Abstract

Water alternating gas (WAG) injection with its first successful field pilot application on the North Pembina field in Alberta, Canada, in 1957, is one of the most prominent EOR methods that substantially prolong the lives of the otherwise depleted and uneconomical oil fields. This technique is well established, but the practical challenges are often of the occurrence of viscous fingering, gravity segregation, and gas channeling or override, and consequently lower oil recovery rates. Previous researches have focused almost exclusively on modifying the salinity and the ionic composition of the injected water, also termed as smart waterflooding which proved to further enhance the oil recovery obtained from waterflooding. However, obscurity exists on whether the deployment of smart water during WAG-CO2 injection will be successful. This paper addresses the impacts of the implementation of a technique which combines smart waterflooding and WAG-CO2 injection on the oil/water relative permeability curves for a light oil reservoir. An analysis on the two-phase relative permeability functions is essential as to predict the effectiveness of the displacement process or the performance of smart water injection applied during WAG-CO2 injection. CMG STARS was used to simulate the effects of fine-tuning the salinity as well as varying the composition of Ca2+ and Mg2+ ions in brine on the oil recovery factor. The optimum brine salinity for maximum oil recovery was also determined. The slight shifting of the relative permeability curves to the right which can be observed proves the capability of the smart water to modify the rock wettability toward a more water-wet system. Yet the findings from the simulation study suggest that the use of smart waterflooding is not ideal or has low potential in increasing the oil recovery during WAG-CO2 injection.

Access provided by Autonomous University of Puebla. Download conference paper PDF

Similar content being viewed by others

Keywords

1 Introduction

WAG injection is a combination of the two conventional secondary recovery techniques, waterflooding, and gas injection. It is a conventional EOR process in which slugs of water and gas are injected alternately to sweep the residual oil not recovered by the primary and the secondary phases of production [6]. The CO2 gas works to reduce the viscosity of oil, cause oil swelling, and increase the relative permeability so the trapped oil is mobilized and can flow more easily through the rock. Due to the low gas density, the unfavorable high mobility ratio leads to poor sweep efficiencies. Thus, after a period of time, the injection switches to water to improve the macroscopic sweep efficiency and these alternate CO2 gas and water injection repeat until the oil production drops below a profitable level.

1.1 Problems Associated with the WAG Process

The ultimate recovery from WAG is relatively low with about incremental recovery of 5–10 % [6]. Christensen et al. [6] presented a comprehensive literature of the WAG processes in about 59 fields and commented on several severe problems which caused the decrease in displacement efficiency when performing WAG-CO2 injection. The major problems of WAG injection are the water and gas breakthrough and decrease in injectivity [6, 7] due to challenges such as viscous instabilities/fingering, gravity segregation, gas override, and gas channeling through high permeability streaks/thief zone.

1.2 Smart Waterflooding

For over 100 years, waterflooding has been widely implemented to accomplish the dual objectives of reservoir pressure maintenance as well as a water drive to displace oil from the injector wells to the producer wells. In the 1990s, the idea of the influences of brine composition on the oil recovery as introduced in the papers published by Jadhunandan and Morrow [10] and Yildiz and Morrow [27] began to shift the industry’s focus to adjusting the ion composition and salinity of the injected fluid. This chemically altered water is termed as “smart water”. Since then, there have been numerous researches done to advance the concept of smart waterflooding and to demonstrate the tremendous potential of this technology.

There is an increasing evidence from the laboratory that reduction in the concentration of salinity leads to higher oil recovery factor than conventional waterflooding in sandstone reservoirs [24] and in carbonate reservoirs [28]. Research done by Tang and Morrow [25] indicated an improvement in the oil recovery efficiency when the salinity of the injection brine was reduced from 15,000 to 1,500 ppm. Apart from corefloods, several field single-well tests and field trials demonstrated the potential of low-salinity waterflooding to improve oil recovery [15, 18, 23]. Webb et al. [26] reported a decrease in the residual oil saturation, Sor as the salinity of the injection brine is varied from 100 to 20 % and finally 5 % of the salinity formation water. The low salinity effect is believed to significantly impact the ultimate oil recovery as a result of different mechanisms acting together. Although there is still no consistent mechanistic explanation of the low-salinity waterflooding phenomenon in sandstone reservoirs, the possible mechanisms which have been proposed up to now are migration of fines [20], pH increase [18], and the multi-ions exchange (MIE) between the clay mineral surfaces and the injected brine [14] triggered by the expansion of the electrical double layer [16].

