Abstract

Lake Michigan and the various beaches throughout Chicago have a long history of surface water contamination issues due to the impermeable landscapes and nonpoint source pollution associated with dense urban environment. During rain events, urban stormwater runoff can collect and concentrate pollutants that are then mobilized to surface waters within the watershed. Pollutants of concern include suspended solids, nutrients, organic chemicals like non-aqueous phase liquids or oils, polycyclic aromatic hydrocarbons, heavy metals, and bacteria. Stormwater management tools such as detention ponds and green infrastructure (bioswales, permeable pavements) are not or may not be practical in urban environments due to limited space and functionality of these tools. The City of Chicago currently must run same day testing for urban beaches to give swimmers notice of potential health risks and beach closures due to elevated E. Coli levels. In-ground reactive stormwater filters might be a viable solution to treat the contamination associated with urban runoff and improve the water quality of Chicago’s beaches. Utilizing three pre-tested filter designs from a previous study, the sustainability of each is evaluated and ranked using a triple bottom line (environmental, economic, and social) sustainability assessment within a conceptual site model in Chicago including contaminant removal efficiency.

Access provided by Autonomous University of Puebla. Download conference paper PDF

Similar content being viewed by others

Keywords

1 Introduction and Project Background

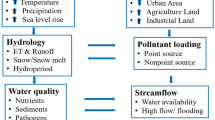

Urban stormwater runoff sometimes poses serious problems to beaches when the stormwater mixed with contaminants finds its way into the beach waters [1]. Beach closures are issued every year repeatedly due to the presence of disease-causing microorganisms and other pollutants in beach water that can harm public health [1]. Impermeable surfaces combined with industrial and human activity create nonpoint sources that are difficult to provide water quality treatment. Urban stormwater management is especially difficult because Chicago, like many other big cities, was not designed with these things in mind. We are now beginning to move in the direction of green infrastructure with recent developments of green roofs, rain gardens, the deep tunnel, permeable pavement, and now possibly in-ground filters. The objective of an in-ground permeable reactive filter strategically located directly at the beach is to remove harmful pollutants before they reach the water.

In Chicago, large-scale laboratory test and field pilot scale demonstrations were conducted recently to evaluate the performance of permeable mixed-media filter systems. Column studies were performed to determine the removal efficiencies of contaminants using different permeable filter medium [1]. Diverse types of contaminants with variable concentrations in actual stormwater were used to develop synthetic stormwater concentrations (mg/L) and are shown in Table 1. Studies included testing different filter materials with different absorption capacity to remove pollutants from synthetic runoff. A pilot scale in-ground filter was constructed at Rainbow Beach in Chicago, IL.

1.1 Technical Design Alternative

The three filter mix designs shown to be effective were: (1) calcite, sand, zeolite (C + S + Z), (2) calcite, sand, iron fillings (C + S + FeO), and (3) calcite, sand, zeolite, and iron filings (C + S + Z + FeO). Figure 1 shows each filter material’s efficiency for the removal of total suspended solids, nutrients, heavy metals, polycyclic aromatic hydrocarbons, and E-Coli. C + S + Z + FeO is the best choice for removing nutrients and heavy metals. This study utilized the results of these filter tests along with technical aspects of the Rainbow Beach pilot-test to evaluate the sustainability of a conceptual design at Oak Street Beach in Chicago. The environmental, economic, and social sustainability assessments will be considered using the triple bottom line approach and condensed into a single score index using MIVES (Sect. 3.4) to weight and rank the components. This model will help stakeholders make decisions in future using real data and a comprehensive method of analysis.

2 Methodology

2.1 Goal and Scope

The goals are to: (1) design an in-ground reactive filter unit with a mixed-media filter system that will prevent pollutants (mostly nonpoint source) from reaching the surface waters of Lake Michigan at Ohio Street Beach, Chicago, IL, USA; (2) identify the most sustainable mixed-media filter for urban stormwater runoff; and (3) evaluate the sustainability of the filters based on triple bottom line sustainability assessment (environmental, economic, and social aspects). In terms of water quality, the efficiency of the filter media during storm events and overall contaminant removal will be evaluated by looking at urban stormwater runoff versus lake water quality standards. The focus will be kept local by following Lake Michigan and Chicago’s rules and regulations including pricing and sourcing materials and labor locally.

