Abstract

This paper reports the use of tunable diode laser absorption spectroscopy (TDLAS) to measure the carbon dioxide (CO2) in the culture vials. The accumulated CO2 concentration in the headspace is linked with the growth of the microorganisms cultured in the vials. The 2004.1 nm spectral line of CO2 is selected as the sensing transition for its strong absorption strength. The proposed TDLAS sensor is calibrated and verified with several CO2 standard gases, yielding a minimum 1σ detection limit of 0.084% with an integral time of 3 s. The suitability of the sensor to the microorganisms is performed, almost the results agree with the growth laws of microbiology. Since the sensor is fast and nondestructive, it can be promising for in-line detection of microbial growth.

Access provided by Autonomous University of Puebla. Download conference paper PDF

Similar content being viewed by others

Keywords

1 Introduction

Aseptic processing is widely used in the food and pharmaceutical manufacturing [1,2,3]. In the aseptic environment, it is periodically verified by filling microbial culture media instead of the food or drug product to ensure the reliability and repeatability of aseptic processing. In traditional way, we often incubate the intact media-filled vial for 7–14 days and then assess the microbial contamination by visual inspection. It suffers from long time and high cost. Besides, the food and drag production also risks of microbial contamination in the packaging, transportation and storage process. Presently, many invasive techniques are utilizing to detect micro-organism growth, because of their selectivity and reliability, such as polymerase chain reaction and bacterial enumeration. It takes several hours and requires professionally trained microbiologists.

Tunable diode laser absorption spectroscopy (TDLAS) is based on gas molecule absorption characteristic at a specific wavelength range. The concentration of gas matter can be determined by measuring absorption strength via Lambert–Beer Law. With increasing maturity and broader availability of laser light sources, TDLAS has found use in numerous applications in food and pharmaceutical manufacturing. For leakage detection of pharmaceutical vials, Yang et al. measured leakage coefficient defined by incident and transmitted light intensities to judge the deterioration of pharmaceuticals in the vials [4]. Cai et al. proposed a TDLAS sensor for accurate measurements of commercial freeze-dried products. The referenced signal was used to reduce the influence of ambient humidity extensively [5]. A fast, invasive and in-line measurement technique was developed in the quality control of food packaging [6]. TDLAS sensor was employed for automatically headspace oxygen sensing in flow-packed products. Brueckner et al. made a comparison of TDLAS and isothermal micro-calorimetry for microbial growth detection in media fills [7]. And it showed the proposed TDLAS sensor was recommended for automating the media-fill inspection.

In this work, a TDLAS sensor has been developed for absolute measurement of the concentration of carbon dioxide in microbial culture vials. During respiration in aerobically respiring microbes, CO2 accumulates by oxidation–reduction process in different phases of growth. Also, aero-tolerant or anaerobic bacteria can metabolize carbon dioxide. Thus, the microbial growth status can be traced by measuring CO2 formation in the vial headspace. The performance of the sensor is firstly calibrated and validated on several CO2 standard gases. It shows the sensor is qualified with 1σ detection limit of 0.084% ranging from 0 to 20%. Secondly, two types of bacteria, Bacillus subtilis (B. subtilis) and Stapbylococcus aureus (S. aureus), are tested by the sensor, showing a good agreement with the microbial growth law.

2 Setups and Methods

The developed automated and non-intrusive TDLAS sensor for detecting microbial growth in the culture vials is illustrated in Fig. 1.

A tunable DFB laser emitting at 2004.1 nm was used as a light source, controlled by a laser controller. The laser beam, collimated by the optical fiber collimator, was then directed through a culture vial with a headspace path length of 3 cm. Then, the transmitted laser beam was focused on a photo detector. Here it is notable that the collimator and detector should be close to the vial’s outline as far as possible. This configuration can effectively eliminate the excess gaseous matter absorption caused by external path length. In order to increase the sensitivity of the CO2 measurement, wavelength modulation spectroscopy (WMS) techniques were adopted. Thus, the laser modulation parameters were set as follows. The laser was scanned by a saw-tooth wave at 10 Hz, overlapped with a 4 kHz high frequency sine-wave carrier. Last, the second harmonic signal of the headspace CO2 gas absorption was demodulated by a lock-in amplifier. The setup was placed inside the incubator to provide suitable microbial growth temperature, and several culture vials were together mounted on a rotating table for automatic sample feed in advance.

