Abstract

Complex engineering projects require compartments from different engineering fields to work in close contact and exchange data from their workflows and specialized software tools regularly. Common data models are an immanent feature of systems engineering applications that can be used to reduce the number of interconnections between software modules. Using common open-source data structures in airship design helps engineers in evaluating and visualizing early designs using several methods. In the presented paper, we used the Extensible Markup Language (XML) data structure Common Parametric Aircraft Configuration Schema (CPACS) and associated high-level software libraries by German Aerospace Center (DLR) for a design optimization. The design optimization maximizes payload of a 15 t airship by its hull shape. Handbook methods for estimating weights and drag as well as a brute force algorithm are used in the design optimization. The result shows an explicit optimum of the design. With the experiences made, we developed an updated version of CPACS, allowing the definition of an additional vehicle category named ‘dirigible’.

Access provided by Autonomous University of Puebla. Download conference paper PDF

Similar content being viewed by others

Keywords

- Lighter than air (LTA)

- Airship

- Common Parametric Aircraft Configuration Schema (CPACS)

- Multi-variable design optimization (MDO)

- Central model

1 Introduction

In this section, we present the background and objectives of our work.

1.1 Background

Powered near equilibrium aerostats, commonly referred to as airships, could and should be a solution of future transport problems. They are eco-friendly with low demand to infrastructure and high safety. Reassessing past designs of successfully operated airships and optimizing preliminary designs are foundations of LTA development.

Optimizing early designs has a huge impact on the overall cost of a project and is at the same time cheap compared to changes made in later design phases. MDO is a technique originated in the aerospace industry. Tools and data commonly used in aircraft industries are not yet implemented for the use with airships. Figure 1 provides an overview of different aircraft categories.

Overview on categories of aircraft [1]

1.2 Objectives

The first objective is to store airship data in a data structure being able to visualize the dirigible easily and visually appealing. Also, the geometry should be parametrized in order to perform quick changes in the geometry and to calculate properties of preliminary designs. Consequently, this data is used for optimization in early design phases. Optimizing one parameter with a simple cost function is the second objective of this work.

2 Problem Definition and Formulation

First steps in designing an airship are to define its principal characteristics to fulfill certain requirements [2]. Aircraft lighter than 15 t with less than 20 passengers may be certified as commuter aircraft [3], which comes with cheaper development and certification costs and should be this design problems driver.

The \((\frac{L}{D})\) of the airships hull (also often referred to as ‘fineness ratio’) influences both the weight and the aerodynamics of the aircraft significantly. Higher slenderness comes with the cost of added structural mass but influences the aerodynamics positively.

The considered design optimization problem can thus be summarized as ‘Finding the optimal \(\frac{L}{D}\) for an airship fulfilling the requirements of the commuter category’.

3 Methodology

This section provides details about airship modeling and the performed calculations for estimation of parameters. The model and estimated values are then used in the design optimization.

3.1 Airship Modeling

Optimizing the geometry of an aircraft requires a parametric model in order to perform automated changes of the geometry. Solving the problem defined in Sect. 2 can be done using CPACS files and methods for the automated generation of varying hull and stabilizer geometries.

Common Parametric Aircraft Configuration Schema (CPACS) method [4]

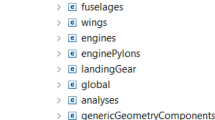

Central model approach Storing airship data in a centralized model is possible using CPACS [4]. CPACS is a XML-based structure developed by the DLR. It stores the parametric description of airplane and rotorcraft geometries and several other parameters such as mission definitions or the inputs and results of various analyses. The idea is having one centralized model as shown in Fig. 2 that is used for different applications. Centralized models are already established in different fields and have been used by airplane and helicopter manufactures for decades.

Using the CPACS data schema has the benefit of the existence of extensive libraries that come with the data structure. When using a CPACS file following the standard XML schema by the DLR, the TiGL Geometry Library (TiGL) C++ libraries and associated Python, MATLAB and Java bindings use the parametric description in the file for full three-dimensional visualization. The TiGL Libraries offer also other functionalities for modification of CPACS files and computation of geometric properties like surface area, volume or largest diameter [5].

For demonstration of the worthiness of a parametric description of airships using a CPACS-file, a historic airship with an actual flight record has been reengineered; see Fig. 3.

