Abstract

Understanding mass exchange processes in polyphase frameworks (gas-fluid) is critical for figuring out their modern purposes and significance in environmental and organic design, particularly during the air circulation process in wastewater and water treatment tasks. A far-reaching audit of exploratory discoveries and theoretical investigations of mass exchange in polyphase frameworks (gas-fluid) utilized in air circulation frameworks in water and wastewater dealing with plants, organic circulated air through filters, power plant cooling frameworks, mineral air pocket floatation and plunging columns, among different applications, have been included for the momentum research. The effect of an assortment of factors on mass exchange boundaries (volumetric mass exchange coefficients, working conditions, stage component properties and reactor math) was likewise examined. The impact of mass exchange in the compound and petrochemical ventures and the instrument of mass exchange engaged with the self-refinement of waterways, streams and cascades by entrainment of air have all been talked about. With the reason for better comprehension, the hydrodynamics associated with the mass exchange and its application in numerous modern areas, the latest writing on mass exchange (gas-fluid) has been gathered and different traditional models have been thought about toward the end.

Access provided by Autonomous University of Puebla. Download conference paper PDF

Similar content being viewed by others

Keywords

1 Introduction

Environmental pollution is one of the serious global challenges which touches almost all parts of the planet. There are various types of pollution like water, land, air and noise pollution and among them, water pollution is the most pernicious because water being a universal solvent can dissolve more substances than any other liquid on the earth [1]. One of the ways to prevent water bodies from getting polluted is to treat the wastewater before it is being discharged into the ecosystem. Liquid–gas mass transfer mechanism plays a major role in wastewater treatment because the oxygen level of wastewater is very less due to the presence of unwanted materials. The gas–liquid mass transfer mechanism is used in wastewater treatment for transferring O2 in biological treatment processes, for stripping solvents from wastewater, and removing volatile gases such as H2S, NH3. Aeration is one of the examples of mass transfer process where interphase diffusion occurs. This process is all about the interaction between ambient air and water with aerodynamic and hydrodynamic forces acting between them. The mass transfer mechanism is used in many processes which include absorption, evaporation, drying, precipitation, membrane filtration and distillation and hence plays a major role in those industries where this mechanism is used in working, such as biological engineering industries, petrochemical industries. Different methods of gas–liquid mass transfer are available to induce dissolved oxygen into water bodies such as diffusion through bubbles, aeration by jet mixtures, gas jet aerators, plunging jet aeration by the means of surface jet aerators and static tube mixtures. The surface jet aeration mechanisms are widely used in this process because of their ease in installation and reliable operation and maintenance cost along with high oxygen transfer efficiency. Factors that affect the gas transfer, like Physical properties of gas and liquid medium are temperature-dependent [2]. A substantial number of researchers carried several experiments in which they used plunging water jets [3,4,5,6,7] to get more insights on the mechanism of gas–liquid interphase mass transfer. In further studies. [7, 8] examined the factors affecting rate of mass transfer. Furthermore, researchers examined the efficiency of gas–liquid diffusion in aerated filters used by biochemical industries [9]. Deswal and Verma [10] studied further and various other models like multiple inclined plunging jets [11] and hollow plunging water jets [12] were tested for oxygen transfer efficiency and gas–liquid mass transfer rate.

2 Theory

Mass transfer in gas–liquid interphase is an integral mechanism followed in various chemical, petrochemical industries and water treatment plants. Therefore, it becomes important to estimate the parameters for measuring the efficiency of the mass transfer mechanism. Furthermore, it is important to determine the factors affecting mass transfer rate like velocity of liquid jet, length of jet, number of jets, diameter of jet during testing several models, discharge through the liquid jet, nozzle shape, etc. to gain better understanding of the mechanism involved in mass transfer. Equations have been presented in this section to determine different parameters affecting mass transfer rate.

