Abstract

Industry 4.0 technologies are finding applications in many industrial sectors. But industrial development is societal, ethically sustainable only when the technologies used are cleaner and ethical sustainable. In this research paper, authors have shortlisted eight technologies that act as major pillars of Industry 4.0 (I4.0). These technologies have been critically examined on aspects of ethical sustainability considering Indian micro and small enterprises. For this study, authors have reviewed 55 research papers from different sources such as science direct, emerald insight, Taylor and Frances. The authors have also developed a framework, which reveals the ten major contributors toward ethical sustainable manufacturing in the digital era. Contributors or enablers such as availability of better software /hardware, reduction in e-wastage and manufacturing cost, and awareness on government policies and supports help to enable ethical sustainable manufacturing in the modern digital era.

Access provided by Autonomous University of Puebla. Download conference paper PDF

Similar content being viewed by others

Keywords

1 Introduction

Industry 4.0 stands for the fourth industrial revolution which is another trending topic and is discussed in both professional as well as academic areas [1,2,3,4,5,6,7,8,9,10,11,12,13,14,15,16,17,18,19,20,21,22,23,24,25,26,27,28,29,30,31,32,33,34,35,36,37,38,39,40,41,42,43,44,45,46,47,48,49,50,51,52,53,54,55]. According to B Sezen et al., “Industry 4.0 can be regarded as a new business mindset that will help businesses and communities move towards sustainable development” [38]. According to Aquilani et al., “The Fourth Industrial Revolution—i.e., Industry 4.0-, today involves the majority of firms and institutions and emerges as a new logic for business models focused on innovation, technology and sustainability” [24]. Smart manufacturing and smart production can be termed as synonyms for the term Industry 4.0, which consists of many technologies used for the development of the value chain resulting in the reduction of lead time, improvement of product quality and efficiency [2]. Because of an insightful availability between assembling frameworks, logistics frameworks, and items/administrations, Industry 4.0 considers progressive new plan, manufacturing, activity, and production frameworks [13]. Also, Industry 4.0 has become another theme for researchers and top managers. Combining systems such as CPS with I4.0 brings in further new features via networking with collaborators in both horizontal and vertical aspects [10].

On the other hand, ethical sustainability, also known as sustainable development, is the “ability to sustain ethically” or “manufacture safe products safely” [15]. The prime focus of sustainability is to meet the present demands without jeopardizing the needs of future generations [35]. Maintaining a sustainable environment has not only become important but essential in the past decades due to the ongoing industrial trends [18]. Sustainability can also be understood as the utilization of resources while considering their depletion and/or how they adversely affect the environment [32]. The significant sustainability issues from the manufacturing point of view include energy utilization, scrap generation, water consumption, and the impact of the manufacturing process on the environment [32]. For coping with the challenges being faced by the industry in meeting the global demand for capital and consumer goods, the industrial value chain ought to be oriented toward sustainability [1]. It, however, pertains to SMEs as the carbon footprint of the poor cannot be factored into the aspects of sustainability, while the MNCs have enough resources and funds to reduce their carbon footprint to an acceptable standard [14, 15, 44].

In this paper, authors have summarized the observations from the literature review done on industry 4.0 and the sustainability of its practices. Finally based on observations authors have developed a framework that reveals the ten major contributors toward sustainable manufacturing in the digital era. Section 2 of the research paper will discuss the literature review. Section 3 will discuss methodology and Sect. 4 will discuss observations of the study. Section 5 will conclude and propose a framework (developed by authors in the current study) on ethical sustainable manufacturing in the digital era of I4.0. This framework highlights the enablers which gives an edge to ethical sustainable manufacturing in the modern era of I4.0. Observations and implications of the study could be beneficial for the manufacturing industries of developing economies.