1.3 Smart Water Applications in WAG

To the best of our knowledge, there are only two prior researches concerning the applications of smart water in WAG. Kulkarni and Rao [13] published their work on the impacts of brine composition on the tertiary oil recovery through an experimental study using 5 % NaCl brine and 0.5815 % NaCl reservoir brine during WAG. They concluded that the WAG recoveries are highly dependent on the brine composition, and the explanation for the decrease in oil recovery at lower brine salinity is because of the rise in the solubility of the gas in the brine.

Jiang et al. [12] progressed the research on the impact of salinity of the injection brine by conducting experiments using two oil models, one of which is a mixture of 50 wt% n-decane and 50 wt% n-hexadecane, and the other is a crude oil from the Cottonwood Creek. According to [12], an increase in the salinity of the injection brine is accompanied by an increase in the tertiary recovery and oil recovery factor of both model oil and crude oil. Their reasoning was similar to that of [13] which is as the salinity of the brine increases, the solubility of CO2 gas in the brine decreases; thus, more CO2 gas are available for the miscible flooding followed by an increase in the WAG recoveries.

1.4 Relative Permeability

The computation of relative permeability is necessary for understanding the crude–brine–rock (CBR) interactions, reservoir performance prediction, finding out the factors contributing to low productivity, and reducing formation damage [9]. The relative permeability can be generally defined as the property of the porous media which can be estimated from the ratio of the effective permeability of a fluid at a given saturation to the permeability of the fluid at 100 % saturation [1, 2]. It corresponds to the ability of the porous media to transmit one fluid when one or more fluids are present [3]. The relative permeability curves are representative of flow characteristics through the formation in the reservoir which is affected by the mechanism by which the reservoir is depleted [21].

Relative permeability is a reservoir dynamic property that is largely affected by several factors including the pore geometry, saturation history, and wettability. The changes in the shape of the relative permeability can be justified due to the uncertainties in rock wettability, saturation history, pore geometry, and fluid distribution in the reservoir [3, 19]. From the curves of relative permeability, the wettability of the reservoir system, whether oil wet or water wet, can be determined. Most of the studies suggested that the oil recoveries from oil-wet reservoirs are generally less than from water-wet reservoirs.

2 Methodology

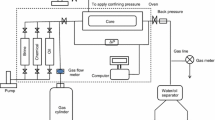

2.1 Synthetic Reservoir Model

The reservoir simulation model has a dimension of 11 × 11 × 6 with a total of 726 grid blocks with the Norne oil field reservoir rock and fluid properties. The length, width, and height of the reservoir simulation model are 550, 550, and 60 m, respectively. The data gathered were first input using the CMG Builder to be simulated or modeled by CMG STARS [4, 8, 17]. Due to the data availability constraints and processing time considerations, only a sector model of the formation with sufficient data was simulated. However, the static model is adequate to model the effects of smart water injection during WAG-CO2 on the relative permeability and oil recovery factor. A quarter five spot injection pattern between the injector and the producer wells was employed. The water and CO2 injector is located at the same position to enable alternate injection of high-salinity water or smart water and CO2 gas.

2.2 Workflow of Smart WAG-CO2 Modeling

The simulated reservoir was first depleted and waterflooded for 6 years before WAG is applied for 9 years. The secondary recovery using waterflooding stops at beginning of the year of 1997 because of the economical limit set using the percentage of water cut of higher than 80 %. The duration of the simulation run is for 15 years from January 1, 1991, up to January 1, 2006. For optimized production, a WAG ratio of 1:1 is used.