where cs is saturated concentration of DO, Q is the jet flow rate, vt represents the quantity of the water in the model tank, vp denotes the volume of water contained in pipes used for circulation and \(K_{L} A\) implies to oxygen transfer factor at non-standard conditions. Further, when, vp is negligible as compared to vt, further when we simplify Eq. (1) we get.

where V denotes the quantity of water in closed testing system and for calculation purposes, its quantity is assumed to be same as the water that tank contains. Now if we integrate Eq. (2) we will get:

where c0 is the DO concentration at the start of the experiment. Since the conditions when the experiments were conducted was not standard, therefor we need to find \(K_{L} A\) value at standard conditions when pressure is 1 atm, and temperature is of 20 °C denoted as (\(K_{L} a\left( {20} \right)\) ). We can compute its value by using the relationship given below:

where by K(20) is Volumetric oxygen transfer factor at standard conditions and non-standard temperature during experiment is denoted by T (c°). Moving further, jet power in mass transfer phenomenon, denoted by P (in kW) can be determined using this relationship.

where ρ is density (Kg/m3), Q is discharge (m3/s), vj is velocity of jet (m/s), j is the jet diameter (m). It can be observed from the Eq. (5) that jet power for mass transfer has a direct proportionality with the jet velocity, the diameter of jet and the number of jets.

3 Literature Review

A compendious review of literature is a crucial part of the research study to understand what work had been done in a particular field along with the main methodology and research techniques used. It helps to understand the gap areas and open questions left in those study, and how further research can help to fill those gap areas. So a comprehensive literature review comprising of major breakthrough in surface jet aeration technology has been presented in the following paragraphs.

Van de Sande and Smith [13] Conducted a comprehensive study to measure the gas transfer rate from bubbles to the liquid media. Experiments were performed with the fixed diameter (dn) of nozzle, velocity of jet and only length of the nozzle was varied and it was found that the amount of air entrained depends on entrainment region. Furthermore, a direct proportionality was observed between total mass transfer from bubbles and the airflow rate.

Tojo and Miyanami [14] Studied distinctive features of the down-flow jet mixer and compared it with up-flow jet mixer based on mass transfer rate using two types of tanks (rectangular and circular) and a circular nozzle. It was found that in a down-flow jet mixer, the gas–liquid mass transfer may increase with upsurge in jet length and velocity of liquid jet while in the up-flow jet mixer with increase in airflow rate, mass transfer rate increases. Based on experimental results, it was concluded that the down-flow jet mixer is more competent for oxygen–transfer (Ka) as compared to the up-flow jet mixer.

Comprehensive study was conducted on plunging liquid jet absorber to study the mechanism of gas–liquid interphase mass transfer on two different systems: one had complete liquid phase and the second had ionic salts mixed in the liquid medium to test the mass transfer behavior [3]. After substantial analysis, it was found that unlike jet length, jet velocity and the angle of inclination had a significant effect on the mass transfer factor. In addition to this, it was found that through an interfacial area of the range 500 to 1000 m2/m3 gas fused rigorously into the liquid phase.

Study was done on plunging jet systems concerning CO2 absorption in water and dependency of the absorption rate was investigated for various factors like diameter of nozzle, velocity of liquid and length of the jet [4]. A set of experiments were conducted by varying nozzle diameter of 1.2, 2, 3, 3.5 and 6 mm and with a liquid flow rate between 1.1 × 10−5 and 23.3 × 10−5m3s−1. After substantial analysis, it was found that the rate of CO2 absorption increases with upsurge in value of nozzle diameter, the liquid velocity at the nozzle and jet length through the gas phase.

