Abstract

One of the most serious issues in the geotechnical engineering is soil erosion which requires an appropriate engineering technique to deal with. The main objective of this paper is to analyze the effectiveness of treated natural fibers in reduction of surface erosion of soil slopes. For this purpose, a laboratory soil slope model of cross-sectional area 90 × 90 cm2 and slope angle of 45° is prepared using red soil. Naturally available jute geotextile fibers are used as surface protection layers on top of soil slope. The jute is treated with alkali activated binder (AAB) with different water to solid ratios (0.35, 0.40, 0.45). An aluminosilicate precursor (fly ash/slag) reacts with an alkaline activator solution including sodium silicate and sodium hydroxide to form AAB. An artificial rainfall arrangement is framed, as splash type soil erosion with two different flow rates of 500 and 900 lit/hr. Based on the discharge, the rainfall simulator arrangement is designed to have 2.97 mm diameter holes with center to center spacing of 5 cm. The runoff is collected over intervals of 5 min from the beginning of the simulated rainfall through 1-h duration, resulting in a total of 12 time intervals. Runoff volumes are measured, and the samples are oven-dried at 105 °C for 48 h to measure the yield of sediment. This procedure is implemented on both unreinforced and reinforced slope. It is observed that 0.35 AAB treated jute reinforcement reduced soil erosion by 93.17%, whereas for untreated jute, the same reduced by 90.6%. The study’s findings are useful to develop a cost-effective and environmentally responsible solution for reducing surface erosion.

Access provided by Autonomous University of Puebla. Download conference paper PDF

Similar content being viewed by others

Keywords

Introduction

Soil erosion has been a major issue for society since the beginning of civilization. Soil erosion is a constant loss of top layer or displacement of soil from one location to another, resulting in soil collapse, ecological degradation, slope failure, and other issues. Soil erosion is mostly caused by heavy rainfall, floods, and wind forces, among other things. Erosion mostly affects soils without cohesion in nature. Soil erosion can take several forms, including splash, sheet, rill, and gully erosion. This type of erosion is more likely to happen on highly inclined slopes than on flat ground. Mostly occurring type of soil erosion in India is due to loss of top soil because of rainfall. Splash erosion is a complex process in which raindrop collisions on the soil surface generate soil particle detachment, followed by short-distance movement of the detached particles. At around 53.34 million hectares of soil is being eroded annually due to rainwater as per Indian Council of Agricultural Research [1]. Understanding soil erosion processes is essential for developing and implementing soil management approaches that reduce and control the risk of soil erosion.

Geotechnical experts, scientists, and research personalities are attempting to understand the erosion of soil slopes in a variety of ways. Using of coir geotextiles in the form of nettings for stabilization of hilly areas along with vegetation showed positive result in controlling soil erosion [2]. In earlier studies, geosynthetics made of synthetic materials like polyolefins and polyesters received the considerable attention. Despite its potential, the utilization of naturally occurring fiber materials for similar applications has received little attention till date [3]. A wide range of temporarily degradable and long-term non-degradable materials have been fabricated into rolls to help with reduction of soil erosion and vegetation growth [4]. Geotextiles made of synthetic fibers pollute the soil and pollute the ecosystem, and their manufacturing process pollutes the environment as well [5]. Rain splash detachment is well controlled by natural geotextiles such as jute and coir. Process of runoff after precipitation which leads to soil erosion can be reduced by applying jute geotextile as cover [6]. Natural geotextiles, such as jute, have the ability to mitigate soil erosion but they are biodegradable within the duration of 180–365 days [7]. Chemical techniques such as alkali treatment, acetylation, and bleaching can improve the durability of natural geotextiles [8]. The use of vegetation and geojute for erosion control on slopes in a subtropical climate resulted in soil erosion reduction, particle displacement, and mulching of the topsoil for enhanced vetiver growth. Vegetable roots grow and take over the role of geojute as it degrades over time. When the side slope was protected with vetiver and geojute, there was no difficulty of erosion [9]. Application of jute geotextile on the shoulder and slope surface leads to retaining of soil particles and prevented its detachment from constructed slope. Soil stability and erosion were improved as a result of the introduction of plants on slopes [10]. The hydraulic prerequisites of landslides were studied by Park and Song [11] by applying artificial rainfall to a homogenous sandy laboratory slope model. Dey and Sengupta conducted a series of centrifuge experiments and numerical calculations on a 55° inclined unsaturated sandy slope with a less permeable, stronger silty-sand layer included inside it [12]. The authors concluded that the factor of safety decreased due to the low porous layer’s effect. The writers also computed the slope’s factor of safety by modeling seepage into the slope caused by rainfall infiltration [13]. During rainstorms, the effect of geocomposite layers on slope stability was explored by Bhattacherjee and Viswanadham [14] on a model silty-sand slope. The geocomposite reinforced slope was found to be stable under rainfall conditions, with negligible deformation as the rainfall progressed.