2 Literature Review

Industry 4.0 has made new changes and vulnerabilities that must be regulated and administered to emphatically affect both business and society [6]. A major transformation can be observed in the way companies are producing goods after the digitalization of manufacturing [8]. The point is to incorporate the maximum number of industries as possible and adjust and upgrade the current innovations to give the necessities of advanced assembling a better fit [11]. The new concept situation originates from the intermingling of various rising advances that permit the progress to a digitized time that presents in the manufacturing plants a keen domain where machines, gadgets, and items are interconnected to adjust, be adaptable, and react rapidly to showcase changes [5].

Industry 4.0 is based upon technologies that can again be classified in many ways. In this paper, the authors have identified eight major technologies, such as Internet of Things (IoT), cloud computing, flexible manufacturing, additive manufacturing, big data analytics, augmented reality (AR), cyber-physical system (CPS), and autonomous robots from review of literature of more than 55 papers. Technologies can be divided into two categories of front and base end technologies. Front end technologies were those which plays a major role such as smart supply chain, smart product, smart manufacturing, and smart work, whereas the base technologies were the supporting ones like IoT, Cloud, Big Data analytics, etc. [4, 43]. Industry 4.0 gives the industry another point of view that enables it to work with innovations to gain the highest efficiency with the negligible utilization of assets in the manufacturing industry; however, it might expose the industry to some cyber threats as well [22].

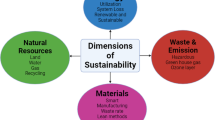

Adoption of Industry 4.0 technologies in an existing manufacturing system is not very easy due to the presence of many challenges, but its adoption not only helps industrial managers to increase process safety, efficiency, and flexibility but also in making the processes more sustainable in economic, social, and environmental terms [7 & 42]. Man and Strandhagen define sustainable business models as those which instead of simply following a neoclassical approach also incorporate the social and environmental aspects [3]. According to Stock and Obenaus, sustainability has three different dimensions, which are social, environmental, and economical [16]. These are also known as the three pillars of sustainability.

The environmental aspect of it pertains to reducing the environmental impact of the technologies involved in the industry as much as possible. Organizations are focusing on reducing their carbon footprint, water consumption, waste created by packaging, especially the usage of plastics. These organizations, however, have found out that the implementation of some technologies in turn also leads to financial improvements, such as the reduction in packaging material not only benefits environmentally but also economically [36]. However, the fields that will always have great environmental impacts, such as the production of food, mining, curb this issue by imposing and setting benchmarks or standards which help monitor the factors that are required to maintain a healthy physical environment [37].

On the social front, what is important are answers to questions like whether the implementation of new technologies in the industry will lead to the huge layoff of the workforce, how is the product being made, whether any unethical means are being utilized in making of the product, such as child labor, or unfair/unpaid wages to the workers, hazardous/toxic working environment, and how much is the risk of cyber-crime. Employees should be satisfied with the work that is being done by the organization, should feel valued and approved of the business being conducted, and their pre-existing knowledge should complement the implementation and integration and not hinder it [40].

The economic front of a sustainable business is that which is profitable, has a competitive advantage and market orientation which is specific, while keeping in mind resource conservation and improved quality of life [16]. Economic viability in industrial terms also means that the project or the changes being implemented are economically feasible in the long run, and also affordable, or viable for SMEs, such as setting up of advanced facilities such as autonomous robots and cyber-physical systems, which requires a very high investment and also needs lots of capital to maintain and run [41, 55]. It is also the incorporation of the profits and the economic aspect such as reduced manufacturing cost that convinces organizations to agree with practicing and implementing sustainable strategies [2]. Figure 1 shows the year-wise publication details.

3 Methodology

In this paper, first, relevant sources of publications were searched and selected like science direct, emerald insight, Taylor and Frances. Research papers related to Industry 4.0, sustainability, ethical sustainability, and their applications were searched. The literature review was made by the method of systematically reviewing papers. The review methodology followed is shown graphically in Fig. 2.

