Abstract

The current practices of containing the waste in dumpsite/landfill are considered as unsustainable due to their negative impact on the environment, society and economy. Remediation of the existing open dumpsite into bioreactor landfills helps in recovering the valuable land area at a faster rate due to the reduction in the time required for waste stabilization process. The problem of leachate treatment can also be addressed effectively during the remediation process. Therefore, remediating an existing dumpsite can be classified as an approach towards achieving the sustainability in landfilling practices. In this study, an approach for remediating an existing municipal solid waste (MSW) dumpsite in Bangalore city is presented by addressing the three major aspects, viz., landfill gas (LFG), leachate and the recovery of air space. Modelling tools are used to estimate the LFG emission and to design the leachate collection and recirculation systems. The methane oxidation potential of the digested MBT waste as a biocover material is evaluated using column experiments. The biocover systems are then designed to mitigate the LFG emissions from the dumpsite.

Access provided by Autonomous University of Puebla. Download chapter PDF

Similar content being viewed by others

Keywords

1 Introduction

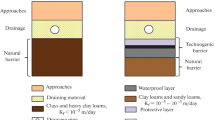

As per the United States Environmental Protection Agency (US EPA 2008) [1], “Sustainability creates and maintains the conditions under which humans and nature can exist in productive harmony, which permits fulfilling the social, economic and other requirements of present and future generations”. Any process, product or technology can be deemed as sustainable when its impact on the social, economic and the environmental aspects is well balanced to create harmony between humans and the nature. The current waste management practices followed in low- and middle-income countries predominantly consist of disposal of municipal solid waste (MSW) in the dumpsites and the landfills [2]. Dumping or landfilling of MSW directly impacts all the three components of the environment, viz., atmosphere (landfill gas emission), hydrosphere (leachate contamination of the groundwater table) and lithosphere (leachate and MSW contaminate the soil) and can be deemed as unsustainable practice. Such practices also ignore the economic value of the waste as the energy and nutrient content of the MSW remain generally untapped. Improvement in the overall sustainability of the landfilling process can be attained by addressing the three major aspects, viz., mitigation of landfill gas (LFG), leachate treatment and the recovery of air space. The above features can easily be incorporated in a new MSW treatment facility consisting of a bioreactor landfill. From the sustainability perspective, bioreactor landfills are preferred to the open dumpsites and conventional landfills due to the social, economic and environmental considerations [3, 4]. In bioreactor landfills, provisions are made for leachate collection through under drainage system, leachate recirculation and collection of landfill gas from the inception stage itself. The schematic representation of the sustainability concept in landfill engineering is shown in Fig. 1. In this concept, the waste treatment facility primarily consists of four bioreactor landfills operating at different waste stabilization phases. After complete stabilization of waste, the biomining activity is carried out before repeating entire process again. Additionally, all the other features which minimize the impact on environment are incorporated in this approach.

The open dumpsites lack the features of bioreactor landfills, and adopting the same for the existing dumpsites would not be possible. Alternatively, open dumps can be retrofitted by providing vertical or horizontal wells to collect and recirculate the leachate and by designing biocover systems to mitigate the landfill gas emissions.

The MSW management rules of 2016 have mandated for the remediation of the existing dumpsites in the country which is in turn a step towards achieving the sustainability in waste management practices. With this in perspective, the sustainable remediation of existing dumpsites for the Indian context is explored in this study. The overall objectives of the study are given below.

-

Suggest a remediation plan for an existing MSW dumpsite of Bangalore city by providing an approach for the design of the,

-

Leachate collection and recirculation system,

-

Biocover system for controlling landfill gas emission.

-

2 Methodology

2.1 Site Description

Several dumpsites are being used by the Bangalore municipality for the disposal of MSW generated from the city. Based on the observations made during the site visits, it can be concluded that the problems encountered at these dumpsites are of the same type. Therefore, the approach suggested in this study is also applicable to most of the other dumpsites in Bangalore. In this study, a typical landfill of 4 acres in area and 10–20 m in depth with the liner system is considered. Total unsegregated municipal solid waste of around 1,00,000 tons is assumed to be dumped during the active landfilling phase (between the year 2017 and 2018). The site description for Bangalore dumpsite considered in this study is given in Table 1.

