Abstract

High quality and uniform perovskite films are fundamental for the performance of planar perovskite heterojunction solar cells. In this paper, phenylethylammonium iodide (PEAI) is adopted to construct 2D/3D hybrid perovskite film, because it can interact with 3D perovskite crystals to motivate the formation of perovskite phase. In addition, PEAI deposited on hybrid perovskite film is adopted to eliminate the surface traps and suppress the recombination. Furthermore, we found that perovskite film exhibits improved crystallinity with PEAI passivation, which is essential for charge transportation in perovskite solar cell. These results demonstrate that PEAI passivation layer is a credible means to enhance the performance of perovskite solar cells.

Access provided by Autonomous University of Puebla. Download conference paper PDF

Similar content being viewed by others

Keywords

1 Introduction

In recent years, hybrid organic–inorganic lead halide perovskite solar cells have triggered much attention ascribed to its remarkably increased efficiency [1]. The uniform perovskite films with complete surface cover is of great significance for optical absorption, charge transportation and device performance of perovskite solar cells (PSCs) [2]. Improving the film crystallinity and morphology are expected to suppress charge trapping and enhance carrier transporting. Nevertheless, it is difficult to prepare high-quality and uniform perovskite films, which are essential to charge dissociation and transportation in PSCs. Here, we present a strategy to enhance crystallinity and morphology of perovskite film. 2D PEAI is adopted to construct 2D/3D hybrid perovskite film and utilized as the passivation layer to suppress interfacial recombination and enhance the crystallinity of perovskite films [3]. The perovskite solar cell is therefore obtained with improved performance.

2 Experiment

2.1 Materials

In this experiment, FAI (Shanghai MaterWin New Materials Co., Ltd), PbI2 (Xi’an Polymer Light Technology Corp), CsI (Alfa Aesar, 99.999%), spiro-OMeTAD, 4-tert-butylpyridine(t-BP)(aladdin company), lithium-bis (tri-fluoromethanesulfonyl) Imie (Li-TFSI),N,N-Dimethylformamide (DMF, ≥ 99.9%, aladdincompany), N-Methyl-2- pyrrolidone (NMP, Sigma-Aldrich, anhydrous, 99.5%), phenethylamine (Aldrich, > 99%), ghydroiodic acid (57 wt % in H2O, Sigma-Aldrich, 99.99%) were of analytical grade and used without further purification.

2.2 Characterization

Crystallinity properties of perovskite film was recorded by X-ray diffraction (XRD) spectra (D2 PHASER) with Cu Ka radiation (λ = 1.5405 Å). The surface morphology was checked with a scanning electron microscope (SEM) (SUF-8010). While UV–visible-NIR spectrophotometer (UV-3600) was carried out to examine the absorption spectra in the wavelength of 300–900 nm. Photocurrent density–voltage (J-V) curves of PSCs were tested at a standard condition with light intensity of AM 1.5 G (100 mW/cm2) and temperature of 25 °C. A metal mask of 0.1 cm2 was clipped on ITO side to ensure the active area of PSCs with scanning rate of 35 mV/s and delay time of 50 ms.

2.3 Experiment Steps

Synthesis of phenylethylammonium iodide.

9.6 g phenethylamine was dissolved into 30 ml methanol in iced bath. 21.6 g ghydroiodic acid was slowly added into the solution. The obtained solids were washed twice with ethyl ether by a magnetic agitator overnight until the solids turned white and then it dried under vacuum to produce a white plate-like solid [4].

Device fabrication.

PSCs were fabricated with the structure of ITO glass/SnO2/perovskite/Spiro-OMeTAD/Ag. A transparent conducting indium-doped SnO2 coated glass substrate (ITO) was sequentially cleaned by deionized water, acetone, anhydrous ethanol and acetone isopropanol for 10 min, respectively. After dried by nitrogen gun, the ITO was dealt with plasma for 20 min. Subsequently, 60 ul of SnO2 colloidal solution (15 wt%) was spin-coated on the ITO glasses with speed of 4000 rpm and then annealed at 150 °C for 20 min in air condition.

The substrate was then treated with plasma before transferring into the glove box. The 3D perovskite precursor solution was prepared with FAI, CsI and PbI2 with a ratio of 0.996: 0.204: 1 in 700 mg anhydrous DMF and 125 mg NMP [5]. 2D/3D hybrid perovskite precursor solution contained a ratio of 0.9466: 0.0334: 0.02: 1 among FAI, PEAI, CsI and PbI2 correspondingly [6].The precursor solution were both spin casted with a speed of 4000 rpm for 30 s with 150 uL chlorobenzene dripped onto the rotating substrate 20 s prior to the finish of the procedure. For the passivation layer, 8.0 mg/mL PEAI/ isopropanol solution was following spin-casted on preheated 3D and 2D/3D perovskite film respectively with the speed of 4000 rpm for 30 s. Perovskite layers were all annealed at 80 °C for 2 min at first, 150 °C for 20 min subsequently. As for the organic hole transporting layer (HTL), 80 mg Spiro-OMeTAD, 29 uL 4-tert-butylpyridine (TBP) and 18 uL LiTFSI solution (520 mg Li-TFSI in 1 mL acetonitrile) were dissolved into 1 mL chlorobenzene. The organic HTL layer was deposited at 4000 rpm for 40 s without annealing. Finally, silver electrode was thermally evaporated under a high vacuum using an Ebeam-Thermal evaporation system through a shadow mask. All the above operations are completed in the nitrogen-filled glove box.

