical scaling relationship:

where K C is the critical size at which the nanosolid melts completely, or the T m(K C) = 0 K. The physics behind the K C is the focus of modeling studies.

2.1.1 Classical Thermodynamics

Classical thermodynamics based on the surface Laplace and the Gibbs–Duhem equations [43] have derived that K C obeys the following relations [41, 44]:

where H m is the latent heat of fusion. ρ is the mass density and σ the interfacial energy. Subscripts s, l, and v represent the phases of solid, liquid, and vapor, respectively. The critical value of R C (= K C d 0) is normally several nanometers. These expressions correspond to three outstanding mechanisms in terms of classical thermodynamics:

-

1.

The homogeneous melting and growth (HMG) model [32, 33] considers the equilibrium between the entire solid and the entire molten particle, which suggests that the melt proceeds throughout the solid simultaneously. This model describes well the case of smallest nanoparticle with K C equal to three or less or otherwise to larger values with void defects being involved.

-

2.

The liquid shell nucleation (LSN) model [34] assumes that a liquid layer of thickness K 0 is in equilibrium at the surface, which indicates that the surface melts before the core of the solid.

-

3.

The liquid nucleation and growth (LNG) model [37, 38] suggests that melting starts by the nucleation of a liquid layer at the surface and moves into the solid as a slow process with a definite activation energy. The LSN and the LNG are valid to the melting of a flat surface or a larger nanoparticle.

2.1.2 Atomistic Models

Models based on atomistic/MD attribute the critical R C to:

The liquid-drop model [47] relates the T m to the E coh of the entire particle of N atoms. With the involvement of surface, the E coh equals the difference between the volume cohesive energy (NE B) and the surface energy (4πd 20 N 2/3γ). The mean cohesive energy per atom with volume v 0 in the solid is E B(R) = E B − E B,S N −1/3, where E B,S = 4πd 20 γ is the cohesive energy for an atom at the surface. The relation between the E B and the E B,S is given empirically as, \( E_{{{\text{B}},{\text{S}}}} = 0.82\,E_{\text{B}} \) [48]. Based on the Lindemann’s criterion of melting, the T m of the bulk material follows [49],

where n is the exponent of the repulsive part of the interaction potential between constituent atoms, Z is the valence of the atom, which is different from the atomic CN (z). The coefficient f e is the thermal expansion magnitude of an atom at T m. At T m, the f e is less than 5 % [50, 51]. The T m depends simply on the mean atomic \( \left\langle {E_{\text{B}} \left( K \right)} \right\rangle \) of the solid. Replacing the E B with the size-resolved E B(K), Nanda et al. [47] derived the liquid-drop model for the T m(K) based on the relation:

where the constant η2b represents 1/z-fold of the enthalpy of fusion and atomization, which is required for evaporating an atom from the molten state. η1b is the specific heat per coordinate in the bulk. The η1b and η2b values are tabulated in Table 14.1 [47]. According to the liquid-drop notation, the critical radius at which T m(K C) approaches 0 K is in the range of 0.34 (for Mn) and 1.68 nm (for Ga) [47].

The surface-phonon instability model [40, 52, 53] suggests that the T m(K) varies with T m(∞) and with the energy for defect formation at the surface. Within the thermodynamic limit (particle radius larger than 2 nm), the effects of size reduction and electronic excitation combine [54].

The lattice-vibration instability model [40, 55–59] extends Lindemann’s vibrational-lattice instability criterion [60]. The melting behavior of a nanosolid is related to the ratio (β) of the root-mean-square displacement (RMSD, δ2) of an atom at the surface to the RMSD of an atom inside a spherical dot. β is a size-independent parameter:

The K C is determined by K 0 = τ (dimensionality) at which all the constituent atoms have surface features. This model indicates that if β > 1, the surface melts below the bulk T m, and vice versa. According to the RMSD, a nanosolid of K C = τ radius will melt at 0 K.

2.2 Overheating: Interface Effect

In the case of embedded nanosolids, the coefficient of surface energy will be replaced by the interfacial energy if surfaces are completely saturated with atoms of the surrounding matrix. Nanda et al. [47] introduced the ratio as a perturbation of surface energy between the matrix and the embedded specimen,

If the surface energy of the matrix γMat > γ, the core nanosolid melts at a temperature that is higher than its bulk counterpart. This expression matches the experimental data of Pb particles embedded in an Al matrix but overestimates the T m for Indium particles embedded in an Al matrix by some 10–20 K using the known γ and γMat values.

Based on the size-dependent magnitudes of the atomic vibrations, Jiang et al. [40, 61] extended the T m(K) model for the overheating, according to which overheating is possible if the diameter of the matrix atoms is smaller than the atomic diameter of the embedded nanosolid. Therefore, adjusting the β value in the RMSD model describes both overheating and undercooling of a nanosolid. Overheating happens when β < 1, which means that the matrix confines the vibration of the interfacial atoms.

However, MD simulations [62] suggest that atoms in the bulk interior of a freestanding nanosolid melt prior to the surface that melts at relatively higher temperatures. This prediction seems to be conflicting with existing database but as discussed shortly for the overheating of the smallest Ge+ and Sn clusters. In contrast, MD calculations [63] of the melting evolution, atomic diffusion and vibrational behavior of bcc metal vanadium nanoparticles with diameters around 2–9 nm suggest that the melting proceeds in two stages. A stepwise pre-melting of the skin of two or three atomic layers happens first and then an abrupt melting of the entire cluster follows. The heat of fusion of nanoparticles is also inversely proportional to the nanoparticle size.

The models of LSN, HMG and LNG suit only the cases of T m suppression (ΔT m < 0) while the liquid-drop and the RMSD models cover both the undercooling and the overheating. For particles larger than several nanometers, all the models worked sufficient well despite the disputable mechanisms.

2.3 BOLS Formulation

A Taylor’s series of the binding energy of a pair of atoms can be decomposed as energies of binding at 0 K, E b(d 0), and the thermal vibration energy, E V(T):

The term of n = 0 corresponds to the minimal binding energy at T = 0 K, E b(d 0) < 0. The term n = 1 is the force [\( \left. {{{\partial u\left( r \right)} \mathord{\left/ {\vphantom {{\partial u\left( r \right)} {\partial r}}} \right. \kern-0pt} {\partial r}}} \right|_{{d_{0} }} \)= 0] at equilibrium and terms with n ≥ 2 correspond to the thermal vibration energy, E V(T). The T C can be any critical temperature for event such as liquid–solid, liquid–vapor, or other phase transition, like magnetic and ferroelectric transitions. By definition, the thermal vibration energy of a bond is,

where r − d 0 is the magnitude of lattice vibration. μ is the reduced mass of a dimer of concern. The term q v = μω2 is the force constant for lattice vibration with an angular frequency ω.

The physical argument for the BOLS iteration is that, if one wishes to peel off or loosen an atom in the solid thermally, one must supply sufficient thermal energy to overcome the cohesion that binds the specific atom to its surrounding neighbors. The thermal energy required to loosen one bond is the separation of E b(T C) − Eb(T), see Sect. 14.2. If the E V(T) is sufficiently large, all the bonds of the specific atom will break and this atom will leave the solid. At the evaporating point of any kind of solid, E total = 0; at the critical point, E total = E C. One may consider step-by-step the energies required for melting (or dissociating) a bond, an atom, and then shell-by-shell of a nanosolid of radius lined with K atoms.

The thermal energy required for loosening a bond of an atom in the bulk by raising the temperature from T to T C equals,

The energy required for melting the entire atom in a bulk is proportional to the EB(0), which is a sum of the single bond energy over all the coordinates.