The conventional brine was set to have water components of 35,000 ppm, whereas the smart water is of different salinities of about 1,000, 3,000, and 7,000 ppm. This is because low salinity effects take place when the injected concentration is below 25 % of the salinity of the connate water with approximate values of 1,000–7,000 ppm for the lower and upper salinity threshold as suggested in the literature [11]. The ion components dissolved in the water are Na+, K+, Ca2+, Mg2+, Cl−, HCO3 2−, and SO4 2−. The composition of the Na+ cations and the Cl− anions defines the salinities of the injection water. The total dissolved solids (TDS) in the water at different salinities are as summarized in Table 1.

Simulation runs were performed for 3 different injection scenarios comprising of conventional WAG-CO2 injection, proposed smart water assisted WAG-CO2 injection, and smart WAG-CO2 injection as presented in Fig. 1.

For the base case study which is the conventional WAG-CO2, alternate injection of high-salinity water of 35,000 ppm and CO2 gas was used. Then, the second injection scenario which is smart assisted WAG-CO2 involving the alternate injection of high salinity and smart waterflooding with CO2 gas was simulated. There are 3 simulation runs which were conducted for this smart water assisted WAG-CO2 injection whereby 3 different salinities of smart water including 1,000, 3,000, and 7,000 ppm were deployed. The next injection scenario is the smart WAG-CO2 injection in which smart waterflooding follows every CO2 gas injection and also runs at 3 different salinities similar to the smart assisted WAG-CO2 case studies.

The interactions between the crude oil and brine are sensitive to the ionic compositions. Tuning the composition of divalent ions, specifically Ca2+ and Mg2+ ions in brine during smart WAG-CO2 injection, plays an essential role in escalating the oil recovery factor. There are 7 simulation runs conducted in order to simulate the effects of the composition of these divalent cations on the oil recovery during smart WAG-CO2 injection. The effects of the composition of Ca2+ and Mg2+ ions in brine on the oil recovery during WAG-CO2 injection are simulated by varying the mole fractions of these divalent ions contained in the brine ranging from 0 up to 300 ppm at 50 ppm intervals.

3 Results and Discussion

3.1 The Effects of Smart Water Injection on the Relative Permeability

The effects of the smart water injection during WAG-CO2 flooding are evident from the results of the relative permeability curves of k RO and k RW versus SW as presented in Fig. 2. The relative permeability curves are shifted to the right when smart WAG-CO2 injection with lower salinity from 35,000 ppm to 7,000 ppm is applied on the sandstone reservoir with light oil. Unlike waterflooding, the relative permeability to oil during smart WAG-CO2 injection decreases instead of increase in relative to the relative permeability to oil during the base case conventional WAG-CO2 injection when lower salinity brine is used. The lower relative permeability to oil implies that smart water injection during WAG-CO2 flooding delays the oil displacement process and results in lower incremental oil recovery and higher residual oil saturation.

At the same time, the relative permeability to water during smart WAG-CO2 also decreases in relative to the relative permeability to water during base case conventional WAG-CO2 injection when lower salinity brine is utilized. This is evident by the fact that solubility of CO2 gas in brine increases with a decrease in the salinity of the brine [5] causing an increase in the viscosity of the water. Subsequently, the mobility of the water decreases and less percentage of water cut because of the reduction in the relative permeability to water during smart WAG-CO2 injection. However, the effects of the dissolved CO2 gas in water on the viscosity of the water are not very drastic [22] which clarifies the small reduction in the relative permeability to water as compared to the larger reduction in the relative permeability to oil during smart WAG-CO2 injection.

The gradual shifting of the intersection point between the relative permeability to oil and to water curves to the right when lower salinity brine is used signifies the change in the wettability toward a more water-wet system induced by the smart water injection. The influence of the smart water injection on the relative permeability is related to the few smart waterflooding mechanisms including the MIE mechanism and expansion of the electrical double layer [14, 16]. The formation of a layer of multivalent cations during smart water injection increases the electrostatic repulsion and thus eases the desorption of oil components from the negatively charged clay.