A comprehensive study on the research works carried out on modeling of slope erosion showed that a number of studies are available on prototype model scale slopes without any geosynthetic reinforcement. However, limited studies are available to measure the erosion rate of soil slopes protected with natural geotextiles. In the present study, the durability of natural jute geotextiles was improved by using alkali activated binder treatment method [15]. The jute was treated with varied water to solid ratios of alkali activated binder (0.35, 0.40, 0.45). An aluminosilicate precursor (fly ash/slag) reacts with an alkaline activator solution including sodium silicate and sodium hydroxide to form AAB. An artificial rainfall arrangement was framed, as splash type soil erosion with two different flow rates of 500 and 900 lit/hr. The soil erosion due to the impact of raindrops was measured for both unreinforced slope and slope reinforced with untreated and AAB treated jute geotextiles.

Materials

Jute

In this study, natural jute geotextile bundles having a width of 0.91 m and a length of 30 m were used. The woven type Corchorus olitorius Tossa jute material was manufactured using newly available raw jute. Jute fibers were removed by retting the stem and outer skin of the jute plant, and then the non-fibrous debris was peeled away. After that, the fibers were spun into yarns. It was guaranteed that the jute fiber had not been scoured or bleached. The jute was found to contain 58% cellulose, 22% hemicellulose, and 14% lignin. The basic parameters of jute, including mass per unit area, aperture opening dimension, and thickness, were determined using the Indian Standard Code IS 15868 (Parts 1–6): 2008 and were tabulated in Table 21.1.

Alkali Activated Binder

The alkali activated binder solution was produced by mixing an alkali activator solution with an alum inosilicate precursor (Class F fly ash). Sodium silicate comprised of (55.9% water, 29.4% silica, and 14.7% sodium oxide) and sodium hydroxide (99% pure pellets) were combined to make an alkali activator solution. The mass percentages of fly ash, sodium hydroxide, and sodium hydroxide in the AAB mix were estimated as 74.07:1.96:2.97 [15].

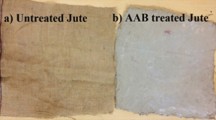

AAB solutions were made using three distinct water to solid (w/s) ratios of 0.35, 0.40, and 0.45. The alkali activator solution is exothermic for the initial 24 h after mixing the ingredients. Fly ash and water are added to the cooled alkali activator solution. Throughout the application process of AAB on jute sheets with paint brushes, the required uniformity was maintained. To gain strength, painted jute sheets were exposed to 40 °C for 24 h. After curing for seven days at 27 °C, AAB treated jute sheets were ready for use. Table 21.2 summarized the quantities of fly ash, sodium silicate, sodium hydroxide, and water required to coat 1 m2 of jute geotextile.

Soil

In the present study, red soil, consisting of 2.36% gravel, 55.47% sand, and 42.17% fines (silt and clay), was used. The soil was taken from a depth of 30 cm below the ground surface to ensure that it was free of undesired things such as debris, plant roots, and other waste material. According to the Unified Soil Classification System (USCS), it was classed as silty sand (SM). The maximum dry unit weight and optimum moisture content of the soil was reported to be 17.9 kN/m3 and 16%, respectively. The soil has an angle of internal friction of 24.5° and a cohesion of 3.4 kN/m2.

Laboratory Scale Slope Model Setup

Artificial Rainfall Setup

The effects of rain on soil erosion were explored in this study. When a raindrop hits the ground, soil particles get detached which leads to erosion. The following approach was used to create an artificial rainstorm arrangement in the laboratory to allow for this type of erosion. In the first phase, a large open container with dimensions of 2.7 × 2.7 m2 and a height of 0.17 m was placed on a flat surface.

Non-recording type rain gauge is the most common type of rain gauge used by the meteorological department. In the present approach, it consisted of a cylindrical vessel 127 mm in diameter. At its top section, a funnel was provided with a circular brass rim which was 127 mm exactly so that it can fit into the vessel well. According to grid iron system methodology, a total of 12 pipes with a spacing of 7.5 cm were arranged. Drippers were fitted to pipe with a 5 cm space between them. Based on the discharge, the rainfall simulator arrangement was designed to have 2.97 mm diameter holes with center to center spacing of 5 cm. This grid pipe network was constructed prior to connecting the main water line, and it was subsequently attached to the wooden rods system. To supply water, a container with a volume of 1 × 1 × 1 m3 was filled with water, and a water pump motor with a capacity of 0.5 Hp was utilized for water supply. The motor pump’s outlet was connected to the grid pipe’s input via an L shape connector. After this setup, water flow through pump and drip system was checked to avoid operational errors.