This concept paper tries to find research which has been conducted in the past related to sustainability and industry 4.0, the keywords used during the search were “Industry 4.0”, “Sustainability”, “Sustainable Manufacturing”, “Industry 4.0 Technologies”, “ethical sustainability” and “Industry 4.0 and Sustainability”. The searches were carried out on the following three websites: “Science Direct”, “Emerald Insight”, and “Taylor and Francis”. Year-wise distribution of research papers has been shown in Fig. 1.

The authors focused on selecting the research papers or case studies relevant in the Indian scenario. Since the review was focused on the manufacturing sector, it was decided to select as many papers related to this field as possible, and eventually narrowed the papers finally studied down to 55.

4 Observations of Study

This paper discussed I4.0 technologies and issues related to ethical sustainability of these technologies. Key analysis of I4.0 technologies, keeping sustainability in background are summarized in Table 1.

5 Conclusion and Proposed Framework on Ethical Sustainable Manufacturing

Many researchers have studied the Industry 4.0 and ethical sustainability as separate issues. Very few studies have been conducted about I4.0 technologies and ethical sustainability aspects holistically considering Indian micro and small enterprises. There is a need to identify the technologies which are globally recognized and ethical sustainable too. Later, these technologies should be checked for their ethical sustainability, individually. Authors developed a framework connecting all the major enablers, which supports or enables the ethical sustainable manufacturing in I4.0. After critically analyzing the industry 4.0 technologies, on three aspects of sustainability, the authors have identified ten enablers for sustainable manufacturing in the digital era (as input enablers for framework). These ten enablers are “Increased customer awareness on Technology”, “Top management support and planning”, “Attracting local/Foreign Investment”, “Infrastructure for new Technologies”, “Availability of advanced software /Hardware”, “Reduction in e-wastage and manufacturing cost”, “Availability of trained workforce”, “Development in E-economy”, “Social responsibility and investor demands”, “manufacture safe products safely” and “Awareness on government policies and support”. These enablers help in making the manufacturing processes more ethical sustainable in the scenario of industry 4.0. As these are supporting factors, the arrows point inward toward the “ethical sustainable manufacturing in the digital era” bubble, showing that they are guiding input. For the future course of action/study, the framework suggested by the authors should be analyzed and examined in the practical scenarios of different developing economies. The two pillars of research, that is academia and industry should do empirical examination on all insights of outcomes and elements of the framework. Figure 3 shows the proposed framework on ethical sustainable Manufacturing in the Digital Era.

References

Stock, T., & Seliger, G.: Opportunities for sustainable manufacturing in industry 4.0. Procedia Cirp. 40, 536–541 (2016)

Kamble, S. S., Gunasekaran, A., & Gawankar, S. A.: Sustainable Industry 4.0 framework: A systematic literature review identifying the current trends and future perspectives. Process Saf. Environ. Protect. 117, 408–425 (2018)

Schuh, G., Anderl, R., Gausemeier, J., Ten Hompel, M., & Wahlster, W. (Eds.).: Industrie 4.0 Maturity Index: Managing the Digital Transformation of Companies. Utz, Herbert (2017)

Frank, A. G., Dalenogare, L. S., Ayala, N. F.: Industry 4.0 technologies: Implementation patterns in manufacturing companies. Int. J. Prod. Econ. 210, 15–26 (2019)

Castagnoli, R., Büchi, G., & Cugno, M.: How Industry 4.0 Changes the Value Co-Creation Process. In: Customer Satisfaction and Sustainability Initiatives in the Fourth Industrial Revolution (pp. 21–36). IGI Global (2020)

Büchi, G., Cugno, M., & Castagnoli, R.: Smart factory performance and Industry 4.0. Technological Forecasting and Social Change, 150, 119790 (2020)