A comprehensive study was done by researchers [2] to check variation of liquid film coefficient when there was change in temperature for gas transfer through the water–air interface. Earlier an empirical formula was used to depict the dependence of KL (liquid film coefficient) on Schmidt number and θ (θ is constant and its value is 1.0241). After the substantial study, an equation was derived to accurately determine the Temperature Correction Factor (fc), which had its dependence on Sc−1/2 (Sc = Schmidt number) and it gave better results than the empirical equation with θ = 1.0241. Different aspects thoroughly related to entrainment of gas by plunging liquid jet such as mechanism involved, conditions of onset environment, amount of the entrained gas and mass transfer was studied in detail in 1988 [6]. After extensive analysis, it was concluded that for nozzles with l/d0 ≥ 4 the entrainment ratio is proportional to \(\left( {\frac{{L_{j} }}{{d_{0} }}} \right)^{0.5}\) to \(\left( {\frac{{L_{j} }}{{d_{0} }}} \right)^{0.5}\) for the value of Lj/d0 < 100 and if Lj/d0 > 100 then it is proportional to \(\left( {\frac{{L_{j} }}{{d_{0} }}} \right)^{0.7}\) where l, Lj, d0 are the length of the cylindrical section of the nozzle, jet length, nozzle diameter, respectively.

Cummings and Chanson [15] examined the mechanism of air entrainment by plunging liquid jets along with new experimental evidence. He performed a set of experiments in large vertical supporting jets with the mean velocity at jet impact (v1) between 0.3 < v1 < 9 ms−1. He found that air bubble responsible for mass transfer is observed only when jet velocity exceeds the critical velocity of about 1.1–2 ms−1 for a two-dimensional vertical jet experiment.

Yamagiwa et al. [7] studied oxygen transfer rate of plunging jet reactors with varying viscosity of liquid. In the experiment Corn Syrup (Newtonian Fluid) of varying concentration from was used, corresponding values of viscosity and density ranged from 2.60–40.5 mPa to 1130–1277 kg/m3, respectively. After substantial analysis, it was found that depending upon the viscosity of liquid air entrainment characteristic was divided into three regions, where oxygen transfer rate sharply decreased, remained constant and slightly increased with the liquid property depending upon jet Reynolds number.

Bagatur et al. [16] studied the aeration performance of plunging jet and conducted a set of experiments by using models of different nozzle shape and keeping velocity of jet between 2 and 20 m/s and with jet length = 0.15 m. It was found that nozzle of elliptical shape gave highest oxygen transfer coefficient for air entrainment by plunging jet and its efficiency to transfer oxygen was higher than circular nozzle.

Chanson et al. [17] examined the factors affecting bubble dispersion and rate of air entrainment by using vertical circular plunging jet models. Three models were studied with a jet nozzle diameter of 6.8, 12.5 and 25 mm & air–water dispersion was calculated wide number of flow conditions but for same Froud Number. After extensive analysis, similar flow patterns were observed for all the three models, for low velocities, no bubbles were observed at the jet impact surface but as the velocity increased bubble entrainment was seen, smaller bubbles in the size of range 0.5–1 mm followed a helicoidal path about the jet center-line. Furthermore, bubble chord size and bubble chord time were measured and the results depicted a direct proportionality between mean chord size and jet velocity for a give cross-section.

Emiroglu and Baylar [18] examined the air entrainment behavior of a venturi device having nozzle shape different than conventional nozzles by varying the numbers and positions of air holes along the convergent-divergent passage. They found that efficiency of oxygen transfer (OE) decreases with increase in jet velocity. Furthermore, air entrainment rate (QA) values of the venturi device was found to be greater than the models with circular shaped nozzle.

Baylar and Emiroglu [8] studied gas entrainment properties of circular nozzles with and without air holes by keeping velocity of water jet at different velocities, between 2.5 and 15 m/s and keeping the plunge angle of the water jet at 45°. Greater value was detected for rate of air entrainment and efficiency of gas transfer in case of circular nozzles with air holes as compared to nozzles without air holes.

Leung et al. [9] studied the effect of water and airflow rate, temperature of liquid and gas holdup on oxygen transfer coefficient by using a bench-scale up-flow BAF column setup (1.3 m high) with spherical support gravel nominal diameter of 19 mm and 25 mm). After extensive analysis of experimental results, it was detected that the coefficient of oxygen transfer (\(K_{L} a\) ) increases with increase in water temperature and liquid velocity. In addition to that gas holdup in clean as well as wastewater increases with upsurge in superficial gas velocity.