Hull geometry modeling In search for the perfect submarine shape, L. Landweber and M. Gertler developed a mathematical description of aerodynamically optimized bodies [6]. Describing the shape of the bodies needs five parameters such as \(\frac{L}{D}\), prismatic coefficient \(c_p\), location of maximum thickness m, bow- and stern-radii \(r_0\) and \(r_1\) [1]. The equation describing the bodies shape as a function of longitudinal distance x is a polynomial of the sixth order.

where \(a_1\) to \(a_6\) can be solved with the formulations of the four other shape parameters that are not used in Eq. (1). Summarized, this equals to

With the body of revolution shape given by Eqs. (1) and (2), radii from a number of sections from \(x = 0\) to \(x=1\) are calculated. The width of each section is then scaled to the model size, and the position is translated to the overall length of the model.

Stabilizer sizing A body of revolution like the one formulated in Sect. 3.1 and all other airship bodies are not stable without stabilizers as counteracting areas at the stern. Without them, a small disturbance is already enough to turn the airship body, and it will always stabilize in a position oblique to the direction of flow. Sizing the stabilizers or fins of an airship is not an easy task due to the inherent instability and complex damping characteristics. A less elaborated approach which is sufficient in pre-design is introduced in [7].

Hull moment Munk’s approach from potential theoretical flow simulation assumes that the lateral force distribution on the hull is proportional to the derivative of the cross-sectional area in cross flows [7].

The moment \(M_{\text {hull}}\) at the position of maximum thickness of the body is described with the density of the surrounding fluid \(\rho \), the velocity v, the overall volume V, the angle of attack \(\alpha \) and two factors \(k_1\) and \(k_2\), describing the additional forces from the movement of the hull. The moment equals to

The angle of attack is chosen to be 5% because drivers of the stabilizers sizing are small obstructions while cruising. The \(k_1\) and \(k_2\) factors are being summarized to the Munk factor k that can be read from a table depending on the diameter over thickness ratio \((\frac{D}{L})\), reciprocal of \(\frac{L}{D}\), found in [8].

Stabilizing moment The induced moment from the hull requires a contradicting moment: the moment \( M_{\text {stab}}\) induced by the stabilizer. The equilibrium of moments is calculated with the distance from the center of volume to the so-called 25% chord line of the stabilizer \(l_{\text {stab}}\) and the induced lateral force by the stabilizer \(F_{\text {stab}}\):

A relative value for the lever arm \(l_{\text {stab}}\) depending on the overall length of the airship and a fixed elongation of the stabilizers \({\Lambda }\) enables the calculation of lift curve slope \(\tfrac{\delta C_a}{\delta \alpha }\) after the theory of wings with small elongation [9]. Further, the force \(F_{\text {stab}}\) required for equaling stabilizer moment and hull moment is calculated from the projected area \(A_{\text {stab,projected}}\) of the stabilizer:

3.2 Parameter Estimation

In this section, we show drag and mass calculations using simplified assumptions. All estimated parameters are being saved in the central CPACS model.

Drag Estimation The drag force of the airship in stationary flight with the cruise speed of 80% of the maximum speed is used as reference drag. The flow is assumed to be fully turbulent, which is a conservative assumption. Laminar flow is, in all cases unlikely, looking at high Reynolds numbers being found in airship aerodynamics.

The total drag is reduced to two parts: the drag induced by the hull and the stabilizers.

Hull The calculation of the drag is done by a number of steps, from which the first is to determine the actual Reynolds number \(\text {Re}\). Cruise speed, \(v_{\text {cr}}\), over all airship length \(L_{\text {OA}}\) and the kinetic viscosity of the surrounding air in International Standard Atmosphere (ISA) \(\nu \) are used to calculate:

The empirical approach by Prandtl’s boundary layer theory gives a frictional drag coefficient value of:

A frictional drag force \(F_{\text {w,friction}}\) is given by the hulls wetted surface area \(A_{\text {hull}}\) as reference area, cruise speed \(v_{\text {cr}}\), and ambient air density \(\rho \). With the before calculated \(c_{\text {w,friction}}\), we get

Applying a form factor based on geometry of rotational bodies, we can now calculate the total drag after Hoerner [10] with the reciprocal fineness ratio \(\frac{D}{L}\) as follows:

Stabilizer Stabilizers contribute the largest share of drag after the hull itself. The reference area is the wetted surface area of the stabilizers \(A_{\text {stab}}\), and the drag coefficient \(c_{\text {w,stab}}\) is estimated to be 0.1. The drag force \(F_{\text {w,stab}}\) induced by the stabilizers is then

Total drag The total drag \(F_{\text {w,tot}}\) is the sum of the single shares. Gondola and other extensions are being neglected, and only an interference share of 3% is added to the drag. The total drag is given by

Mass Estimation Aircraft masses are classified into several categories. This section provides the classification used for the design optimization.