Kumar, R.: Sustainable Supply Chain Management in the Era of Digitalization: Issues and Challenges. In: Editor, Efosa C. Idemudia, Handbook of Research on Social and Organizational Dynamics in the Digital Era. IGI Global, 2020. 446–460. Web. 1 Aug. 2019. doi:https://doi.org/10.4018/978-1-5225-8933-4.ch021. (Publisher & ISSN/ISBN No. 290319–062455). Arkansas Tech University, USA. (2020)

Iyer, A.: Moving from Industry 2.0 to Industry 4.0: A case study from India on leapfrogging in smart manufacturing. Procedia Manuf. 21, 663–670 (2018)

Dalenogare, L. S., Benitez, G. B., Ayala, N. F., & Frank, A. G.: The expected contribution of Industry 4.0 technologies for industrial performance. Int. J. Prod. Econ. 204, 383–394 (2018)

Chiarini, A., Belvedere, V., & Grando, A.: Industry 4.0 strategies and technological developments. An exploratory research from Italian manufacturing companies. Prod. Plann. Control, 1–14 (2020)

Kumar, A., Nayyar, A.: si 3-Industry: A Sustainable, Intelligent, Innovative, Internet-of-Things Industry. In: A Roadmap to Industry 4.0: Smart Production, Sharp Business and Sustainable Development (pp. 1–21). Springer, Cham (2020).

Javaid, M., Haleem, A.: Current status and challenges of Additive manufacturing in orthopaedics: an overview. J. Clin. Orthopaedics Trauma 10(2), 380–386 (2019)

Matt, D. T., Rauch, E.: SME 4.0: The Role of Small-and Medium-Sized Enterprises in the Digital Transformation. In: Industry 4.0 for SMEs (pp. 3–36). Palgrave Macmillan, Cham (2020)

Henao-Hernández, I., Solano-Charris, E. L., Muñoz-Villamizar, A., Santos, J., Henríquez-Machado, R.: Control and monitoring for sustainable manufacturing in the Industry 4.0: A literature review. IFAC-PapersOnLine 52(10), 195–200 (2019)

Caiado, R.G.G., Leal Filho, W., Quelhas, O.L.G., de Mattos Nascimento, D.L., Ávila, L.V.: A literature-based review on potentials and constraints in the implementation of the sustainable development goals. J. Clean. Prod. 198, 1276–1288 (2018)

Stock, T., Obenaus, M., Kunz, S., & Kohl, H.: Industry 4.0 as enabler for a sustainable development: A qualitative assessment of its ecological and social potential. Process Safety Environ. Protect. 118, 254–267 (2018)

Windolph, S.E.: Assessing corporate sustainability through ratings: Challenges and their causes. J. Environ. Sustain. 1(1), 5 (2011)

Yadav, G., Luthra, S., Jakhar, S., Mangla, S. K., Rai, D. P.: A framework to overcome sustainable supply chain challenges through solution measures of industry 4.0 and circular economy: An automotive case. J. Clean. Prod. 120112 (2020).

Culot, G., Nassimbeni, G., Orzes, G., Sartor, M.: Behind the definition of industry 4.0: Analysis and open questions. Int. J. Prod. Econ. 107617 (2020)

Lass, S., Gronau, N.: A factory operating system for extending existing factories to Industry 4.0. Computers in Industry, 115, 103128 (2020)

Corallo, A., Lazoi, M., & Lezzi, M.: Cybersecurity in the context of industry 4.0: A structured classification of critical assets and business impacts. Computers in Industry, 114, 103165 (2020)

Ingaldi, M., Ulewicz, R.: Problems with the implementation of Industry 4.0 in Enterprises from the SME Sector. Sustainability, 12(1), 217 (2020)

Ford, S., Despeisse, M.: Additive manufacturing and sustainability: an exploratory study of the advantages and challenges. J. Clean. Prod. 137, 1573–1587 (2016)

Aquilani, B., Piccarozzi, M., Silvestri, C., & Gatti, C.: Achieving Environmental Sustainability Through Industry 4.0 Tools: The Case of the “Symbiosis” Digital Platform. In: Customer Satisfaction and Sustainability Initiatives in the Fourth Industrial Revolution (pp. 37–62). IGI Global (2020)