Melting a nanosolid comprising N atoms in a shell-by-shell manner requires thermal energy that is proportional to the cohesive energy of the entire solid:

If the bond nature in the solid is homogenous, the Ecoh may vary from material to material, but for a specific sample, the fraction of the Ecoh needed for the phase transition is fixed for a specific process occurring to the specimen [49]. The relative change in T m(K) and T C(K) is then:

The temperature is always the same throughout the specimen in operation whereas the intrinsic T C,i may vary from site to site if the sample contains atoms with different CN, such as atoms at the surface, grain boundary, or sites surrounding voids or stacking faults.

This mechanism explains why the latent heat of fusion of a solid has a broad range of measured values rather than appearing as a sharp peak [41, 64]. For a solid with numerous randomly distributed defects, the mechanism of random fluctuation melting [39] could dominate because energies required for breaking one bond or dissociating an individual atom with different CN are different. This mechanism also explains the broad temperature range for glass transition of an amorphous state as the random distribution of atomic CN imperfection in the amorphous solid. Glass transition happens in a range of temperatures and it is material processing condition dependent [65].

On the other hand, from a classical thermodynamic point of view, the thermal energy E T required for the liquid–solid phase transition can be estimated by integrating the specific heat over the entire solid with and without CN imperfection from zero to the T m:

with the assumption of C P(K, T) ≅ C P (∞, T) ≅ C V (∞, T) = constant in the entire temperature range [66]. It is true in fact that C P (K, T) ≠ C P (∞, T) ≠ C V (∞, T) ≠ constant. The Debye temperature and therefore the specific heat C P are size and temperature dependent [56, 67]. This effect results in a 3–5 % deviation of the C P value. Besides, (C P − C V)/C V ~ 3 % [66]. Compared with the precision in determining the size and shape of a nanosolid, such errors are negligible.

Actually, measurements [68–70] revealed that the C P varies insignificantly with the particle size in the measuring temperature range. Therefore, it is acceptable to simplify the C P as a constant in the integration. Such simplification may lead to slight deviation in the integration in Eq. (14.14) from the true value. Nevertheless, one should particularly note that the deviation of the integration from true value only affects the precision of the m value or the effective z ib, and it does not change the nature of the phenomenon.

2.4 Verification: Liquidation and Evaporation

Equation (14.13) indicates that the size-dependent ΔT m(K)/T m(∞) originates from the relative change in the E B,i of a surface atom to the bulk value. The ΔT m(K)/T m(∞) follows the scaling law given in Sect. 14.2. Figure 14.3 compares predictions using parameters given in Table 14.2 with the measured size-dependent melting behavior of metals, semiconductors, inert gases, and methyl chloride polymer (m-Cl), as well as embedded systems showing overheating effects. The size-dependent evaporating temperatures (T eva) of Ag and CdS nanosolids also follow the trend of prediction.

Agreement between predictions (solid lines) and experimental observations of the size-and-shape dependence of the T m suppression of a Sn and Al on Si 3 N 4 substrate [66, 70], b In and Pd, c Au on C [33], W [32] and embedded in Silica [78], d Ge and Si, e Bi and CdS, f Kr, Ne and O, and m-Cl, g overheating of embedded In and Pb, h Teva of Ag and PbS nanosolids [79]. Parameters and references are given in Table 14.2 (Reprinted with permission from [7])

The matching between BOLS prediction and measurements provides additional information about the mode of epitaxial crystal growth and the bonding status between the nanosolid and the substrate. Results show that Al nanosolids grown on a SiN substrate are more plate-like (τ = 1) throughout the measured size but Sn on SiN and Au on C are more spherical-like (τ = 3) at particle sizes smaller than 10 nm. The melting profiles show that at the smaller size range, Au/W interface promotes more significantly the melting of Au (undercooling) than the Au/C interface. The silica matrix causes a slight overheating of the embedded Au solid compared with the curves for Au on the other two substrates. The deviation from theory and experiment also provides information about the difference in interfacial energy between the particles and the substrates.

The BOLS premise indicates that the overheating of In/Al (T m,In/T m,Al = 530/932), Pb/Al (600/932), Pb/Zn (600/692), and Ag/Ni (1235/1726) [71] results from the interfacial bond strengthening. An atom performs differently at a free surface from this atom at the interface. Although the coordination ratio at the interfaces suffers little change (z ib ~ 1), formation of the interfacial compound or alloy alters the nature of the interatomic bond that should be different in strength. In this case, one may replace the z ib C −m i with a parameter α to describe the interfacial bond enhancement, as indicated in panel (g).

Numerical fitting turns out the α value of 1.8, which indicates that an interfacial bond is 80 % stronger than the bond in the parent bulk. If one considers the bond contraction, 0.90 ~ 0.92 [72], as the As and Bi impurities in CdTe compound, the m value is around 5.5–7.0. The high m value indicates that bond nature indeed evolves from a compound with m around four to a value of more covalent nature. Therefore, the deformed and shortened interfacial bond is much stronger. This finding means that electrons at an interface are deeply entrapped and densified. Therefore, it is understandable that twins of nanograins [73] and the multilayered structures [74] are stronger and thermally more stable.

It is anticipated therefore that a thin insulating layer could form in a hetero-junction interface because of the interfacial bond nature alteration and the charge trapping effect. This anticipation explains the high interfacial stress (σP) of junction dislocations in aluminum [75] and provides new insight into the deformation of ultrafine-grained metals. The interface bond strengthening also explains the fact that a monolayer GaAs coating on a Ge(110) surface could raise the T m (1211 K) with an association of a dramatic drop of the diffusion coefficient of the Ge atoms. In contrast, a Ge monolayer coating on a GaAs(110) surface lowers the T m of GaAs (1,540 K) by 300 K. Therefore, overheating is subject to the configuration of the hetero-junction interface and their respective T m(∞) as well.

The T m of Si and CdS nanosolids appeared to be lower than the expected values with m = 4.88 for Si. The reason of the deviation could be the definition of melting temperature that may refer to temperature of coalescence or complete melting. For instance, MD calculations revealed that [76] coalescence occurs at temperatures lower than the cluster T m, and that the temperature difference between coalescence and melting increases with cluster size reduction. In the normalization of the scaling relation, the coalescence temperature is lower than the T m and the coalescence T drops faster than T m with solid size. The size-dependent T m of Kr, Ne, and O solids follow the curve of m = 4.88 as well, despite the accuracy of measurement. The In particle encapsulated in silica exhibits overheating while the In embedded in Vycor glass shows no overheating effect. From the RMSD instability point of view, the interfacial binding constrains the RMSD of the interfacial atom to be smaller than that of a bulk atom [40].

Equation (14.13) indicates that the quantity \( \alpha = z_{i} /z_{\text{b}} C_{i}^{ - m} \) dictates the process of overheating (\( \alpha \) > 1, T m elevation for chemically capped nanosolids) or undercooling (\( \alpha \) < 1, T m suppression of freestanding nanosolids). For a capped nanosolid, z i /zb ~ 1, the \( \alpha \) represents the interfacial bond strength. For a freestanding nanosolid, there are two possibilities for \( \alpha \) > 1. One is that the m increases as z i is reduced and the other is that the C i is much lower than the prediction [77].

2.5 T m Oscillation

2.5.1 Observations

The hardness of a bulk material is proportional to its T m. However, the skin of a solid is generally harder, but the melts more easily than the core interior. XRD in ultrahigh vacuum [44] reveals that the T m of Pb nanosolids drops with crystallite size, which follows the liquid-skin melting mechanism. Such melting behavior is demonstrated via the reversible growth of a 0.5-nm (2 atomic diameters)-thick liquid skin on 50-nm-sized crystallites.