Operating Empty Mass The operational empty mass (\(m_{\textrm{OEM}}\)) includes all masses of the airship except fuel mass and payload which are recorded separately. We use Normand’s scaling method for estimation of the \(m_{\textrm{OEM}}\).

Burgess describes the application of Normand’s equation to estimating the sizes and weights of airships [2]. Here, the mass of an airship design is divided into 14 weight groups. With the fixed characteristics and independent variables that need to be assumed by the designer, the mass of each weight group can be scaled by the dependent variables.

J. Eissing further improved the approach by including more dependent variables [11]. He also adapted Burgess approach to a selection of real-world airships [12]. Following his approach and taking the scaling parameters calculated by averaging the real-world airships, weights from the 14 weight groups can be estimated for a given hull shape with few parameters.

The individual masses of the weight groups \(m_i\) sum up to the total mass

Fuel mass The assumptions made for calculating the fuel mass are that the airship travels with a constant cruise speed ISA at sea level. Contradicting airplanes fuel consumption, a near equilibrium airship does not need a lot of additional power for starting, making the assumption more valid. Also, the simulation is simplified to a single powertrain including motor, drivetrain, gears and rotor.

Aerodynamic power \(P_{\text {aero}}\) is given by

and the ratio of aerodynamic power and shaft power (delivered power) according to [13] by

Calculating \(P_{\text {shaft}}\) with Eq. (15) and adding an overall drivetrain efficiency \(\eta _{\text {drivetrain}}\) gives the required motor power that is multiplied with the trip duration \(t_{\text {cr}}\) and a specific fuel consumption of the motor \(c_{\text {fuel,cr}}\) to get the fuel mass \(m_{\text {fuel}}\) with

This mass is assumed as a static mass, whereas a more detailed simulation would respect the mass loss due to fuel burn.

Payload Payload can be cargo of different kind or passengers. The monetary value of the payload highly depends on the kind of cargo that is being transported. The payload \(m_{\text {payload}}\) is the mass that remains when subtracting all other masses from the total mass \(m_{\text {TOT}}\) of the airship:

3.3 Design Optimization

Optimization problems are best approached with a structured method. MDO is a systems engineering approach where a number of disciplines are considered for solving design problems. Using CPACS has the advantage that the central-based approach of the data format can be used in different tools of the MDO. Solving airship design problems using MDO enables designers for a fast evaluation of different designs.

Set up Simplicity and reproducibility are the driving forces in this optimization setup. Using a single free variable as input of the design helps in visualizing the problem and making it comprehensible. CPACS is a geometrically driven data format and offers parametric description of geometries, thus choosing a geometric parameter for a variation of the designs is consistent. Using an algorithm for creating Gertler shapes, following Sect. 3.1 enables simple variation of the parameters used.

Variable parameter The fineness ratio is an important characteristic influencing the appearance, weight and drag of an airship significantly.

Using the algorithm for the creation of hull shapes, we created a set of shapes with varying \(\frac{L}{D}\) from 5 to 10 and a step width of 0.1 (Fig. 4).

Fixed parameters There are a number of fixed parameters. Table 1 lists the most important fixed parameters. The total mass is chosen at \(0.98 \cdot {15}\,{t}\), which is an important limit for the certification of aircraft. Airships below 15 t carrying less than 20 passengers may be certified as ‘commuter airships’.

The cruise speed is a fraction from the maximum speed. 70knots is the airspeed just above 12beaufort which the structure of the airship must withstand while moored to the mast. Thus, designing an airship with lower maximum speed does not reduce structure mass.

Cost function The cost function must depend upon the variable parameters and have a non-discrete number as function value. The cost function calculates the payload as the results of the airships total mass less \(m_{\textrm{OEM}}\) and \(m_{\text {fuel}}\), which depends on the drag. Both values drag and \(m_{\textrm{OEM}}\) depend on \(\frac{L}{D}\).

Optimizer The type of optimizer chosen for the given optimization problem is a brute force (BF) optimizer. BF optimization is a method where the cost function is evaluated at each of a given number of points. The optimal design is then found by choosing the maximum value from all evaluated cost function points. This method is connected to a high demand of hardware resources and needs more calculation time for complex problems than other methods, but is a fast and simple approach for solving optimization problems of lower complexity. The optimizing algorithm can be simplified by the steps in Algorithm 1.