2.2 Study Area

The watershed area at Ohio Street Beach in Chicago, IL includes two parks: The Jane Addams Memorial Park and the Olive Park Woodlands. Both parks partially drain into the beach. An online publicly available elevation tool [2] was used to determine trends in the topography to calculate the drainage area. Since the elevation of the parks peaks right down the center, the assumption is that anything outside of the drainage area shown in Fig. 2 would drain to the stormwater conveyance systems on Grand Avenue, Chicago.

2.3 Technical Design of the Filter

The in-ground tank made of concrete includes an access gate for maintenance, three different mixed-media filters, one primary inlet, and four small outflow pipes placed under the filter materials [3–5]. The design materials include filter materials (calcite, zeolite, sand, and iron filings), pre-cast concrete, construction equipment, fluid cement (mortar) for the foundation and setting the drainage inlet, 200 feet of polyethylene slotted inlet pipe to capture the watershed runoff, a cast iron grate for maintenance, CA-7 limestone for the drainage layer, CA-6 limestone for the subbase of the filter bed, and 28 feet of perforated polyethylene pipe for outflow drainage. A typical design for an in-ground reactive filter is included in shown in Fig. 3.

The technical design of an in-ground filter starts with the rational method for peak flow which includes rainfall intensity, values for permeable versus impermeable areas, and the total drainage or watershed area. The permeable surfaces refer to the grass and the sand at the top of the beach. Rainfall intensity in Chicago is 8.57 inches for a 24-h, 100-year storm. The area is about 3.78 acres for the watershed area. The peak flow is 0.4 cubic feet per second, and a factor of safety of 1.25 was included, making the peak flow equal to 0.5 cubic feet per second, which is used for filter capacity design in this study.

A 100-year 24-h storm event in Northeastern Illinois was assumed to get the rainfall intensity (Bulletin 70). The tank design was assumed to be based on the lowest hydraulic conductivity with calcite and sand being the limiting factors, each had a hydraulic conductivity (K) of 0.30 cm/s. The velocity through the filter was 0.00984 ft/s. The surface area for the filter material was found to be 50 square feet.

The design surface area was 5 × 10 ft, with a wall thickness of 0.5 ft. The hydraulic calculations for the filters include three different mixture ratios. Mixture #1 includes calcite, zeolite, and sand at a ratio of 1:1:1. Mixture #2 includes calcite, sand, and iron fillings at a ratio of 1:1:2. Mixture #3 includes calcite, zeolite, sand, and iron fillings at a ratio of 1:1:1:2. The bulk densities vary from 1.1 to 2.5 g/cm3. The characteristics of each specific filter material are listed in Table 2.

A filter depth of 4 feet was chosen, so the volume needed was 200 cubic feet. This volume with an additional 1 foot of depth for the tank to store water before filtration gives the interior dimensions of 5 × 10 × 5 ft. The wall thickness is 0.5 ft gives an exterior dimension of 6 × 11 × 6 ft, as shown in Fig. 4. The concrete volume needed is 146 ft^3, with a corresponding weight of 10.6 tons. The collection pipe is a slotted inlet pipe that is 6-inches by 200 feet, however, we also added 20 feet for contingency. Our outflow corrugated perforated PE pipes are 4-inches in diameter and placed at the bottom of the filter at a length of 7 feet, coming out to a total of 28 ft. The perforated polyethylene pipes were designed to collect runoff further down the beach.

