Abstract

Vertical drains are often used to accelerate the consolidation settlement in soft clays subjected to preloading. Even though there are a variety of ground improvement techniques available, prefabricated vertical drains (PVD) in combination with preloading have become a popular method for soft soil problems as it provides an effective solution. Marine clay is one such type of soft soil which is highly compressible and causes severe distress to the structure constructed over it. In this study, a numerical investigation is carried out to explore a better insight into consolidation behavior of Marine clay improved with PVD. A surcharge load of 25 kPa is applied to accelerate the consolidation process. The analysis is carried out using the finite element software ABAQUS, employing the modified Cam-Clay theory. The aim of this study is to investigate the effect of smear on the settlement rate with different drain spacing (Drain spacing ratio n = 10, 15, 20) and for two different thickness of clay layers.

Access provided by Autonomous University of Puebla. Download conference paper PDF

Similar content being viewed by others

Keywords

1 Introduction

Due to the rapid increase in population and fast development of infrastructure throughout the world utilization of low-lying marshy areas and reclaimed land is the need of the hour. Most of such lands are composed of highly compressible and weak soils up to significant depths. Soft marine clay and alluvial deposits have very low-bearing capacity and excessive settlement characteristics, which imposes serious issues to the structures constructed over it. Therefore, it becomes essential to stabilize the existing soil before commencing any construction over it for both long-term and short-term stability.

Prefabricated vertical drains is one of the most widely used ground improvement technique among the various available methods for improving the engineering properties of the soft clay deposit. Application of preloading combined with prefabricated vertical drain is most popular and successfully adopted technique in many projects including high-rise buildings, roads and railways [1,2,3]. PVDs are often preferred over another method because of its low cost and lesser installation period [3, 4].

Preloading is the application of surcharge load on the soil before actual construction of the permanent structure over it until a major part of the primary consolidation occurs. The time taken for consolidation settlement will be very long for soils having very low permeability and high compressibility even with the application of fairly high surcharge load. This makes it very difficult to achieve desired consolidation for projects with tight construction schedule. Hence, a system of geosynthetic PVD is often introduced to achieve a radial drainage and rapid consolidation. The PVDs are installed in triangular, square or rectangular pattern [5] in the field with center to center distance varying about 1–3.5 m [6].

A behavior of soft clay foundations treated with vertical drains can now be computed with reasonable accuracy due to significant improvement in rigorous numerical analysis in the past decades. A unit cell theory representing single vertical drain surrounded by the influence zone of cylindrical soil by assuming equal vertical strain was proposed by Barron [7]. Later, Hansbo [] modified the solutions developed by Barron [7] with simplified assumptions including the effects of smear and well resistance. Single drain analysis with small strain condition is limited to embankment center line where zero lateral displacements occur. Predictions made based on this analysis becomes less accurate toward embankment toe where large lateral displacement may occur because of non-uniform surcharge load distribution. Hird et al. [8], introduced an equivalent two-dimensional (2D) plane strain concept to predict the performance of soft clay behavior improved with a system of vertical drains. Due to common usage of plane strain concept in finite element analysis Indraratna and Redana [9] extended unit cell theory to convert axisymmetric parameters such as permeability coefficient to equivalent plain strain parameters and also considered the smear effect caused by mandrel intrusion. However, this study is limited to finite element analysis of a single drain placed at the center of the unit cell. The factors affecting the drain performance such as smear zone and drain influence zone are discussed in this paper.

2 Drain Properties

2.1 Drain Influence Zone

The influence zone around the drain can be described as the maximum coverage area of water movement around the drain. The influence zone varies based on the drain spacing and the pattern of installation adopted in the field. Usually in the field, PVDs are installed either in square or triangular pattern. Square pattern is easy for layout and installation whereas, triangular pattern provides more uniform consolidation. Diameter of influence zone can be determined by following equation.

where De is the diameter of influence zone and S is the drain spacing.

2.2 Equivalent Diameter

PVDs are generally manufactured in rectangular cross section to make ease of storage, transportation and installation. As their shapes are not equivalent to the circular cross section considered in the unit cell theory, PVD with a polygon influence zone must be converted to a cylindrical drain with a circular influence zone. The formulations for conversion to equivalent circular drain available from previous studies are highlighted below [10,11,12].

where dw is equivalent PVD diameter and a and b are width and thickness of PVD, respectively. Above all, the equation proposed by Hansbo [11] was used to determine equivalent diameter of the drain in this study.