It is surprising, however, that a freestanding nanosolid at the lower end of the size limit, or clusters containing 10–50 atoms of Ga+ or IV-A elements, melts at temperatures that are 10–100 % or even higher than the bulk T m(∞) [29, 97–100]. For example, \( {\text{Ga}}_{{39 {-} 40}}^{+} \) clusters melt at about 550 K, while a \( {{\text{Ga}}^{+}}_{17} \) cluster does not melt even up to 700 K compared with the T m(∞) of 303 K [97]. Small Sn clusters with 10–30 atoms melt at least 50 K above the T m(∞) of 505 K [22]. Numerical optimizations suggest that \( {{\text{Ga}}^{+}}_{13} \) and \( {{\text{Ga}}^{+}}_{17} \) clusters melt at 1,400 and 650 K [98] and Snn (n = 6, 7, 10 and 13) clusters melt at 1,300, 2,100, 2,000, and 1,900 K, respectively [100]. For a Sn10 cluster, the structural transition happens at 500 and 1,500 K and the structural transition of a Sn20 cluster occurs at 500 and 1,200 K [101]. The \( {\text{Sn}}_{10}^{ + } \) and \( {{\text{Sn}}^{+}}_{11} \) clusters survive up to 1,073 K while Sn clusters containing n > 19 and n < 8 atoms are less thermally stable as melting occurs at 773 K or below [102]. Sn19 can remain solid up to 673 K while Sn20 melts below 673 K.

Calculations [99] suggested that the IV-A elements, Cn, Sin, Gen, and Snn (n ~ 13) clusters melt at temperatures higher than their T m(∞). The measured T m for Bi particles of 7 nm in radius was similar, being up to 50 K above the value predicted by the homogeneous melting model [103]. The C13 cluster prefers a monocyclic ring or a tadpole structure, which is most probable to appear in the simulated annealing when the temperature is between 3,000 and 3,500 K. Numerical calculations, suggested that at the smallest sizes, carbon atoms tend to form tubes or fullerene rather than tetrahedron diamond. Although the T m may be overestimated to some extent for the smallest clusters [100], the calculated T m elevation follows the trend of measurement.

The T m elevation of the smallest Ga and Sn nanosolid corresponded either to the bond nature alteration from covalent-metallic to pure covalent with slight bond contraction [98, 104], or to the significant geometrical reconstruction as Ge, Si, and Sn clusters are found to be stacks of stable tricapped trigonal prism units [105].

2.5.2 BOLS Formulation

The generality of the atomic clusters is the atomic CN that is one or two lower than the atomic CN at a flat surface, four. As demonstrated in Sect. 14.3, only one CN loss makes a great difference—the bond is much shorter and stronger than the bonds at the surface.

The T m oscillation over the whole range of sizes for Sn and Ga+ clusters can be formulated by varying the bond nature index m as a function of z. Optimization leads to the relation that expresses the m value over the range from seven at z = 2 to one at z > 4:

Figure 14.4 shows that the T m curves drop generally with size and then bends up at K > 3 (Log(K) > 0.5, or z > 3) for higher m values. If the T m rise originates from the Cz deviation without bond nature change, the bond will contract to C z = 0.77 = 0.082. A 92 % bond contraction is impossible. Therefore, the m value, or the bond nature, must change with CN for these elemental solids. As the smallest clusters are not spherical in shape, the equivalent size might be subject to adjustment.

Comparison of the predicted T m ossification with those measured from \( {\text{Ga}}_{{13{-}17}}^{ + } \) [91, 97], \( {\text{Sn}}_{{10{-}19}}^{ + } \) [102], \( {\text{Sn}}_{{19{-}31}}^{ + } \) [22], \( {\text{Ga}}_{{39{-}40}}^{ + } \) [97], Sn500 [112], and Sn nanosolid on Si3N4 substrate [64]. The T m deviation of \( {\text{Al}}_{{50{-}60}}^{ + } \) clusters [109] from the predictions indicates that the bond nature alteration of Al is less significant compared to Sn and Ga bonds. Ideal fit is reached with a function of m(z) = 1 + 12/[1 + exp(z − 2)/1.5] to let m transit from 7 at z = 2 to 1 when z > 4 [113]

The m(z) modification matches closely the measurement of \( {{\text{Ga}}^{+}}_{17} \), \( {{\text{Ga}}^{+}}_{39{-} 40} \), Sn19–31, and Sn500 clusters, and Sn nanosolids deposited on Si3N4 substrate as well [64]. Calculations [100] show that the T m transition for Sn6–13 happens at Sn7. Results indicate that the nature of the Sn–Sn and the Ga–Ga bond indeed evolves from metallic covalent to pure covalent as atomic CN reduces to much lower values, as expected by Chacko et al. [98].

This bond nature evolution also complies with findings that the Al–Al bond for under-coordinated or distorted Al atoms at grain boundaries [106] and at free surfaces [107] becomes shorter (~5 %) and stronger with increasing covalent character [108]. However, bond nature evolution in \( {{\text{Al}}^{+}}_{49{-}60} \) clusters appears not as significant as occurred in Sn and Ga, as the T m for \( {{\text{Al}}^{+}}_{49{-}63} \) is 300 K lower than the T m(∞). The abrupt T m rise (~180 K) for \( {{\text{Al}}^{+}}_{51{-}54} \), \( {{\text{Sn}}^{+}}_{10{-}11} \) and \( {{\text{Sn}}^{+}}_{19{-}20} \) clusters [109] may be partly due to the closed shell structures that are highly thermally stable [110, 111].

Results show that bonding to two neighbors is stronger for an IV-A atom than bonding with three or more due to the bond nature evolution. This mechanism explains why a C13 cluster prefers a ring or a tadpole structure with each atom having two bonds, or tubes, or GNR sheet, or fullerene having three neighbors rather than the densely packed tetrahedron structure of four neighbors [99]. For the covalent, Si (m = 4.88) and C (m = 2.56) clusters should also show the T m elevation (bending up) at K < 3 with fewer than four neighbors.

The bond nature evolution may be the unique property of the III-A and IV-A elements with a larger number of electrons as compared to Al (m ~ 2), Ga (m = 6–7), C (m = 2.56), Si (m = 4.88), and Sn (m = 6–7).

2.6 Remarks

The BOLS premise has reconciled the undercooling, overheating, and oscillating of the T m over the whole range of sizes of various specimens to the effect of atomic CN imperfection and bond nature alteration. Atomic CN revised cohesive energy of the under-coordinated system determines the geometrical reconstruction, surface lattice/phonon instability, and surface energy. Actually, the surface and interfacial energy, surface stress, the local mass density of liquid and solid are all functions of atomic separation and bond energy that are subject to the BOLS correlation.

The T m suppression is directly related to the atomic CN imperfection and its effect on the bond strength. The T m elevation of embedded system is related to the strengthening of the interfacial bond. The T m oscillation over the whole range of size of III-A and IV-A elements results from atomic CN variation and bond nature evolution.

3 Solid Phase Transition

3.1 Observations

With reduction in a solid size, the phase stability of the solid becomes lower as well. The T C of ferromagnetic [114–116], ferroelectric [117–119], and superconductive [120–122] nanosolids can be modified by adjusting the shape and size of the nanosolid. The tunable T C will be an advantage for sensors or switches that can be functioning in a designed temperature range.