3.2 The Effects of the Composition of Ca2+ and Mg2+ Ions in Brine

The results are represented as a plot of the cumulative oil produced versus Ca2+ and Mg2+ ions composition in brine as shown in Fig. 3. An increase in the composition of the Ca2+ and Mg2+ ions in the brine yields a higher oil recovery. The observed incremental recovery behavior as the concentration of Ca2+ and Mg2+ ions in the brine increases from 0 up to 300 ppm is ascribed to the presence of more divalent ions available for the cations exchange reaction between the clay minerals and the injected brine which further reduces the ion binding between the crude oil and rock surface. These divalent ions act as potential determining ions that are reactive and have the capability of changing the rock surface charges and thus allow the release of the negative carboxylic oil component from the rock surface. This eventually alters the rock wettability toward a more water-wet system and improves the ultimate oil recovery.

3.3 The Optimum Brine Salinity for Maximum Oil Recovery

In this simulation study, 7 different WAG-CO2 injection schemes with the same injection rate are simulated for a sandstone reservoir with light oil. As illustrated in the Fig. 4, the injection timeline of the oil reservoir is mainly divided into 2 stages which are the secondary recovery via pre-waterflooding and the post-waterflooding or EOR. The pre-waterflooding stops early 1997 due to percentage of water cut of 81.5768 % exceeding the economic constraint of 80 %. To obtain a clearer picture of the difference in oil recovery between the 7 injection scenarios, the cumulative oil recovery plot is magnified to the comparison plots from year 2005 to 2006 as in shown in Fig. 5. The oil recoveries from waterflooding are the same for all the case studies which is 456,942 m3 or 2,874,029.81 bbl. The conventional WAG-CO2 injection gives the highest oil recovery followed by smart assisted WAG-CO2 using 7,000, 3,000, and 1,000 ppm and then smart WAG-CO2 using 7,000, 3,000, and 1,000 ppm.

Although there is a no very significant difference in oil recovery in the various approaches, the correlation between salinity and oil recovery that can be observed is that as the salinity of the injected brines decreases, the oil recovery decreases. This means that the decrease in the salinity of the injection brine during WAG-CO2 injection has adverse effects on the oil recovery. This is obviously very different from the smart water injection during secondary waterfooding whereby a decrease in the salinity contributes to a higher oil recovery [14, 24].

The proposed reason for the lower oil recovery during smart WAG-CO2 injection is because of the decrease in solubility of CO2 gas in oil but increase in solubility of CO2 gas in water when the salinity of the brine decreases. The CO2 gas solubility in water increases with pressure but decreases with a decrease in the temperature and salinity of water [5]. Thus, there is less amount of CO2 gas available for mixing with the hydrocarbons to form a zone of miscible CO2 and light hydrocarbons which works to reduce the viscosity of oil and cause oil swelling [12]. The increase in solubility of CO2 gas in the smart water consequently hinders the oil displacement efficiency and reduces the ultimate oil recovery during WAG-CO2 injection.

However, as compared to the smart WAG-CO2 injection, the smart water assisted WAG-CO2 injection achieves a higher oil recovery. Based on the Table 2 and Fig. 5, it is also obvious that the smart water assisted WAG-CO2 has higher oil recovery than the smart WAG-CO2 but lower oil recovery than the conventional WAG-CO2 injection. These occurrences may be due to the approach of alternate injection of conventional brines and smart water after each CO2 gas injection. The first conventional brine injected after the first cycle of gas injection functions to increase the macroscopic efficiency through better gas–oil mobility control and stabilized displacement of oil. On the other hand, the smart water injection which follows the second cycle of gas injection aims to increase the microscopic sweep efficiency via altering the wettability of the reservoir rocks toward more water wet. Therefore, this combined approach makes a perfect scheme in increasing the overall sweep efficiency, yielding a lower water cut as well as higher oil recovery factor than the smart WAG-CO2 injection. Besides that, the smart water assisted WAG-CO2 injection may reduce the required expenses for the desalination of the brines.

All in all, the conventional WAG-CO2 injection yields the highest oil recovery factor. Hence, the optimum brine salinity for maximum oil recovery in this simulation study is 35,000 ppm. This suggests that the potential use of smart water injection is low during WAG-CO2.

