Abstract

In the past decades, membrane technology has been widely utilized in various separation processes, because of their low-energy consumption, low-cost, reliability, and scalability when compared with conventional separation processes like distillation, extraction, or crystallization (Sholl and Lively in Nat News 532:435–437, 2016; Yang et al. in Chem Soc Rev 49:5359–5406, 2020). In order to further increase the competitiveness, intensive efforts have been made from improving the separation efficiency of existing membrane processes to exploring new applications. As the core part, membrane materials with high permeability, high selectivity, and high stability are extremely desired since they can significantly accelerate the practical application of membrane technology.

Access provided by Autonomous University of Puebla. Download chapter PDF

Similar content being viewed by others

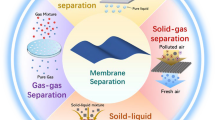

In the past decades, membrane technology has been widely utilized in various separation processes, because of their low-energy consumption, low-cost, reliability, and scalability when compared with conventional separation processes like distillation, extraction, or crystallization [1, 2]. In order to further increase the competitiveness, intensive efforts have been made from improving the separation efficiency of existing membrane processes to exploring new applications. As the core part, membrane materials with high permeability, high selectivity, and high stability are extremely desired since they can significantly accelerate the practical application of membrane technology [3, 4]. To date, plenty of membranes with different pore sizes have been developed, such as polymer membrane, ceramic membrane, two-dimensional (2D) lamellar membrane, molecule sieving membrane, hybrid membrane, and composite membrane [5,6,7,8,9,10]. These membranes have been widely used for different separation processes including, microfiltration, ultrafiltration, nanofiltration, reverse osmosis, gas separation, and proton/ion conduction, etc. [11, 12].

For each category of membrane, the physical and chemical environments of transfer channels are of great importance in manipulating the comprehensive properties. The physical environments are dictated by the connectivity, tortuosity, and size of transfer channels, while the chemical environments are dictated by the type, amount, and distribution of functional groups within transfer channels [13]. Generally, ideal transfer channels should integrate the following attributes: (i) they should be short with appropriate transfer environment to endow membranes with high permeability, (ii) the channel size distribution should be narrow to endow membranes with high selectivity, and (iii) the chemical and mechanical stability should be high to endow membranes with long-term operation stability [14]. Currently, polymers are the dominant membrane materials, due to their easy processability and high scale-up capability. For conventional polymer membranes, breaking the permeability–selectivity or permeability–stability trade-off remains a challenge. The great progress in polymer membranes over the past decades has brought about the booming of novel kinds of structured membranes including, hybrid membrane, composite membrane, and phase-separated membrane, which push the separation performances of polymer membranes to new records [15,16,17,18].

Hybrid membrane is an intricately structured membrane configuration, owing to its merit of coupling the good flexibility and processability of polymers with the regular topological structure as well as the tunable functionality of fillers [19, 20]. Impermeable fillers such as silica particles, graphene oxide (GO) nanosheets, and organic/inorganic nanorods can induce a distortion of chain alignment to improve the free volume property or induce the construction of long-range, ordered transfer channels in membrane [21, 22]. Permeable fillers such as metal–organic frameworks (MOFs), covalent organic frameworks (COFs), and zeolite can afford additional transfer pathways and mechanisms to membrane including, molecule sieving, and selective adsorption [23, 24].

Composite membrane for molecule transfer is generally a heterogeneous membrane with dense separation layer and porous support layer, where the separation layer and the support layer can be separately optimized to achieve simultaneously high separation performance and stability [25, 26]. Particularly, the fabrication of composite membrane with an ultrathin separation layer is deemed as a delicate strategy to achieve highly permeable membrane, which is one of the most important pursuits for membrane technology [27, 28]. At present, researches related to composite membranes mainly focus on the precise manipulation of physical structure and chemical component of separation layer; however, these remain challenging due to the pursuit of ultrathin thickness. For proton/ion separation, electrospinning is increasingly recognized as a powerful mean for introducing unique phase-separated architectures into composite membranes [29]. Indeed, it allows the elaboration of composite membranes with a rather facile mean to control of the long-range organization/distribution/percolation of hydrophilic and hydrophobic domains of the ionomer by adjusting the type of electrospun material, the volume fraction of nanofibers, and the experimental conditions [30]. Moreover, electrospinning can impart uniaxial alignment of polymer chains within nanofibers, resulting in enhanced mechanical properties. Importantly, it can promote the formation of interconnected transfer channels, which facilitate the improvement in proton/ion conduction [31].