2.4 Life Cycle Assessment

Life cycle assessments (LCAs) are generally from cradle to grave and include major stages during the lifetime of the product [6]. Typical stages are raw material acquisition, manufacturing/production, operation/maintenance/use, and recycling/disposal. Transportation is often an overarching component affecting the other four stages and broadly incorporated in the assessment. When applying triple bottom line sustainability environmental, economic and social aspects are evaluated using the LCA approach. Environmental sustainability is addressed by using software such as SimaPro which evaluates the environmental impact of the product, in this case an in-ground reactive filter. Economical LCA aspects include direct cost, indirect cost, and maintenance cost. Social aspects include general social impacts as well as 4 specific social categories; socio-individual, socio-communal, socio-economic, and socio-environmental impacts. Considering the life and operation of the filters was a key component in having a complete picture in the assessment. Stormwater filtration systems constructed with mixed media showed a significant decrease of infiltration capacity after 5–7 years of operation due to the formation of a clogging layer at the surface of the filters, while the lifespan of the materials themselves were 20–35 years with proper maintenance. Hydraulic performance of the system could be recovered by scraping off the surface accumulated particle layer and replacement of the geotextile on periodic bases, approximately every 7 years. Thus, the mixed media must be inspected at least twice annually to determine if the permeability has decreased.

3 Sustainability Assessment

Environmental sustainability of the filter designs was determined using LCA SimaPro 8.0 [7]. The inputs, outputs, and system boundaries of four stages; raw material acquisition, transportation, construction, and maintenance are shown in Fig. 4. The functional unit of an in-ground reactive filter box design was considered to understand the operation and evaluate filter mix options, construction, and maintenance using a lifespan of 20 years. Economic sustainability was determined using standard materials, equipment, and labor from locally sourced vendors and reputable publicly available rates. Transportation was calculated based on mode of transit, fuel consumption, and weight of load. Other indirect and social costs were included using StepWise from SimaPro and the USEPA Social Cost of Carbon. Some costs were not included because they were either negligible or the same across every design. Social sustainability was done using the SSEM tool developed by Reddy et al. [8], and a survey was conducted to assess the social sustainability.

3.1 Environment Sustainability

The goal was to evaluate the environmental impacts of raw material acquisition, transportation, construction, and maintenance of an in-ground reactive filter box. Using the technical design specifications, side-by-side comparisons of the TRACI 2.1 V1.01/US 2008 methodology were run for environmental impact assessment of each filter mix design in order to have quantitative data associated with each design.

The quantitative outputs evaluated were ozone depletion, global warming, smog, acidification, eutrophication, carcinogens, as well as non-carcinogens, respiratory effects, ecotoxicity, and fossil fuel depletion.

3.2 Economic Sustainability

This involves evaluating the impacts of different processes and materials in the life cycle stages on monetary value. This project consisted of generating a cost estimate for the filter bed materials, the construction process costs, equipment and labor, maintenance costs, as well as the three different filter media mixtures, and transportation costs.

The maintenance costs were calculated by assuming that it will occur twice annually to check on the filter material and the tank. 10% contingencies were added to the original maintenance inspections. The maintenance inspection includes filter permeability, cracks, clogged pipes, and potential leakage.

The social cost of carbon was monetized using different monetization techniques: USEPA and StepWise. USEPA technique quantifies the emissions using SimaPro and was converted into the corresponding costs using USEPA 3% discount rate—42$ per metric ton of CO2 emissions in the year 2020, the present value of climate change damages. The StepWise technique allows for the full monetization of environmental impacts (expressed in USD 2002 that converted to USD 2020). StepWise is calculating the cost of carbon to be more than two and a half times the prediction of USEPA social cost of carbon.

3.3 Social Sustainability

The social impacts were evaluated using SSEM. Since the difference between design alternatives is only the filter material, the social evaluation mostly will be affected by the site construction and how it will affect the community. Hence, only the filter scenario (remediation) versus no filter (no remediation) was evaluated. This was conducted with the team’s opinion as well as 17 peer opinions via a survey. The scoring was +2 for ideal social sustainability, +1 for improved, 0 for no impact or not applicable, −1 for diminished, then −2 for unacceptable. The focus was on the effects of the proposed scenario on quality-of-life issues post-construction, public health and wellness, effect on local businesses and life during construction, and the degree to which the project will improve water quality and/or reduce contaminants.

3.4 Integrated Sustainability Assessment

The overall sustainability of the three mixed-media filter options was assessed with the help of integrated value model for sustainability assessment (MIVES) method involving value functions [9]. For the environmental, the indicators were the impact categories obtained from the LCA. For the economic, the indicators were the various direct and indirect costs associated with the project. For the social, the indicators were the ones defined for the survey.