4 Results

The airships drag force is higher at lower \(\frac{L}{D}\) values, which represents a basic rule in aerodynamics: Slender bodies show lower drag. The drag is rising again at above 8.5 because of frictional resistance. Slender bodies do have a larger wetted surface when we keep volume constant and more wetted surface equals more frictional resistance.

The counteracting effect is the airships mass. Here, we see an almost linear rise of structural mass over fineness ratio. The sphere is the optimal shape in terms of surface or structure needed to encase a volume. Deviation from the structural ‘perfect’ shape, in this case represented by slenderness, results in higher structural weight.

The results in Fig. 5 emphasize the counteracting effects driving the design optimization and the resulting payload. The optimum at \(\tfrac{L}{D} = 6.3\) gives a payload of 3363.7 kg.

5 Discussion and Conclusions

With the methods used, this work introduced a common data structure for airships and further demonstrated the benefits of the data structure by performing a MDO. Further, the designs can be visualized from the parametric descriptions. The results are reproducible and met expected performance despite major simplifications in the methods used.

A cutout from a CPACS schema showing the attributes and elements of the three vehicle elements. Elements, that are not a copy of aircraft or rotorcraft elements, are marked in yellow. Attributes can be recognized by the absence of a slash behind their name, whereas elements names are followed by one, indicating that they have subordinate attributes and/or elements

We have two proposals for future work: first, an expansion of the underlying CPACS open-source schema shown in Fig. 6 and second several ideas for the further development of the design problem optimization:

-

Adding more optimization variables.

-

Using more elaborated solvers, preferably gradient based.

-

Setting up a constraint optimization where the airship has to fit into a hangar.

References

Eissing J, Design considerations for cargo airships (15 Mar 2019)

Burgess CP (2004) Airship design. University Press of the Pacific, Honolulu

Federal Aviation Administration: LFLS: Airworthiness requirements for the type certificate of airships in the categories normal and commuter. https://www.faa.gov/aircraft/air_cert/design_approvals/airships/airships_regs/media/aceAirshipLFLS.pdf (13 Apr 2001). Accessed 09 Dec 2021

Alder M, Moerland E, Jepsen J, Nagel B (2020) Recent advances in establishing a common language for aircraft design with CPACS. In: Aerospace Europe conference 2020

Siggel M, Kleinert J, Stollenwerk T, Maierl R (2019) TiGL: an open source computational geometry library for parametric aircraft design. Math Comput Sci 13(3):367–389. https://doi.org/10.1007/s11786-019-00401-y

Landweber L, Gertler M (1950) Mathematical formulation of bodies of revolution. Washington

Munk M (1979) The aerodynamic forces on airship hulls

Funk TL, Wagner S (2002) Experimentelle untersuchungen von rumpf-leitwerk interferenzen bei luftschiffen. In: Deutscher Luft- und Raumfahrtkongress (ed) Tagungsband Deutscher Luft- und Raumfahrtkongress 2002 (23–26 Sept 2002)

Frank P (1990) Die Auslegung von Flugzeugen mit geringstem Antriebsleistungsbedarf

Hoerner SF (1965) Fluid-dynamic drag: practical information on aerodynamic drag and hydrodynamic resistance. Hoerner Fluid Dynamics, 16 Dec 2021

Eissing J (2015) Normand scaling tool

Lancaster JW, Feasibility study of modern airships, phase 1. vol. 4: Appendices. https://ntrs.nasa.gov/api/citations/19750023962/

Eissing J (2003) Widerstand und propulsion von luftschiffen

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2023 The Author(s), under exclusive license to Springer Nature Singapore Pte Ltd.

About this paper

Cite this paper

Eissing, C.S., Richter, A., Schlipf, D. (2023). CPACS LTA—Using Common Data Structures for Visualization and Optimization of Airship Designs. In: Shukla, D. (eds) Lighter Than Air Systems . Lecture Notes in Mechanical Engineering. Springer, Singapore. https://doi.org/10.1007/978-981-19-6049-9_2

Download citation

DOI: https://doi.org/10.1007/978-981-19-6049-9_2

Published:

Publisher Name: Springer, Singapore

Print ISBN: 978-981-19-6048-2

Online ISBN: 978-981-19-6049-9

eBook Packages: EngineeringEngineering (R0)