Deswal and Verma [19] conducted a comprehensive study on a conical shaped plunging jet of diameter 64.5 mm and having plunge angle of 600, to determine the coefficient of oxygen transfer and its efficiency. The thickness of the jets was kept as 1.9 mm, 2.72 mm and 3.77 mm and results were analyzed for different flow rates. It was found that the coefficient of oxygen transfer increases with upsurge in the jet velocity, thickness of the jet and jet power.

Deswal and Verma [10] studied multiple plunging jets to compute its air entrainment efficiency and coefficient of oxygen transfer by varying number of jets and jet diameter used and the jet number was varied as 1, 4, 8 and16. After substantial analysis, it was detected that with increase in number of the jets both coefficient of oxygen transfer as well as air entrainment efficiency increases. Furthermore, air entrainment efficiency of multiple plunging jets was found to be greater than single jet when jet power is kept constant.

Deswal [11] conducted a set of experiments to compute coefficient of oxygen transfer (\(K_{L} a\left( {20} \right)\)) and efficiency of oxygen transfer of multiple inclined plunging liquid jets (plunge angle kept at 60°) at different jet flow rate of 1.33 × 10−3, 1.8 × 10−3, 2.5 × 10−3, 3.1 × 10−3 m3/s with varying jet diameters and number of jets. It was found that (\(K_{L} a\left( {20} \right)\)) for multiple inclined plunging liquid jets increases with upsurge in jet velocity. Coefficient of oxygen transfer of multiple inclined plunging jet was also found to be greater than that of single jet if jet power is not varied.

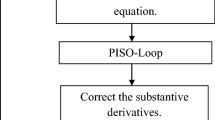

Deswal [12] conducted a set of experiments with hollow plunging jet models by varying thicknesses of jets (tj = 1.95, 2.85 and 3.97 mm). The model was examined at different jet flow rate, viz., 1.33 × 10–3, 1.88 × 10–3, 2.5 × 10–3 and 3.1 × 10–3 m3/s. It was found that coefficient of oxygen transfer in case of hollow plunging jet increases with upsurge in velocity of jet and (P/V) value of jet, while oxygen transfer efficiency decreased with upsurge in (P/V) (Fig. 1).

Variation of oxygen transfer factor w.r.t. different inputs parameters [12]

Kumar et al. [20] studied various regression techniques predict the coefficient of oxygen transfer (\(K_{L} a\)) and its efficiency for hollow jet aerator models. The models were tested for jet velocity and discharge maintained from 1.69 to 9.74 m/s and 2.18 to 15.5 L/s. it was found that (\(K_{L} a\)) value increases with the upsurge in jet velocity while oxygen transfer efficiency decreases with upsurge in jet velocity for all configuration of apparatus used in experiment. Furthermore, it was concluded that the RBF kernel-based Gaussian process regression (GPR) technique is best to predict coefficient of oxygen transfer.

Shukla and Goel [21] conducted a comprehensive study to estimate oxygen transfer factor (\(K_{L} a\left( {20} \right)\)) of aerator model by varying total number and area of opening. The experimental models were tested for different discharge rate viz., 1.11 \(\frac{l}{s}\), 2.1 \(\frac{l}{s}\), 2.96 \(\frac{l}{s}\), 3.83 \(\frac{l}{s}\), 4.69 \(\frac{l}{s}\). It was found that the factor of oxygen transfer is directly proportional to discharge regardless of the number of openings of jets and when discharge was fixed aerators those had a larger area of openings had greater values of oxygen transfer (OE).

Kumar et al. [22] studied the application of various regression techniques such as Gaussian Process Regression (GPR) techniques and Support Vector Regression (SVR) for determining the coefficient of volumetric oxygen transfer for plunging hollow jet models. It was deduced that SVR model can predict oxygen transfer factor more accurately by using radial basis function as kernel function as compared to other regression models using different kernel function.

