Abstract

Reliability-based design optimization (RBDO) plays an important role in optimal design because this optimal design method is achieved taking into account uncertainty and is very reliable. This paper applies the RBDO approach to analyze and design the CNC router structure for machining wood materials. With the desired reliability R*, the inverse reliability analysis method is utilized to transform the RBDO problem into a deterministic optimization problem. Monte Carlo simulation (MCS) is utilized to analyze the reliability of the machine structure after optimal design in accordance with the stiffness and strength criteria. The reliability analysis results, according to the MCS method, are compared with the desired reliability R* of the body structure. The obtained findings highlighted that body structure after optimized design according to the RDBO method is satisfactory.

Access provided by Autonomous University of Puebla. Download conference paper PDF

Similar content being viewed by others

Keywords

1 Introduction

The uncertainties of the structural system (i.e., loads, materials, dimensions, models, etc.) in deterministic design optimization are taken into account in an indirect and subjective method, based on partial safety factors determined in design ranges. Therefore, the level of reliability can be reduced when using deterministic optimal solutions (Beck and Santana Gomes 2012; Thuy and Nguyen 2018). The objective of a RBDO method is to optimize structures, and make sure that a minimum reliability level is upholded by the optimum structure.

The optimization algorithms of the RBDO method use the reliability methods to evaluate the probability constraints, and the objective functions are utilized to prescribe the reliability (Chiralaksanakul and Mahadevan 2005; Royset et al. 2001). In RBDO methods, the commonly used design parameters are the mean of random system parameters and solve a mathematical nonlinear programming problem to determine the optimized cost according to the prescribed probabilistic constraints. Therefore, the solution from RBDO supplies not only improves the design quality but also increases the reliability of the design, reduces the production cost and improves the model more beautiful (Youn and Choi 2004a; Tu et al. 2001).

There are two different methods used to evaluate the RBDO incorporating probabilistic constraints, the performance measure approach (PMA) and the reliability index approach (RIA) (Youn et al. 2003; Tu et al. 1999; Cheng et al. 2018). According to the RIA method, the probability constraint is defined as reliability. Nevertheless, RIA does not converge for some problems or converges slowly. To avoid this shortcoming, PMA is recommended by solving an inverse problem for the first-order reliability method (FORM) (Youn and Choi 2004b; Enevoldsen and Sørensen 1994; Padmanabhan et al. 2006).

For reliability analysis, FORM has proven to be effective and widely used. Therefore, to evaluate the objective functions and the number of probabilistic constraints, the previous RBDO methods used FORM. Over the years, the structural and engineering disciplines have adopted. Several first-order RBDO methods have been shown to be more effective than previous RBDO methods (Loc et al. 2019).

2 Theoretical Background

RBDO problem in system parameter design is introduced as follows (Nguyen 2015; Wang and Ma 2017):

To minimize f(X),

Subject to:

\(\begin{array}{*{20}c} {P(g_{j} ({\mathbf{X}},{\mathbf{p}}) \ge 0)) \ge R_{j}^{*} ;\quad j = {1},{2}, \ldots n_{g} } \\ {h_{k} ({\mathbf{X}},m_{p} ) \le 0;\quad k = {1},{2}, \ldots n_{h} } \\ {X_{i}^{{\text{l}}} \le X_{i} \le X_{i}^{n} ;\quad i = {1},{2}, \ldots n.} \\ \end{array}\)

where Xi is the design variable (deterministic or random), X is the design variable vectors (including deterministic and random), p are random parameter vectors (mean value is mp), gj(X, p) is the limit state function, f(X) is the objective function, n are the numbers of design variables, ng are the numbers of probability constraints, Rj* are the desired reliability and Xil, Xin are the upper and upper limits of the design variable.

The inverse reliability analysis method is used to transform the RBDO problem into a deterministic optimization problem. To solve this problem, it is first necessary to determine the limit state function value gF correspond with the desired reliability Rj*. The steps are as follows (Fig. 2).

Find the value of limit state function \(g^{F}\) correspond with a failure probability F:

The new limit state function is obtained after estimation by an approximation method:

Assume the most probable point (MPP) of a function \(P\left( {g^{\prime}\left( X \right) < 0} \right) = P\left( {g\left( X \right) < g^{F} } \right)\) is u*, according to the FORM, if the probability of failure F is known in advance, the index of reliability β is determined as follows:

In Fig. 1, the most probable point u* is the point of contact of a circle of radius gF and the function \(g\left( X \right) - g^{F} = 0\). In other words, it is the point of contact that determines the shortest distance from the limit state function surface \(g\left( X \right) - g^{F} = 0\) to the origin O in U space.

At the MPP u*:

In the kth loop:

where

Convergence conditions are used to finish the loop:

After determining the MPP u*, the value of the function \(g^{F}\) is determined as follows:

In summary, the algorithm to find the MPP according to the inverse reliability analysis method is presented as Fig. 2.