In recent years, 2D nanosheets, with a thickness of one to a few atoms, have become the promising building blocks for advanced membranes [32]. Moreover, the nanosheets can be designed with precise pore size along with targeted chemical functionality, enabling their extraordinary physical or chemical selectivity [33]. Through a facile filtration process, 2D lamellar membranes can be fabricated with either porous or nonporous nanosheets. The transfer channels based on nonporous nanosheets refer to the interlayer channels of lamellar membranes, differing from the pores of porous nanosheet-based lamellar membranes [34]. To date, a large number of nonporous nanosheets have been developed including, graphene oxide (GO), hexagonal boron nitride (h-BN), MXenes, transition metal dichalcogenides (TMDs), layered double hydroxides (LDHs), etc., most of which are easy to fabricate. For 2D lamellar membranes fabricated with nonporous nanosheets, the researchers are mainly concentrated on controlling the physical structure and chemical component of interlayer channels. However, the interlayer channel is usually tortuous. To this end, intrinsically porous nanosheets are developed. The transfer channels based on this kind of nanosheet refer to the channels from the intrinsic pores on nanosheets [35]. Intrinsically porous nanosheets can be 2D zeolites, 2D MOFs, 2D COFs, etc.

In this work, we focus on the application of membrane technology on organic solvent nanofiltration, hydrogen fuel cell, and lithium ion battery. We prepared several kinds of membranes, including hybrid membrane, composite membrane, nanofiber composite membrane, and 2D lamellar membrane, and the microstructure and performance of membrane were efficiently manipulated. In addition, the relevant transfer/separation mechanisms were deeply studied, and the transfer model equations were established. For organic solvent nanofiltration, the category of membrane mainly contains hybrid membrane, composite membrane, and 2D lamellar membrane. For hydrogen fuel cell, the category of membrane mainly includes hybrid membrane, nanofiber composite membrane, and 2D lamellar membrane. With respect to lithium ion or lithium–sulfur battery, hybrid membrane and 2D lamellar membrane are investigated in detail. The microstructures and performances as well as the structure-performance relationships of membranes are systematically investigated. Based on this, we preliminarily disclose the mass transfer mechanism in confined spacing and obtain a series of high-performance membranes and membrane materials. Hopefully, this work will offer some guidance on the design of advanced membranes with diverse transfer channels for applications in separation, catalysis, energy conversion, and storage, etc.

References

D.S. Sholl, R.P. Lively, Seven chemical separations to change the world. Nat. News 532, 435–437 (2016)

L. Yang, S. Qian, X. Wang, X. Cui, B. Chen, H. Xing, Energy-efficient separation alternatives: metal-organic frameworks and membranes for hydrocarbon separation. Chem. Soc. Rev. 49, 5359–5406 (2020)

H. B. Park, J. Kamcev, L. M. Robeson, M. Elimelech, B. D. Freeman, Maximizing the right stuff: the trade-off between membrane permeability and selectivity. Science, 356, eaab0530 (2017)

S. Wang, L. Yang, G. He, B. Shi, Y. Li, H. Wu, R. Zhang, S. Nunes, Z. Jiang, Two-dimensional nanochannel membranes for molecular and ionic separations. Chem. Soc. Rev. 49, 1071–1089 (2020)

A.C. Balazs, T. Emrick, T.P. Russell, Nanoparticle polymer composites: where two small worlds meet. Science 314, 1107–1110 (2006)