As the laser beam propagates in the vial headspace over an absorption path length of L, the beam will be absorbed in situ by the gas molecules of interest. The absorption of laser intensity is related to the molecular absorption coefficient, molecular mass concentration and absorption length, based on the Beer-Lambert law. The transmitted intensity I can be described as follows [8, 9].

where I0 is the incident laser intensity in the absence of absorbing species, σ is the molecule absorption coefficient in standard state, as a function of ambient temperature and pressure and so on, C is the concentration of the absorbing species in molecules per unit volume and L is the optical path length. In WMS scheme, it is only concerned about weak absorption, i.e., the value of σCL is much less than 1. In this situation, Eq. (1) can be expanded in a Fourier cosine series and the second harmonic signal obtained by demodulation could be simply expressed as [10]

It reveals that the product of the incident laser intensity I0, the gas concentration C is proportional to the calculated second harmonic signal value I2f. The I0 was simultaneously processed with I2f to reduce the influence of the laser intensity fluctuation reaching the detector. The optical length L was fixed after the fabrication of the sensor and the absorption coefficient σ was also a constant in standard state, and thus the gas concentration could be able to solely and correctly derived from the equation.

3 Experimental and Results

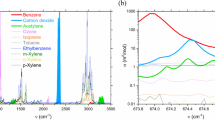

The proposed sensor was firstly calibrated and validated by measuring CO2 content in the vials flushed with several CO2 standard gases of 1, 5, 10, 15 and 20% volume concentrations. It was carried out in a constant temperature and humidity laboratory, with the environment condition of 30 °C, 65.5% and 101.3 kPa. The inset of Fig. 2 shows the tendency of the 2f absorption spectra at different CO2 gas concentrations. The valley of the absorption spectrum drops gradually with the increment of the CO2 concentration, while the peak changes in the contrary way. This means the use of the peak to valley value of the absorption spectra will gain a maximum measurement sensitivity. The peak to valley value versus concentration was plotted in the Fig. 2. It shows that the linear fitting degree is 99.98% in the measurement range from 0 to 20%. The good linear characteristics indicate the sensor can detect the CO2 concentration inside the headspace of the culture vials.

To verify the sensor’s stability, CO2 measurements with 10% gas concentration were performed over a period of ~1 h, and the measured data were recorded as shown in Fig. 3. An Allan deviation is utilized to analyze the detection limit, and a standard deviation to the stability. The left part of Fig. 3 exhibits the Allan deviation as a function of the integral time. The plot indicates that the 1σ detection limit is 0.121% for a 0.1 s measurement time, and also shows an optimum integral time of 3 s corresponding to a minimum 1σ detection limit of ~0.084%. The measured concentration fluctuations at 10% CO2 is depicted, with a standard deviation of 0.079%, in the right part of Fig. 4. Therefore, the sensor is qualified with a good measurement stability, with respect to the full scale range of 20%.

To validate the suitability of the sensor, the experiments was performed on two types of bacteria, Bacillus subtilis (B. subtilis) and Stapbylococcus aureus (S. aureus), both being of importance in food and drug safety, in sealed vials and fostered in culture-medium based on beef extract and tryptone soya agar. The sensor was put in a temperature-controlled incubator. The experiments were conducted at ~35 °C and ~65% RH. Two sealed vials were mounted on the rotating stage and were rotated every half an hour.

The experiment was conducted for about seven days, and the record data of the former two days was plotted in Fig. 4. At the beginning of measurement, the content of CO2 in the headspaces of the vials was ~1.0%, much higher than that in air. Regardless of the difference of the vials and bacteria, the CO2 contents in the headspaces of the samples change in a similar way and keep almost unchanged in the first 24 h of monitoring. This period is called lag phase. After that, CO2 began to accumulate and reached the maximum at ~38 h. The maximal growth rate of CO2 contents occurred after 30 h. It represents the same growth trend for the microbial organisms and shows the lag time of S. aureus is ~24 h, a little bit shorter than that of B. subtilis, and they reach decline phase at ~38 h, which almost agrees with the growth laws of microbiology.