The problems associated with the dumpsites that were observed during the site visits are as follows. Majority of the landfills in Bangalore do not have the leachate or the gas collection systems. The landfill site considered in the study does not have a cover system, but a proper liner system is present at the bottom. The waste is dumped directly on the liners and is not compacted to achieve the target density of MSW. The provision for the leachate or the landfill gas collection systems is absent. Therefore, the waste contained in the landfill gets saturated during the rainy season and thus increases the risk of groundwater contamination. High leachate head was observed during the site visit (almost up to the surface). The LFG emissions are not controlled, which may cause fire hazards and contribute to global warming.

2.2 Sustainable Approach

The goal of the sustainable approach is to remediate/operate the dumpsite in a way that reduces the human and environment risk in a cost-effective manner. The sustainability approach suggested in this study includes:

-

Landfill gas emission control,

-

Leachate collection system,

-

Leachate recirculation system,

-

Biomining and land space recovery.

2.3 Landfill Gas Emission Control

LandGEM model version 3.02 developed by USEPA is used to estimate the total landfill gas emissions from landfill site. The model parameters required for the estimation of LFG generated are the waste intake time duration, capacity of the landfill, methane generation rate (k, year−1), methane generation capacity (L0, m3/Mg) and waste acceptance rate [5]. The MSW composition affects the values of methane generation rate and methane generation capacity. The MSW composition of Bangalore and the derived composition of the MSW used for estimation of ultimate methane yield are given in Tables 2 and 3 respectively.

2.4 Methane Oxidation Experiment in Biocovers

Cover system in landfills aids in reducing odour, vectors, flies and helps in the control of storm water and leachate. In addition to these, biotic system helps in converting methane gas into carbon dioxide by oxidation when landfill gas is passed through it. This process is achieved by the action of a group of microorganism known as methanotrophs [9]. The most widely used biotic systems are biofilters, biowindrows and biocovers. Column studies were conducted in laboratory to explore the potential of the mechanically biologically treated waste as an effective biocover material.

The MBT waste used for experiments was collected from Mavallipura landfill site and was anaerobically digested for 470 days. The details pertaining to waste sampling, characteristics and anaerobic treatment are given in Lakshmikanthan [3]. The methane oxidation studies were carried out in a PVC column of 15.4 cm diameter and 100 cm in height. The schematic diagram of the setup is shown in Fig. 2.

Schematic diagram of column experiment for methane oxidation in biocovers (Reprinted from sughosh et al. [10]. With permission from ASCE)

A gravel bed of 100 cm was placed at the bottom of the column which acted as a support and as the gas distribution layer. A geonet layer was placed above this, and the media was filled in five layers of 5–10 cm thick. 99.95% CH4 gas was fed to the bottom of the column, and a constant flow rate of 13.6 mL/min was maintained by using rotameter. At the top headspace of the column, a humidified air flow of 100–300 mL/min was maintained to simulate the atmospheric boundary condition. Both the methane and air flow rates were periodically checked by using bubble flow meters. The experiment was conducted at room temperature. A provision for collecting the gas sample for the column was made with the help of a septa arrangement connected to a narrow 1-mm-diameter pipe embedded in a fine cloth to filter the dust particles. This arrangement was placed all along the depth of the column. The gas samples were analysed using gas chromatograph for CO2, O2, N2 and CH4 concentration. The quality of gas was measured by manual injection of the sample into a portable gas chromatograph (Make–Mayura Analyticals, BGA-Model) with thermal conductivity detector and hydrogen as the carrier gas (30 mL/min flow rate). The HayeSep-A and molecular sieve columns were used in series to get a clear separation of CO2, O2, N2 and CH4 gases. Calibration using the standard biogas mixture was performed before each test. The chromatographs were analysed using Peak ABC software.

2.5 Leachate Collection and Recirculation System

Quantification of leachate generated

Visual Hydrologic Evaluation of Landfill Performance (HELP) model developed by US Army corps is used to estimate amount of leachate generated in landfill site. It is quasi-two-dimensional hydrologic model of water movement across, into, through and out of landfills. Landfill systems including various combinations of vegetation, cover soils, waste cells, lateral drain layers, low permeability barrier and geomembrane liners can be modelled. The average head above the liner and the volume of leachate generated was estimated for the existing site condition. The input data for Bangalore weather conditions are used from the repository of the software. The bulk density and field capacity of the waste were 521 kg/m3 and 0.3, respectively. Table 4 shows the three different conditions considered for analysis in HELP model.

