Abstract

Pool boiling is mainly used in flooded evaporators for heat pumps, refrigeration and air-conditioning systems as well as within the process industry, e.g. in the liquefaction of natural gas. Although many theoretical and experimental investigations on the integral heat transfer of various boiling liquids are presented in the literature, however the secondary conditions for the experimental investigations are often not reported. Therefore a new method is presented to calculate the heat transfer, taking into account the interdependence of the surface roughness and the thermophysical properties.

Access provided by Autonomous University of Puebla. Download conference paper PDF

Similar content being viewed by others

1 Introduction

Pool boiling is mainly used in flooded evaporators for heat pumps, refrigeration and air-conditioning systems as well as within the process industry, e.g. in the liquefaction of natural gas. Although many theoretical and experimental investigations on the integral heat transfer of various boiling liquids are presented in the literature, however the secondary conditions for the experimental investigations are often not reported. Heat transfer in pool boiling is mainly influenced by saturation pressure, heat flux, as well as micro- and macrostructure of the heating wall and thermophysical properties of the boiling liquid.

Current approaches try to separate these influencing parameters for the calculation of the heat transfer coefficient, e.g. the VDI correlation by Gorenflo [1]. This method is justified when the impact of certain influencing parameters is to be assessed. Nevertheless, the influencing parameters are interdependent, and a more accurate description of physical interconnections in pool boiling is gained by examining this interdependence. As thermophysical properties of liquids have not yet been investigated in the literature, this study focuses on their influence during pool boiling and their interaction with other parameters, especially the surface roughness.

2 Modelling

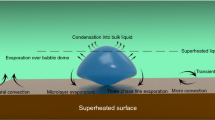

It is essential to consider heterogeneous nucleation in cavities on a solid surface to describe the influence of thermophysical properties on two-phase heat transfer, as it is critical for the integral heat transfer coefficient. The influence of surface roughness is included in the VDI correlation [1] through the standard arithmetic mean roughness value. Activation of vapour bubbles, their growth and departure diameter and frequency is highly dependent on the shape of the nucleation site or cavity. This integral parameter is insufficient, as it neither includes the shape of the cavity nor the wetting of the surface.

Therefore, it is necessary to identify a parameter that considers cavity shape, surface wetting and fluid properties. Several cavity parameters have been defined which are obtained by the envelope method by Schömann [2]. Luke [3] modifies the cavity parameters by Schömann [2]. Thus, a characteristic parameter

is given for a potential nucleation site with the volume VK of a sphere with the diameter d as the maximal distance between the surface profile and the envelope. The pressure dependence of active nucleation sites and thereby the heat transfer is given with the choice of the spherical radius RK used in the envelope method. In addition, the wetting of the heating surface by the boiling liquid influences RK resp. the cumulative distribution of P5*. A characteristic size of P5* must be chosen from the cumulative distribution according to

with the reduced pressure p* and the contact angle Θ. The critical nucleation radius can be calculated for low saturation temperatures using the Thomson and the Clausius–Clapeyron equations. A new parameter is defined to include this interaction between heating surface and boiling liquid for the calculation of the heat transfer for different fluids on the basis of the VDI correlation by Gorenflo [1]. In this factor, the bond number Bo, with the mean value or function of P5* as the characteristic length, and the fluid parameter

defined by Kotthoff and Gorenflo [4] include the interaction between the heating surface and the boiling liquid.

3 Results

Heat transfer measurements are performed in a standard boiling apparatus according to Goetz [5] to fit Eq. (2) and the function for the characteristic length used in Bo with experimental data and develop the parameter that includes Bo and Pf in the VDI correlation by Gorenflo [1]. The product of Bo and Pf is shown in Fig. 1 for different values of P5* as function of the reduced pressure.

The critical nucleation radius is reduced at higher reduced pressure, and therefore smaller nucleation sites are activated at increased pressure for the same superheat. This trend is represented by the factor with Bo, Pf and a reference value of Pf in Fig. 1.

A stochastic distribution of cavities is required to ensure that nucleation sites are evenly distributed on the surface of the heating tube to ascribe active nucleation sites to a characteristic cavity. Accordingly, the surface is fine sandblasted with Pa = 0.5 μm. Roughness measurements are performed with a mechanical stylus system and an ultrasonic stylus to determine the cavity parameters. To avoid damage to the heating surface, contactless measuring methods are chosen. The distribution of P5* for the sandblasted surface is calculated by comparing the surface topography with the envelope areas in Fig. 2.

4 Conclusions

Experimental heat transfer measurements are carried out to find a mathematical description for interaction between boiling fluid and microstructure of the heating surface in pool boiling regime. The bond number, the fluid parameter Pf and the cavity parameter P5* are identified as important influences to create this parameter. In future, the heat transfer measurements are used to fit the new parameter to the experimental data.

References

D. Gorenflo, H2 pool boiling, in VDI Heat Atlas, 11th edn. (Springer, Berlin, 2010)

H. Schömann, Beitrag zum Einfluss der Heizflächenrauhigkeit auf den Wärmeübergang beim Blasensieden. Dissertation, University of Paderborn (1994)

A. Luke, Thermo- and fluid dynamic in boiling—connection between surface roughness, bubble formation and heat transfer, in Proceedings of 5th International Conference on Boiling Heat Transfer, Montego Bay, Jamaica (2003)

S. Kotthoff, D. Gorenflo, Heat transfer and bubble formation on horizontal copper tubes with different diameters and roughness structures. Heat Mass Transf. 45, 893–908 (2009)

J. Goetz, Entwicklung und Erprobungeiner Normapparatur zur Messung des Wärmeübergangs beim Blasensieden. Dissertation, University of Karlsruhe (1980)

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2021 Springer Nature Singapore Pte Ltd.

About this paper

Cite this paper

Buchholz, N., Luke, A. (2021). Analysis of the Influence of Thermophysical Properties on the Coupled Heat and Mass Transfer in Pool Boiling. In: Wen, C., Yan, Y. (eds) Advances in Heat Transfer and Thermal Engineering . Springer, Singapore. https://doi.org/10.1007/978-981-33-4765-6_27

Download citation

DOI: https://doi.org/10.1007/978-981-33-4765-6_27

Published:

Publisher Name: Springer, Singapore

Print ISBN: 978-981-33-4764-9

Online ISBN: 978-981-33-4765-6

eBook Packages: EngineeringEngineering (R0)