3 Results and Disscusstion

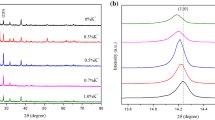

Planar heterojunction PSCs are fabricated with 3D and 2D/3D hybrid perovskite, respectively. XRD spectrum of perovskite film in Fig. 1a demonstrates a typical diffraction pattern of trigonal perovskite phase. The stronger diffraction peaks of 2D/3D hybrid perovskite layer indicate that the crystalline quality of perovskite becomes better with PEAI doping. The PEAI can interact with 3D perovskite crystals, which is helpful for the formation of perovskite phase, making the grain boundaries functional after crystallization. The scanning electron microscopic (SEM) images in Fig. 1b depict the changes in morphology of the as-prepared perovskite films. A uniform and flat film has been achieved with the 2D/3D hybrid perovskite, with crystalline characteristics on hundreds of nanometers, eliminating the shunting and current leakage caused by uncovered 3D perovskite.

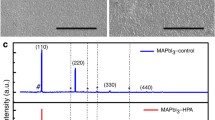

Passivation layer is further introduced to perovskite solar cell here with fabrication processes schematically depicted in Fig. 2a and PEAI is capped on perovskite surface to inhabit the surface recombination [7, 8]. The XRD spectrum in Fig. 2b illustrates dramatic improvement of crystalline quality with the PEAI layer. The photocurrent density voltage (J-V) curves and detailed photovoltaic parameters of these devices are shown in Fig. 3 and Table 1, respectively. VOC, JSC and FF are significantly improved with the passivation layer. The increased VOC and FF result from the passivated surface recombination. While the improvement of JSC can be ascribed to the better crystalline quality. Consequently, the perovskite solar cell shows the best power conversion efficiency with PEAI layer and its VOC, JSC, FF and PCE are 1 V, 14.8 mA/cm2, 0.56, 8.34% respectively.

The stability is an important reflection of device performance. We have checked the device performance on the device with PEAI layer after stored for 10 days in glove box, as shown in Fig. 3b and Table 1. The PSC exhibits a stable output with ~3.6% efficiency raise after storage. The stability can be explained by a better passivation at the interface and the highly crystalline properties of the perovskite absorber [9,10,11].

4 Conclusion

In this paper, highly uniform, dense perovskite film is successfully obtained via PEAI passivation layer. 2D/3D hybrid perovskite film is constructed through incorporating 2D PEAI into the 3D precursor solution. The hybrid film demonstrates obviously improved crystallinity and morphology. Besides, the coated PEAI further inhibits surface defect recombination and enhances perovskite crystallinity, and thus increases the PCE. The PSC based on PEAI layer also exhibits better stability. However the PCE of our devices are generally low, which might be caused by the damaging EB evaporation. This work gives us a new choice for preparing perovskite film with enhanced morphology and crystallinity for efficient and stable PSCs.

References

NREL efficiency chart. https://www.nrel.gov/pv/cell-efficiency.html

Tan H (2017) Efficient and stable solution-processed planar perovskite solar cells via contact passivation. Science 355:722–726

Cho K (2018) Selective growth of layered perovskites for stable and efficient photovoltaics. Energy Environ Sci 11:952–959

Lee J (2018) 2D perovskite stabilized phase-pure formamidinium perovskite solar cells. Nat Commun 9:3021

Jeon N (2015) Compositional engineering of perovskite materials for high performance solar cells. Nature 517:476–480

Lin Y (2018) Enhanced thermal stability in perovskite solar cells by assembling 2D/3D stacking structures. J Phys Chem Lett 9:654–658

Jiang Q (2017) Planar-structure perovskite solar cells with efficiency beyond 21%. Adv Mater 29:1703852

Jiang Q (2019) Surface passivation of perovskite film for efficient solar cells. Nat Photonics 13:460–466

Guo P (2019) Anti-colloidal-solutions: laser-generated nanocrystals in perovskite: universal embedding of ligand-free and sub-10 nm nanocrystals in solution-processed metal halide perovskite films for effectively modulated optoelectronic performance. Energy Mater 9:1970134

Tan H (2017) Efficient and stable solution-processed planar perovskite solar cells via contact passivation. Science 355(6326):722–726

Guo P (2019) Surface & grain boundary co-passivation by fluorocarbon based bifunctional molecules for perovskite solar cells with efficiency over 21%. J Mater Chem A 7:2497

Author information

Authors and Affiliations

Corresponding authors

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2021 The Author(s), under exclusive license to Springer Nature Singapore Pte Ltd.

About this paper

Cite this paper

Rong, X., Yao, X., Liu, Z. (2021). Hybrid 2D/3D Perovskite Film with Enhanced Crystallinity via PEAI Passivation in Perovskite Solar Cells. In: Peng, Y., Dong, X. (eds) Proceedings of 2019 International Conference on Optoelectronics and Measurement. Lecture Notes in Electrical Engineering, vol 726. Springer, Singapore. https://doi.org/10.1007/978-981-33-4110-4_20

Download citation

DOI: https://doi.org/10.1007/978-981-33-4110-4_20

Published:

Publisher Name: Springer, Singapore

Print ISBN: 978-981-33-4109-8

Online ISBN: 978-981-33-4110-4

eBook Packages: EngineeringEngineering (R0)