The water flow was controlled by a rotameter, and after multiple trials, two flow settings were established: a low flow rate of 500 L per hour and a high flow rate of 900 L per hour. The rainfall intensities obtained for low and high flow rates are 5.68 mm/min and 17.76 mm/min, respectively. Figure 21.1 showed the schematic diagram of the experimental setup.

To preserve uniformity, all trials were carried out in the same position relative to the rainfall simulators. The runoff was collected at 5-min intervals from the start of the simulated rainstorm to the end of the hour, for a total of 12 time periods. The amount of runoff was determined, and the samples were oven-dried for 48 h at 105 °C to determine the sediment production. The average of at least 10 cycles was considered to calculate the average value of precipitation. Figure 21.2 showed the images of eroded soil with water and the dried soil.

Laboratory Scale Slope Model

In this research laboratory, soil slope model was set up to calculate the soil erosion. Based on following procedure, slope model setup was arranged. An acrylic container of size 1.8 × 1.8 m2 and height 30 cm was made. It was taken care that no leakage of water through it while rainfall hits on soil slope and one opening of 0.15 × 0.15 m2 was made to collect the eroded soil and runoff water. The soil was compacted to 90–95% of maximum dry density value to achieve field compaction value. The soil slope model was in right angle trapezoidal shape with long base of 90 cm and short base of 45 cm and angle between long base to slope side is maintained at 45º. The soil was tampered in three layers to achieve the desired compaction. After compaction, the soil surface was smoothened using a wooden trowel, which helped to reduce the number of voids or cracked paths created in it. Figure 21.3 showed the soil slope model.

A total of 5 sets of experiments were carried out on the slope without any reinforcement, and reinforced slope with untreated and 0.35, 0.40, and 0.45 AAB treated jute geotextiles. The jute geotextiles were spaced 5 cm apart, with each sheet measuring 0.25 m in width and 0.9 m in length. To avoid movement, all of the reinforcement sheets were nailed to the soil. Figure 21.4 showed pictures of a slope model with reinforcement.

Analysis of Erosion Rate

The soil erosion was computed in gm/m2/hr as per the following equation.

The percentage reduction in surface erosion of soil slope for various reinforcements when exposed to rainfall was shown in Fig. 21.5. When a rain drop fell from certain height, it hit the soil and detached the soil particles which lead to displacement of soil particles along with runoff water. After separating the water from soil particles, they were dried to calculate the weight of eroded soil. Considering unreinforced slope, around 965.9 gm of soil was eroded with effect of low rainfall, whereas the same increased to 5482.3 gms for high rainfall. However, the amount of soil eroded after reinforcement with untreated jute was 90.7 gm for low rainfall and 305.8 gm for high rainfall effect. For 0.35 AAB treated jute reinforced soil slope, 65.9 gm and 191.1 gm of soil was eroded at low and high rainfall intensities, respectively. With increase in w/s ratio, the amount of erosion increased to a small extent. For 0.40 AAB treated jute reinforced soil slope, 73.3 and 212.2 gm of soil were eroded for low and high rainfall intensities. In a similar line, for 0.45 AAB treated jute reinforced soil slope, 84.6 gm and 245.1 gm of soil were eroded for low and high rainfall, respectively. To compare the variation, the corresponding soil erosion for all of these forms of reinforcement is computed based on a particular duration of rainfall, i.e., 5 min.

From these results, it could be observed that comparatively 0.35 AAB treated jute geotextile reduced surface erosion to a maximum extent of around 93.1% for low intensity rainfall and 96.5% for high intensity rainfall. From the figure, it was noteworthy to mention that there is only 6.5% difference in reduction of surface erosion between untreated and AAB treated jute geotextiles. This might be attributed to the fact that 0.35 AAB treated jute has the highest consistency and the number of micropores developed in this treatment was less compared to others, which led to maximum protection against erosion. However, it must be noted that untreated jute geotextile had a high susceptibility to biodegradation, while the AAB treated jute helped to increase the durability of the natural geotextiles [15]. After 90 days of soil burial exposure, it was noticeable that jute geotextiles treated with 0.35 AAB had the highest tensile strength, 63.04%, when compared to untreated jute geotextiles. The results from the study can be utilized as an economic and eco-friendly solution for reduction of surface erosion (Fig. 21.6).

Conclusions

Rainfall-induced slope failure is a major geotechnical disaster that has occurred in many parts of the world. The present study aims to analyze the effectiveness of treated natural fibers to reduce of surface erosion of soil slopes. This experimental study presents a novel approach of reducing surface erosion of soil slopes due to rainfall effect by employing alkali activated binder treatment to jute geotextiles. Two flow rates are considered to simulate low and high intensity rainfall. According to the findings of the study, 0.35 AAB treated jute geotextile reduced surface erosion to a maximum degree of roughly 93.1% for low intensity rainfall and 96.5% for high intensity rainfall. Although treatment of naturally available jute geotextile with AAB having different w/s ratio improved the rate of reduction of surface erosion by a marginal extent, however, the AAB treated jute contributed to the natural geotextiles’ increased durability. The study’s findings can be used to reduce surface erosion in a cost-effective and environmentally responsible manner.