A. Kusoglu, A.Z. Weber, New insights into perfluorinated sulfonic-acid ionomers. Chem. Rev. 117, 987–1104 (2017)

L. Chen, G. Shi, J. Shen, B. Peng, B. Zhang, Y. Wang, F. Bian, J. Wang, D. Li, Z. Qian, G. Xu, G. Liu, J. Zeng, L. Zhang, Y. Yang, G. Zhou, M. Wu, W. Jin, J. Li, H. Fang, Ion sieving in graphene oxide membranes via cationic control of interlayer spacing. Nature 550, 380–383 (2017)

H. Wang, M. Wang, X. Liang, J. Yuan, H. Yang, S. Wang, Y. Ren, H. Wu, F. Pan, Z. Jiang, Organic molecular sieve membranes for chemical separations. Chem. Soc. Rev. 50, 5468–5516 (2021)

S. Karan, Z. Jiang, A.G. Livingston, Sub-10 nm polyamide nanofilms with ultrafast solvent transport for molecular separation. Science 348, 1347–1351 (2015)

M.Y. Jeon, D. Kim, P. Kumar, P.S. Lee, N. Rangnekar, P. Bai, M. Shete, B. Elyassi, H.S. Lee, K. Narasimharao, S.N. Basahel, S. Al-Thabaiti, W. Xu, H.J. Cho, E.O. Fetisov, R. Thyagarajan, R.F. DeJaco, W. Fan, K.A. Mkhoyan, J.I. Siepmann, M. Tsapatsis, Ultra-selective high-flux membranes from directly synthesized zeolite nanosheets. Nature 543, 690–694 (2017)

T. Matsuura, Synthetic membranes and membrane separation processes (CRC Press, 2020)

H. Strathmann, Membrane separation processes: current relevance and future opportunities. AIChE J. 47, 1077–1087 (2001)

G. He, Z. Li, J. Zhao, S. Wang, H. Wu, M.D. Guiver, Z. Jiang, Nanostructured ion-exchange membranes for fuel cells: recent advances and perspectives. Adv. Mater. 27, 5280–5295 (2015)

L. Wang, M.S. Boutilier, P.R. Kidambi, D. Jang, N.G. Hadjiconstantinou, R. Karnik, Fundamental transport mechanisms, fabrication and potential applications of nanoporous atomically thin membranes. Nat. Nanotechnol. 12, 509–522 (2017)

D.W. Shin, M.D. Guiver, Y.M. Lee, Hydrocarbon-based polymer electrolyte membranes: importance of morphology on ion transport and membrane stability. Chem. Rev. 117, 4759–4805 (2017)

E.B. Trigg, T.W. Gaines, M. Maréchal, D.E. Moed, P. Rannou, K.B. Wagener, M.J. Stevens, K.I. Winey, Self-assembled highly ordered acid layers in precisely sulfonated polyethylene produce efficient proton transport. Nat. Mater. 17, 725–731 (2018)

Y. Cheng, Y. Ying, S. Japip, S.D. Jiang, T.S. Chung, S. Zhang, D. Zhao, Advanced porous materials in mixed matrix membranes. Adv. Mater. 30, 1802401 (2018)

J. W. Barnett, C. R. Bilchak, Y. Wang, B. C. Benicewicz, L. A. Murdock, T. Bereau, S. K. Kumar. Designing exceptional gas-separation polymer membranes using machine learning. Sci. Adv. 6, eaaz4301 (2020)

R.D. Noble, Perspectives on mixed matrix membranes. J. Membr. Sci. 378, 393–397 (2011)

T.C. Merkel, B.D. Freeman, R.J. Spontak, Z. He, I. Pinnau, P. Meakin, A.J. Hill, Ultrapermeable, reverse-selective nanocomposite membranes. Science 296, 519–522 (2002)

R. Kannan, B.A. Kakade, V.K. Pillai, Polymer electrolyte fuel cells using Nafion-based composite membranes with functionalized carbon nanotubes. Angew. Chem. Int. Ed. 47, 2653–2656 (2008)

B.G. Choi, J. Hong, Y.C. Park, D.H. Jung, W.H. Hong, P.T. Hammond, H. Park, Innovative polymer nanocomposite electrolytes: nanoscale manipulation of ion channels by functionalized graphenes. ACS Nano 5, 5167–5174 (2011)