2.3 Smear Zone

The installation of PVD by mandrel causes significant remolding of subsoil, especially in the immediate surroundings of the mandrel. This disturbed zone in the vicinity of PVD is called smear zone. The permeability and compressibility of the clay near the drains are changed because the installation process alters the structure of clay. The combined effect of compressibility and permeability within the smear zone causes distinctive behavior from the undisturbed soil. Many researchers have studied the diameter of smear and its effect on consolidation [13,14,15]. There are two parameters needed to evaluate smear zone effect, namely (1) smear zone ratio which indicates the extent of smear zone (ds/dm) where ds and dm are diameter of smear zone and mandrel, respectively, and (2) the hydraulic conductivity ratio (kh/ks) where kh and ks are permeability of undisturbed zone and smear zone.

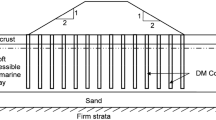

3 Numerical Modeling of Vertical Drain

A finite element program ABAQUS was used to simulate a unit cell of vertical drain. Due to the circular shape of influence zone, axisymmetric model was used for the analysis. The soft soil was modeled using the Modified Cam-Clay model [16] to capture the inelastic behavior of the material whereas, the elastic part of the deformation was defined by using the porous elastic material. The Modified Cam-Clay properties are shown in Table 1. The soft soil is modeled for a depth of 12 m with varying smear zone ratio and drain spacing ratio. All the analyses were carried out for the surcharge load of 25 kPa. The displacement boundary conditions were as follows: for the bottom boundary both vertical and horizontal displacements were fixed and for vertical boundaries on right and left, horizontal displacement was fixed which allows to move freely in the vertical direction. Drainage was allowed at the top surface by setting up zero pore pressure at the surface. The bottom and vertical boundaries were made impermeable. The element chosen was 8-node axisymmetric quadrilateral element with bilinear displacement and bilinear pore pressure (CAX8RP). In this study, diameter of drain was calculated based on the equation proposed by Hansbo [11]. The diameter of the smear zone ds was taken as 2 based on the studies conducted by Bergado et al. [13]. From the laboratory studies on various clay sample, the average values of kh/ks varies from 1 to 5. Based on this study, the permeability ratio was taken as 3.

4 Results and Discussion

In this study, finite element analysis is carried out to study the effect of smear. Two models were created to simulate the conditions of with and without smear. Figure 1 shows the settlements at the surface and at depth intervals of 4 m with time. The settlement at the surface shows higher magnitude and the settlement decreases with depth, which supports the observation of Bergado et al. (1992).

The maximum settlement observed at a depth of about 8 m is 47 and 57 mm for cases a and b, respectively, which is only 13 and 12.5% of the surface settlement.

Figure 2 shows the comparison of settlement observed at the ground surface for both the cases. The maximum ground settlement was 425 mm and 375 mm for the case with and without smear, respectively. The case with smear condition shows lesser rate of settlement when compared to perfect drain condition. However, the difference in settlement rate diminishes toward the end of consolidation.

As it is evident from the study that the smear zone influences the time period of consolidation, a parametric study was conducted by varying the smear zone ratio. Based on the various studies carried out by many researchers, smear zone was varied from 2 to 6. Figure 3 depicts the settlement behavior of soft clay with varying smear zone ratio. Higher settlements and faster rate of consolidation is observed for smear zone ratio of 2. The consolidation rate decreases on increasing the smear zone ratio from 2 to 3 and further reduces on increasing it to 4. For the smear zone ratios of 5 and 6, almost similar settlement behavior is observed. Hence, it can be concluded that the smear zone influences the consolidation rate up to the smear zone ratio of 4.

Spacing is another factor which controls the rate of consolidation. Drain spacing is determined based on required degree of consolidation to be achieved within particular time. To investigate the effect of spacing and thickness of clay, three different drain spacings were considered in the analysis. The analysis is carried out for perfect drain condition for drain spacing ratio of n = 10, 15 and 20. Figure 4 shows the settlement behavior for various spacing ratio. It is observed that the rate of settlement decreases with increase in spacing ratio. For drain spacing ratio of 10, the settlement occurs at faster rate and final settlement occurred in 18 days whereas the settlements kept increasing for higher drain spacing ratio which required higher time for full consolidation to occur because of higher spacing.

Figure 5 represents the settlement behavior of clay layers having two different thickness of 12 and 15 m. It can be seen that clay layer having higher thickness undergoes more settlement since the magnitude of settlement is proportional to clay thickness.