References

Reddy LR, Arumairaj PD, Janaki Raman S, Nancy DS (2019) A study on erosion of soil in slopes using laboratory slope model. Int J Eng Adv Technol 8(2):356–359

Lekha KR (2004) Field instrumentation and monitoring of soil erosion in coir geotextile stabilised slopes—a case study. Geotext Geomembranes 22(5):399–413. https://doi.org/10.1016/j.geotexmem.2003.12.003

Ogbobe O, Essien KS, Adebayo A (1998) A study of biodegradable geotextiles used for erosion control. Geosynth Int 5(5):545–553. https://doi.org/10.1680/gein.5.0131

Allen SR (1996) Evaluation and standardization of rolled erosion control products. Geotext Geomembranes 14(3–4 SPEC):207–221. https://doi.org/10.1016/0266-1144(96)00011-8

Bhattacharyya R, Smets T, Fullen MA, Poesen J, Booth CA (2010) Effectiveness of geotextiles in reducing runoff and soil loss: a synthesis. CATENA 81(3):184–195. https://doi.org/10.1016/j.catena.2010.03.003

Kalibová J, Jačka L, Petru J (2016) The effectiveness of jute and coir blankets for erosion control in different field and laboratory conditions. Solid Earth 7(2):469–479. https://doi.org/10.5194/se-7-469-2016

Sanyal T (2017) Jute geotextiles and their applications in civil engineering

Rosa MF et al (2009) Effect of fiber treatments on tensile and thermal properties of starch/ethylene vinyl alcohol copolymers/coir biocomposites. Bioresour Technol 100(21):5196–5202. https://doi.org/10.1016/j.biortech.2009.03.085

Islam MS, Nasrin S, Islam MS, Moury FR (2013) Use of vegetation and geo-jute in erosion control of slopes in a sub-tropical climate. World Acad Sci Eng Technol 73:1162–11

Choudhury PK, Sanyal T (2010) Embankment slope stabilization with jute geotextiles—a case study in NH-2 Allahabad by-pass. In: Proceedings of Indian geotechnical conference–2010

Park JY, Song YS (2020) Laboratory experiment and numerical analysis on the precursory hydraulic process of rainfall-induced slope failure. Adv Civil Eng 2717356. https://doi.org/10.1155/2020/2717356

Dey N, Sengupta A (2020) Effect of a less permeable stronger soil layer on the stability of non-homogeneous unsaturated slopes. Front Struct Civ Eng 14(6):1462–1475. https://doi.org/10.1007/s11709-020-0674-8

Dey N, Sengupta A (2018) Effect of rainfall on the triggering of the devastating slope failure at Malin, India. Natural Hazards 94:1391–1413. https://doi.org/10.1007/s11069-018-3483-9

Bhattacherjee D, Viswanadham BVS (2018) Effect of geocomposite layers on slope stability under rainfall condition. Indian Geotech J 48(2):316–326. https://doi.org/10.1007/s40098-017-0280-4

Sachin Chakravarthy G, Anasua GuhaRay, Arkamitra Kar (2021) Effect of soil burial exposure on durability of alkali activated binder treated jute geotextile. Innov Infrast Solut 6(62) https://doi.org/10.1007/s41062-020-00441-5

Acknowledgements

We would like to appreciate Auto Traders in Secunderabad for contributing the jute.

Funding

This work is supported by Department of Science and Technology (DST), International Bilateral Cooperation Division, Govt. of India through Indo-Austria bilateral grant (Project ID: INT/AUSTRIA/BMWF/P-22/2018).

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2023 The Author(s), under exclusive license to Springer Nature Singapore Pte Ltd.

About this paper

Cite this paper

Sachin Chakravarthy, G., GuhaRay, A. (2023). Reduction of Surface Erosion of Soil Slopes Using Alkali Activated Binder Treated Jute Fibers. In: Muthukkumaran, K., Umashankar, B., Pitchumani, N.K. (eds) Earth Retaining Structures and Stability Analysis. IGC 2021. Lecture Notes in Civil Engineering, vol 303. Springer, Singapore. https://doi.org/10.1007/978-981-19-7245-4_21

Download citation

DOI: https://doi.org/10.1007/978-981-19-7245-4_21

Published:

Publisher Name: Springer, Singapore

Print ISBN: 978-981-19-7244-7

Online ISBN: 978-981-19-7245-4

eBook Packages: EngineeringEngineering (R0)