L. Xiang, L. Sheng, C. Wang, L. Zhang, Y. Pan, Y. L. Amino-functionalized ZIF-7 nanocrystals: improved intrinsic separation ability and interfacial compatibility in mixed-matrix membranes for CO2/CH4 separation. Adv. Mater. 29, 1606999 (2017)

H. Dou, M. Xu, B. Wang, Z. Zhang, G. Wen, Y. Zheng, D. Luo, L. Zhao, A. Yu, L. Zhang, Z. Jiang, Z. Chen, Microporous framework membranes for precise molecule/ion separations. Chem. Soc. Rev. 50, 986–1029 (2021)

H. Fan, Q. Shi, H. Yan, S. Ji, J. Dong, G. Zhang, Simultaneous spray self-Assembly of highly loaded ZIF-8-PDMS nanohybrid membranes exhibiting exceptionally high biobutanol-permselective pervaporation. Angew. Chem. Int. Ed. 126, 5684–5688 (2014)

J.E. Gu, S. Lee, C.M. Stafford, J.S. Lee, W. Choi, B.Y. Kim, K.Y. Baek, E.P. Chan, J.Y. Chung, J. Bang, J.H. Lee, Molecular layer-by-layer assembled thin-film composite membranes for water desalination. Adv. Mater. 25, 4778–4782 (2013)

R.W. Baker, J.G. Wijmans, Y. Huang, Permeability, permeance and selectivity: a preferred way of reporting pervaporation performance data. J. Membr. Sci. 348, 346–352 (2010)

H. Li, Z. Song, X. Zhang, Y. Huang, S. Li, Y. Mao, H.J. Ploehn, Y. Bao, MYu. Ultrathin, Ultrathin molecular-sieving graphene oxide membranes for selective hydrogen separation. Science 342, 95–98 (2013)

R. Sood, S. Cavaliere, D.J. Jones, J. Rozière, Electrospun nanofibre composite polymer electrolyte fuel cell and electrolysis membranes. Nano Energy 26, 729–745 (2016)

S. Cavaliere, Electrospinning for advanced energy and environmental applications (CRC Press, 2015)

M.V. Kakade, S. Givens, K. Gardner, K.H. Lee, D.B. Chase, J.F. Rabolt, Electric field induced orientation of polymer chains in macroscopically aligned electrospun polymer nanofibers. J. Am. Chem. Soc. 129, 2777–2782 (2007)

G. Liu, W. Jin, N. Xu, Two-dimensional-material membranes: a new family of high-performance separation membranes. Angew. Chem. Int. Ed. 55, 13384–13397 (2016)

H.W. Kim, H.W. Yoon, S.M. Yoon, B.M. Yoo, B.K. Ahn, Y.H. Cho, H.J. Shin, H. Yang, U. Paik, S. Kwon, J.-Y. Choi, H.B. Park, Selective gas transport through few-layered graphene and graphene oxide membranes. Science 342, 91–95 (2013)

L. Ding, Y. Wei, L. Li, T. Zhang, H. Wang, J. Xue, L. Ding, S. Wang, J. Caro, Y. Gogotsi, MXene molecular sieving membranes for highly efficient gas separation. Nat. Commun. 9, 1–7 (2018)

C. Zhang, B.H. Wu, M.Q. Ma, Z. Wang, Z.K. Xu, Ultrathin metal/covalent-organic framework membranes towards ultimate separation. Chem. Soc. Rev. 48, 3811–3841 (2019)

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2023 Science Press

About this chapter

Cite this chapter

Wang, J., Wu, W. (2023). Introduction to Membrane. In: Wang, J., Wu, W. (eds) Functional Membranes for High Efficiency Molecule and Ion Transport. Springer, Singapore. https://doi.org/10.1007/978-981-19-8155-5_1

Download citation

DOI: https://doi.org/10.1007/978-981-19-8155-5_1

Published:

Publisher Name: Springer, Singapore

Print ISBN: 978-981-19-8154-8

Online ISBN: 978-981-19-8155-5

eBook Packages: Chemistry and Materials ScienceChemistry and Material Science (R0)