After determining gF, the RBDO problem turns into a deterministic optimization problem and the first constraint of the RBDO problem (1) become gj(X, p) ≥ gF.

3 Numerical Example

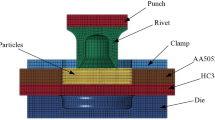

RBDO approach is used to optimize the design of the CNC router structure as shown in Fig. 3. Supposing that the CNC router structure is composed of four elements linked together such as the head (1), crossbeam (2), column (3) and the base (4). To simplify the calculations, it is accepted that the head, crossbeam and column are the cantilever beam correspond with the length L1, L2, L3 and the base L4 which is fixed by 2 supports.

The applied forces FX1, FY1, FZ1 and MZ1 are put into the computational model. During machining, force components FX1, FY1, FZ1 and torque MZ1 from the cutting tool are applied to the spindle of the machine body structure (Nguyen and Tran 2022).

If we consider the planar problem, the element (1) is subjected to bending and compression. The compressive stress in the Z direction is usually small compared to the bending stress, so it can be ignored. The planar problem with element (1) is then only subjected to bending and torsion. Elements (2), (3) and (4) are similarly considered. Therefore, the structural design problem of the machine body is to solve the problems for elements (1), (2), (3) and (4), respectively, which are considered as bars and beams. Then, combining the solutions obtained together, we have the preliminary dimensions of the body. We separate elements (1), (2) and (3) from the model, convert the model to s simple form and set the force conditions (cutting force is constant) as shown in Fig. 4.

Preliminary selection of body structure geometry dimensions: The basis for preliminary selection of the geometric dimensions of the body structure is as follows: The CNC router on the market were analyzed, and it is found that the working area of the medium CNC router according to X is less than 1000 mm, Y less than 2000 mm and Z less than 100 mm. In addition, wood workpiece in sheet form is common, so the thickness in the Z direction is usually less than 100 mm. On that basis, the dimensions of the machine structure are preliminary selected as follows: L1 = 250 mm, L2 = 1000 mm and L3 = 350 mm.

For the preliminary design of the CNC router body structure, the desired reliability R* = 0.999 is selected and the RBDO method is used. Two design variables that represent the height Vi and width Hi are determined and given in Table 1.

Material for all elements is steel C45, yield strength σy = 360 MPa and standard deviation Sy = 6 MPa. Coefficient of variation of forces and moment is 0.1. Mechanical properties of steel materials C45 are in Table 2.

The processing material is Goldden oak wood, whose scientific name is Homalium Caryophyllaceum Benth with the density of 1000 kg/m3, durability at 70 MPa, hardness at 7.7 HB and humidity of 15%. The components of the applied force are defined rely on a cutting force in a woodworking process. Components of the applied force are presented in Table 3 (Wang and Ma 2017).

According to the strength criteria, the limit state function is written as follows:

According to the stiffness criteria, the limit state function is written as follows:

The RDBO problem for the elements is presented as follows:

Design variable: \(V_{i} ,H_{i}\).

Objective function: \(m_{i} = \rho L_{i} V_{i} H_{i} \quad \to \min\).

Subject to:

where limit displacement uilim = 0.035 mm and desired reliability Ri* = 0.999.

The inverse reliability analysis method is utilized to shift the RBDO problem into the deterministic optimization problem. After four loops, the function gF at the MPP has the following value in Table 4.

Thus, the RBDO problem is transformed into the deterministic optimization problem as follows:

Design variable: \(V_{i} ,H_{i}\).

Objective function: \(m_{i} = \rho L_{i} V_{i} H_{i} \quad \to \min\).

Subject to:

The genetic algorithm method in Tool Optimization of MATLAB is utilized to solve the design optimization problem. The results achieved after optimizing of the machine head, horizontal beam and vertical column of the CNC router are presented in Table 5.

Equivalent stresses σeq1, σeq2, σeq3 and displacement u1max, u1max, u1max, respectively, of machine head, crossbeam and vertical column of CNC router are all smaller than the limit strength value σy and displacement ulim.

The MCS method is used to analyze the reliability of the machine structure after optimal design. The reliability analysis results according to the MCS method are compared with the desired reliability of the body structure. Simulation results with sample number N = 5.106 are presented in Figs. 5 and 6.

The results of the reliability analysis of the MCS method: according to the strength criteria RMCSσ = 0.99977 and stiffness criteria RMCSu = 0.99973. Because RMCSσ and RMCSu are more than R* = 0.999, the body structure after optimizing the design according to RDBO method is satisfactory.

After the complete design, CAD model has the form as shown in Fig. 7a, an analysis and a test are conducted according to strength and stiffness on the CAE system as shown in Fig. 7b, c. The results of the test in accordance with the stiffness and strength criteria is satisfactory.