Tang, C. S., Veelenturf, L. P.: The Strategic Role of Logistics in the Industry 4.0 Era. Forthcoming in: Transportation Research Part E: Logistics and Transportation Review (2019)

Ball, D., Ross, P., English, A., Patten, T., Upcroft, B., Fitch, R., ..., Corke, P.: Robotics for sustainable broad-acre agriculture. In Field and Service Robotics (pp. 439–453). Springer, Cham (2015)

Bechtsis, D., Tsolakis, N., Vlachos, D., Iakovou, E.: Sustainable supply chain management in the digitalisation era: The impact of automated guided vehicles. J. Clean. Prod. 142, 3970–3984 (2017)

Zhou, K., Liu, T., Zhou, L.: Industry 4.0: Towards future industrial opportunities and challenges. In: 2015 12th International conference on fuzzy systems and knowledge discovery (FSKD) (pp. 2147–2152). IEEE (2015, August)

Marilungo, E., Papetti, A., Germani, M., Peruzzini, M.: From PSS to CPS design: a real industrial use case toward Industry 4.0. Procedia Cirp. 64, 357–362 (2017)

Wlodarczyk, T. W., Rong, C.: On the sustainability impacts of cloud-enabled cyber physical space. In: 2010 IEEE Second International Conference on Cloud Computing Technology and Science (pp. 597–602). IEEE (2010, November)

Mourtzis, D., Vlachou, E., Zogopoulos, V., Fotini, X.: Integrated production and maintenance scheduling through machine monitoring and augmented reality: An Industry 4.0 approach. In: IFIP International Conference on Advances in Production Management Systems (pp. 354–362). Springer, Cham (2017, September)

Ibarra, D., Ganzarain, J., Igartua, J. I.: Business model innovation through Industry 4.0: a review. Procedia Manuf. 22, 4–10 (2018)

Strandhagen, J. O., Vallandingham, L. R., Fragapane, G., Strandhagen, J. W., Stangeland, A. B. H., Sharma, N.: Logistics 4.0 and emerging sustainable business models. Adv. Manuf. 5(4), 359–369 (2017)

Lee, J., Kao, H. A., & Yang, S.: Service innovation and smart analytics for industry 4.0 and big data environment. Procedia Cirp, 16, 3–8 (2014)

Sreenivasan, R., Goel, A., Bourell, D.L.: Sustainability issues in laser-based additive manufacturing. Physics Procedia 5, 81–90 (2010)

Kumar, R.: Espousal of industry 4.0 in Indian manufacturing organizations: Analysis of enablers. In: Editor, Gaur, L. & Others, Handbook of Research on Engineering Innovations and Technology Management in Organizations, IGI Global, ISBN13: 9781799827726|ISBN10: 1799827720|EISBN13: 9781799827733. https://doi.org/10.4018/978-1-7998-2772-6 (2020)

Bhanot, N., Rao, P.V., Deshmukh, S.G.: Enablers and barriers of sustainable manufacturing: results from a survey of researchers and industry professionals. Procedia CIRP 29, 562–567 (2015)

Çankaya, S. Y., Sezen, B.: Industry 4.0 and Sustainability. In: Handbook of Research on Creating Sustainable Value in the Global Economy (pp. 67–84). IGI Global (2020)

Botlíková, M., Botlík, J.: Local extremes of selected industry 4.0 indicators in the European space—structure for autonomous systems. J. Risk Financial Manage. 13(1), 13 (2020)

Vaidya, S., Ambad, P., & Bhosle, S.: Industry 4.0–a glimpse.Procedia Manuf. 20, 233–238 (2018)