Horizontal trenches were considered for the design of leachate recirculation system (LRS). Hydrus 2D was used to estimate the number and the spacing of trenches in the landfill. The properties of fresh waste such as hydraulic conductivity and unsaturated properties were taken from Reddy et al. [11] and Wu et al. [12], respectively.

3 Result and Discussion

3.1 Landfill Gas Generation

The maximum total landfill gas and methane flux calculated are 5.266 × 105 and 2.633 × 105 m3/year, respectively. The output of the LandGEM model is given in Fig. 3.

Total landfill gas and methane gas emission from Landfill (Reprinted from sughosh et al. [10]. With permission from ASCE)

Biocover

Biocovers are used to reduce the potential impact of direct emission of methane to the atmosphere. Biocovers systems are economically feasible and are generally used in place of the gas extraction or flaring systems, especially in the landfills with low methane emission rates.

Figure 4 shows the methane oxidation rates (MOR) calculated from the column experiment as a function of depth. The oxidation efficiency at 20 cm depth was much higher than at the bottom layers. These higher oxidation efficiencies indicated the presence of CH4-oxidizing bacterial community in the top layers. A decrease in oxidation efficiency was observed with depth and indicated the extent of the oxic zone in the cover material. Maximum oxidation rates of 81.21% were observed in the top layers of the columns where oxygen availability was highest.

Methane reduction potential with respect to depth (Reprinted from sughosh et al. [10]. With permission from ASCE)

The design of biocover system involves determining the methane emission rate at the landfill site and the laboratory-scale studies to estimate the methane oxidation potential of the selected biocover material. From the column studies, the biocover system has a methane oxidation efficiency of 81.21% for a flux rate of 700.35 g/m2/d. Therefore, an area of 848 m2 is required to construct a biowindrow system. The digested MBT waste of 0.8 m depth with a moisture content of 30% compacted to a bulk density of 750 kg/m3 is sufficient to oxidize the methane emission from the dumpsite.

Biowindrows of 53 × 53 m × 0.8 m can be provided and will be sufficient to reduce the methane emissions from the entire landfill. Some of the other major factors affecting the performance of such bio windrows at field condition include climatic conditions (temperature, precipitation, etc.), moisture content, landfill gas composition and the gas application rate.

3.2 Leachate Generation

The Visual HELP model was run and the yearly variation in the precipitation, evaporation, runoff, lateral drainage from layer 3 (lateral drainage layer), recirculation rate and percolation or leakage through layer 5 (barrier soil liner) were analysed for the three conditions stated below.

-

(a)

Existing site condition

Figure 5 represents the analysis result, and the average leachate head by the end of the first year was around 2.28 m against the prescribed limit of 0.3 m (USEPA, 2004). By the end of 10 years, the value reached 15.4 m. These conditions greatly affect the stability and degradation of waste. The potential risk of groundwater contamination is also high under these conditions.

HELP Model output for existing landfill site condition (Reprinted from sughosh et al. [10]. With permission from ASCE)

-

(b)

Leachate collection and removal

A drastic decline in leachate head is observed when the leachate is drained from the landfill (Fig. 6). The percolation or leakage through layer 5 reduces in comparison with the previous case. This clearly indicates that draining the leachate out of the landfill decreases the risk of groundwater pollution.

HELP model output for leachate drainage and collection (Reprinted from sughosh et al. [10]. With permission from ASCE)

-

(c)

Leachate collection and 50% recirculation

The leachate head increased marginally in this condition but is within the permissible limit. Recirculation of leachate enhances the waste degradation rate and reduces the time required for stabilization of the waste. From Fig. 7, it is evident that with 50% leachate recirculation, the average leachate head on the liner reduces and, in the process, enhances the biodegradation of waste (Fig. 8).

HELP model output for leachate collection and 50% recirculation (Reprinted from sughosh et al. [10]. With permission from ASCE)

Schematic diagram for retrofitting an existing dumpsite in Bangalore city (Not to scale). (Reprinted from sughosh et al. [10]. With permission from ASCE)

Design of leachate recirculation system

Hydrus 2D result shows that the horizontal trenches with a recirculation rate of 5.5 m3/day are efficient enough to saturate the waste with a moisture content of 70% up to a distance of 10 m. Therefore, a total of 52 horizontal trenches of 10 m × 0.6 m × 1 m dimension distributed through the landfill area are sufficient to maintain the required moisture content in waste.