4 Results and Discussion

4.1 Environmental Sustainability

The final outputs from SimaPro are shown in Figs. 5 and 6. Environmental impact categories as listed in Sect. 3.1 can be seen shown below with respective contributions from each LCA stage. The most environmentally friendly design was filter mix 2. The dark green and dark blue represent the raw material acquisition and typically represent the most negative influence for each indicator. Only the maintenance of the designs is comparable but is taking into account a 20-year lifespan of operating the system. Ozone depletion is also most heavily influenced by transportation and gas/diesel fuel consumption from combustion engines.

Using the TRACI 2.1 V1.01/US 2008 methodology, filter mix 2 had the best outcomes regarding environmental sustainability. In each and every category, mix design 2 was less impactful than mix designs 1 and 3 as can be seen in Fig. 6. This is mostly due to the use of zeolite. While zeolite is phenomenal at removing E. Coli from contaminated stormwater, the tradeoff is the environmental impacts of mining the resource. While filter mix 3 also uses zeolite, the combination of using all 4 materials somehow reduces the contamination removal efficiency. Since, filter mix 2 is able to adequately reduce concentrations across a broad array of pollutants, and it also uses more environmentally materials in its design.

Some exceptions to the SimaPro model include: components that were the same across all the 3 filter designs, a total account of end of life—recycling and waste management, as well as the net positive impacts of surface water quality improvements. In addition to the quantitative analysis, the impacts of global warming and respiratory health effects to the most negative components of construction the filters all together were also evaluated.

4.2 Economic Sustainability

The costs for filter designs 1, 2, and 3 were approximately $44,460, $51,077, and $54,278, respectively. Filter design 1 is the cheapest, and filter design 3 is the most expensive, entirely due to transportation costs of zeolite. The filter material zeolite is sourced from Idaho, and even after checking the environmental impacts had it been sourced locally—there is still not much of a difference due to the invasive materials acquisition and mining process. It is still the most expensive due to the distance, it must be transported—which is not economically sustainable for a filter project. The labor costs included about 80 people at an average of $175 per hour, which came to a total of about $14,000 for each filter unit. The construction costs were also the same for each unit with 19 cubic yards of site work and about $21 per hour for excavation and equipment, making a total of $400. The materials included calcite, zeolite, sand, iron fillings, limestone, pre-cast concrete tank, fluid cement, soil disposal, slotted 6″ pipe, 4″ perforated polyethylene pipes, cast iron grate, excavator, and an aggregate mixer.

The indirect costs were derived as an output via the SimaPro program. An inflation rate of 43% for USD 2002 to 2020 was assumed. Filter design 1’s indirect cost was given as $4,840 to $6,923.59. Filter design 2’s indirect cost went from $2,720 to $3,890.95, and design 3 went from $4,260 to $6,093.91.

The social costs of carbon were derived from the USEPA [10] and StepWise results. StepWise is calculating the cost of carbon to be more than 2.5 times the prediction of USEPA social cost of carbon. The results are shown in Table 3.

In MIVES, the cost estimates and environmental impacts were weighted for direct cost, maintenance cost, indirect cost, and social cost at weighted values of 60%, 29%, 7%, and 3%, respectively. The direct cost has the highest weight and focuses on design materials, equipment, setup, and installation, as well as transportation and labor. The results for economic assessment showed filter design #1 as the best and most affordable, followed by filter design #2 and filter design #3. The filter mixes #1 has the most effective cost and direct cost. The filter mixes #2 has the most effective indirect cost, which means it has the lowest impact on the environment.

4.3 Social Sustainability

The team scored different dimensions of social sustainability as ideal, improved, diminished, or unacceptable. A survey was then sent out to various academic peers to compare the team predictions with a poll opinion. As an overall trend, the social dimension had improved social sustainability with the filter for both our assessment and the survey results. For the socio-institutional dimension, the team results were similar to the survey. For the socio-economic dimension, the ‘no filter’ option was at a negative score compared to the survey because of a loss of job creation for construction and maintenance. For the socio-environmental dimension, the team results were similar to the survey for the filter option, however, the survey results for no filter came back at a very low score. In the end, having a filter is better for the community than not having a filter to protect the beach from pollutants. The filter had an overall positive impact on social sustainability, whereas no filter had either no impact or a negative impact on social sustainability.