3.1.1 Ferromagnetic T C

For ferromagnetic nanosolids, such as Fe, Co, and Ni and their alloys or compounds [123–125], the T C reduces with the particle size or with the thickness of the films [114, 116, 126–133]. The T C of Prussian blue nanowire is also reduced with respect to the bulk [134] due to the diminution of the average number of nearest magnetic neighbors and magnetic exchange interaction constants. According to the scaling theory [135], a spin–spin correlation length (SSCL, or ξ) limitation model [136, 137] defines the SSCL as the distance from a point beyond which there is no further correlation of a physical property associated with that point. Values for a given property at distances beyond the SSCL are purely random. The SSCL depends functionally on temperature as ξ = ξ 0(1 − T/T C)−v, with v being a universal critical exponent. The SSCL premise indicates that the ξ is limited by the film thickness. If the ξ exceeds the film thickness K, the T C will be lower than the bulk value. The SSCL mechanism gives rise to the power-law form of T C(K) that involves two freely adjustable parameters, λ and C (or C 0). The λ value varies from unity to 1.59 for the mean-field approximation and the three-dimensional Ising model, respectively [127, 135, 137]:

An alternative non-continuous form based on the mean-field approximation covers the thinner scales [138]:

This relation shows that T C varies linearly with K and approaches to zero at K = 1 (single atom). If λ ≠ 1, there is a discontinuity at K = ξ.

The T C change in a spherical nanosolid is often related to the counts of surface bonds [139]. If the number of exchange bonds per unit volume inside the bulk is z, the number of bonds for the magnetically active surface atom is z/2 or less. The T C is proportional to the mean number of exchange bonds per unit volume, and then, the relative change in the T C is:

where ΔK is the thickness of the layer with half-depleted exchange bonds. The quantity ΔK is an average that characterizes the features of the surface CN-deficient structure of a nanosolid. If ΔK is independent of the particle radius K, the T C drops with K and the critical K C at which T C is zero is τΔK/2. This relation characterizes qualitatively the interrelation between the degree of magnetic structure disorder and the particle size for Fe3O4 spherical dots [140] by setting the critical thickness ΔK of half (for larger size) and two (for the smallest size) atomic sizes.

3.1.2 Superconductive T C

Highly dispersed superconducting nanosolids can be coupled due to the proximity effect when the interparticle spacing is of the order of twice the penetration length of the superconducting order parameter in the normal phase [141, 142]. The electronic energy levels of the sample are discrete, with a mean-level spacing of Kobo gap δ K for fine metallic particles [143, 144]: δK = 4E F/3n ∝ 1/V ∝ K−3. As pointed out by Anderson [145], superconductivity would not be possible when δ K becomes larger than the bulk E G. Thus, the relation between the superconducting phase transition and the energy-level spacing for spherical granules follows the relation [146, 147]:

Index m j is the magnetic quantum number. Estimation using this relation yields a 2.5 nm critical size for the disappearance of superconductivity of Pb nanosolid. Experiments of Giaver and Zeller [122] on Sn confirmed the existence of a metastable energy gap only for particles larger than 2.5 nm. However, the T C for Pb is detectable when the grown Pb atomic layers on Si substrate are four and more [148]. The T C suppression of Pb embedded in the Al-Cu-V matrix [121] does not follow this relation but the following:

with T C(∞) = 7.2 K for Pb [120]. Due to the finite number of electrons in each particle (between 1,000 and 64,000 depending upon the grain size), the conventional BCS approach loses its validity because the bulk BCS theory of superconductivity assumes an infinite number of electrons. Small size implies fewer electrons at the Fermi surface and the increased separation of Kubo levels. Additionally, energy-level spacing may be larger compared to thermal energy k B T. Therefore, the assumption of metallic behavior of these particles is subject to examination.

The T C of superconductive MgB2 thin films decreases and the residual resistance increases when the epitaxial MgB2 thin films become thinner [120, 149]. At sizes larger than 300 nm, the T C saturates at 41.8 K. The resistivity also saturates to the bulk value of 0.28 Ω cm at 300 nm. A possible explanation of higher T C is the strain in the film, while the grain size is not likely to be the direct cause of the thickness dependence of T C. XRD revealed that the a lattice expands from the bulk value of 0.3086 to 0.3095 nm while the c lattice contracts from 0.3524 to 0.3515 nm for a 230-nm-thick MgB2 film [150]. Hur et al. [151] reported a higher-than-bulk T C in MgB2 films on boron crystals and suggested that it is due to tensile strain. A T C elevation is possible by compressing the c-axis [152]

3.1.3 Ferroelectric T C

Unlike ferromagnetic and superconductive nanosolids that show smaller critical sizes for T C = 0 K, a ferroelectric nanosolid often shows larger critical size at which the ferroelectric feature disappears [153]. Reducing the grain size from 1,200 to 50 nm results in a progressive reduction in tetragonal distortion, heat of transition, T C, and relative dielectric constant of BaTiO3 crystal [154]. The critical size for ferroelectricity disappearance is in the range of 10–30 nm. A combination of the size effect and the size-dependent ‘dilution’ effect of a grain boundary ‘dead’ layer could be the cause depressing the relative permittivity. The remnant polarization of the nanoscaled Pb(Zr, Ti)O3 thin films decreases from 6.0 to 2.5 μC/cm2, while the coercive field increases from 50 to 150 kV/cm, with the decrease in film thickness from 152 to 32 nm [155].

Theoretical approaches for the ferroelectric depression include: (1) pseudospin theory based on the Ising model in a transverse field, (2) macroscopic Landau theory with consideration of surface effects, and (3) a polaron model for the very-long-wavelength region. The Landau-type model of Zhong et al. [156] considers the surface and non-equilibrium energy by introducing a surface extrapolation length δ to the size-depressed T C of ferroelectric nanosolids, expressed using the Ising premise, J ij = J/r σ ij . σ = 0 corresponds to an infinite-range interaction and σ = ∞ to a nearest-neighbor interaction [157].

Bursill et al. [158] assumed that the Landau-Ginzburg-Devonshire (LGD) coefficients in the Gibbs energy change with particle size. Huang et al. [159] combined the LGD theory and the BOLS correlation to study the size effect of ferroelectrics. The model assumes that the surface bond contraction is the origin for the size effect [160], which was confirmed by measurements. For example, barium titanate particles consist of a shell of cubic material surrounding a core of tetragonal material [161–163].

The following scaling relation is widely used to fit the T C suppression of ferroelectric nanosolids [118],

where C and the K C are adjustable parameters. The proper form of the dividend seems to be K + K C instead of K = K C. Jiang et al. [164] adopted their model for T m suppression to the size-dependent T C of the ferroelectric nanosolids as:

where S0 is the transition entropy and RS is the ideal gas constant. α is the thermal expansion coefficient and β the compressibility. The constant α90 denotes the density of 90° domain walls. This relation reproduces the measured T C suppression of BaTiO3 and PbTiO3 nanosolids with the known S0 values.

3.1.4 Antiferromagnetic Transition

When a sufficiently large magnetic field is applied along the preferred axis, the so-called spin-flop reorientation occurs, i.e., a 90° rotation of the sublattice vectors, in the antiferromagnetic α-Fe2O3 nanosolids [165]. Both the spin-flop field, HS-F (T = 0), and the Morin transition temperature (T M) decrease with particle size in a K−1 way and approach to zero when the diameter is smaller than 8 nm, for spherical particles [166]. Table 14.3 features the size-dependent HS-F and T M values.

The CN of the surface spins determines a variety of reversal paths and in turn affects both the exchange and anisotropy fields [165]. Therefore, the surface spins undergo spin-flop instability at field that is much lower than the field for the bulk. For Ho films, the helical antiferromagnetic ordering temperature, called Néel temperature (T N ), decreases with film thickness [167]. The offset thickness is 11 ML for metallic Ho films in comparison with the value of 16 ML for Cr in sputtered, epitaxial Fe/Cr(001) superlattice [168]. In the Pr0.5Ca0.5MnO3 nanowires, a ferromagnetic transition occurs at ~105 K; the antiferromagnetic transition happens at 175 K; and the charge ordering transition is suppressed from the bulk value of 245 K [169].