After the complete design, CAD model has the form as shown in Fig. 7a, an analysis and a test are conducted in accordance with the stiffness and strength on the CAE system as shown in Fig. 7b, c. The results of the test in accordance with the stiffness and strength criteria are satisfactory.

4 Conclusions

This paper applies the RBDO approach to analyze and design CNC router structure. With desired reliability R*, the inverse reliability analysis method is utilized to transform the RBDO problem into a deterministic optimization problem.

Genetic Algorithm method in Tool Optimization of MATLAB is utilized to solve the design optimization problem. The results obtained after design optimization include equivalent stresses σeq1, σeq2, σeq3 and displacement u1max, u1max, u1max, respectively, of machine head, crossbeam and vertical column of CNC router are all smaller than limit strength value σy and displacement ulim.

MCS is used to analyze the machine structure reliability after an optimal design according to strength and stiffness criteria. The reliability analysis results according to the MCS method are compared with the desired reliability R* of the body structure. The obtained findings highlighted that body structure after optimizing the design according to the RDBO method is satisfactory.

References

Beck, A.T., de Santana Gomes, W.J.: A comparison of deterministic, reliability-based and risk-based structural optimization under uncertainty. Probabilistic Eng. Mech. 28, 18–29 (2012)

Van Thuy, T., Nguyen, H.L.: Investigation on influence of cutting parameters on spindle vibration of CNC wood milling machine. MATEC Web Conf. 213, 01007 (2018)

Chiralaksanakul, A., Mahadevan, S.: First-order approximation methods in reliability-based design optimization (2005)

Royset, J., Kiureghian, A.D., Polak, E.: Reliability-based optimal design of series structural systems. J. Eng. Mech. 127, 607–614 (2001)

Youn, B.D., Choi, K.K.: An investigation of nonlinearity of reliability-based design optimization approaches. J. Mech. Des. 126, 403–411 (2004a)

Tu, J., Choi, K.K., Park, Y.H.: Design potential method for robust system parameter design. AIAA J. 39, 667–677 (2001)

Youn, B.D., Choi, K.K., Park, Y.H.: Hybrid analysis method for reliability-based design optimization. J. Mech. Des. 125, 221–232 (2003)

Tu, J., Choi, K.K., Park, Y.H.: A new study on reliability-based design optimization (1999)

Cheng, Q., Zhao, H., Zhao, Y., Sun, B., Gu, P.: Machining accuracy reliability analysis of multi-axis machine tool based on Monte Carlo simulation. J. Intell. Manuf. 29, 191–209 (2018)

Youn, B.D., Choi, K.K.: A new response surface methodology for reliability-based design optimization. Comput. Struct. 82, 241–256 (2004b)

Enevoldsen, I., Sørensen, J.D.: Reliability-based optimization in structural engineering. Struct. Saf. 15, 169–196 (1994)

Padmanabhan, D., Agarwal, H., Renaud, J.E., Batill, S.M.: A study using Monte Carlo simulation for failure probability calculation in reliability-based optimization. Optim. Eng. 7, 297–316 (2006)

Loc, N.H., Van Thuy, T., Trung, P.Q.: Reliability-based analysis of machine structures using second-order reliability method. J. Adv. Mech. Des. Syst. Manuf., 13, JAMDSM0063-JAMDSM0063 (2019)

Nguyen, H.L.: Reliability based Design and Analysis of Mechanical Systems, National University publisher HCMC, Viet Nam (2015)

Wang, G., Ma, Z.: Hybrid particle swarm optimization for first-order reliability method. Comput. Geotech. 81, 49–58 (2017)

Nguyen, H.L., Tran, V.T.: Applying FCCCD response surface method in studying the cutting power of wood materials. Solid State Phenom. 329, 25–31 (2022)

Acknowledgements

We acknowledge Ho Chi Minh City University of Technology (HCMUT), VNU-HCM for supporting this study.

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2023 The Author(s), under exclusive license to Springer Nature Singapore Pte Ltd.

About this paper

Cite this paper

Nguyen, H.L., Tran, V.T. (2023). Design of the CNC Router Structure for Machining Wood Materials Using Reliability-Based Design Optimization Method. In: Agarwal, R.K. (eds) Recent Advances in Manufacturing Engineering and Processes. ICMEP 2021. Lecture Notes in Mechanical Engineering. Springer, Singapore. https://doi.org/10.1007/978-981-19-6841-9_3

Download citation

DOI: https://doi.org/10.1007/978-981-19-6841-9_3

Published:

Publisher Name: Springer, Singapore

Print ISBN: 978-981-19-6840-2

Online ISBN: 978-981-19-6841-9

eBook Packages: EngineeringEngineering (R0)