4.4 Integrated Assessment

The final MIVES score or integrated sustainability index for each filter mix is shown in Fig. 7. Equal weightages were given to the three pillars of sustainability: environmental, economic, and social. Filter design #2 appeared to be the most sustainable option among the three filter designs.

5 Conclusions

Using the MIVES, filter design #2 proved to be the most sustainable design. In the environmental assessment, filter design #2 came out to be the most sustainable, followed by filter design #3 and filter design #1, respectively. For the economic assessment, filter design #1 has the most effective total cost and direct cost, whereas filter design #2 has the most effective indirect cost with the lowest environmental impacts. The social sustainability assessment ranking filter versus no filter conducted through the SSEM found the addition of filter at Ohio Street Beach to be favored over no filter; when coupled with the MIVES analysis, filter design #2 had the preferable social sustainability.

Environmental impacts were most influenced by the raw material acquisition, and finding sustainable sources of materials is a key component to a design with less environmental impacts. The indirect costs of any sort of major civil construction can have more influence than expected. Social and environmental costs can easily be thousands of dollars and are worth considering. Social sustainability is hard to quantify. When possible if the details of a design can be differentiated regarding social impacts to the point that people can accurately assess the design; then, the value of social quantification/statistics is immensely more beneficial in analysis.

References

Reddy KR, Kumar G (2017) Permeable reactive filter system for treatment of urban stormwater runoff with mixed pollutants. Geotechnical frontiers, Orlando, FL

Topographic Maps (2019) Chicago topographic map, relief map, elevations map. OVH SAS, 2 rue Kellermann, 59100 Roubaix, France. Web. https://en-gb.topographic-map.com/maps/lpjy/Chicago/

Reddy KR, Xie T, Dastgheibi S (2013) PAHs removal from urban storm water runoff by different filter materials. J Hazard Toxic Radioact Waste 18(2):04014008

Reddy KR, Xie T, Dastgheibi S (2014) Removal of heavy metals from urban stormwater runoff using different filter materials. J Environ Chem Eng 2(1):282–292

Reddy KR, Xie T, Dastgheibi S (2014) Mixed-media filter system for removal of multiple contaminants from urban storm water: Large-scale laboratory testing. J Hazard Toxic Radioact Waste 18(3):04014011

International Standardization Organization (ISO) (2006) Environmental management—life cycle assessment—principles and framework ISO 14040

Pré. SimaPro 8.5 LCA software. Amersfoort, The Netherlands (2018)

Reddy KR, Sadasivam BY, Adams JA (2014) Sustainability evaluation matrix (SSEM) to quantify social aspects of sustainable remediation. In: ICSI 2014: Creating infrastructure for a sustainable world, pp 831–841. ASCE

Reddy KR, Kumar G (2019) Application of triple bottom line sustainability framework to select remediation method at industrial contaminated site. In: Proceedings of geocongress, ASCE, Reston, VA

USEPA (2017) The social cost of carbon. https://19january2017snapshot.epa.gov/climatechange/social-cost-carbon_.html. Accessed 29 Jan 2018

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2023 The Author(s), under exclusive license to Springer Nature Singapore Pte Ltd.

About this paper

Cite this paper

Fiocca, A., Barbeau, A., Payasok, A., Yousef, F., Chetri, J.K., Reddy, K.R. (2023). Sustainable In-Ground Permeable Reactive Filter for the Treatment of Urban Stormwater Runoff. In: Reddy, K.R., Kalia, S., Tangellapalli, S., Prakash, D. (eds) Recent Advances in Sustainable Environment . Lecture Notes in Civil Engineering, vol 285. Springer, Singapore. https://doi.org/10.1007/978-981-19-5077-3_22

Download citation

DOI: https://doi.org/10.1007/978-981-19-5077-3_22

Published:

Publisher Name: Springer, Singapore

Print ISBN: 978-981-19-5076-6

Online ISBN: 978-981-19-5077-3

eBook Packages: EngineeringEngineering (R0)