Shukla et al. [23] conducted a set of experiments to examine solid jet aerators for their oxygenation performance with circular opening by varying length of the jet and area of the flow. It was found that Oxygen transfer coefficient (\(K_{L} a\)) for solid jet holds a direct proportionality with the jet velocity, length of the jet and discharge. Furthermore, it was observed that Oxygen transfer efficiency (OE) decreases with the upsurge in discharge and velocity.

Kumar et al. [24] studied different regression techniques of modeling such as multiple nonlinear regression technique (MNLR), artificial neural network (ANN), in addition to that he used adaptive neuro-fuzzy inference system (ANFIS) and multivariate adaptive regression splines (MARS) to analyze different experimental data. He compared different regression techniques to determine best modeling technique for predicting the value of oxygen transfer factor (\(K_{L} a\)) of hollow plunging liquid jets. He found that ANFIS as well as ANN are best regression techniques for predicting (\(K_{L} a\)) value in comparison to MNLR, MARS and GRNN.

4 Conclusion

This paper summarizes the extensive research done on gas–liquid multiphase mass transfer mechanism using various models with different liquid jet velocity, jet length, discharge through the liquid jet, nozzle shape, jet diameter and following conclusions have been drawn on basis of the present study:

-

After substantial analysis, it was found that the rate of gas–liquid mass transfer increases if there is increase in nozzle diameter, velocity of jet and jet length through the gas phase. Furthermore, it was found that geometry of nozzle plays a significant role in mass transfer rate.

-

Bubbles responsible for mass transfer were only observed when velocity of jet was larger than the critical velocity of about 1.1 to 2 ms−1 for a two-dimensional vertical jet experiment.

-

Upsurge in coefficient of oxygen transfer (\(K_{L} a\)) was detected if there was increase in water temperature, velocity of jet, thickness of the jet, jet power and number of jets.

-

Rate of mass transfer for circular shaped nozzles without air holes was found to be less than that of circular shaped nozzle with air holes.

-

It was also concluded that inclined jets are more efficient for mass transfer in gas–liquid phase as compared to the vertical jets.

-

There has not been any study to examine the effects of multiple aerators in a single model.

References

B.K. Shukla, A. Gupta, P.K. Sharma, A. Bhowmik, Pollution status and water quality assessment in pre-monsoon season: A case study of rural villages in Allahabad district, Uttar Pradesh, India. Mat. Today: Proceed. 32, 824–830 (2020)

E.I. Daniil, J.S. Gulliver, Temperature dependence of liquid film coefficient for gas transfer. J. Environ. Eng. 114(5), 1224–1229 (1988)

A.K. Bin, J.M. Smith, Mass transfer in a plunging liquid jet absorber. Chem. Eng. Comm. 15(5–6), 367–383 (1982)

D. Bonsignore, G. Volpicelli, A. Campanile, L. Santoro, R. Valentino, Mass transfer in plunging jet absorbers. Chem. Eng. Process.: Process Intensif. 19(2), 85–94 (1985)

K. Funatsu, Y.C. Hsu, M. Noda, S. Sugawa, Oxygen transfer in the water-jet vessel. Chem. Eng. Commun. 73(1), 121–139 (1988)

A.K. Bin, Gas entrainment by plunging liquid jets. VDI Forschungsheft 648(88), 1–36 (1988)

K. Yamagiwa, A. Ito, Y. Kato, M. Yoshida, A. Ohkawa, Effects of liquid property on air entrainment and oxygen transfer rates of a plunging jet reactor. J. Chem. Eng. Jpn. 34(4), 506–512 (2001)

A. Baylar, M.E. Emiroglu, An experimental study of air entrainment and oxygen transfer at a water jet from a nozzle with air holes. Water Environ. Res. 76(3), 231–237 (2004)