4 Conclusion

We have demonstrated a TDLAS sensor operating at 2004.1 nm, combined with WMS technology, for monitoring the CO2 concentration inside the microbial culture vials. The sensor owns a minimum detection limit of ~0.084% in the range of 0–20%. The experimental results show the sensor is suitable for monitoring the microbial growth by the CO2 content detection in the headspace. It’s very stale, fast and noninvasive, thus has a potential application in food and pharmaceutical manufacturing areas.

References

Danilović B, Savić D, Cocola L, Fedel M, Poletto L (2018) Determination of CO2 content in the headspace of spoiled yogurt packages. J Food Qual 8121606

Moriaux A, Vallon R, Parvitte B, Zeninari V, Liger-Belair G, Cilindre C (2018) Monitoring gas-phase CO2 in the headspace of champagne glasses through combined diode laser spectrometry and micro-gas chromatography analysis. Food Chem 264:255–262

Hu P, Pan S, Chen Z, Guo G, Zhang J, Li G, Chen N (2017) Hydrogen peroxide detection based on near-infrared TDLAS and Herriott cell. In: 16th international conference on optical communications and networks (ICOCN). Wuzhen, China, pp 1–3

Yang H, Chen J, Luo X, Liu C, Qi D, Xin X (2019) Leakage detection of closed vials based on two-line water-vapor TDLAS. Measurement 135:413–417

Cai T, Wang G, Cao Z, Zhang W, Gao X (2014) Sensor for headspace pressure and H2O concentration measurements in closed vials by tunable diode laser absorption spectroscopy. Opt Lasers Eng 58:48–53

Cocola L, Fedel M, Giuseppe Tondello G, Frazzi G, Poletto L, Bardenshtein A (2018) Design and evaluation of an in-line system for gas sensing in flow-packed products. Food Packag Shelf Life 17:91–98

Brueckner D, Roesti D, Zuber UG, Schmidt R, Kraehenbuehl S, Bonkat G (2016) Comparison of tunable diode laser absorption spectroscopy and isothermal micro-calorimetry for non-invasive detection of microbial growth in media fills. Sci Rep 6(1):27894

Peng Z, Ding Y, Chen L, Li X, Zheng K (2011) Calibration-free wavelength modulated tdlas under high absorbance conditions. Opt Express 19(23):23104

Cocola L, Allermann H, Fedel M, Sonderby S, Tondello G, Bardenstein A (2016) Validation of an in-line non-destructive headspace oxygen sensor. Food Packag Shelf Life 9:38–44

Zarin AS, Chakraborty AL (2015) Absolute concentration measurements of bacterial CO2 emission using a 2004 nm vertical cavity surface emitting tunable diode laser. Workshop on recent advances in photonics (WRAP), Bangalore, India

Acknowledgements

This work was supported by National Natural Science Foundation of China under grant Nos. 41605101 and 41805108.

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2021 The Author(s), under exclusive license to Springer Nature Singapore Pte Ltd.

About this paper

Cite this paper

Chen, Z., Hu, P., Pan, S., Zhang, J., Guo, G., Liu, S. (2021). Tunable Diode Laser Absorption Spectroscopy for Non-invasive Detection of Microbial Growth. In: Peng, Y., Dong, X. (eds) Proceedings of 2019 International Conference on Optoelectronics and Measurement. Lecture Notes in Electrical Engineering, vol 726. Springer, Singapore. https://doi.org/10.1007/978-981-33-4110-4_22

Download citation

DOI: https://doi.org/10.1007/978-981-33-4110-4_22

Published:

Publisher Name: Springer, Singapore

Print ISBN: 978-981-33-4109-8

Online ISBN: 978-981-33-4110-4

eBook Packages: EngineeringEngineering (R0)