4 Conclusions and Recommendations

From the simulation study conducted, the following conclusions and recommendations can be drawn:-

-

1.

During WAG-CO2 injection, the smart water injection causes both the relative permeability to oil and relative permeability to water to decrease in relative to that of conventional brine injection. In another words, smart water injection during WAG-CO2 hinders the flow of oil through the porous medium resulting in a lower oil recovery factor and also percentage of water cut. A slight shifting of the intersection point between the relative permeability to oil and to water curves to the right suggests that the smart water injection during WAG-CO2 flooding modified the rock wettability toward a more water-wet system.

-

2.

An increase in the composition of Ca2+ and Mg2+ ions in brine yields a higher oil recovery factor via reducing the ion binding between the negative carboxylic oil component and the rock surfaces.

-

3.

A decrease in the brine salinity during WAG-CO2 injection has unfavorable effects on the oil recovery factor. Therefore, the optimum brine salinity for maximum oil recovery during WAG-CO2 injection in this simulation study is 35,000 ppm. All these findings are significant as to evaluate the performance of smart water injection applied during WAG-CO2 injection which is mainly characterized by the relative permeability.

-

4.

It is recommended that further research be undertaken to examine the effects of smart water on the three-phase relative permeability models which is much more complicated. Further works might explore or concentrate on experimental or laboratory works to compare and prove the results obtained from the simulation runs in this research. It is also imperative to determine the optimum WAG ratio to maximize oil recovery and optimize fluid injection.

References

Ahmed, T. 2001. Principles OfWaterflooding. In Reservoir Engineering Handbook, second edition. Houston,Texas: Gulf Professional Publishing.

Amyx, J. W., Bass, D. M. and Whiting, R. L. 1960. Petroleum reservoir engineering: physical properties, 174-209. New York City: McGraw-Hill.

Anderson, W. G. 1987. Wettability literature survey part 5: The effects of wettability on relative permeability. Journal of Petroleum Technology, 39(11), 1453-1468.

Awolola, K. A. 2012. Enhanced Oil Recovery For Norne Field (Statoil) C-Segment Using Alkaline-Surfactant-Polymer Flooding. PhD diss., Norwegian University of Science and Technology.

Chang, Y. B., Coats, B., and Nolen, J. 1998. A compositional model for CO2 floods including CO2 solubility in water. SPE Reservoir Evaluation & Engineering, 1(2), 155-160.

Christensen, J. R., Stenby, E. H., and Skauge, A. 2001. Review of WAG field experience. SPE Reservoir Evaluation & Engineering, 4 (2), 97-106.

Gorell, S. B. 1990. Implications of water-alternate-gas injection, for profile control and injectivity. In SPE/DOE Enhanced Oil Recovery Symposium.

Hasanov, B. 2010. Application of low salinity water injection to NORNE field E-segment.

Honarpour, M.M. and Maloney, D.R. 1990. Relative Permeability Technology And Applications. Paper NIPER 9008 presented at the 4th Annual SCA Conference.

Jadhunandan, P. P., and Morrow, N. R. 1995. Effect of wettability on waterflood recovery for crude oil/ brine/rock systems. SPE Reservoir Engineering, 10 (1), 40-46.

Jerauld, G.R., Lin, C.Y., Kevin J. Webb, and Jim C. Seccombe. 2008. Modeling Low-Salinity Waterflooding, Paper SPE 102239 presented at Conference and Exhibition, San Antonio, Texas, 24–27 September.

Jiang, H., Nuryaningsih, L., and Adidharma, H. 2010. The Effect of Salinity of Injection Brine on Water Alternating Gas Performance in Tertiary Miscible Carbon Dioxide Flooding: Experimental Study. SPE Western Regional Meeting. Anaheim, California, USA.

Kulkarni, M. M., and Rao, D. N. 2004. Experimental investigation of various methods of tertiary gas injection. SPE Annual Technical Conference and Exhibition. Houston, Texas, USA.

Lager, A., Webb, KJ., Black, CJ.J., Singleton, M., and Sorbie, K.S. 2006. Low Salinity Oil Recovery- An Experimental Investigation, Paper SCA 2006-36 presented at the International Symposium of the Society of Core Analysis, Trondheim, Norway.