Paravizo, E., Chaim, O. C., Braatz, D., Muschard, B., Rozenfeld, H.: Exploring gamification to support manufacturing education on industry 4.0 as an enabler for innovation and sustainability. Procedia Manuf. 21, 438–445 (2018)

de Amorim, W. S., Deggau, A. B., do Livramento Gonçalves, G., da Silva Neiva, S., Prasath, A. R., & de Andrade, J. B. S. O.: Urban challenges and opportunities to promote sustainable food security through smart cities and the 4th industrial revolution. Land Use Policy, 87, 104065 (2019)

Cohen, B.: Urbanization in developing countries: Current trends, future projections, and key challenges for sustainability. Technol. Soc. 28(1–2), 63–80 (2006)

Sukkasi, S., Chollacoop, N., Ellis, W., Grimley, S., Jai-In, S.: Challenges and considerations for planning toward sustainable biodiesel development in developing countries: Lessons from the greater Mekong subregion. Renew. Sustain. Energy Rev. 14(9), 3100–3107 (2010)

Ghobakhloo, M.: Industry 4.0, digitization, and opportunities for sustainability. J. Clean. Prod. 119869 (2019)

Singh, S., Jeong, Y.S., Park, J.H.: A survey on cloud computing security: Issues, threats, and solutions. J. Netw. Comput. Appl. 75, 200–222 (2016)

Thakur, S., & Chaurasia, A.: Towards Green Cloud Computing: Impact of carbon footprint on environment. In: 2016 6th International Conference-Cloud System and Big Data Engineering (Confluence) (pp. 209–213). IEEE (2016, January)

Čolaković, A., Hadžialić, M.: Internet of Things (IoT): A review of enabling technologies, challenges, and open research issues. Comput. Netw. 144, 17–39 (2018)

Bibri, S.E.: The IoT for smart sustainable cities of the future: An analytical framework for sensor-based big data applications for environmental sustainability. Sustainable Cities and Society 38, 230–253 (2018)

Alcácer, V., Cruz-Machado, V.: Scanning the industry 4.0: A literature review on technologies for manufacturing systems. Eng. Sci. Technol. Int. J. (2019)

Kellens, K., Mertens, R., Paraskevas, D., Dewulf, W., Duflou, J.R.: Environmental impact of additive manufacturing processes: Does AM contribute to a more sustainable way of part manufacturing? Procedia CIRP 61, 582–587 (2017)

Bag, S.: Flexible procurement systems is key to supply chain sustainability. J. Transp. Supply Chain Manage. 10(1), 1–9 (2016)

Wang, L., & Wang, G.: Big data in cyber-physical systems, digital manufacturing and industry 4.0. Int. J. Eng. Manuf. (IJEM), 6(4), 1–8 (2016)

Witkowski, K.: Internet of Things, Big Data, industry 4.0–innovative solutions in logistics and supply chains management. Procedia Eng. 182, 763–769 (2017)

Dutta, G., Kumar, R., Sindhwani, R. and Singh, R.: Digital transformation priorities of India’s discrete manufacturing SMEs—a conceptual study in perspective of Industry 4.0. Compet. Rev. Int. Bus. J. (Forthcoming). https://doi.org/10.1108/CR-03-2019-0031 (2020)

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2021 The Editor(s) (if applicable) and The Author(s), under exclusive license to Springer Nature Singapore Pte Ltd.

About this paper

Cite this paper

Garg, D., Mustaqueem, O.A., Kumar, R. (2021). Industry 4.0 Technologies and Ethical Sustainability. In: Phanden, R.K., Mathiyazhagan, K., Kumar, R., Paulo Davim, J. (eds) Advances in Industrial and Production Engineering. Lecture Notes in Mechanical Engineering. Springer, Singapore. https://doi.org/10.1007/978-981-33-4320-7_17

Download citation

DOI: https://doi.org/10.1007/978-981-33-4320-7_17

Published:

Publisher Name: Springer, Singapore

Print ISBN: 978-981-33-4319-1

Online ISBN: 978-981-33-4320-7

eBook Packages: EngineeringEngineering (R0)