3.2 BOLS Formulation

An extension of the BOLS correlation into the Ising model could improve the insight into size-induced T C suppression of ferromagnetic, ferroelectric, and superconductive nanosolids as well as the T M and HS-F for antiferromagnetic heminatite.

3.2.1 Ising Model

The Hamiltonian of an Ising spin system in an external field B is expressed as [138],

The H ex is identical to the atomic E B under zero external field, B = 0. S i and S j is the spin operator in site i and site j, respectively. J ij is the exchange strength between spins, which is inversely proportional to atomic distance. The sum is over all the possible coordinates, z i . For phase transition, the thermal energy required is in equilibration with a certain portion of the exchange energy. This mechanism leads to the case being the same as for T m suppression as described in Eq. (14.13).

3.2.2 High-Order CN Imperfection: The Dual-Shell Model

For ferroelectric systems, the exchange energy also follows the Ising model, but the S j here represents the quanta of a dipole or an ion (called quasi-dipole) that is responsible for the ferroelectric performance. The difference in the correlation length is that the dipole system is longer than that of a ferromagnetic spin–spin system. Usually, dipole–dipole Van der Vaals interaction follows the r −6 type whereas the superparamagnetic interaction follows an r −3 relation. Hence, it is insufficient to count only the exchange bonds within the nearest neighbors for atoms with distant interaction in a ferroelectric system.

A dual-shell model describing the short- and the long-range interactions in the ferromagnetic nanosolid is necessary [170]. A critical exchange correlation radius K C can be defined to count contributions from all atoms within the sphere of radius K C. Therefore, the sum in Eq. (14.13) changes from the z i neighbors to atoms within the K C-sized correlation volume.

For a ferroelectric spherical dot with radius K, one needs to consider the interaction between the specific central atom and its neighbors within the critical volume V C = 4πK 3C /3, in addition to the BOLS correlation limited to the skin. The ferroelectric property drops down from the bulk value to a value smaller than 5/16 (estimated from Fig. 14.5) when one goes from the central atom to the edge along the radius. If the surrounding volume of the central atom is smaller than the critical V C, the ferroelectric feature of the central atom attenuates; otherwise, the bulk value remains. For an atom in the ith surface layer, the number of the exchange bonds loss is proportional to the volume V vac that is the volume difference between the two caps of the V C-sized sphere as illustrated in Fig. 14.5a. Therefore, the relative change in the ferroelectric exchange energy of an atom in the ith atomic layer to that of a bulk atom due to volume loss becomes,

The dual-shell model for the short- and long-range interactions in nanosolid ferroelectric nanosolid. a Schematic of the high-order exchange bonds loss of an atom in a spherical nanosolid with radius K. K C is the critical correlation radius. The V vac loss (the shaded portion) is the difference between volumes of the two spherical caps: \( \begin{array}{l} V_{{{\text{vac}},i}} = \pi (K_{\text{C}} + K_{i} -K\cos \theta )^{2} (K_{\text{C}} - \frac{{K_{\text{C}} + K_{i} - K\cos \theta}}{3}) \hfill \\ -\pi (K - K\cos \theta )^{2} (K - \frac{K -K\cos \theta }{3}) \hfill \\ \end{array} \) , where the angle θ is determined by the triangle O1O2A. b Correlation radius K C dependence of the T C shift of ferroelectric and superconductive nanosolids. For K C = 5 example, BOLS lowers the T C by −41.1 %, the high-order bond loss contributes to the T C suppression by −53 %, and the overall T C shift is −94 %. K C ≤ 4, T C = 0 [171] (Reprinted with permission from [7])

3.2.3 Generalization of T C Suppression

Considering the BOLS correlation for the nearest neighbors and the volume loss of long-order CN imperfection, we have a generalized form for the T C suppression for the ferromagnetic, ferroelectric, and superconductive nanosolids (m = 1 in the Ising model):

For a short-order spin–spin interaction, the sum is over the outermost three atomic layers in terms of BOLS whereas for a long-order dipole–dipole interaction, the sum is within the sphere of the critical volume V C. Therefore, ΔK in Eq. (14.17) is not a constant. In the BOLS premise, the γ i is not always proportional to the inverse radius, which drops instead from unity to infinitely small when the particle grows from atomic scale to macroscopic size. Meanwhile, the z i and the C i vary with the curvature of the sphere.

Figure 14.5b shows the general K C dependence of the ferroelectric T C shift involving both the volume loss and the BOLS effect. For K C = 5 example, bond contraction lowers the T C by −41.1 % and the volume loss lowers the T C by −53 % and the overall T C shift is −94 %.

3.3 Verification: Critical Size

Least-root-mean-square linearization of the measured size-dependent T C represented by Eq. (14.20) gives the slope B′ and an intercept that corresponds to the bulk T C(∞). The B′ = KΔCOH for a ferroelectric system. For a ferromagnetic system, B′ = KΔB is a constant without needing numerical optimization. Calculations based on Eq. (14.20) were conducted using the average bond length (appendix A2) and the known T C(∞) values listed in Table 14.4.

Figure 14.6 shows the T C suppression for ferromagnetic Ni, Co, and Fe3O4 nanosolids. For ultrathin films, the measured data are closer to the predicted curve for a spherical dot. This coincidence indicates that at the beginning of film growth, the films prefer island patterns that transform gradually into a continuous slab. For a ferroelectric system, we need to optimize the K C value by in computation to match theoretical curves to the measured data.

Figure 14.7 shows the T C suppression of ferroelectric PbTiO3 [117], SrBi2Ta2O9 [119], BaTiO3 [173], and antiferroelectric PbZrO3 [174] nanosolids. For ferroelectric and superconductive nanosolids, T C = 0 K occurs at V vac = V C, which means that K C corresponds not to T C = 0 K, but to a value that is much lower than room temperature. The difference in the optimized K C by different approaches, as compared to Table 14.4, lies in that the γ i is not a constant but changes with particle size.

Comparing the BOLS prediction to the measured T C suppression of superconductive MgB2 nanosolids in Fig. 14.8 leads to an estimation of the critical radius K C = 3.5 of measurement (R C ~ 1.25 nm) [175]. For the smallest MgB2 crystals, the relative Bragg intensities of the allowed reflections can only match during Rietveld refinement by introducing statistically distributed B-vacancies, with the refined value falling from 1 to 2/3. This fact means that the average CN of Mg to B atoms falls from 12 to 8, which indicates the loss of superconductivity due to the under-coordination effect [176]. Therefore, long-range interaction is important to the superconductive T C. For an Al–Cu–V embedded Pb nanosolid [121], the K C is around 1, being the same to the ferromagnetic solid. For the antiferromagnetic α-Fe2O3, a spin-flop transition at a critical size of 8 nm results also from the high-order CN imperfection. Therefore, the long-order interaction dominates the T C for all the ferroelectric, antiferroelectric, and superconductive nanocompounds.

4 Diffusion and Crystal Growth

4.1 Diffusivity

4.1.1 Observations

The kinetics of diffusion occurring in nanostructured materials is a subject of intensive study [178, 179]. Materials at the nanoscale showed sharp acceleration of diffusion [180], indicating the lowered activation energy of diffusion. The activation enthalpies for the interfacial diffusion are comparable to those for surface diffusion, which are much lower than those for diffusion along grain boundaries [181, 182].