4 Conclusion

The study presents the approach to convert the existing dumpsite into sustainable landfill. This can be carried out by the design of leachate collection, recirculation and biocover systems. The recirculation of the leachate can be achieved by providing 52 horizontal trenches. The landfill gas emission can be prevented by providing bio windrows of size 53 × 53 × 0.8 m. Even though the features provided to improve the performance of the landfills are site-specific, the approach presented here can easily be applied to most of the other dumpsites in India with minor modifications.

References

US EPA. https://www.epa.gov/landfills/bioreactor-landfills. Last accessed 22 Jan 2019

Hoornweg, D., Bhada-Tata, P.: What a waste: a global review of solid waste management. Urban development series knowledge papers no. 15. The World Bank, Washington, DC (2012)

Lakshmikanthan, P., Sivakumar Babu, G.L.: Performance evaluation of the bioreactor landfill in treatment and stabilisation of mechanically biologically treated municipal solid waste. Waste Manag. Res. 35(3), 285–293 (2017)

Sughosh, P., Anusree, N., Sivakumar Babu, G.L.: Life cycle analysis as a tool to assess the sustainability of waste management practices in Bangalore City. Geo-Congress 2019: Geoenvironmental Engineering and Sustainability 2019. Reston, VA: American Society of Civil Engineers (2019)

Alexander, A., Burklin, C.E., Singleton, A.: Landfill gas emissions model (LandGEM) version 3.02 user's guide. US Environmental Protection Agency, Office of Research and Development (2005)

Chanakya, H.N., Ramachandra, T.V., Shwetmala, K.: Towards a sustainable waste management system for Bangalore. In: 1st International Conference on Solid Waste Management and Exhibition on Municipal Services, Urban Development, Public Works IconSWM. Kolkata, India (2009)

Eggleston, S., Buendia, L., Miwa, K.: IPCC guidelines for national greenhouse gas inventories. Institute for Global Environmental Strategies, Kanagawa, Japan (2006)

Staley, B.F., Barlaz, M.A.: Composition of municipal solid waste in the United States and implications for carbon sequestration and methane yield. J. Environ. Eng. 135(10), 901–909 (2009)

Gebert, J., Groengroeft, A.: Passive landfill gas emission—influence of atmospheric pressure and implications for the operation of methane-oxidising biofilters. Waste Manag. 26(3), 245–251 (2006)

Sughosh, P., Prathima, B., Murali Arunkumar, Anusree, N., Sivakumar Babu, G.L.: Remediation of typical municipal solid waste dumpsite in Bangalore City. J. Hazard. Toxic Radioactive Waste. 25(1), (2021)

Reddy, K.R., Hettiarachchi, H., Parakalla, N.S., Gangathulasi, J., Bogner, J.E.: Geotechnical properties of fresh municipal solid waste at Orchard Hills Landfill, USA. Waste Manag. 29(2), 952–959 (2009)

Wu, H., Wang, H., Zhao, Y., Chen, T., Lu, W.: Evolution of unsaturated hydraulic properties of municipal solid waste with landfill depth and age. Waste Manag. 32(3), 463–470 (2012)

Tolaymat, T., Kremer, F., Carson, D., Davis-Hoover, W.: Monitoring Approaches for Landfill Bioreactors. National Risk Management Research Laboratory, Office of Research and Development, Ohio (2004)

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2021 The Author(s), under exclusive license to Springer Nature Singapore Pte Ltd.

About this chapter

Cite this chapter

Sughosh, P., Anusree, N., Prathima, B., Sivakumar Babu, G.L. (2021). Sustainable Remediation of a Dumpsite. In: Patel, S., Solanki, C.H., Reddy, K.R., Shukla, S.K. (eds) Indian Geotechnical Conference 2019. Lecture Notes in Civil Engineering, vol 140. Springer, Singapore. https://doi.org/10.1007/978-981-33-6590-2_6

Download citation

DOI: https://doi.org/10.1007/978-981-33-6590-2_6

Published:

Publisher Name: Springer, Singapore

Print ISBN: 978-981-33-6589-6

Online ISBN: 978-981-33-6590-2

eBook Packages: EngineeringEngineering (R0)