S.M. Leung, J.C. Little, T. Holst, N.G. Love, Air/water oxygen transfer in a biological aerated filter. J. Environ. Eng. 132(2), 181–189 (2006)

S. Deswal, D.V.S. Verma, Air-water oxygen transfer with multiple plunging jets. Water Qual. Res. J. Can. 42(4), 295–302 (2007)

S. Deswal, Oxygen transfer by multiple incliend plunging water jets. Int. J. Eng. Appl. Sci. 4(8), 57–63 (2008)

S. Deswal, Oxygenation by hollow plunging water jet. J. Institute of Eng. 7(1), 1–8 (2009)

E. van de Sande, J.M. Smith, Mass transfer from plunging water jets. Chem. Eng. J. Netherlands 10, 225–233 (1975)

K. Tojo, K. Miyanami, Oxygen transfer in jet mixers. Chem. Eng. J. Netherlands. 24, 89–97 (1982)

P.D. Cummings, H. Chanson, Air entrainment in the developing flow region of plunging jets—Part 1: Theoretical Development. J. Fluids Eng. 119(3), 597–602 (1997)

T. Bagatur, A. Baylar, N. Sekardag, The effect of nozzle type on air entrainment by plunging water jets. Water Qual. Res. J. Canada 37, 599–612 (2002)

H. Chanson, S. Aoki, A. Hoque, Physical modelling and similitude of air bubble entrainment at vertical circular plunging jets. Chem. Eng. Sc. 59, 747–758 (2004)

M.E. Emiroglu, A. Baylar, Study of the influence of air holes along length of convergent divergent passage of a venture device on aeration. J. Hyd. Res. 41, 513–520 (2003)

S. Deswal, D.V.S. Verma, Performance evaluation and modelling of a conical plunging jet aerator. Int. J. Mech., Aerospace, Industrial, Mechatronic Manuf. Eng. 1(11) (2007)

M. Kumar, S. Ranjan, N.K. Tiwari, R. Gupta, Plunging hollow jet aerators—oxygen transfer and modeling. ISH J. Hydraulic Eng. 24(1), 61–67 (2017)

B.K. Shukla, A. Goel, Study on oxygen transfer by solid jet aerator with multiple openings. Eng. Sci. Tech., An Int. J. 21(2), 255–260 (2018)

M. Kumar, N.K. Tiwari, S. Ranjan, Kernel function based regression approaches for estimating the oxygen transfer performance of plunging hollow jet aerator. J. Achievements Mat. Manuf. Eng. 2(95), 74–84 (2019)

B.K. Shukla, P.K. Sharma, A. Goel, Study on oxygenation performance of solid jet aerator having circular opening corresponding to variable jet length and flow area. J. Phys: Conf. Ser. 1531(012117), 1–7 (2020)

M. Kumar, N.K. Tiwari, S. Ranjan, Soft computing based predictive modelling of oxygen transfer performance of plunging hollow jets. ISH J. Hydraulic Eng., 1–11 (2020)

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2023 The Author(s), under exclusive license to Springer Nature Singapore Pte Ltd.

About this paper

Cite this paper

Imtiyaz, I., Krishnakant, Shukla, B.K., Varadharajan, S., Bharti, G. (2023). A Comprehensive Review of Mass Transfer Phenomenon in Gas-Liquid Phase Flow During Aeration in Wastewater Treatment. In: Agnihotri, A.K., Reddy, K.R., Chore, H.S. (eds) Proceedings of Indian Geotechnical and Geoenvironmental Engineering Conference (IGGEC) 2021, Vol. 2. IGGEC 2021. Lecture Notes in Civil Engineering, vol 281. Springer, Singapore. https://doi.org/10.1007/978-981-19-4731-5_11

Download citation

DOI: https://doi.org/10.1007/978-981-19-4731-5_11

Published:

Publisher Name: Springer, Singapore

Print ISBN: 978-981-19-4730-8

Online ISBN: 978-981-19-4731-5

eBook Packages: EngineeringEngineering (R0)