Measuring grain boundary diffusion fluxes of Cu and creep behavior of coarse-grained and nanostructured Ni samples at 423 and 573 K [183] revealed that the creep acceleration behavior is grain size-dependent because of the high diffusivity in the finer grain material. Fe-tracer diffusion in submicrocrystalline Pd powders demonstrates that interfacial diffusion occurs at relatively low temperatures accompanied by a substantial recovery of grain growth [184]. Atomic defects trigger the recovery processes and the crystal growth occurring in a main recovery stage at 500 K. The under-coordinated atoms surrounding the defects are responsible for the onset of diffusion in the interfaces as these atoms are mobile in this temperature regime.

By means of surface mechanical attrition treatment (SMAT) to a pure iron plate, Wang et al. [185] fabricated a 5-μm-thick Fe surface layer composed of 10–25-nm-sized grains without porosity or contamination on the Fe plate. They measured Cr diffusion kinetics within a temperature range of 573–653 K in the nano-Fe-coated plate. The diffusivity of Cr in the nanocrystalline Fe is 7–9 orders higher in magnitude than that in a Fe lattice and 4–5 orders higher than that in the grain boundaries (GBs) of α-Fe. The activation energy (E A) for Cr diffusion in the Fe nanophase is comparable to that of the GB diffusion, but the pre-exponential factor is much higher. The enhanced diffusivity of Cr in Fe corresponded to a large volume fraction of non-equilibrium GBs and a considerable amount of triple junctions in the presence of the nanocrystalline Fe samples.

Under the given conditions, copper atoms were not detectable in the coarse-grained Ni even at a depth of 2 μm. However, the diffusive copper fluxes in nanostructured Ni penetrate into a depth greater than 25 and 35 μm at 423 and 573 K, respectively [183]. This information leads to the GB diffusion coefficients of copper in nanostructured nickel as derived as follows.

As no migration of the GBs in nanostructured Ni was observed at 423 K, the diffusion coefficient, D b, can be determined using the equation describing the change in the GB impurity concentration versus time t of the diffusion at annealing [186]:

where c 0 is the concentration of copper in the skin. The depth x is the distance from the surface at which log c = −1 (c = 0.1 %, which corresponds to the resolution limit of the SIMS unit). An extrapolation of the experimental concentration curve at x → 0 gives the value of c 0. In this case, D b = 1 × 10−14 m2/s (t = 3 h).

Grain growth occurs in nanostructured nickel annealed at 573 K, and the grain boundary migration occurs at the velocity of V ~ 7 × 10−11 m2/s. In this case, the D b follows [186]:

Considering the diffusion width of the boundary βb = 10−8 m, one can obtain the D b = 1.4 × 10−12 m2/s, which is two orders higher than that for the same sample annealed at 423 K. These experimental data demonstrate the increase in the GB diffusion coefficient of copper in nanostructured Ni in comparison with that happens in the coarse-grained nickel.

The interdiffusion between Ag and Au is enhanced when the Au particle size is reduced [187]. For the very small particles (<4.6 nm initial Au-core size), these two metals are almost randomly distributed within the particle; for larger particles, the diffusion boundary is only one monolayer. These results are beyond the scope of surface pre-melting effect. Defects at the bimetallic interface seemed to enhance the radial migration of one metal into the other [187].

In situ four-point probe measurements of the onset temperature at which the electrical resistivity deviates from linearity during the temperature ramping [188] revealed that at the deviation point, the Ag thin films become unstable due to void formation and growth during annealing. In vacuum, Ag thin films thicker than 85 nm on SiO2 substrates are thermally stable. Using the Arrhenius relation in terms of onset temperature and film thickness, an E A of 0.326 ± 0.02 eV is obtained for the onset of Ag agglomeration ramped at a rate of 0.1 °C per second. This value is consistent with the E A for surface diffusion of Ag in a vacuum. Therefore, Ag agglomeration and surface diffusion share the same E A, both of which depend on the atomic cohesive energy.

The high diffusivity at the nanoscale also enhances diffusion of a liquid into the nanosolid [189]. Powder nanosolids as electrodes in chemical sensors show much improved diffusion efficiency (10–104) [189]. Further, the powder ultramicroelectrode can significantly enhance the mass transportation rate from solution to the nanosolids surface, being irrespective of particular catalytic material [190, 191].

4.1.2 BOLS Formulation

According to the BOLS, atomic CN imperfection suppresses the E B that is responsible for the E A loss in atomic diffusion, agglomeration, and glide dislocation. The diffusivity D follows the Arrhenius relation,

where the activation enthalpy of diffusion is E A(∞) = 1.76 eV and the pre-exponential factor is D 0 = 0.04 cm2 s−1 for gold. Incorporating the BOLS into the interdiffusion and nanoalloying by letting E A ∝ E B and hence the EA is atomic CN dependent.

Diffusing an atom into the solid requires energy to relax partially the bonds for atom dislocations. Applying Eq. (14.12)–(14.21) by considering the size effect, one has,

Therefore, the nanodiffusivity increases at the nanoscale because of the reduced atomic EB. The D(K, T) drops with the T m(K)/T m(∞) ratio in an exponential way. This formulation provides a feasible mechanism for the nanoalloying, nanodiffusion, and nanoreaction in the grain boundaries where under-coordinated atoms dominate.

However, oxidation resistance of a Si nanorod exhibits oscillation features [192]. At the lower end of the size limit, Si nanorod can hardly be oxidized, as oxide tetrahedron formation is strongly subject to the atomic geometrical environment. For instance, oxidation happens preferentially at the densely packed diamond [111] plane of C3v symmetry rather than the loosely packed (110) surface [193]. The high surface curvature of Si nanorod and the shortened surface bond resists the formation of an oxide tetrahedron.

Figure 14.9 compares the measured size-dependent T m suppression and diffusion-coefficient enhancement of silica-encapsulated gold particles [78] in comparison with BOLS prediction. The trend similarity shows the correlation between the diffusivity and activity in terms of activation energy.

Size dependence of the T m and the diffusivity of silica-encapsulated gold particles. a The solid curve (right-hand side axis) is the calculated Au self-diffusion coefficient [78]. b BOLS predicted size-dependent diffusivity

4.2 Crystal Growth

4.2.1 Liquid–Solid Epitaxy

Knowing the initial stages of growth of nanometer-sized crystals from the molten or amorphous matrix is a challenging issue. This process largely determines the resulting microstructure of a polycrystalline material, which is extremely difficult to study experimentally due to the small size of the clusters and the short time period involved. MD simulation results on the homoepitaxial growth and melting of Si provide an example for the understanding in terms of the transition-state theory of crystal growth.

According to transition-state theory, the driving force, F C, for the movement of the liquid–crystal interface is the free energy difference between the liquid and bulk crystal. This difference is approximately proportional to the magnitude of the undercooling, T m − T. The velocity of the moving interface, V, is proportional to the driving force V = kF C, where k is the mobility of the liquid–crystal interface. This interfacial mobility determined by the movement of the atoms in the liquid phase as atoms residing in the crystalline phase are far less mobile. Therefore, this mobility is proportional to the thermally activated atomic diffusion in the liquid phase. As is well established, T m suppression happens in a cluster of finite size due to atomic CN imperfection, which contributes to the free energy of the liquid–crystal interface.

The T m drop with solid size is a reflection of the reduced atomic EB and the mobility activation energy E A (∝ atomic E B) of the liquid–crystal interface, which is essentially the same to that for liquid diffusion. In the study of growth and melting of Si, the crystal front velocity follows the Stillinger–Weber (SW) potential that consists of additive two-body and three-body energy terms. The three-body term is zero for the perfect-crystal structure at T = 0 K, but even at high temperature, the three-body term is relatively low in the crystalline phase (e.g., the three-body energy is about 0.1 eV/atom at T = 1,200 K). In contrast, the liquid phase is characterized by a larger three-body energy (−1 eV/atom). Using this large difference, Keblinski [86] calculated the amount of crystal and liquid phase present in the simulated cell simply by monitoring the total three-body energy and using it as reference for the corresponding values of the bulk liquid and bulk solid at the same temperature.