5 Conclusion

Finite element analysis has been carried out to study the effect of various factors influencing the rate and magnitude of consolidation. It can be concluded that the smear zone affects the rate of consolidation during the initial time period and its effect diminishes with time. Also drain installed at closer spacing provides faster consolidation when compared to higher drain spacing ratio. However, the problem of overlapping of smear zone arises in the field when the drains are installed at closer spacing. The analysis carried out with different clay layer thickness depicts higher magnitude of settlement for thick clay layer.

References

Arulrajah, A., Bo, M., Chu, J., Nikraz, H.: Instrumentation at Changi land reclamation project, Singapore. Geotech. Eng. 162(1), 33–40 (2009)

Bergado, D.T., Balasubramaniam, A.S., Fannin, R.J., Holtz, R.D.: Prefabricated vertical drains (PVDs) in soft Bangkok clay: a case study of the new Bangkok International Airport project. Can. Geotech. J. 39(2), 304–315 (2002)

Bo, M.W., Arulrajah, A., Nikraz, H.: Preloading and prefabricated vertical drains design for foreshore land reclamation projects: a case study. Ground Improve. 11(2), 67–76 (2007)

Shen, S.L., Chai, J.C., Hong, Z.S., Cai, F.X.: Analysis of field performance of embankments on soft clay deposit with and without PVD-improvement. Geotext. Geomembr. 23(6), 463–485 (2005)

Bergado, D.T., Long, P.V., Balasubramaniam, A.S.: Compressibility and flow parameters from PVD improved soft Bangkok clay. Geotech. Eng. 27, 1–20 (1996)

Holtz, R.D.: Preloading with prefabricated vertical strip drains. Geotext. Geomembr. 6(1–3), 109–131 (1987)

Barron, R.A.: Consolidation of fine-grained soils by drain wells. Trans. Am. Soc. Civ. Eng. 124, 718–742 (1948)

Hird, C.C., Pyrah, I.C., Russell, D., Cinicioglu, F.: Modelling the effect of vertical drains in two-dimensional finite element analyses of embankments on soft ground. Can. Geotech. J. 32(5), 795–807 (1995)

Indraratna, B., Redana, I.W.: Plane-strain modeling of smear effects associated with vertical drains. J. Geotech. Geoenviron. Eng. 123(5), 474–478 (1997)

Atkinson, M.S., Eldred, P.J.L.: Consolidation of soil using vertical drains. Geotechnique 31(1), 33–43 (1981)

Hansbo, S.: Consolidation of clay by band shaped prefabricated drains. Ground Eng. 12(5) (1979)

Long, R.P., Covo, A.: Equivalent diameter of vertical drains with an oblong cross section. J. Geotech. Eng. 120(9), 1625–1630 (1994)

Bergado, D.T., Asakami, H., Alfaro, M.C., Balasubramaniam, A.S.: Smear effects of vertical drains on soft Bangkok clay. J. Geotech. Eng. 117(10), 1509–1530 (1991)

Indraratna, B., Redana, I.W.: Laboratory determination of smear zone due to vertical drain installation. J. Geotech. Geoenviron. Eng. 124(2), 180–184 (1998)

Sharma, J.S., Xiao, D.: Characterization of a smear zone around vertical drains by large-scale laboratory tests. Can. Geotech. J. 37(6), 1265–1271 (2000)

Roscoe, K.H., Burland, J.B.: On the generalized stress strain behavior of wet clay. Eng. Plastic. (1968)

Chai, J.C., Carter, J.P., Hayashi, S.: Ground deformation induced by vacuum consolidation. J. Geotech. Geoenviron. Eng. 131(12), 1552–1561 (2005)

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2021 The Author(s), under exclusive license to Springer Nature Singapore Pte Ltd.

About this paper

Cite this paper

Prabavathy, S., Rajagopal, K., Kumar Pitchumani, N. (2021). Numerical Modeling of Soft Clay Improved with Prefabricated Vertical Drains. In: Patel, S., Solanki, C.H., Reddy, K.R., Shukla, S.K. (eds) Proceedings of the Indian Geotechnical Conference 2019. Lecture Notes in Civil Engineering, vol 137. Springer, Singapore. https://doi.org/10.1007/978-981-33-6466-0_39

Download citation

DOI: https://doi.org/10.1007/978-981-33-6466-0_39

Published:

Publisher Name: Springer, Singapore

Print ISBN: 978-981-33-6465-3

Online ISBN: 978-981-33-6466-0

eBook Packages: EngineeringEngineering (R0)