Lager, A., Webb, K., Collins, I., and Richmond, D. 2008. LoSal enhanced oil recovery: Evidence of enhanced oil recovery at the reservoir scale. SPE/DOE Symposium on Improved Oil Recovery, Tulsa, Oklahoma, USA.

Ligthelm, D.I., Gronsveld, J., Hoffman, I.P., Brusse, N.J., Marcelis, F. and Van Der Linde, H. 2009. Waterflooding Strategy by Manipulation of Injection Brine Composition. Paper SPE 119835.

Maheshwari, Y. K. 2011. A Comparative Simulation Study of Chemical EOR Methodologies (Alkaline, Surfactant and/or Polymer) Applied to Norne Field E-Segment, PhD diss., Master thesis, NTNU.

McGuire, P.I., Chatman, J.R., Paskvan, F.K., Sommer D.M., and Carini F.H. 2005. Low Salinity Oil Recovery: An Exciting New EOR Opportunity for Alaska’s North Slope. Paper SPE 93903 presented at 2005 SPE Western Regional Meeting, Irvine, CA.

Molina, N.N.1980. A Systematic Approach To The Relative Permeability Problem in Reservoir Simulation. Paper SPE 9234 presented at the 55th Annual Fall Technical Conference and Exhibition of the SPE, Dallas, Texas, 21 – 24 September.

Morrow, N. R., Tang, G. Q., Valat, M., and Xie, X. 1998. Prospects of improved oil recovery related to wettability and brine composition. Journal of Petroleum science and Engineering, 20 (3), 267-276.

Osoba, J. S., Richardson, J. G., Kerver, J. K., Hafford, J. A., and Blair, P. M. 1951. Laboratory measurements of relative permeability. Journal of Petroleum Technology, 3(2), 47-56.

Sayegh, S. G., and Najman, J. 1987. Phase behavior measurements of CO2‐SO2‐brine mixtures. The Canadian Journal of Chemical Engineering, 65 (2), 314-320.

Seccombe, J., Lager, A., Webb, K., Jerauld, G., and Fueg, E. 2008. Improving Wateflood Recovery: LoSalTM EOR Field Evaluation. In SPE/DOE Symposium on Improved Oil Recovery.

Tang, G. Q., & Morrow, N. R. 1997. Salinity, temperature, oil composition, and oil recovery by waterflooding. SPE Reservoir Engineering, 12 (4), 269-276.

Tang, G. Q., & Morrow, N. R. 1999. Influence of brine composition and fines migration on crude oil/brine/rock interactions and oil recovery. Journal of Petroleum Science and Engineering, 24(2), 99-111.

Webb, K. J., Black, C. J. J., and Edmonds, I. J. 2005. Low salinity oil recovery–The role of reservoir condition corefloods. In 13th European Symposium on Improved Oil Recovery.

Yildiz, H. O., and Morrow, N. R. 1996. Effect of brine composition on recovery of Moutray crude oil by waterflooding. Journal of Petroleum Science and Engineering, 14(3), 159-168.

Yousef, A., Al-Saleh, S., Al-Kaabi, A., and Al-Jawfi, M. October. Laboratory investigation of novel oil recovery method for carbonate reservoirs. In Canadian Unconventional Resources and International Petroleum Conference.

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2015 Springer Science+Business Media Singapore

About this paper

Cite this paper

Yip, P.M., Alta’ee, A.F. (2015). Simulation Study of the Effect of Smart Water on Relative Permeability During WAG-CO2 Injection for Light Oil Reservoir. In: Awang, M., Negash, B., Md Akhir, N., Lubis, L. (eds) ICIPEG 2014. Springer, Singapore. https://doi.org/10.1007/978-981-287-368-2_10

Download citation

DOI: https://doi.org/10.1007/978-981-287-368-2_10

Published:

Publisher Name: Springer, Singapore

Print ISBN: 978-981-287-367-5

Online ISBN: 978-981-287-368-2

eBook Packages: EnergyEnergy (R0)