The size-dependent T m(K) contributes to the growth/melt behavior of clusters with various initial sizes as a function of temperature. The free energy of the cluster results from the surface and the bulk contributions. The surface contribution, U S, approximates the product of the surface area and the liquid–solid interfacial free energy, γ ls , such that U S = Aγ ls K 2, where A is a geometrical constant (for a spherical dot, A = 4πd 20 ). The bulk contribution, U B, approximates the product of the volume of the cluster and the difference in free energy densities between solid and liquid, Δu, such that U B = BΔuK 3, where B is another geometrical constant (for a spherical cluster B = 4πd 30 /3).

The difference between crystal and liquid free energy densities in the vicinity of the T m is proportional to the magnitude of undercooling (or overheating), Δu = u 0(T − T m(K)), where u 0 is a constant (Δu correctly vanishes at T m). For a given temperature, the critical cluster size corresponds to the maximum of the free energy U = U S + U B. By differentiating the free energies with respect to the cluster size K, one finds the maximum at T = T m(K) − cγ sl /K, where c is a constant depending on A, B, and u 0. The linear dependence of the T m on the inverse of the crystalline size implies that the interfacial energy, γ sl , does not change significantly with temperature, from the first-order approximation. In reality, the interfacial energy varies with both size and temperature.

In order to understand the temperature dependence of the growth rate in terms of undercooling and thermally activated interfacial mobility, one may assume that in the classical nucleation theory, growth takes place on an atom-by-atom basis. Hence, the average rates of crystallization and dissolution are [86]:

where \( \Delta A \) = A n+1 − A n is an increase in the interfacial area due to the attachment of an atom to the crystal. The ν is the thermal vibration frequency of the interfacial atom. The cluster growth velocity resulting from the difference between ν + and ν −, which yields

The argument of the hyperbolic sine is small near the T m (it is exactly zero at the T m(K)). Equation (14.23) indicates that the rate of the growth/melting is driven by the lowering of the free energy, \( {\Delta }u - {\Delta }A \)γ sl , while the interfacial mobility is determined by the E A for diffusion jumps of the interfacial atoms. Noting that \( {\Delta }A \) is proportional to K−1 and Δu = u 0(T − T m(K)), and then, the scaling law for melting applies ΔT m(K) ~ γ sl /K. (T m(K) is the temperature at which V grow = 0.) For planar growth, the interfacial contribution to the free energy disappears; thus, V grow is zero exactly at the T m(∞) (Δu = 0).

For a given cluster size, the free energy term can be expanded around its T m(K) such that

This process describes the kinetics of liquid-nanosolid dissolution and growth. The EA obtained from the best fits are 0.75 ± 0.05 eV for 2.0- and 2.6-nm solids and 0.85 ± 0.05 eV for 3.5-nm solids, respectively. This result complies with the BOLS expectation that the mean atomic EB increases with solid size. Incorporating the BOLS correlation to the T m(K) and E A (K), Eq. (14.24) becomes,

The exponential part is the same to the diffusivity (see Eq. (14.22)). Size-induced perturbation appears twice in this formulation. Results in Fig. 14.9a show the mobility of the liquid–solid interface that is determined by diffusion in the adjacent bulk liquid, which is exactly the case of homoepitaxial growth.

4.2.2 Vapor Phase Deposition

The knowledge of size-dependent melting provides guidelines for controlling the size of nanosolid growth on heated substrates in vapor deposition and modulating the crystal size by annealing. For a given substrate temperature (T S), there will be a minimum critical size of the grown particle. Thus, any particle larger than this critical size will grow and remain. If the incident sourcing cluster size is smaller than the critical size, the particles will melt upon deposition and they will coagulate to produce clusters equal to the critical size or larger. If the T S is higher than the T m, the landed clusters merge and then evaporate [79]. This intuition implies that the T S should be as low as possible if one wants to obtain smaller particles.

This mechanism also applies to controlling the sinterability of nanosolids. In fact, the solid size of an oxide increases with annealing temperature [195] and agglomeration happens at a certain size range at room temperature in the process of ball milling [196, 197]. The T S-related nucleation and agglomeration explains why the topmost Bi layers on graphite start to lose long-range order at 10–15 K below the T m(∞) of Bi, 544.52 K and why nucleation occurs at ~125 K below the T m(∞). The temperature of melting and solidification of the same surface is different [198].

Normally, the T S(K) for growth is around 0.3 times the T m(K) [194, 199],

which gives the thermally stable critical size at the given T S:

The constant Δ′B = −2.96 for a spherical metallic dot (m = 1; τ = 3; K C > 3). The critical size and the number of atoms in the deposited nanosolid depend on the \( {{T_{\text{S}} \left( {\tau ,K} \right)} \mathord{\left/ {\vphantom {{T_{\text{S}} \left( {\tau ,K} \right)} {0.3T_{\text{m}} \left( \infty \right)}}} \right. \kern-0pt} {0.3T_{\text{m}} \left( \infty \right)}} \) ratio.

Figure 14.10b formulates the R C (= K C d) dependence on the T S. With the known atomic size d and T m(∞), one is able to control the crystal size [200]. This relation predicts that a monatomic layer of metals (τ = 1) could only growth at T S = 0 K or nearby. This prediction is in accordance with observations, For instance, monolayer Pd forms on Si surface only at 4 K or below [148].

a MD simulation of size and temperature dependence of Si nanosolid melting (negative) and growth (positive) [86]. b Agreement between BOLS predictions with measurements [194] of TS = 0.3T m dependence of critical sizes for W (T m(∞) = 3,695 K), Ni (1,728 K), and Ag (1,235 K) nanocrystal growth. ZnO Size control of c the crystal size and d the EPL and EPA by a programmable annealing at: (1) as-grown, (2) 773 K, (3) 873 K, and (4) 923 K (Reprinted with permission from [7])

4.3 Thermally Control of Crystal Size and Bandgap

Grain size that determines the bandgap of a nanosolid semiconductor is controllable by programming the growing or annealing temperature T S [195]. For the post-annealing process, the as-grown particle size (K 0) and threshold temperature (T th) are involved. The high-energy grain boundary does not gain mobility until reaching T th, at which grains grow upon heating to minimize the overall energy. With T th and K 0 being taken into consideration, Eq. (14.26) evolves into the form describing the T a dependent of the critical size:

This relation indicates that the crystal size is dominated by the term (T a − T th )/[0.3T m(∞)]; grain grows as T a rises when T a > T th. The grain radius K is hence controllable by tuning the T a.

The inset in Fig. 14.10 shows the SEM micrograph of spontaneous grain growth at different temperatures. Both the crystal size and the bandgap agree with the BOLS expectation on the T a dependence of the physical properties.

5 Summary

The BOLS correlation has enabled the thermodynamic behavior of a nanosolid to be consistently formulated and understood in terms of atomic cohesive energy modulation. The difference between the cohesive energy of an atom at the surface and that of an atom inside the solid determines the fall or rise of the T m of a surface and a nanosolid. The T C suppression for ferromagnetic, ferroelectric, and superconducting nanosolids follows the same trend of T m whose change follows the BOLS prediction including the short- and the long-range interactions.

Numerical match between predictions and measurements for a number of specimens reveals that the short spin–spin correlation dominates the exchange interaction in the ferromagnetic Fe, Co, Ni, and Fe3O2 nanosolids, whereas the long-range interaction dominates the exchange energy for the ferroelectric PbTiO3, PbZrO3, SrBi2Ta2O9, and BaTiO3, and the superconductive MgB2 nanosolids.

The BOLS premise also reconciles the activation energy for diffusion, agglomeration, and nucleation in crystal growth and the temperature dependence of the crystal size in annealing and vapor–solid epitaxial growth. It is possible to tune the crystal size and properties such as the band gap of noncrystallite by controlling the processing temperatures.

References

W.H. Qi, M.P. Wang, Size effect on the cohesive energy of nanoparticle. J. Mater. Sci. Lett. 21(22), 1743–1745 (2002)

D. Xie, M.P. Wang, W.H. Qi, A simplified model to calculate the surface-to-volume atomic ratio dependent cohesive energy of nanocrystals. J. Phy.-Condens. Matter 16(36), L401–L405 (2004)

W.H. Qi, M.P. Wang, G.Y. Xu, The particle size dependence of cohesive energy of metallic nanoparticles. Chem. Phys. Lett. 372(5–6), 632–634 (2003)

D. Tomanek, S. Mukherjee, K.H. Bennemann, Simple theory for the electronic and atomic-structure of small clusters. Phys. Rev. B 28(2), 665–673 (1983)

Q. Jiang, J.C. Li, B.Q. Chi, Size-dependent cohesive energy of nanocrystals. Chem. Phys. Lett. 366(5–6), 551–554 (2002)

H.K. Kim, S.H. Huh, J.W. Park, J.W. Jeong, G.H. Lee, The cluster size dependence of thermal stabilities of both molybdenum and tungsten nanoclusters. Chem. Phys. Lett. 354(1–2), 165–172 (2002)

C.Q. Sun, Size dependence of nanostructures: Impact of bond order deficiency. Prog. Solid State Chem. 35(1), 1–159 (2007)

T. Gorecki, Vacancies and changes of physical-properties of metals at melting-point. Z. Metallk. 65(6), 426–431 (1974)

M.W. Finnis, The Harris functional applied to surface and vacancy formation energies in aluminum. J. Phys.-Condens. Matter 2(2), 331–342 (1990)

H. Brooks, Impurities and Imperfection (American Socienty for Metals, Cleveland, 1955)

W.H. Qi, M.P. Wang, Size dependence of vacancy formation energy of metallic nanoparticles. Phys. B-Condens. Matter 334(3–4), 432–435 (2003)

E.A. Brands, Smithells Metals Reference Book, 6th edn. (Butterworths, London, 1983)

A.R. Miedema, Surface energies of solid metals. Z. Metallk. 69(5), 287–292 (1978)

A.N. Goldstein, C.M. Echer, A.P. Alivisatos, Melting in semiconductor nanocrystals. Science 256(5062), 1425–1427 (1992)

J.G. Dash, History of the search for continuous melting. Rev. Mod. Phys. 71(5), 1737–1743 (1999)

J. Penfold, The structure of the surface of pure liquids. Rep. Prog. Phys. 64(7), 777–814 (2001)

V.P. Modak, H. Pathak, M. Thayer, S.J. Singer, B.E. Wyslouzil, Experimental evidence for surface freezing in supercooled n-alkane nanodroplets. Phys. Chem. Chem. Phys. 15(18), 6783–6795 (2013)

J.I. Akhter, Size-dependent superheating in confined Pb(111) films. J. Phys.-Condens. Matter 17(1), 53–60 (2005)

H.W. Sheng, G. Ren, L.M. Peng, Z.Q. Hu, K. Lu, Superheating and melting-point depression of Pb nanoparticles embedded in Al matrices. Philos. Mag. Lett. 73(4), 179–186 (1996)

H.W. Sheng, G. Ren, L.M. Peng, Z.Q. Hu, K. Lu, Epitaxial dependence of the melting behavior of In nanoparticles embedded in Al matrices. J. Mater. Res. 12(1), 119–123 (1997)

Y. Lereah, G. Deutscher, P. Cheyssac, R. Kofman, A direct observation of low-dimensional effects on melting of small lead particles. Europhys. Lett. 12(8), 709–713 (1990)

A.A. Rouse, J.B. Bernhard, E.D. Sosa, D.E. Golden, Variation of field emission and photoelectric thresholds of diamond films with average grain size. Appl. Phys. Lett. 75(21), 3417–3419 (1999)

N. Hamada, S. Sawada, A. Oshiyama, New one-dimensional conductors—graphitic microtubules. Phys. Rev. Lett. 68(10), 1579–1581 (1992)

V.P. Skripov, V.P. Koverda, V.N. Skokov, Size effect on melting of small particle. Phys. Status Solidi A-Appl. Res. 66(1), 109–118 (1981)

J.F. Pocza, A. Barna, P.B. Barna, Formation processes of vacuum-deposited indium films and thermodynamical properties of submicroscopic particles observed by in situ electron microscopy. J. Vacuum Sci. Technol. 6(4), 472–474 (1969)

Y.J. Lee, E.K. Lee, S. Kim, R.M. Nieminen, Effect of potential energy distribution on the melting of clusters. Phys. Rev. Lett. 86(6), 999–1002 (2001)

S.C. Santucci, A. Goldoni, R. Larciprete, S. Lizzit, M. Bertolo, A. Baraldi, C. Masciovecchio, Calorimetry at surfaces using high-resolution core-level photoemission. Phys. Rev. Lett. 93(10), 106105 (2004)

P. Bergese, I. Colombo, D. Gervasoni, L.E. Depero, Melting of nanostructured drugs embedded into a polymeric matrix. J. Phys. Chem. B 108(40), 15488–15493 (2004)

I.S. Hwang, S.H. Chang, C.K. Fang, L.J. Chen, T.T. Tsong, Observation of finite-size effects on a structural phase transition of 2D nanoislands. Phys. Rev. Lett. 93(10), 106101 (2004)

L. Miao, V.R. Bhethanabotla, B. Joseph, Melting of Pd clusters and nanowires: A comparison study using molecular dynamics simulation. Phys. Rev. B 72(13), 134109 (2005)

F.G. Shi, Size-dependent thermal vibrations and melting in nanocrystals. J. Mater. Res. 9(5), 1307–1313 (1994)

P. Buffat, J.P. Borel, Size effect on melting temperature of gold particles. Phys. Rev. A 13(6), 2287–2298 (1976)

P. Pawlow, The dependency of the melting point on the surface energy of a solid body (Supplement). Zeitschrift Fur Physikalische Chemie–Stochiometrie Und Verwandtschaftslehre 65(5), 545–548 (1909)

H. Reiss, P. Mirabel, R.L. Whetten, Capillarity theory for the coexistence of liquid and solid clusters. J. Phys. Chem. 92(26), 7241–7246 (1988)

H. Sakai, Surface-induced melting of small particles. Surf. Sci. 351(1–3), 285–291 (1996)

K.J. Hanszen, Theoretische untersuchungen uber den schmelzpunkt kleiner kugelchen—ein beitrag zur thermodynamik der grenzflachen. Z. Angew. Phys. 157(5), 523–553 (1960)

P.R. Couchman, W.A. Jesser, Thermodynamic theory of size dependence of melting temperature in metals. Nature 269(5628), 481–483 (1977)

R.R. Vanfleet, J.M. Mochel, Thermodynamics of melting and freezing in small particles. Surf. Sci. 341(1–2), 40–50 (1995)

B. Vekhter, R.S. Berry, Phase coexistence in clusters: an ‘‘experimental’’ isobar and an elementary model. J. Chem. Phys. 106(15), 6456–6459 (1997)

Q. Jiang, Z. Zhang, J.C. Li, Superheating of nanocrystals embedded in matrix. Chem. Phys. Lett. 322(6), 549–552 (2000)